The magnitude of the hydraulic pressure in the power steering of trucks

EXECUTION ORDER

- After thoroughly cleaning the connection between the high pressure hose and the power steering pump, disconnect the hose from the pump and install special equipment (oil pressure sensor, connecting pipes). Tighten each nut with the appropriate torque.

- Special tool: (A) - 09915-77411 (oil pressure sensor)

- (B) - 09915-77420

To check the pressure in the power steering , first you need to place the car on a special two-post jack.

Then it is necessary to remove the protective casing installed on the engine oil pan.

Next, check the level of working fluid in the oil tank of the power steering system (refill if necessary) and the tension of the pump drive belt (loosen or tighten if necessary).

Hydraulic power steering (power steering) in a car

It would be easier to answer your question if you provided the vehicle model.

All modern power steering pumps have a pressure relief valve, which is initially configured to a certain value.

In domestic vehicles it ranges from 90 to 125 atmospheres, in foreign cars - from 60 to 100 atmospheres. 1 atmosphere is equal to 1.01325 bar.

All about measuring pressure in the power steering at home

To more accurately measure the back hydraulic pressure in the power steering system, it is necessary that the car is idling, at medium speeds, and the steering wheel is in one position.

When measuring back pressure, the pressure gauge should display values of no more than 1000 kPa (10 kg/cm2, 142 psi).

If the reading is higher than required, there is most likely a problem with the control valve or the hydraulic pipes are dirty.

Please note => Young family Biysk 2019

What is the pressure in the power steering system?

For passenger cars, the main purpose of power steering is to ensure comfort. Driving a vehicle equipped with hydraulic power steering is easy and convenient.

In addition, the driver does not need to make a full five or six turns of the steering wheel in the direction of the turn to complete the maneuver.

This state of affairs is especially important when parking and maneuvering in narrow areas.

Hydraulic pressure in the power steering system

Of course, this is an extremely simple description and does not affect small but important details, however, these are the main nodes.

Now let's talk about each of the components so that by the end of their description we have a general picture of the operation of the car's power steering.

As you describe the components, return to the big picture above, and you will have a clearer understanding of the connections between the components and their purposes in the system.

Operating principle of power steering

This mechanism is a double-acting hydraulic cylinder. It has a piston that divides the cylinder into two cavities.

During rotation, the distributor supplies fluid to the required cavity, which, due to pressure, forces it to move in the required direction.

In this case, the piston is connected to the steering mechanism, so when moving it transmits force to the mechanism.

Hydraulic power steering of a car

- Oil is pumped through the system, and excess pressure is sent to the expansion tank until the driver begins to turn the steering wheel.

- When turning the steering wheel, the distributor torsion bar senses the direction of rotation, due to which one of the two valves is activated, opening the flow of hydraulic fluid to the cylinder piston.

- The oil presses on the piston on one side, forcing it to push the rack or rod in the desired direction until the driver stops turning the steering wheel. When the steering wheel stops in any position, the distributor closes the valve and the piston stops pushing the rack.

- When the steering wheel rotates in the opposite direction, the first valve closes and the second one immediately activates. Fluid enters the piston from the other side, causing it to move and push the rack in a different direction.

Unloading pressure

To determine the maximum pressure in the power steering , it is necessary to increase the engine speed to at least 1500 rpm. To measure the relief pressure in the power steering system, you must slowly close the check valve while watching the arrow on the pressure gauge.

The pressure for the G16 motor is 6200-7000 kPa (62 - 70 kg/cm2, 882 - 995 psi). For the J20 motor, the unloading pressure is 6700-7500 (67 - 75 kg/cm2, 953 - 1067 psi). If the pressure gauge value is higher than required, then, as a rule, the check valve is faulty, and if it is lower, the oil pump is not working well or the check valve spring is stuck.

Source

Typical power steering malfunctions

Malfunctions in the operation of the hydraulic booster can be easily identified by characteristic signs. Among them:

Recommendations for operation and maintenance of power steering

In order for the power steering and its system to operate normally, as well as to extend their service life, you must adhere to several simple rules:

Cost of replacing fluid and pumping power steering

If you plan to carry out work on replacing the fluid and pumping the power steering yourself, then you will only need to buy oil in a volume of 1 to 3 liters (including flushing, while the volume of the power steering system of a passenger car is up to 1 liter). The price of the liquid depends on the brand and store. It is within $4.15 per liter. If you do not want or cannot carry out such work yourself, contact a service station for help. Approximate prices for January 2021 are:

The most common power steering failures

Most often, the repair of such power steering breakdowns consists of timely replacement or adjustment of the belt, adding fluid to the reservoir, repairing or completely replacing the power steering pump, eliminating leaks in the power steering system, and possible depressurization of the system as a whole. It would seem like a small thing, but you shouldn’t joke with the steering, since the road does not forgive mistakes.

The principle of operation of a car's power steering

To understand how a car’s power steering works, let’s consider several options, or rather different wheel turning situations. One of the most common situations is when the car is standing still, but with the engine running. In this case, the liquid is simply pumped from the tank through the system and back into the tank.

Another very common situation is when the driver turns the steering wheel.

. In this case, the torque is applied to the shaft, and subsequently to the torsion bar, which in turn begins to twist about its axis. As a rule, at such a moment the rotary spool does not work due to the wheels, due to which the liquid enters the cavities of the hydraulic cylinder under pressure (depending on which direction the steering wheel is turned). Excess fluid from the other cavity of the hydraulic cylinder flows back into the tank through the line. The basis of everything here can be considered the rod; due to the pressure of the liquid on the piston with the rod, the steering rack can move, and accordingly the wheels can turn.

Signs of a faulty power steering

There are a number of typical symptoms that indicate that the power steering in a car needs to be repaired or, at a minimum, the oil in it should be changed. Thus, power steering diagnostics must be performed if at least one of the following situations occurs:

Often, the signs of a power steering malfunction in a car are very similar to the breakdown of other elements of the steering system, such as the rack, tie rods, ends and others. Therefore, it is advisable to perform a comprehensive diagnosis.

Functions and design of power steering

To deal with possible power steering malfunctions, let’s briefly consider why it is needed at all and what its operating principle is.

The main function of power steering is to increase the comfort of driving by facilitating the effort on the steering wheel. This is ensured by the operation of a hydraulic pump built into it, which creates and changes pressure in the hydraulic steering system.

Power steering malfunction video

The main mechanism of hydraulic power steering is a pump, which is driven by a belt from the crankshaft of the car engine. Its main task is to pump up the necessary pressure in the system (usually it is about 50...100 atmospheres). Another element of the system is the distributor; it monitors the force on the steering wheel and gradually helps turn the steered wheels. A torsion bar or sensor is used for tracking. The system also has a valve whose task is to release excess fluid under pressure into the system.

When the steering wheel is straight, the metering channels of the hydraulic fluid distributor are closed, and the oil is drained back into the expansion tank through the valve. When the steering wheel is turned in one direction or another, the spool opens the oil channels, and the fluid goes into the steering rack actuator, which turns the wheels. The design also provides safety valves that are activated when the steering wheel is turned all the way in one direction or another, since at this moment the pump receives the greatest load.

Cost of repairs and power steering parts

If we talk about repairing the power steering, and in particular about the cost of parts, then everything depends on the make, model and the device of the car itself. The price may be proportional to the cost of the car, or repairs will cost a minimum price. Let's take a look at the cost of parts using a certain model as an example.

| Brand and model name | Detail | Cost, rub. | Cost, UAH. | Cost, dollars |

| Chevrolet Lacetti | Power steering pump | 5255 | 2076 | 77 |

| BMW 3-Series 2003 | Power steering reservoir | 1898 | 750 | 28 |

| Daewoo Lanos 2008 | Power steering pump and pulley | 2506 | 990 | 37 |

| Mercedes-Benz Vito 2008 | Power steering pump | 4036 | 1594 | 59 |

| Hyundai Tucson 2.0 | Pump belt | 381 | 150 | 6 |

| Hyundai Tucson 2.0 | Power steering hose | 790 | 312 | 12 |

As you can see, the prices for power steering parts are not astronomical, so you should not save on this and carry out repairs in a timely manner. As for the cost of repair services, it is better to provide approximate prices, since they may differ depending on the service station. We will provide approximate prices for power steering repair services.

| Name | Cost from, rub. | Cost from, UAH. | Cost from, dollars |

| Repair of double-circuit power steering pump | 4050 | 1600 | 60 |

| Repair of a single-circuit power steering pump | 2279 | 900 | 35 |

| Replacing the power steering pump | 1773 | 700 | 25 |

| Power steering piston repair | 3797 | 1500 | 55 |

| Replacing the pump belt | 510 | 200 | 10 |

The price for repair services is also not particularly high, but still, if you do not pay attention in time and do not eliminate the problem, in the future it can turn into serious consequences. If we talk about power steering (power steering), then this is an indispensable system in a modern car. Control dynamics, comfort and safety are the things that involve a modern power steering mechanism.

Video review of the operating principle of power steering:

Source

Causes of power steering malfunction

Depending on which part of the hydraulic booster has failed, there may be a reason for this. However, when the power steering does not work, the reasons are the following:

In addition to the listed reasons for power steering malfunction related to the technical field, it also makes sense to highlight two reasons related to the so-called human factor. In particular:

Therefore, the driver himself is often to blame for the fact that the hydraulic booster fails prematurely. So troubleshooting the gyroscope will directly depend on the cause that the diagnostics showed.

Power steering malfunctions

Power steering malfunctions not only lead to a deterioration in driving comfort, but also directly affect the safety of driving the car on the road. Thus, typical breakdowns of the power steering are leaking oil seals in its hydraulic system, insufficient fluid level or untimely replacement, insufficient drive belt tension, partial failure of the drive pump and some others. In many cases, the power steering is completely repairable, including in a garage. Let's look at typical faults, repair methods and preventive maintenance of power steering.

How to check the power steering for a malfunction

For those who have wondered how to determine whether the power steering is faulty, there are a number of test steps that even a beginner can easily handle. Let us list in order how to determine a power steering fault yourself.

Liquid level in the tank

The first thing you need to pay attention to when there are problems with the hydraulic booster is to check the level of its working fluid in the reservoir. Every car equipped with power steering has a special small expansion tank with working fluid in the engine compartment, which is generally accessible, which is used for lubrication and cooling. On the walls of the tank there are MIN and MAX marks (there may be other similar marks, including pictures), which indicate, respectively, the minimum and maximum fluid levels in the system. It is necessary to constantly ensure that there is enough fluid. A noticeable decrease in its volume is a reason to look for the cause of a leak in the system, that is, its depressurization.

Belt tension

The next mandatory check is the tension of the drive belt. For each car, the corresponding value is indicated in the manual. Information that it has weakened can only be obtained by checking its tension with your hand, or by the main symptom, which is the squeaking of the belt during a cold start of the engine, especially in the cold season. Tensioning is performed using special tools and drive rollers. As a temporary measure, you can use a belt conditioner. But then you still need to do the appropriate stretching.

Liquid leakage

Diagnosing power steering faults necessarily involves inspecting all of its lines for hydraulic fluid leaks. Leak locations can be very different, usually shafts, bearings, fittings, pipelines. It is imperative to check the power steering pump itself for leaks.

Fluid and filter condition

When checking, be sure to pay attention to the condition of the filter element, as well as the hydraulic fluid. This is especially true when they are used for a long time after replacement. Changes in color to very dark or the appearance of a burning smell are reasons to change it immediately!

Airing the system

The driver can be “informed” of two signs that air has entered the power steering fluid. The first is the presence of foam on the surface of the liquid in the expansion tank. Moreover, it can even seethe if you turn the steering wheel from side to side. The second sign is that the steering wheel may spontaneously turn slightly to one side or the other. Please note that this is a very dangerous signal, and the system must be pumped as quickly as possible!

Pump stator and rotor

When dismantling the pump, be sure to inspect the condition of its rotor and stator. If the pump has been running for a long time on dirty working fluid and has overheated greatly, then there is a high probability that scuffs and scratches will appear on the working surfaces. Often the shaft is also damaged. In this case, either the working pair or the entire pump is changed. Unless, as a temporary solution, you can take out the records and turn them over. This way the pump will be able to operate for some time, but then it definitely needs to be replaced with a new, similar one.

Bearing check

If there is significant noise from the pump, wear on its blades and/or damage to the inside of the housing, it makes sense to check the pump bearing for wear. To do this, you need to remove the pump from its seat. After this, just tug the bearing in different planes with your fingers. And if minimal play is allowed along the axis, then in a plane perpendicular to the axis the play is unacceptable, since in this case the blades will touch the internal surfaces of the pump during movement.

Similar reasoning is valid for the bushing. However, in this case, it is not the bushing that needs to be replaced, but the body, since, firstly, the bushing is often simply soldered into the body, and secondly, there is a high probability that the bushing has already broken the body, and it will obviously be damaged.

Bypass valve

When there is a malfunction of the power steering bypass valve, then on a hot engine and high ambient temperature, great forces will have to be applied to the steering wheel when turning. When dismantling the valve, it is necessary to check for burrs inside the valve seat. If these two factors occur, then the valve must be replaced.

How does power steering work?

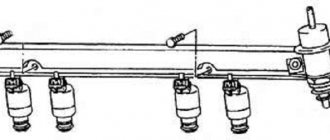

Today it is almost impossible to imagine a car that does not have power steering. From the name itself it becomes clear that the basis of the entire mechanism is hydraulics, due to which the pressure changes. There are no special requirements for this system; it is installed on any type of steering mechanism; in passenger cars, as a rule, it is a rack and pinion mechanism. Often the list of parts for such an amplifier includes an oil pump, a fluid reservoir, a spool valve, connecting mechanisms and hoses, as well as a hydraulic cylinder. Now let's look at each detail separately.