A car's spar is a rectangular tube that runs through the front or rear of the body. Since the designs of this part are different, there are several types of power beams that pass right through between the car bumpers.

The concept of “power structure of the car” helps to understand what a car spar is. The body has many panels and reinforced parts. Its design also includes areas of programmable deformation, which serve to absorb impact energy during a collision.

What is a side member in a car?

Initially, all cars used a frame supporting part.

That is, all the elements of the car were attached to a special structure - the frame. There were several modifications of such a load-bearing part, but the most widespread was the staircase frame. It consisted of two parallel longitudinal beams - spars, connected to each other by cross members, which gave this structure the appearance of a staircase. Frame body structure

As the automotive industry developed, the frame structure was replaced by a monocoque body. That is, all the elements of the car were already attached to the body, and the need for a frame disappeared, although not entirely. The frame bearing part is still used on trucks and heavy SUVs. The thing is that the supporting body is not able to withstand heavy loads, that is, this design is not used for trucks or large SUVs with significant mass.

But even in passenger cars, not all the load from the components falls on the body. If this were done, then it, made of thin sheet metal, simply would not withstand the load, and the component parts would simply fall off, breaking the metal. Therefore, it is impossible to do without the use of side members when installing a load-bearing body.

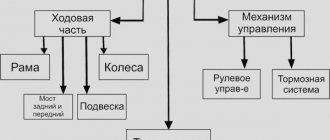

Vehicle spar frames

In cars, carriages and locomotives, two spars connected by transverse elements are a complex-shaped metal box that forms a frame (chassis), which serves as a support for the frameless body, as well as for attaching springs, wheels and other parts.

In other words, a spar is a metal pipe that has a rectangular cross-section, most often it is a pair of parts - for the rear and front parts. The classic version of such a frame resembles a staircase in appearance and design, so in everyday life it can sometimes be called a staircase

(ladder frame). Spar frames consist of two longitudinal spars and several cross members, also called “traverses,” as well as fastenings and brackets for mounting the body and components. The shape and design of the side members and cross members may be different; Thus, there are tubular, K-shaped and X-shaped cross members. Spars usually have a channel cross-section, which is usually variable in length - in the most loaded areas the section height is often increased. Sometimes they have a closed cross-section (box) for at least part of their length. On sports cars, tubular spars and round cross members could be used, which had a better weight-to-stiffness ratio. By location, the spars can be parallel to each other, or located relative to each other at a certain angle. Frame parts are connected by rivets, bolts or welding. Trucks usually have riveted frames, while passenger cars and heavy-duty dump trucks have welded frames. Bolted connections are usually used in small-scale production. Modern heavy-duty trucks and trailers also sometimes have bolt-on frames, making them much easier to service and repair, requiring special precautions to prevent the bolts from loosening themselves.

The traditional type of spar frame provides the car with fairly high rigidity, especially in the case of the presence of developed cross members (K-shaped, X-shaped), and from a technical point of view is not outdated to this day, however, it has a significant drawback - its spars pass under the floor of the body, so that it has to be placed quite high. As long as mass-produced passenger cars remained relatively tall, this did not present a problem, but in the second half of the 1950s, the fashion for squat bodies spread, which, in the case of using a traditional type of frame, forced the seats to be made very low in order to ensure sufficient distance between the seat cushions and the roof, and this reduced comfort. The solution was to switch to either a monocoque body or a fork-spine or peripheral type frame, in which the spars somehow bypass the passenger compartment (either placed on the sides of it or located in the central tunnel of the body), allowing the floor to be lowered and combining a small common height of the car with sufficient space in the cabin. On cars that do not have such requirements, for example, SUVs with high bodies, the spar frame is still used today in its original form. One of the latest examples of the use of a spar frame on a regular passenger car is the East German Wartburg, which was produced until the end of the 1980s.

Spar frame with X-shaped cross member.

Spar frames are used on almost all trucks, and in the past they were widely used on passenger cars - in Europe until the late forties, and in America until the late eighties - mid-nineties. On SUVs, spar frames are still widely used to this day. Due to such wide distribution, usually in popular literature the word “frame” is understood as a spar frame.

A number of sources also classify as spar frames peripheral (often classified as a separate type) and X-shaped frames (the latter are classified by other sources as a type of spinal frame).

The design of the spar and what are they for?

The functions of the frame are performed by the body in the form of spars

The main task of the side members is to absorb all loads, both internal (car components, passengers, additional cargo, etc.) and external (vibrations transmitted from the wheels). A spar is a damper that is located between the suspension and the body and dampens vibrations.

The spar is a regular pipe of rectangular cross-section. Moreover, in different places this section can change to ensure the necessary rigidity of the body. There are technological holes made in them, with the help of which the components of the car are installed and fastened, and ventilation is also performed so that moisture does not accumulate inside them, which is a catalyst for the formation of corrosion processes.

But unlike a frame structure, where the frame is a completely separate element of the car, in passenger cars the side members are integrated into the body, that is, they are an integral part of it and many body elements are attached to them by welding.

Hydraulic stretch

Hydraulic stretching is used in body repair for stretching using the extrusion method. There are various hydraulic extensions that provide different forces from 4 tons and above. An example of the use of this device is pulling out the side pillars of the body by squeezing it out from inside the passenger compartment. Spars that are shifted to the side can be straightened. And also, straightening deformed doorways and windshield and rear window openings. Typically, bodybuilders purchase a set that includes several types of extensions of different lengths, attachments, the extension itself and a hydraulic pump, but you can buy each element separately.

Design features and types of spars

Front side members are marked in red

Spars in passenger cars can be of either a separate design or one-piece. By separate we mean that a certain part of the body has its own spars. They are installed in the front part (strengthening the engine compartment), the middle part of the body (to strengthen the bottom of the cabin) and the rear (strengthening the rear of the body). But since there are a large number of body types, it is not necessary that all of the specified spars can be used. For example, some cars may not have middle or rear side members, but there are always front ones.

This is explained by the fact that the front of the car experiences the heaviest loads - it bears the weight of the power plant and transmission, and the suspension is attached to it.

Also, in the monocoque body, solid side members can be used, stretching along the entire car from the front to the rear bumper. This design is more reliable, but also more difficult to manufacture, since it is necessary to give the spars a special shape (the bends of the wings) while maintaining all the strength indicators.

But no matter what types of side members are used on cars, separate or solid, they are always paired and located parallel to each other. Although in some cases these elements are used, located at a slight angle.

Also, the spars can be either composite or representing a single integral element. The first ones look like a certain set of parts connected to each other. Each of them has its own good qualities and disadvantages. Thus, the composite design makes repairs easier, since it is possible to replace only the damaged part, without replacing the entire structure. But the strength and reliability indicators of this type of spars are lower. The one-piece type is capable of withstanding significant loads due to its single structure, but if it is damaged, its restoration is almost impossible.

To ensure that the spars can withstand heavy loads, titanium or aluminum alloys, as well as composite materials, are used as the material for their manufacture. The formation of these elements is carried out either by stamping or using milling machines.

Types of existing load-bearing structures

The large group of different types of spars is based on the principle of their location. Different types of parts are suitable for different cars; there is no universal type.

- Parts in trucks are arranged horizontally parallel to each other.

- A horizontal position at a certain angle is typical for passenger SUVs.

- The curved, vertical arrangement of the load-bearing beams allows for a lower center of gravity. In this case, the floor in the cabin is located at a lower level.

- In a curved, horizontal position, the floor level in the cabin also decreases. Moreover, in the event of a side collision, passive safety will be at a higher level.

Between the beams there are cross members, we have already mentioned them. These crossbars are also divided into varieties depending on their shape:

- straight;

- in the form of the letter X;

- K-shaped.

The material for their manufacture is a curved metal profile. In truck-type vehicles, rivets are used to connect the crossbars to the main beam. When assembling passenger cars, a welding seam is used. To secure all the component elements of the body to the spar, brackets are used, which also differ in shape.

What functions do spars perform?

Based on the foregoing, it becomes clear that side members in passenger cars are the main strength element in the design. But if in trucks it is a load-bearing part, then in cars it only strengthens the body. But at the same time, its functions are very important, since it takes on all the loads acting on the body. And they are multidirectional, so the spar works in very harsh conditions.

In addition to reinforcement, these elements also serve as shock absorbers, ensuring as even a distribution of vibration effects as possible throughout the entire body, and not just in a certain part of it.

On airplanes

Double spar wing

In airplanes, the spars, together with the stringers, form a longitudinal set of the wing, fuselage, tail, rudders and ailerons. The longitudinal elements of the frame usually run along the entire length of the fuselage. Together with the skin, they absorb normal forces when bending the fuselage. Simple stringers and spars are usually made from extruded or bent sections. Spars differ from stringers in being more rigid. For heavy loads, composite spars can be used, consisting of several interconnected profiles. To frame large cutouts in the fuselage, box-section spars are often used - beams, which consist of pressed profiles connected by walls and skin.

Spars are highlighted in red

The ribs are fixed to the longitudinal strength set (spars, edges, stringers) and are the basis for fastening the skin.

A spar wing includes one or more longitudinal load-bearing elements—spars—that perceive a bending moment. In addition to spars, such a wing may contain longitudinal walls. They differ from side members in that the skin panels with a stringer set are attached to the side members. The spars transfer the load to the aircraft fuselage frames using moment units.

Side member malfunctions

Since these elements of the body structure perform a number of important functions, all of which are associated with the perception of significant loads, the occurrence of deformation is a matter of time.

Gradually, the metal “fatigue” occurs, due to which its properties change - strength and elasticity decrease. Therefore, the likelihood of deformation from even a minor impact increases significantly.

Because of this “fatigue,” cracks may form, which usually begin from the technological holes. After a crack appears during further operation, it will “grow” and if no action is taken, it will ultimately lead to the destruction of the spar.

And, of course, strong shock loads, for example, during an accident, can change the geometry of the element itself, and this is already a rather serious problem. Because many body elements, as well as car components, are attached to the side members. And if during an accident the spar “leads”, then this will affect the geometry of the body and change the position of the units and components. Because of this, the gaps in the body may increase significantly and the tightness may be compromised. Displacement of units can lead to additional loads at the joints, which will lead to increased wear.

Also, changing the geometry of the body almost always affects the handling of the car. Due to the fact that the side members are “moved,” the position of the wheels changes, which is why the car can constantly “drive” to the side, and tire wear will also increase significantly.

Problems related to spars

Under the influence of loads, the side members still deform over time, especially the front one (the load from the engine and its systems) suffers. Just like the front ones, the rear ones can crack and get tired. The word “get tired” implies the initiation of a crack, which over time grows throughout the entire part. Of course, an accident can also leave a significant mark.

What does operating a car with damaged side members entail? Some parameters of the car are violated: slightly, but the position of the doors, connectors of body parts, and the position of the power plant changes. The suspension geometry also suffers. Due to all these shortcomings, the car's handling is reduced. Therefore, if the body is damaged, you need to take the car for diagnostics - this decision will be correct.

If the spar completely bursts, then the entire body structure will be completely destroyed. It is because of this that after an accident, experts look at the degree of deformation of these elements. The position in which the side members are in the car also plays an important role.

Statistics: Approximately 90% of all work associated with this part occurs on the front spar. Such damage can be resolved quickly only with a frame spar - there it is simply replaced. As for the supporting body, sometimes the spars simply cannot be replaced. Let's say it was slightly dented in an accident: such damage can be corrected using a special carolin stand. For example, on the stand there are front left and rear side members - using a convenient location, mechanics measure all the parameters necessary to correct the problem.

It happens that the side members of a car are in such a state that the only option left is replacement. Changing parts entails a significant change in the properties of the entire body. After all, the shape, material and weight are calculated by the manufacturing company - in automotive centers you have to improvise. When the main parts of the spar are in good condition, a partial replacement is performed using arc gas welding.

When making repairs, you must insist that the new spar is no larger in size and weight than the old one. Some people prefer to harden a new one, but one must remember that such a decision may lead to a loss of shock-absorbing properties upon impact. Constant blows will lead to more serious consequences. Do not forget that in the event of an accident, the side members are checked first, and then everything else.

https://kuzovspec.ru

Methods of restoration and repair

Video: How to pull out a spar with your own hands, IN THE FOREST)

The main problem with using side members in a monocoque body is their very difficult restoration and repair. But you can’t do without them in the design of a car.

As already noted, composite-type spars, consisting of several parts, can still be repaired by replacing the damaged element, but this also has its own nuances. In this way, only cracks and other minor damage to this element can be eliminated.

You can also weld cracks using a welding machine, although here, too, not everything is simple. Titanium and aluminum alloys are very difficult to weld, so such work should be carried out by a professional who knows all the features of working with such metals.

If the spar has “begun” or there are minor deformations, then it is possible to restore its geometry on a special stand – a caroliner. But this operation is not easy, since to access the damaged element you have to disassemble almost the entire car.

Partial replacement of the spar is allowed. It is performed when only a small area at the end of the element is deformed. In this case, the damaged part is cut off and a new one is welded in its place. But such an operation is possible only on the condition that the main part of the element does not have any damage.

Complete replacement of a deformed spar is a very risky operation. Proof of this is that if this element is severely damaged, the body is considered unsuitable for further use.

And yet such an operation is performed. But at the same time, no one will provide a complete guarantee that the body geometry will be restored, but the problem can easily be aggravated by attempting to replace the spar. And such work itself is very expensive, so it is not always advisable to do it, given that all interventions in the body structure will certainly affect safety.

How does the body stretch?

This article will be of interest to beginners in auto body repair who are interested in the process of stretching a car body after an accident. We will look at some points that are known to professionals, but unclear to beginners.

So, before repairing a damaged car body, it is important to carefully examine and understand the logic of the damage. What has shifted and where, what can be repaired and what needs to be changed. It is necessary to determine whether the geometric parameters of the body have been changed.

What is a spar in a car?

The front side members are two metal profile pipes.

The spar is supported by the main elements of the car - the engine, wheels, seats, body parts.

The spar consists of two metal profile pipes that are located at the bottom of the car and hold the main elements - the engine, wheels, seats, body parts. In most SUVs, the frame serves as the supporting structure. For passenger cars, a more universal solution is to use side members. They are much lighter, which reduces the weight of the car.

Do-it-yourself car body exhaust

Body stretching is a very complex process, which is usually performed after an accident, when all distortions in the geometry of the car body are eliminated by applying the opposite force to that received during the accident.

What does it take to pull out damage?

To correct damage of this nature, special tools are always used that can return any part of the car to its previous state; these are hydraulic and screw jacks, which can be used on:

Why check the spar

When buying a car second hand, you must check the side members. If the spar moves, this can lead to deformation of the entire body, resulting in incorrect camber and increased tire wear, and an increase in the gap between body parts. Additionally, if a side member has rotted or burst, the vehicle is considered unsafe and cannot be driven. At high speeds, insufficient body rigidity can lead to loss of controllability. In the event of an accident, the spar provides passive safety, preventing the car body from being crushed and injuring the driver and passengers.

Causes and consequences of deformation

What is ABS in a car and why is ABS needed? The principle of operation of the anti-lock braking system

Over time, the metal, under the influence of variable loads, succumbs to the effect of fatigue - cracks form on it. After ten years, the seemingly strong structure weakens and loses its former endurance. Neither nitriding nor chemical-thermal treatment helps. When a car gets into an accident, the side members are severely deformed, simultaneously worsening the overall technical characteristics of the car. It is possible that the engine, suspension and transmission parts may be displaced. And the entire body loses its inherent strength and geometry when the spar bursts. That is why, when inspecting a car on the secondary market, a specialist first checks these parts.

It is easier to restore the frame structure. On load-bearing structures, things are much worse: here the spar acts as part of the body, and in particularly unfortunate cases, changing it is pointless or simply impossible.

Bend over time

The spar can be repaired with a slight, not sharp bend. For this, a hydraulic stretching machine or winch is used. A sharp bend with an acute angle is already a loss of the basic shape. Such an element is almost impossible to restore: it is more advisable to replace part of the pipe or the entire beam.

If the side members are bent after an accident

The parts simply become wrinkled and lose their original shape. If the spar is not bent too much, it can be straightened on a slipway or caroliner. If it bursts from an impact, there is no point in repairing it. The only option left is overcooking, partial or complete. The old part is cut off with a grinder, then a new piece of pipe is installed. Anti-corrosion treatment of parts and painting are required.

Crack or complete break

Small cracks and minor damage can be repaired. A welding machine will help in this case. It is necessary to carefully weld the cracks if the parts are not aluminum or titanium: such spars are difficult to weld.

A complete spar rupture is bad. The entire body structure suffers, especially the load-bearing type. More often than others, the front side members of the car are damaged beyond repair.

The consequences of deformation or destruction of the spar are extremely negative for the car. Incorrect camber and increased tire wear, increased play between body parts, and decreased body safety are just a few examples of a sad outcome. At high speeds, weak body rigidity can lead to loss of control, injury and loss of life.

How to check the side members

Rotten front spar

It is possible to detect slight curvature of the side members and changes in body geometry only on a stand. However, serious problems with spars can be identified independently. To do this, you need to check for the following symptoms:

You can find out where the side members are located according to the instructions for a specific car.

- Camber and toe. If there are problems with the side members, there will be incorrect camber and toe-in of the car's wheels. Even with adjustment, it will quickly go astray and the tires will wear unevenly.

- Gaps between body parts. If there are problems with the side members, the gaps between the parts will be uneven; this should be visible by eye. In addition, the doors, trunk and hood will be difficult to close and open .

- External defects. Problems with side members can also be determined visually. Externally, this manifests itself in a violation of the geometry of the body. You can also check them from the inside, from the inspection hole. There should be no welds, cracks or other defects on the side members. You can find out where the side members are located according to the instructions for a specific car. Typically, the front spar supports the engine. The rear spar runs under the trunk and the tow bar and rear bumper are attached to it.

Pulling out the shock absorber cups

As mentioned above, when measuring the “geometry” of the body, it is important to check the location of the shock absorber cups. The diagonals of the segments are measured from the centers of the upper bolts for attaching the struts to the bolts for attaching the hood brackets to the body. Also, the diagonal distances between the centers of the bolts of both body cups are checked.

When moving the shock absorber cups, a special device is used. It allows you to pull the cup in any direction.

Spar repair

The most common problem is the deformation of the spar during an accident. In this case, it simply wrinkles and loses its original shape. As a rule, if the deformation was not severe, such a spar can be straightened without replacement. For this purpose, special equipment is used - a slipway. Extracting the spar without a slipway is also possible, but it is almost impossible to carry out repairs of sufficient quality. The car is completely disassembled and installed on a stand. Then the spars are pulled out by the slipway with great effort. At the same time, the geometry of the body is constantly checked and monitored. If the spar goes inside, then it is squeezed out into its place. You can also pull out the spar yourself, although this is not recommended. As a rule, this option is resorted to in cases where the car is inexpensive or there is no money for quality repairs. The side members may be pulled out with a jerk when the cable is tied to another vehicle. You can also use a jack and various lever mechanisms. Before pulling out the spar at home, it is better to study its design in detail. If you pull the spar too far in the opposite direction, it will no longer be possible to correct it. On average, pulling out a spar costs about 5,000 rubles, taking into account disassembling and assembling the car and checking the geometry on a stand.

How to stretch car bodies

Pulling out a car or a car body at a cost even if there has been a minor accident or other damaging factors is quite expensive.

Although, it seems that there is nothing difficult when performing such work. The main thing is desire, free time and the necessary tools, then repairing the car body is possible on your own. How the body is stretched and pulled out, let’s figure it out step by step:

First, you need to determine the amount of work required, and then the car must be washed, then thoroughly inspected. First of all, you need to make sure that the spatial geometry of the body is not broken. You can check the geometry by measuring the distances between all control points.

When there is no information on these points, then you can navigate by the visible power structure. For example, the distances between the suspension mounts and engine mounts are symmetrical.

When the geometry of the body is damaged, then restoring the car with your own hands will be extremely difficult. Because you not only need to know how the body is pulled, you need specific equipment, in fact, you need a whole stand that allows you to pull the body in any desired direction. The equipment is bulky and expensive.

Of course, you can try to use the means at hand, for example, guy ropes or jacks, however, it is very difficult to efficiently restore the car body using such means.

If you do not have the opportunity to use the appropriate stand (for example, rent), then there is no point in purchasing a stand - repairs will be cheaper in the service.

The second thing you should pay close attention to is rust stains. Moreover, through corrosion cannot be ignored. The appearance of a rusty spot on the surface does not mean that the body is not completely rotten - there may already be no metal under the paint. Such places should be checked (with a simple tap, everything will immediately become clear by the sound).

As a rule, body repairs begin only because minor damage appears in a visible place. However, it won’t hurt to check the other points.

And if the dents are not large, there are no tears or pulling out of the metal, and the stiffening ribs are not affected, then they can be straightened out carefully, and subsequent painting will not be needed. This is achieved by restoring the shape through mechanical action, while preserving the paint layer; the work is complex and requires experience.

In more complex work, it is not possible to preserve the paintwork, so after straightening, priming and painting are required.

Geometry restoration

The process consists of stretching a certain point of the body in three-dimensional space, for which it is necessary to “calculate” the desired point geometrically, and then predict the behavior of the body when stretched, and this requires some experience. Therefore, you need to consider a simpler, often necessary type of repair.

Replacing the spar

If the spar has burst, then there is no point in pulling it out. In this case, only overcooking the spars will help. Since it is attached by welding, it needs to be overcooked. It can be replaced either completely or partially. The old spar or part of it is cut off with an angle grinder, and then a new part is installed. Before welding the side members, all adjacent body parts are dismantled. After installing a new part, anti-corrosion treatment is carried out. Typically, primer is applied and then paint. It is also advisable to treat the spar from the inside.

Measuring distances between body control points

Measuring the distances between control points must be done before, during and after pulling. Measuring the geometric parameters of the body helps determine the direction of pulling. Measuring while drawing helps to check that the drawing is correct. Measurements after pulling show the correctness of the final result. Measurements can be taken with a tape measure or a special ruler to check the geometry of the body. You need to take diagonal measurements and length measurements between points. You can read more about measurements in the article “Checking body geometry”. It is advisable to have data on the distances between test points, which can be found in repair manuals.

An example of a diagram with the location of control points and the distances between them.

The test points must be returned to the original factory position. An error of several millimeters is allowed.

Prevention of spars

After installing the new spar, it is subjected to anti-corrosion treatment, a primer is applied, and then paint.

In order for the car to serve for a long time, it is advisable to monitor the condition of the side members and carry out preventive maintenance. Correcting the spar is very expensive, so it is better to monitor it and carry out routine preventive maintenance. Since the inside of the spars is hollow, dirt and moisture can accumulate in them, which leads to metal corrosion. Therefore, it is advisable to apply anti-corrosion mixtures at least once a year before winter. You can find out what the spar looks like from the instructions for the car, which shows the load-bearing elements. This also usually shows drainage holes through which a protective anti-corrosion agent should be applied. In addition, it is advisable to avoid excessive loads on the car body. Under severe overload and operation in difficult conditions, the side members may burst or bend. If it is necessary to use the machine in difficult conditions, a spar amplifier can be installed. This part allows you to reduce the load and extend the service life of the spar. It is necessary to monitor the condition of the car, especially the supporting elements. If it is operated in difficult conditions or driven at high speed on bad roads, it is advisable to regularly check the condition of the side members. Many used cars are sold after cosmetic repairs. In this case, the side members may be rotten or burst, although the car body looks like new.

Replace or pull out a damaged spar?

First of all, you need to decide whether to repair or replace the spar.

The decision to replace the spar should be made based on the degree of damage.

With a smooth, not sharp bend, the spar can be repaired to a condition comparable to the whole. On this car, the right side member (in the left photo) was restored, and the left one (in the right photo) was replaced.

Sometimes both front side members, during a side impact, simultaneously (since they are connected to each other by the bumper reinforcement and the lower beam) are displaced a considerable distance, but are not even damaged.

In this case, it is enough to secure the car and pull out both side members using lateral action (hydraulic extension or winch). The left spar, which cannot be restored, was replaced.

The right spar has been straightened. If there is a sharp bend (with an acute angle), or loss of its basic shape, it will be difficult to repair the spar to the condition it had before the accident.

Replacement can be either complete or partial. With a partial replacement, only the part that is not suitable for restoration is replaced. You can read more about replacing the spar in the article “Replacing the front spar”. The spar after repair should have the same rigidity as before the accident. If the strength of the spar is weaker or the spar becomes more rigid, this may affect the accident safety of the car. The airbags will deploy a little earlier or a little later, which is unacceptable.

How to pull out the spar yourself

The main part of the body of each car can be called side members; this is a rectangular pipe, or, as they say in another way, a longitudinal beam of the body. The spar passes through the entire body, and the entire load, shock absorption and impact in an accident falls on it. The standard car design has left and right side members, and they themselves are divided into front, rear and middle. As a rule, the front side members are slightly higher than the rear ones; this design is made in order to place the car's engine in front. A variety of materials are used for them, it can be:

- titanium alloy;

- Aluminium alloy;

- composite layers.

Spar

Main types

The spars are installed in different positions, which depend on the type of car:

- Parallel and horizontal.

- Horizontally and at an angle.

- Curved elements arranged vertically.

- Curved power beams placed horizontally.

Horizontal parallel beams are installed on trucks, while on SUVs they are placed at an angle, due to which the steering axis of the wheels is larger. Elements curved vertically allow the car's center of gravity to be lowered. The vehicle's horizontally curved side member improves passive safety in the event of a side impact.

Causes of damage

As we have already found out, the spar absorbs the bulk of the shock absorption when driving; manufacturers specially develop special designs for this part so that it absorbs all the kinetic energy and takes on the entire impact force in an accident. But even if the car has never been in an accident, the spar may crack over time from driving on our roads.

If you notice that the car is starting to pull sideways, or the doors are not closing well, the rubber is rubbing against the body - these are the first signs that the spar is cracked or misaligned. But don’t panic, how to pull out the spar is described in this article, and you can solve this problem yourself or turn to the services of a car repair shop. In today's article we will look at the method of drawing out a spar with our own hands using the example of a VAZ car.

To damage or bend the spar, it is not necessary to make a head-on collision at “crazy speed”; this can also happen in a light collision, as a result of which the entire car body changes its geometry.

How to push a stuck car alone - Autoblogs - MirTesen media platform

A modern person cannot imagine his life without a vehicle. Cars are used for transportation, transportation of various goods, racing and other entertainment. According to their characteristics, they can be divided into cars, crossovers, SUVs and others.

No matter what car you have, sometimes even the most adaptable vehicles cannot resist the powerful forces of nature.

In addition, having a powerful SUV at his disposal, a person very often overestimates its capabilities, deliberately heading into the most difficult areas, and this is where the problem subsequently arises of how to pull out a stuck car alone.

How to pull a car out of the snow yourself

The first thing to consider is what to do if your car gets stuck in the snow. People face this problem most often, since in order to get into a snow trap they do not need to turn somewhere and go outside the city.

Required materials and tools

I would like to warn you right away that the further possibility of using the car depends on a high-quality hood, so this problem should be taken seriously.

- powerful electric grinder (impeller);

- welding machine;

- gas stove);

- grinding machine with a full set of discs;

- a stationary stand with the necessary template and chain grips (they are easier to work with);

- metal spatula and automotive primer;

- sealant tape;

- straightening hammer for metal;

- You will also have to find a table for the make of your car with data about the factory body geometry.

When the entire list has been collected, you can begin to work.

Body clamps

To directly attach a chain from a pulling device (winch or tie) to a damaged element, various body grips are used.

Sometimes metal loops and plates with loops are welded in places where it is impossible to use a body grip, or in the absence of special grips.

Some modern body clamps have a self-clamping design. By adding pulling force, the gripper is compressed more, which prevents it from slipping out.

Sequencing

Before starting work with a VAZ car, you need to remove all the parts that stand in the way of the spar. It is also necessary to disconnect wires and electrical devices in vehicles. After all these manipulations, you will see the spar itself and can now easily reach it. Next, let’s begin the extraction process itself, fix the car and cut off the heavily damaged parts of the part with a grinder - this must be done carefully using a protective mask and gloves. We attach the chains to the spar and make a smooth tension, at the same time giving it its original appearance. After you have cut off the “unnecessary” parts and made a hood, check whether the car door can be closed correctly. If the door closes as it should, then you are on the right track, otherwise you will have to manipulate the tension several more times. Further in the work, using the table of technical characteristics of the VAZ car, we restore the geometry of the points of the body spar. To make it easier to set dots in such conditions, you can use colored tape to mark those same dots. It is necessary to pull out the spar so that the adhesive tape marks coincide with the marks indicated in the technical specifications. Don't forget to check if the side members and wheel arches are parallel.

Using a straightening hammer, you can correct part of the wheel arch and other dents that appeared during work. The next step is to remove the old sealant coating by heating it with a gas torch. If during work small irregularities and surface roughness arise, then using a grinding machine you can get rid of them yourself. The final stage will be to prepare for painting the VAZ car, apply a new layer of sealant and primer, and after drying, paint. When the paint is completely dry, you can reassemble the body, installing the parts in the reverse order, as during disassembly.

If you are confident in your abilities, then you can safely get to work and pull out the spar on a VAZ car with your own hands, but if you have even the slightest doubt, then it is best to contact a qualified and experienced professional at a service station.