05/19/2021 3,994 Consultation with a specialist

Author: Ivan Baranov

The sensor on the panel has stopped showing the engine temperature, but the fan turns on. (Sergey)

Good day, Sergey. In all likelihood, you are faced with a malfunction of the motor temperature sensor. We will try to give you recommendations to solve the problem.

[Hide]

Unpleasant surprises from engine maintenance.

Hello. Today I want to talk about the coolant temperature sensor and the malfunctions associated with it.

Picture from free access to the Internet. Brief information

.The coolant temperature sensor (TES) is an important element of the electronic engine control system (ECM).

The sensor is designed to measure engine temperature.

Based on a signal from this sensor, the ECM, according to the program embedded in it, controls the fuel supply, adjusts the ignition angle, turns the engine cooling system fan on and off. Structurally, the sensor is a thermistor that has a negative temperature coefficient, i.e., as the temperature increases, its resistance decreases.

The thermistor itself is placed in a heat-conducting housing with a thread. A plastic connector with 2 thermistor leads is built into the case.

The sensor must have direct contact with the coolant.

In fact, this seemingly simple sensor can bring a lot of unpleasant moments to the car owner.

Symptoms of a malfunction of this sensor may be the following:

- jerking and jerking when the car is moving;

- increased fuel consumption (black carbon deposits on spark plugs);

- increased idle speed;

- poor starting when hot, and in some cases also when cold;

- engine overheating due to incorrect DTOZ values.

The most common reasons: a break inside the DTOZh or the wires leading to it. In this case, the engine malfunction lamp comes on, error: “Engine temperature sensor circuit malfunction.”

But there are also more insidious reasons: the DTOZh can give incorrect readings on the coolant temperature, that is, show a temperature lower than it actually is. For example, it can lower the temperature by 10-15 degrees. In this case, the fault lamp does not light up. The ECM does not send a signal to the engine cooling fan relay in time. The coolant level in the reservoir begins to rise, which can lead to engine overheating. In this case, only the indicator on the instrument panel can show the real temperature.

In this case, you can remove the DTOZH, heat it separately in a kettle and measure with a tester how its resistance changes according to the table.

But it’s better to buy a new one, since these sensors are inexpensive.

The next problem is poor starting on a cold engine. In this case, the error does not appear either. The temperature sensor, on the contrary, shows too high a temperature. For example, the outside temperature is -10 degrees, but the sensor shows +25 degrees. With such a difference, the engine may not start at all. It simply doesn't have enough fuel to start.

Many times such cars were dragged on a cable. When you connect the scanner, everything becomes clear.

I hope the article will be useful to diagnosticians and car enthusiasts.

I would be grateful if

you subscribe to the channel and like the article . If you have any questions, write in the comments, I will try to answer them.

Source

Car repair and maintenance

General information about the engine temperature sensor

The engine temperature sensor (ETS), or as it is more often called, the coolant temperature sensor (ETS), is an engine temperature recorder and is a thermistor, i.e. a resistor whose resistance changes significantly even with a slight change in temperature. The sensitive elements of such sensors are substances that can change some property or parameter (usually electrical resistance) when heated or cooled.

The sensor is screwed into the flow pipe of the engine cooling system and its sensitive element is constantly in the coolant flow. At low engine temperatures, the sensor has a high resistance (about 100 kOhm at -40 °C), and at high temperatures it has a low resistance (10...30 Ohms at 130 °C).

The electronic engine control unit (engine ECU) supplies a stabilized voltage of 5 V to the sensor through a resistance of a certain value and, using a divider, measures the drop in this voltage across the sensor. The voltage drop will be significant when the engine is cold and small when the engine is warm. Based on the measured voltage drop across the sensor, the control unit uses a program to determine the temperature of the coolant and engine. This temperature affects the operation of most systems controlled by electronic automation.

For example, the composition of the air-fuel mixture (TV-mixture) is adjusted based on the engine temperature: for a cold engine the mixture should be enriched, for a warm engine it should be lean. The ignition timing is also adjusted according to engine temperature.

Temperature sensor malfunctions

An open (poor connection) in the coolant temperature sensor circuit is interpreted by the engine electronic control unit (ECU) as low engine temperature. In this case, the TV mixture becomes excessively enriched, and the engine begins to operate uneconomically and pollutes the environment. The fault recorder (in the memory of the engine ECU) will record the code “Engine running on a rich TV mixture.”

A short circuit or malfunction of the coolant temperature sensor is interpreted by the ECU as engine overheating. The fuel injection system will form an over-lean fuel mixture, and engine operation will become unstable. The fault code “Engine operation on a lean TV mixture” will be recorded in the memory of the engine ECU recorder.

The coolant temperature sensor should be checked in the following cases:

- when corresponding codes are detected in the fault recorder;

- when starting is difficult, unstable operation or engine stops at idle;

- with increased fuel consumption, detonation or increased concentration of carbon monoxide CO in the exhaust gases;

- when the “engine overheating” warning light does not go out (if equipped).

Checking engine cooling system components

Before checking the coolant temperature sensor, you should ensure that the engine cooling system is working properly.

The cooling system must be properly filled with coolant. The radiator and expansion tank must be filled to normal levels. It should be remembered that the cap on the radiator or expander can only be removed when the engine is cool, otherwise coolant with an operating temperature of more than 100 ° C may splash out under vapor pressure and cause burns. For normal operation of the sensor, its working part must be constantly in the coolant flow.

The radiator cap must be sealed, otherwise air pockets may form in the cooling system and the temperature sensor readings will be incorrect. The type of coolant must comply with the manufacturer's recommendations. The fan must work properly to prevent the engine from overheating. If a thermostat or electrical contact thermal switch is installed in the cooling system, then you need to make sure that they are working.

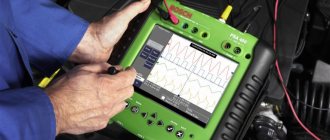

Diagnostics of DTOZH using a multimeter and contact pyrometer

Using a multimeter, check the resistance of the thermistor in the coolant temperature sensor disconnected from the harness. The sensor output voltage is checked with the harness connected. Both of these parameters must be within specification.

Directly with the car engine running, the temperature of the sensor being tested can be monitored using a contact pyrometer. A pyrometer is a device for contact or non-contact (remote) measurement of the temperature of an object (Fig. below). If the temperature sensor is normal and the corresponding fault code is stored in the engine ECU memory, then most likely there is a problem with the connecting harness. The wiring between the sensor and the engine ECU is checked according to the manufacturer's methods and diagnostic cards.

A faulty sensor will not meet standard parameters and must be replaced as it cannot be repaired. The nominal (operating) coolant temperature varies depending on engine models. On some models, the thermostat opens at a temperature of 82 °C, on others - at 90 °C and above. Before replacing the sensor, ensure that the engine is operating within specification temperature.

In homemade conditions, checking a temperature sensor using a multimeter can be done by immersing the sensor alternately in hot and cold liquid (for example, water). The sensor's thermistor must respond to changes in temperature by changing its resistance, which can be determined by reading the ohmmeter in a multimeter. Of course, such a test only approximately diagnoses the correct operation of the sensor and compliance of the thermistor resistance parameters with specifications.

The temperature indicator in the instrument panel does not work

Using the example of a dial indicator for the temperature of the coolant (antifreeze, antifreeze) in the instrument panel of a VAZ 21093 car with a carburetor engine, we will find out why it does not work.

There are most often two options for a malfunction of the temperature indicator: either the indicator arrow is constantly at the beginning of the scale, or the arrow is constantly in its red zone. In addition, the indicator may give incorrect information about the actual coolant temperature.

Causes of the malfunction: “the coolant temperature gauge does not work”

The reasons for the failure of the temperature indicator on a VAZ 21093 car are:

— malfunction of the coolant temperature indicator sensor (it is installed in the engine block head and works in tandem with the indicator);

— malfunction of the electrical circuit of the pointer;

— malfunction of the temperature indicator itself.

How to determine the “culprit” of a temperature gauge malfunction

If the coolant temperature gauge needle is constantly at the beginning or end of the scale, and the car’s engine cooling system is functioning normally: the engine warms up as usual, the thermostat is completely hot, the heater “warms”, the coolant does not boil.

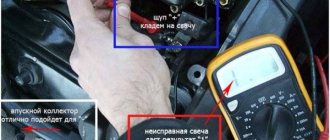

Checking the serviceability of the temperature indicator sensor

Turn on the ignition, remove the wire from the sensor and short it to ground (touch the engine or body); if the gauge needle rises from the beginning or end of the scale, the temperature sensor is faulty.

If the arrow does not deviate, the sensor is working, you need to check the pointer itself.

Checking the serviceability of the coolant temperature gauge

Remove the instrument panel. We disconnect the white block of the wiring harness from it. Turn on the ignition. We check the voltage supply to the positive terminal of the pointer (pin 12 of the block). We use a multimeter (tester) with voltmeter mode or a test lamp. If voltage is present, check the negative section of the circuit. This is pin 5 of the block (common minus). We connect the negative and positive terminals of the block with multimeter probes. The voltage must be at least 12 V. If everything is in order, check the “minus” from the sensor.

We attach the block to the instrument panel and, with the ignition on, connect its terminal 2 (negative from the sensor) to ground with a piece of wire. If the pointer arrow has deviated, the pointer is working and you will need to check the wire to the sensor for a break or short to ground. If the arrow does not deviate, the temperature gauge is faulty and must be replaced.

Checking the electrical circuit of the temperature indicator

According to the diagram, using a multimeter (tester) or a test lamp, we check the serviceability of individual sections of the electrical circuit.

Notes and additions

The coolant temperature dial indicator is installed in the instrument panel of the VAZ 21093 car. Its needle is connected to a rotating magnet, which changes its position depending on the strength of the magnetic field acting on it. The electrical circuit of the coolant temperature indicator includes a coolant temperature sensor installed in the engine block head. The sensor is the “mass” of the pointer. It contains a thermistor that changes the resistance of the circuit depending on the coolant temperature. The hotter the antifreeze or antifreeze, the lower the circuit resistance, the stronger the magnetic field affecting the sensor needle, the more it deviates.

About DTOZh breakdowns

- no contact with the sensor;

- loss of insulation, broken contacts;

- device failure;

- the fan does not work systemically.

- the engine is not even warmed up yet, but the fan is already running;

- a warm engine does not want to work;

- gasoline began to be consumed more.

We recommend: Error codes Lada Kalina 1

Before checking the coolant temperature sensor, remember, the main thing is not to confuse it with the coolant temperature indicator sensor!

What to do in such cases?

The engine temperature sensor provides data to the instrument panel as a result of analyzing the coolant temperature. Any breakdowns associated with this regulator can cause problems in the operation of the exhaust system and increase gasoline consumption. After all, most likely, the breakdown of the device is a consequence of the fact that the motor control system cannot activate the closed-loop operating mode.

But as practice shows, in most cases the regulator itself is in good working order as a result of its diagnosis, and breakdowns are mainly associated with wiring or oxidation of contacts. What to do in such cases? First of all, you need to start with a visual diagnosis of the device. As a rule, people who are faced with its inoperability notice oxidation at the joints and contacts upon visual inspection. It is likely that there is a crack on the regulator body itself through which antifreeze is escaping.

Do-it-yourself dismantling of DTOZH

But basically, in order to identify a breakdown, you have to measure the resistance and voltage. If your vehicle has a digital gauge, the readings will be displayed in Fahrenheit and Celsius. If the engine is cold, then the temperature will be outside or room temperature; if it is running, then it will be about 200 degrees. If there are no indicators at all or they are incorrect, then the problem is either in the device itself or in its wiring.

There is an option to measure the internal resistance and then compare it with the indicators. It will immediately be clear whether the device is shorted or open; if this turns out to be the case, then it needs to be changed. If everything is normal with the resistance, as well as with the temperature, then the cause of the breakdown may lie directly in the motor control unit, and the regulator itself operates in open-loop mode. To check this, contact a service station for help or purchase a regulator simulator. This device sends readings to the control unit, and if there is no damage to the wiring and the circuit is closed by the control unit, the problem will lie with the ECU. In general, more accurate data will be obtained through high-quality computer diagnostics performed on specialized equipment.

Symptoms of malfunction

To ensure that the correct data from the coolant temperature sensor is transmitted to the electronic control unit, it must be properly installed.

Unscrew

The DTOZH location is located near the thermostat housing. The sensor tips must be in contact with the coolant.

Therefore, the root cause of the incorrect operation of the DTOZh may be its banal incorrect installation.

Some symptoms will allow even an inexperienced motorist to determine that the problem lies in this sensor:

- Exhaust gases are of very low quality due to a disturbed air-fuel mixture;

- Fuel consumption figures have increased noticeably;

- Exhaust gases have a deteriorated composition;

- The engine becomes difficult to control;

- A malfunction code is displayed on the dashboard, or a warning light begins to blink, indicating overheating of the power unit;

- It is difficult to start the engine.

Many people immediately drive the car into the garage and begin replacing the coolant temperature sensor on their VAZ 2110. But often the cause of such symptoms is the presence of damaged wiring or poor contact of connections. Therefore, check them first.

It is also possible to determine externally that the sensor has failed. The presence of traces of rust, corrosion on the device, and deposits indicate that it is better not to use this sensor in the future.

You can arm yourself with a voltmeter or multimeter to determine the resistance. When cold, normal sensor readings should be 2V, and if the engine is hot, then 0.5V. Any deviations from the norm indicate failure of the meter.

Causes of malfunction

Arrow stuck on dashboard

It’s probably no secret to anyone that the arrows hanging on the dashboard are inextricably linked with the electrical circuits in the car. To troubleshoot the problem, the car enthusiast will need some knowledge of auto electrics, as well as design knowledge of the VAZ-2114.

As practice shows, most motorists, when such a breakdown occurs, turn to a car service center, but this problem can be eliminated on their own. But, first of all, it is necessary to find the immediate cause of the effect.

What are the options?

So, let's look at the possible options for the engine temperature indicator arrow to hang on the dashboard:

- The magnetic motor of the pointer drive is broken.

- Breaks and disturbances in the operation of the electrical circuits of the dashboard.

- Short circuit in the circuit board of the device itself.

- Freeze related to temperature sensor.

- Problems with the ECU.

Elimination methods

Once the root causes have been identified, you can move directly to methods to resolve the problem.

To carry out repair and diagnostic operations, you will need some tools, namely: a multimeter, an OBD II cable, a tablet or laptop, as well as a set of keys and screwdrivers for dismantling the main and auxiliary components.

So, now that the motorist is fully armed, you can proceed directly to the diagnostic and repair process.

The magnetic motor of the arrow drive is broken

The process of repairing and disassembling the dashboard

The most common problem with the arrow hanging or not responding on the instrument panel is a breakdown of the drive motor . To diagnose this device, you need to use a multimeter to close the winding contacts to an electrical circuit or resistance.

If the tester does not show anything, then most likely the winding is burned out or there is a break in contact with the board.

To troubleshoot the problem, of course, it is recommended to contact an auto electrician, who will do everything quickly and efficiently, but if the car enthusiast has the necessary skills and abilities in repairing such equipment, then he will be able to independently replace the motor and solder the necessary contacts.

Breaks and disturbances in the operation of the electrical circuits of the dashboard

Wiring related fault determination

Another common reason for a stuck sensor is a break in the electrical circuit from the coolant sensor to the dashboard . It is quite simple to identify this; you need to remove the ground wire from the sensor and connect it to any other “minus” so that the electrical circuit is closed.

If the wire is not broken, then the arrow will begin to move; if not, then according to the electrical diagram it is necessary to find the wire in which the break occurred and eliminate the fault. As practice shows, motorists do not change the wire, but simply connect and insulate the contacts at the break point.

Short circuit in the board of the device itself

Detection of short circuits on the instrument board

There have been numerous cases when a short circuit in the instrument panel board caused the needle to freeze.

But, in this case, an indirect sign is that nearby signs also fail. So, the tachometer and other indicators may not show. Here, troubleshooting is to replace the instrument panel assembly.

How to replace it yourself

Preparatory stage:

- Open-end wrench set to “19”;

- Rags;

- Additional lighting as needed;

- New "measuring device".

Replacement algorithm:

- We install the VAZ 2114 in the perimeter of the repair area;

- We turn off the engine, open the hood;

- We provide priority safety measures: block the rear row of wheels with wheel chocks, squeeze the parking brake;

- Remove the terminals from the DTOZH, unscrew the sensor with a key;

- We replace the device with a new one, screw it in, and put on the power terminals again.

We turn the key in the ignition, activate it, and check the functionality of the equipment. Add the missing amount of antifreeze as needed.

We recommend: Cardan shaft crosspiece

Why is the coolant temperature light on?

It was already mentioned earlier that the cooling system indicator lights up if there is any deviation from the optimal temperature. This can happen both when the engine temperature increases and when it decreases. Often the light comes on when there is not enough coolant in the tank and it needs to be refilled as quickly as possible. Mixing antifreeze is not allowed in all cases, and in general you should choose the coolant for your car very carefully.

It is especially worth noting that when the coolant indicator lights up when the engine is hot, you should absolutely not add antifreeze. You must wait until the engine cools down. Otherwise, due to the temperature difference between the hot parts of the engine and the coolant, cracks will occur in the cylinder head.

It is also important to remember that the coolant light does not always light up only if there are any problems with the antifreeze. It is possible that there is a malfunction in one of the elements of the cooling system. In this situation, it is worth contacting a service workshop, where, using special diagnostics, the technician will determine what exactly the problem is.

Symptoms of a problem

Information about coolant temperature must be obtained constantly . It is by this that one judges whether the engine is warmed up or not, and also by the indicator one can determine that the motor is overheating. In many cases, such an element saves many drivers from expensive repairs, which is why it is important to identify its malfunction in time and also change it in time.

Let’s make a reservation right away that such a sensor cannot be repaired, it can only be replaced. The fact is that it is not collapsible, but consists of one tightly sealed part, inside of which there is a thermistor.

To determine if the sensor is faulty and start checking it, just pay attention to its behavior.

- The arrow is constantly in the initial position and does not deviate when the temperature changes. Most likely, there is an open circuit in the circuit that prevents the passage of electric current.

- The coolant temperature sensor is giving incorrect readings. For example, the engine has not yet warmed up, but the needle has already reached 90 degrees Celsius. Before changing it, it is necessary to take into account that minor errors are still acceptable.

- The arrow always shows engine overheating, even when the engine is cold. Here we can say that a short circuit has occurred inside the device, and the circuit resistance has become exactly zero. This is also one of the most famous malfunctions.

As soon as you discover these oddities in the behavior of the device, you must immediately check the serviceability of the DTOZH. How to do this will be described below.

Why the coolant temperature light may be on: opinions of car owners

1. The reasons may be different.

“When the temperature warning light starts flashing while the car is moving, you need to look at what level the coolant is. It is possible that the level is not high enough or the coolant has reached too high temperatures. It happens that the level remains within normal values and then it may make sense to check the operation of the fan fuse. If everything is in order there, then it’s better to go to the nearest workshop, trying to adhere to a low speed limit.”

2. The result is obvious.

“I was very concerned that the coolant temperature light was constantly on. In this case, there is no level sensor in the car. Following the advice posted on the forums, I removed the dashboard and soldered the connector and everything that was in doubt. As a result, the temperature light stopped blinking.”

3. I spent a lot of energy.

“I’ll share one story with you... I observed the coolant light blinking chaotically. It happened to burn at idle, and in motion, and at speed, and without. At times it stopped blinking.

As a result, the following actions were taken:

- The fuses have been checked and replaced.

- Checked belt tension.

- Checked coolant level.

- Due to the low level of antifreeze, a flushing and purging was done and the coolant was replaced.

- Replaced instrument panel

- Checked for leaks from the stove.

- Thermostat checked.

A lot of effort and time was spent on finding out the reason, but in the end everything turned out to be simpler - the cause of the light bulb turning out to be the wiring...”

4. Just tightened the nut.

“Not long ago I noticed that the coolant temperature light was on and blinking. At times the temperature sensor did not work. It turned out that the mass securing nut, which is located at the bottom of the engine, had become loose. When the motor was turned on, one end of the mass came into contact with the engine for forced passage of liquid, and the second generally clung to something incomprehensible. After I tightened the nut, the light bulb began to work as it should.”

The temperature indicator came on

If this indicator lights up when the ignition is turned off, then there is no reason to worry. But make sure that this light goes out a few seconds after the engine starts running. Is she still signaling? This means that the degree of solution in the cooling system is critically low, or the system has completely failed. It also happens: the indicator lights up during travel, this indicates a possible lack of antifreeze, otherwise the cooling technology is not able to work with high temperatures.

By the way, each car has its own display color scheme. Blue color indicates a low engine temperature level, while red color indicates a high level. You can read all such details by looking at the operating instructions for your machine.

What happens if you ignore the coolant temperature icon

If you unknowingly continue driving your Renault with this warning light on, the engine will overheat. As a result, parts of the CPG, engine lubrication and cooling systems will be seriously damaged.

In particular, the block head may become deformed. Extreme temperatures can cause cylinders to crack and valves to become distorted. The piston rings may rupture or the engine may “catch a wedge,” that is, the valves will meet the cylinders.

The degree of damage can be so serious that they will refuse to even restore the engine - and you will have to look for a new or contract used engine at Renault.

What to do

First, turn on the heating system, this will help reduce the high temperature of the device. Then stop the car in a quiet place. Before turning off the engine, open the body and see if the fan responsible for cooling the radiator is working. Then start the car and touch the battery: if it is cold, then the thermostat is broken, if it is warm, the pump or the radiation system itself is faulty.

Pause to allow the engine to cool. When working with hot equipment, you can easily get burned by the steam. With optimal cooling, the softness of the water pipes will be restored. After this, you should open the battery and reduce the cooling solution to an acceptable temperature. Do not pour anti-freeze liquid under any circumstances, because the block head can easily crack.

What happens if you continue driving when the car is overheated?

When the engine overheats, the coolant boils and hot steam starts coming out from under the hood. True, in new cars that have a more sealed engine compartment, such steam can be noticed already when the engine is very overheated. If you ignore the boiling of antifreeze and the increase in the value on the temperature sensor, you risk that the engine in your car will fail - to the point that a piston or several pistons may seize. By the way, this is fraught not only for the engine, but also for you. Can you imagine the danger you expose yourself to while driving if the engine seizes?

Please note that not only pistons, but also many engine parts can fail. Including the block head and its components.

That's why as soon as you notice an increase in engine temperature, you should urgently stop your car and check the antifreeze level or a possible leak. You should also seek professional help if necessary.

Why doesn't the engine temperature gauge rise?

Checking the coolant level

The first thing to do if the engine temperature is abnormal is to check the coolant level.

Sometimes a situation may arise when the engine temperature is quite normal, but the arrow does not point to the correct parameter. This may be due to a lack of coolant. To prevent the engine from “boiling” during the trip, it is necessary to check its level before starting to drive. If a deficiency is detected, top up to the optimal level. Incorrect readings may also be displayed if the temperature sensor is faulty . It often fails:

- by service life;

- after an accident or strong shaking;

- due to a wiring problem.

We recommend: Transmission oil service life

As can be seen from the above, the answers to the question of why the engine does not warm up to operating temperature may be different. They are often associated with breakdowns of car parts. If there is no special knowledge, the driver should contact a car service center who can quickly determine the cause and eliminate it.

What happens if the cooling fan fails?

The most important parts of an engine cooling system are the fans, which cool the engine when antifreeze cannot handle it. Typically, two fans are used in the engine compartment: one runs almost always, while the other is activated at certain engine temperatures. Some cars use one fan. Typically, a cooling fan helps cool the engine when the car is moving at slow speeds or is stationary (when there is not enough air flow to cool the antifreeze in the radiator).

See also Cylinder head gasket defects, causes, consequences and how to avoid them

Unfortunately, if your machine uses two fans, if one fan fails, the engine will not cool enough in certain situations. That is why, if the engine overheats when the antifreeze level is normal, in addition to the thermostat, you must first check the cooling fan. We also recommend that you check the performance of the cooling fans before the start of the summer season, so as not to encounter engine cooling problems in a summer traffic jam.

How to check if the sensor is working properly

Even at home, the driver can check whether the electronic temperature meter is working properly. When indirect manifestations of a breakdown are noted, the inspection can confirm or, on the contrary, exclude the malfunction of certain units that are in doubt. If the test was successful, it means the breakdown is somewhere else, and you may have to contact a car repair shop to identify it.

To check the thermal sensor, you need to remove it from the car, following this algorithm:

- Wait until the engine cools down to +40…+50 °C. This way you won't burn your hands when you start working with it. Then you need to drain the antifreeze from the cooling system. You can pour out all or part of the liquid.

- Disconnect the battery from the network and remove the negative wire.

- Disconnect the block with wires from the thermocouple.

- Using the correct size wrench, unscrew the part.

When the device is at the top point of the system, there is no need to pour out all the liquid completely; it is enough to empty it of antifreeze by one third. However, when the thermoelement is located at the bottom of the radiator, the antifreeze has to be drained completely.

To carry out the necessary checks, you will need:

- a multimeter or other device that allows you to measure the resistance of a circuit;

- Small water container, even a standard glass will do;

- thermometer with a scale up to +100 °C.

We recommend

“Wheels with a diameter larger than the factory ones: how they will affect the car” More The presence of a thermometer is due to the need to determine accurate resistances, which are checked against a table of reference measurements specific to each specific car. If you don’t have such a table, you can determine whether the part is working or not without a thermometer. It is enough to evaluate the principle of operation of the unit, according to which the higher the temperature of the water in the glass, the lower the resistance values available on the contacts will become.

Before you start checking the coolant temperature sensor under heating, you need to test its contacts using an ohmmeter. It is possible that the device simply burned out or a short circuit occurred. In such a situation, there is no point in doing anything further, since it is obvious that repair is impossible and the element must be replaced.

In the case when the multimeter shows a specific resistance, it is necessary to lower the thermocouple into a glass of cold water and remember or write down the data. After this, you should add hot water and see what happens to the resistance. Ideally, it should change downward. If there are no changes, it is recommended to purchase and install a new temperature sensor.

If the tests are successfully completed and changes in the device are recorded when the water temperature increases, it is necessary to check the connecting wires and clean the contacts. It is these minor flaws that are often the main cause of failure.

Checking the performance of the DTOZH

In order to check the functionality of the above sensor, you must:

- Start the car and pay attention to the dashboard. If the temperature gauge shows the maximum value while the engine is still cold, you should disconnect all existing contacts from the temperature meter. If after this procedure the needle drops “from heaven to earth”, it’s time to replace the sensor.

- But if the needle remains at its maximum values, you need to pay attention to the sensor contact. Most likely, it was simply shorted to the mass of the car itself.

- If the engine warms up normally, but the needle either doesn't move at all or constantly jumps, it's time to check the fuses.

- If the fuses are in order, the contact should be closed to vehicle ground. If you notice that the arrow has jumped up, the problem lies in the performance of the temperature sensor.

There is another proven method, following which you need to perform the following actions:

- the multimeter is set to ohmmeter mode;

- We stock up on a thermometer that can show temperatures exceeding 100 degrees Celsius and a container that can withstand hot antifreeze;

- multimeter probes are attached to the output and the sensor body;

- the temperature sensor is disconnected and placed in a container into which coolant was previously poured;

- We monitor the readings of the thermometer and ohmmeter.

They should be combined like this:

Temperature reading: Ohmmeter reading:

If these indicators are not combined, we can safely say that the DTOZH is in a faulty condition.

If the DTOZH does not show the temperature of the VAZ-2114 engine, of course, you can try to replace it yourself. But this can only be done if you know at least a little about cars. Otherwise, it is best to contact a specialized service.

The fact is that the reasons for the breakdown of this part may be hidden in other, more serious problems in your car. For example, when checking the performance of the DTOZH, you accidentally removed the ignition module. And in order to correctly install it in its place, you need not only to try hard, but also to be a true master of your craft.

Having replaced the DTOZh in the service, you will receive not only high-quality work done, but also a guarantee for it. Each part of the car that was touched by the master’s hand will be placed in its proper place and securely fastened. If you try to save money and replace the DVT yourself, you can only incur additional costs. Remember, the miser pays twice.

A modern car is filled with a huge number of electronic systems that monitor all parameters of the engine’s condition and provide them to the driver. No exception is the DTOZH, which receives information about the coolant temperature and transmits it to the pointer. There are situations where you need to be reassured about the condition of this device, so it is important to learn how to check the coolant temperature sensor.

Engine temperature value

The internal combustion engine of modern cars is quite complex in design. And its operation is directly affected by the temperature regime, which is a key factor that has a direct impact on the motor.

If the engine temperature is below the optimal level, then the process of forming the fuel solution in the cylinders will be greatly affected. The result will be rapid engine breakdown and a decrease in its power. Overheating is no less dangerous: such a process can lead to a change in the shape of the cylinder head, and the cooling system and lubrication will lose their impenetrability. You may also notice that with this damage, oil will be consumed much faster than usual, and the antifreeze level will constantly drop. As a result, the piston rings will lose their elasticity, and the cylinder walls will be damaged, as will a jammed engine. In general, it is better to notice the problem right away and fix it than to spend both time and money on extensive car repairs.

Source

Operating principle and design features

The VAZ 2114 coolant temperature sensor, for all its importance for the normal operation of the car, is a fairly simple device. DTOZH is a resistor with variable resistance, which changes as the temperature of the antifreeze in the system increases.

The sensor has only two contacts - the first of them transmits information about the current coolant temperature to the brains of the fourteenth, and the second sends a signal to turn on the fan (when the coolant temperature reaches a certain point).

Based on the received readings, the fourteenth ECU determines the composition of the fuel mixture supplied to the combustion chambers: the colder the engine, the richer the mixture. The coolant temperature affects how almost all engine control systems will operate: this data is taken into account when adjusting the ignition angle (the moment the spark is supplied for fuel combustion in the cylinders), the time the fan is turned on for forced cooling of the power unit, and much more.

The DTOZH is a fairly durable design; it rarely breaks down, but if the unit breaks down, its repair is impossible - the device must be replaced with a new one. The cost of DTOZh varies between 400-550 rubles. for domestically produced models (the VAZ 2115 coolant temperature sensor costs about the same).