Device and main causes of problems

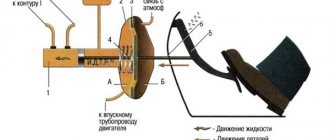

The arrows show the main elements of the system

The main task of power steering (power steering) is to make driving easier. In addition, power steering compensates for shocks when driving on uneven roads and, most importantly, if the front wheel is punctured, power steering reduces the likelihood of an accident. The main element of the power steering is the pump, which, like any other unit, can fail for the following reasons:

- The power steering fluid level is low due to a leak in the pipeline or reservoir.

- Foreign impurities have entered the power steering system.

- The power steering fluid has not been changed for a long time and has completely exhausted its service life.

- Over time, layers have formed on the walls of the pipelines, impeding the circulation of liquid, which leads to rapid overheating of the pump.

- One or more air pockets have appeared in the piping system.

Ways to improve the power steering system

In addition to simply unscrewing the pump and then installing a new one, there are several other required processes. First of all, this is the creation of a vacuum in the hydraulic system, because otherwise it will function intermittently or not work at all. Also, it is imperative to restore the loss of hydraulic fluid, some of which leaked out while unscrewing the hoses. Of course, it is more efficient to pour liquid into a running car, but in this case this is impossible, since the battery is disconnected when changing the pump.

In order to increase the temperature of the hydraulic system, you can use a regular hair dryer. However, you should also be careful here, because there is a risk of burning the tubes.

In the same way, you can increase the temperature of the hydraulic fluid.

When choosing a fluid, you need to carefully study the markings on the label in order to choose the best option for your car.

As noted above, after disconnecting the hose from the power steering, it must be lowered into a container. The easiest way is to use a regular bottle as a container.

Next, we pour the leaked liquid back into the tank, and place the tube back into the bottle. Then you need to crank the starter so that the hydraulic fluid is driven through the system and poured back into the bottle. We perform this operation several times.

After this, we attach the tube with the reservoir, turn the starter again so that the liquid is again circulated through the system, it is advisable to move the steering wheel parallel to the left and right in order to develop the hydraulics after stagnation. It is strictly not recommended to start the engine because most likely due to high pressure the hydraulic tube will break and a complete leak of fluid will occur.

This completes the process of replacing and upgrading the power steering pump. You need to put the entire system back together and make sure that the barrel of hydraulic fluid is filled to the maximum. Next, you should start the engine and drive the car for several laps.

While driving, it is advisable to turn the steering wheel as much as possible when turning to make sure there are no problems. You can also ask another person to watch the front wheels while turning the steering wheel, because system malfunctions are more visible from the side.

Diagnosis of power steering faults

It is quite easy to identify problems with the pump. Here are the main signs to look out for:

- The driver requires significantly more effort to turn the steering wheel when driving at low speeds. Even more effort is required if the car is stationary and the engine is idling. But after overclocking, these problems disappear.

- When you turn the steering wheel, a characteristic creak appears, which is clearly audible even in the cockpit.

- The power steering bearing begins to emit a thin whistle at idle speed, which may disappear when accelerating.

- When leaving the parking lot, stains of power steering fluid are visible on the asphalt, and characteristic streaks are visible on the pump itself and the pipelines.

Main components of the hydraulic booster

Depending on the model and make of the car, the design of the hydraulic booster may differ, but still, the main parts are always there.

First of all, it is a pump, which is designed to maintain pressure and movement of fluid in the system. Distributor - supplies fluid to certain cylinders of the system, this does not in any way affect the engine cylinders. A hydraulic cylinder, which helps, through pressure, moves the piston, which in turn transmits force to the wheels to facilitate turning. And of course, you can’t do without connecting hoses, which help circulate fluid in the system and transfer fluid from one part to another. If you find a fault in the hydraulic booster, do not put off repairing or replacing parts until later. Sometimes repairs can correct the situation, but there are times when you only need to replace the damaged part. Replacing the entire power steering is not so easy; you will have to remove the car's engine and disassemble half of the front chassis. In new foreign cars the mechanism is much more complex and it is better to immediately contact a service center.

The average price for a replacement at a service station is from $30, since the complexity depends on the car. Service centers are much more expensive because they use original spare parts.

For example, let's consider replacing the power steering pump, since most often it becomes unusable.

Checking the power steering pump

The first step is to identify by external signs what the breakdown of the pump is. Here are some common problems:

- When the seals are worn out,

there should be a fluid leak and its level in the tank will be reduced. It is worth paying attention to the pipes connected to the pump: their fittings must be dry. - If you notice the steering wheel sticking

or erratic forces appear, air may have penetrated into the device, which ultimately created air locks. To correct the situation, you need to pump the unit by repeatedly rotating the steering wheel all the way in both directions. It is important that the engine is turned off at this point. Traffic jams can also occur due to clogged distributor valves. It is necessary to wash all parts of the pump assembly. - There is noise

, which means the issue is worn out bearings, but it is better to make sure by pulling the pump drive pulley and the shaft in opposite directions, while removing the belt. The play can be easily felt by touch. Also, the appearance of noise may be due to scuffing of the ends of the elements and plates of the pump stator. - When the bearings are worn out

, the seals will not work for long and will quickly fail. Bearings can wear out not only due to dirty fluid, but also due to an overtightened pulley drive belt.

If a malfunction is identified, then do not put off repairing or replacing the pump until later. Changing the entire hydraulic booster is difficult, because you need to remove the engine and disassemble the front chassis of the car. Therefore, in order to avoid mistakes, let’s consider how to replace the power steering pump?

Leaks on the power steering

In foreign cars, replacing the power steering pump is more difficult, since the mechanisms are more complicated with new elements. In this case, it would be appropriate to visit a service station.

You need to put the pump in place in the same sequence, but there are some features:

- Place a sock over the high-pressure tube so that it fits well and does not come into contact with anything. Remember that the low pressure inlet must be sealed with a transport cap at this time.

- Next, lightly bolt the pump onto the exhaust manifold side. Mark the location of the pipe relative to the body.

- Reinstall the pump. Fill it with power steering fluid. Insert all tubes back and press them with clamps, check for any contact.

- We fasten the belt and set the tension according to the markings.

- We are bleeding the system. The main thing is not to start the engine, as during the process the fluid will fly out of the power steering. You should start by lightly warming up the tank and channels with a technical hair dryer. You can also slightly warm up the transmission fluid itself. Lower the return hose into the container. We pour the liquid into the tank and turn the starter, which turns the pump itself, and it is already pumping the liquid. Then through the return pipe, it goes into the container. When to stop pumping can be determined by the color of the drained liquid. Then we connect the hose to the reservoir and again turn the starter, simultaneously turning the steering wheel in different directions by 25% of the revolution.

- Then again add power steering fluid to the reservoir to the required “MAX” level. We are in no hurry to start the engine. Turn the steering wheel 5 times all the way left and right. We make sure that there is no air leakage and pour the liquid in time. Open the air intake pipe and start the car. We determine by ear whether there are any extraneous noises or beats. At the same time, turn the steering wheel and hold the extreme points on the stop for several seconds. Again add liquid to the desired level.

- We attach back the manifold protective clamp and the box with the air filter, and the replacement of the power steering pump is complete.

In modern cars, manufacturers install additional systems to ensure better vehicle controllability. For this purpose, the car is equipped with power steering. With its help, at low speed the steering wheel rotates much more easily.

However, due to intensive use, the unit may be subject to wear. In such cases, you will need to either contact a service center or repair the power steering pump yourself. If the broken parts turn out to be repairable, then the driver will receive a working unit after restoration and at the same time save money.

Before removing and disassembling, it is necessary to familiarize yourself with the design of the pump, because if it is assembled incorrectly, after the repair is completed, you can also end up with a non-functional unit. Dirt and debris should not get inside the unit; to do this, it is washed from the outside. To pump out excess fluid from the system, use a large syringe.

Dismantling begins with unscrewing the coupling screws from the steering shaft. It is necessary to remember or sketch the location of the coupling relative to the shaft. It can be moved if you use a pry bar and slide it along the slots.

We disconnect the steering rods from the bipod using a puller. Next, jack up the “driver’s” front wheel and remove it to provide access to the unit. Do-it-yourself power steering repairs must be carried out with safety in mind. To do this, the car is blocked using anti-rollbacks.

We loosen the fixed hydraulic booster by unscrewing the bolts securing it to the side member. Most often, you will need a 15mm hex head. A couple of bolts can be removed completely, and using the remaining fasteners we disconnect from the hoses. We install a wide container under the assembly to collect the waste, and after disconnecting the hoses and fittings, wait for the excess liquid to drain off.

Having closed the cavity with a clean rag, unscrew the remaining bolt. This must be done carefully so that the gearbox does not fall. Now you can flush the node before resuscitating it.

Common faults

Most experienced drivers know that during operation, steering hydraulics require virtually no attention from the car owner. Therefore, before repairing the power steering pump, you need to know that it is customary to distinguish two types of faults:

- mechanical wear or damage;

- hydraulic problems.

In the first case, the culprits are large gaps that violate the tightness, pump failure, or wear out of individual elements. In the second case, attention switches to the properties of the liquid, loss of its performance characteristics, and insufficient level in the system.

When operating a vehicle with a damaged or inoperative power steering, various manifestations of this problem are possible. Let's look at the most popular of them and some troubleshooting methods.

When, when turning the steering wheel to one side, the driver is forced to exert more force than usual, this is the cause of a pump malfunction. To fix it, you will need to replace the seals or repair the pump itself.

The appearance of reverse shocks indicates a weak tension or wear of the belt on the drive.

The defect can be eliminated by replacing the belt or increasing the tension.

If the steering wheel turns tightly in both directions, this is often a consequence of a low fluid level or insufficient idle speed, or low pump pressure, or the presence of air in the system. It is also possible that the belt drive may become loose. In some cases, it is necessary to clean the tank filter.

When the steering wheel is stiff in the middle position, most likely the reason lies in a mechanical fault in the steering. You also need to check the functionality of the pump.

A characteristic noise that appears from the steering column may indicate a low fluid level in the system. It can escape through the safety valve. The poor performance of the latter is noticeable by an audible whistle from the engine compartment when the steering wheel is in the extreme position. A non-working valve can be replaced separately from the pump or together with it.

When obvious vibration is felt while driving, the reason lies in an air lock that has appeared. You need to get rid of it, and also eliminate the cause of air in the hydraulics.

Instructions for replacing and repairing the pump

The mechanism can be checked at home. It is possible that repairing the power steering pump yourself will only involve replacing the worn-out bearing element. Often the cause of breakdowns is the formation of air jams in the lines of the unit, so first of all it is necessary to pump the hydraulics and get rid of the plugs.

So, how to overhaul and replace the power steering pump at home:

- First you need to slightly loosen the bolt that secures the pump itself to the bracket; for this, use the hole located on the pulley. It is necessary to completely unscrew the lock nut of the tensioner device and dismantle the strap.

- Using a syringe and tube, you need to pump out the consumables from the expansion tank. To ensure that the fluid leaves the system as much as possible, you can turn the steering wheel in different directions during the process.

- Then you need to slightly loosen the clamp on the pipe coming from the tank; this section of the line can be dismantled.

- After these steps, unscrew the bolt securing the high-pressure pipe that goes from the device to the system. Then you can remove the axial screw that secures the assembly to the bracket and install a screwdriver in its place. Having done this, you can unscrew the nut securing the device pulley.

- Next, you need to pull the pump itself up, then remove it and place it in a place prepared for this. All dust and smudges should be removed from the mechanism body. Using a special puller, it is necessary to dismantle the retaining ring of the bearing element.

- Then you can unscrew the bolts securing the back cover. Carefully and effortlessly pry it up with a screwdriver and remove it, being careful not to let the rotor blades fall out. Remove the blades themselves and place them on paper; it is advisable to number the pieces of paper in advance, otherwise you may make mistakes during assembly.

- Then remove the plate and all the components that are underneath it. Now you need to knock out the shaft; to do this, gently tap it with a hammer or screwdriver.

- The bearing element must be pressed out from the assembly shaft. If it is worn out, replace it with a new one.

- Diagnostics of system elements for defects and damage, clean all surfaces from dust. According to experts, such cleaning will reduce gaps and increase the service life of the unit as a whole. The assembly procedure is carried out in the reverse order of dismantling. Before assembly, check the oil seal and rubber seals; if the washers are in poor condition, replace them.

Bleeding the pump after installation

The power steering pump is assembled in reverse order

. After assembly, the power steering may make a buzzing noise, but you should not be afraid of this, since the parts will wear in after 300-500 kilometers. Some car owners keep the power steering fluid, but I would recommend adding new fluid. Usually it is filled until the tank is completely filled. The system is filled with the engine running. It is important to prevent air from entering the system. If this could not be avoided, as happened to me, then after the fluid had foamed, I stood for about thirty minutes with the reservoir open, constantly adding it to the power steering. And even after that, for two hours the power steering jerked at times.