In this article we will talk about such important aspects related to piezoelectric injectors as:

- Piezoelectric injector device

- The operating principle of a piezoelectric injector;

- Advantages of piezo injectors;

- Causes and consequences of incorrect operation of piezoelectric injectors;

- Checking piezo injectors.

A little about the piezoelectric injectors themselves. A piezo injector or piezoelectric injector is presented to us by injector manufacturers as a unique mechanism that supplies fuel to a car. Its main advantages are high accuracy of fuel dosing and response speed. Thanks to this, the injector provides multiple fuel injections during one operating cycle.

Piezoelectric injector device

The structure of a piezoelectric injector

is clearly shown in the picture and includes the following elements: Theoretically, three main blocks of a piezoelectric injector can be distinguished:

- Executive;

- Hydraulic;

- Manager.

There is a piezoelectric element on top. In the middle there is a hydraulic cylinder and a switching valve. And at the bottom there is a sprayer and a throttle plate. Next, we will study these elements in more detail. A piezoelectric element is essentially a piezoelectric crystal consisting of connected ceramic plates. A pulse of electricity is applied to it, causing it to expand by 80 micrometers in 0.1 milliseconds. To increase its effectiveness, it also includes zirconium and palladium. It is curious that energy is consumed exclusively when the voltage is turned on, but after it is turned off it is regenerated. The hydraulic cylinder is located inside the shock-absorbing spring. Its body contains interdependent pistons, the distance between which is filled with gasoline at a pressure of 10 bar. Gasoline plays a shock-absorbing role here, and the cylinder itself connects the piezoelectric element and the switching valve. The switching valve is responsible for the transition from the low to high pressure area and back. The sprayer's operating method is similar to that of an electromagnetic injector - gasoline under high pressure is supplied simultaneously from different ends of the needle, which keeps the injector closed. Above it there is a throttle plate containing holes through which gasoline moves between the high pressure channel, the atomizer and the switching channel.

Questions on the topic

Filter:AllOpenSolvedClosedWaiting for response

Injector correction exceeded - error Answered by User Answered 2 months ago • Fuel system

12 views 1 answer. 1 vote.

What is the service life of the injectors? Answered by User answered 2 months ago • Fuel system

9 views 1 answer. 0 vote.

From which car can gasoline injectors be suitable for Ford Focus 2? Answered by User answered 2 months ago • Fuel system

13 views 1 answer. 0 vote.

Water got into the injectors, is this dangerous? Answered by User answered 2 months ago • Fuel system

10 views 1 answer. 0 vote.

Noise from Chevrolet Cobalt II injectors Answered by User Answered 2 months ago • Fuel system

7 views 1 answer. 0 vote.

How to clean the injectors on an Audi 100 and will it be of any use? Answered by User answered 2 months ago • Fuel system

9 views 1 answer. 0 vote.

Ask a Question

The operating principle of a piezoelectric injector

A piezoelectric injector

, like a conventional injector, uses

principle

. When the nozzle is closed, the needle remains seated under high pressure. The electrical signal passes from the control unit to the piezoelectric element, as a result of which its length increases, opening the switching switch. When gasoline goes into the return line, the pressure above the needle drops, and as a result, it rises from below, supplying gasoline. The amount of gasoline supplied depends on the duration of the signal and its pressure in the fuel rail. Piezoelectric atomizers operate on the electromagnetic principle, the difference being that a piezoelectric element acts as a movable core. The response speed of a piezo injector is several times higher than that of electromagnetic injectors. The short turn-on time of the piezo injector allows you to effectively control each stage of fuel supply. By pre-injecting gasoline before the main cycle, an increase in pressure and temperature in the combustion chamber is achieved and the ignition delay of the main injection is reduced. This has a positive effect on the degree of pollution of the vehicle exhaust.

Advantages of piezo injectors

Among the main advantages of piezoelectric injectors, the following can be emphasized:

- High response speed;

- High response frequency;

- Number of injections per injector operating cycle;

- High accuracy of fuel dosing;

- Reducing motor noise;

- Increasing environmental friendliness by reducing exhaust pollution.

Causes and consequences of incorrect operation of piezoelectric injectors

Features of the device in case of malfunction are manifested in the following possible car problems:

- the car stalls under load or at idle;

- engine tripping;

- loss of traction;

- formation of dark smoke under load.

The consequences described above can appear for various reasons, but often the main reason is faulty injectors. If the above symptoms are identified, it is recommended to undergo appropriate diagnostics of the operation of the fuel system and specifically the injectors.

| Signs of malfunctioning piezo injectors | Consequences | Possible cause of piezo injector malfunction |

| Engine stops running under load or idling | Injector does not hold pressure | Damage to the switching valve, Depressurization of the drain system |

| The engine stalls and loses traction | Failure of the injector or piezoelectric element | Closed wedge Insufficient piezoelectric capacitance (or low resistance) |

| The engine does not start or stops running after a short time | Injector short to ground | The insulation layer of the piezoelectric element is broken |

Through progress

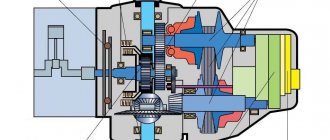

The introduction of the Common Rail system, which took place in the late nineties, became a new milestone in the development of the Diesel engine. An inline high-pressure fuel pump (HPFP) replaced the main pump, and hydraulic injectors gave way to injectors with electronically controlled solenoid valves.

Unlike the previous design, where the opening of the spray needle occurred only due to pressure, electrohydraulic nozzles work somewhat differently. At rest, the fuel pressure at the cone of the nozzle needle and in the chamber of the control valve located above the needle is the same, the spring-loaded needle closes the nozzles, and no injection occurs. When a signal is received from the control unit, the solenoid valve is activated, the pressure above the needle is released, it rises, opening the nozzles, and injection occurs.

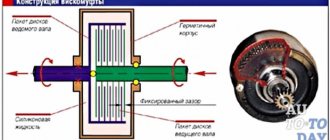

Piezo injectors work in a similar way, in which instead of an electromagnet with a movable core, another performer is used - a piezoelectric element. It has the shape of a square column consisting of many ceramic plates stacked on top of each other and sintered together. Under the influence of current, a piezoelectric effect occurs in them, due to which the structure is able to quickly change its length, acting on the control valve. Compared to an electromagnet, the piezoelement provides faster response, the time of which is about 0.1 ms (versus 0.5 ms for an injector with an electromagnet), and is also capable of creating greater force on the control valve and has higher precision for quick shutoff fuel supply.

Design of a piezoelectric injector: 1 - piezoelement; 2 — hydraulic compensator; 3 - control valve; 4 — throttle washer; 5 - spray needle

The use of a piezoelectric element in the injector allowed designers to implement up to ten injections per engine cycle - preliminary, main, post-injection. At the same time, the portions themselves, their volume and frequency can be flexibly adjusted based on the operating modes of the engine. Thus, the engine achieves smooth and complete combustion of fuel, reducing noise and toxicity. For modern diesel engines in passenger cars, piezoelectric injectors are becoming an integral element in the design of the fuel system. But high technology comes at a price.

Checking piezo injectors

Testing piezo injectors

is a rather complex process and requires not only complex special equipment, but also qualified personnel with the necessary skills.

Piezoelectric injectors are very sensitive to the quality of gasoline, in the absence of which various disturbances described above quickly arise in them.

You can

check piezo injectors low prices

.

For this purpose, we use the Carbon Zapp GD1R high pressure injector test bench. Checking piezo injectors

with preliminary external ultrasonic cleaning costs 600 rubles.

for 1 piece The cost of new original injectors from manufacturers such as Bosch, Delphi, Denso and Siemens. is quite high and, depending on the model, ranges from 10,000 to 40,000 rubles. Therefore, a preliminary check of piezo injectors will save significant money on the purchase of new ones.

Advantages of piezo injectors

- speed and frequency of operation

- number of injections per injector operating cycle

- fuel dosage accuracy

- reduction of engine noise

- nozzle operation at high pressures

- environmental friendliness

As mentioned above, the speed of the piezo injector allows the fuel supply to be divided into a large number of micro-doses: first, several preparatory injections occur, then the main one and after that the so-called post-injections.

Fuel injection occurs in such a way that a small amount of fuel enters the cylinder - pilot injection (about 1.5 ml). It enriches and warms up the fuel-air mixture, smoothly preparing the system for the main fuel supply. This achieves uniform pressure distribution in the combustion chamber. The more such pre-injections , the softer the combustion occurs, and, accordingly, the quieter the engine runs.

After this, a large dose of fuel is supplied, which plays a major role in creating the fuel-air mixture. At the end of the combustion cycle, the remaining fuel is burned using post-injections . This reduces the toxicity of exhaust gases. Also, fuel supplied in this way at the end of the injector operating cycle helps to clean and regenerate the particulate filter.