The problem when a car loses speed is known to almost every car owner. This can happen almost both at start and while driving, when the car stalls when the speed decreases or jerks and stalls while driving.

Sometimes the car may start poorly or do so every once in a while, and then the engine stops starting altogether. But what are the reasons for this car behavior and how to eliminate them?

Idle speed on an injection engine

To solve this problem, you need to understand how idle speed works on an injection engine.

The entire operation of a modern power unit is controlled by an electronic unit (ECU), which uses the readings of various sensors installed on the engine crankcase. Several such parts are responsible for idling, namely:

Each of them has a specific functionality and can affect the engine speed without load. The ECU receives data from these nodes and, processing it, selects the optimal operating mode of the car engine.

Sometimes the cause of a malfunction in which the idle speed drops may be the failure of any sensor. In case of such a breakdown, it is best to contact a car service station, which has specialized diagnostic equipment and is able to quickly identify the defective part. If this is not possible, you will have to conduct your own search. And they should start with the idle speed control valve.

Why do engine vibrations occur at idle?

Under normal engine operating conditions, there are no vibrations in idle mode. In this mode, torque is not transmitted through the gearbox to the driveshaft, so it must operate steadily and not create unnecessary vibrations. If the internal combustion engine has strong vibration at idle or low speed, make sure that the cause is the engine.

To do this, simply depress the clutch pedal (to disconnect the engine from the gearbox). If the shaking remains when the clutch is disengaged, this means that the problem is in the engine, if not, then the result of the jerking is problems in the clutch or gearbox.

During normal operation of the internal combustion engine, imbalances are allowed, which do not greatly affect the comfort of driving the vehicle. During the winter season, the engine may vibrate more when starting. However, when warming up (after 5-10 minutes), the level of shaking returns to normal. In this case, there should be no jerks, dips or extraneous sounds when the motor is running. If the nature of the twitching in idle speed mode has changed, this indicates certain malfunctions in the internal combustion engine.

Increased vibrations arising from engine operation negatively affect both the condition of the internal combustion engine and the technical serviceability of other parts and elements of the vehicle. Therefore, it is necessary to quickly diagnose the source of vibration and eliminate it.

Auto mechanics identify the following main factors due to which engine vibrations increase in idle mode:

1. Wear of the power unit supports.

2. Crankshaft imbalance, incl. after repair.

3. Engine tripping.

Reason No. 1 - Malfunction of engine support pads

These car parts perform two functions:

- The power plant is attached to the body (frame) of the vehicle;

- Its vibrations are dampened.

The supports are made of special rubber, which wears out during use. Therefore, when cracks, tears, etc. appear. they cease to eliminate vibrations that are transmitted to the body and are clearly felt in the cabin. If only one damper is damaged, then the others are more likely to be worn out, but this has not yet become apparent. In this regard, all supports must be inspected and replaced.

Let's consider how to determine that the source of increased vibrations is a malfunction of the engine mounts.

- Conduct a visual inspection of the motor silent blocks. They should not have large cracks, tears or peel off from metal parts.

- Having installed a rolling jack with a rubber spacer, lift the engine one by one on each side where the cushion is located (the lifting location should be as close as possible to the power unit support). Observe engine operation after each change of jack location. When lifting the engine from the side of the faulty mount, the strength of vibrations transmitted to the car body will decrease.

- In addition, diagnostics can be carried out without using a jack. This requires one more person. We open the hood and rock the car, sharply changing the direction of movement. In this case, the assistant should look at the angle of roll of the engine in different directions. If the cushions are in good condition, the power plant will swing in all directions evenly and equally. The motor will tilt more towards the faulty support, which needs to be replaced.

Reason #2 - Imbalance

If increased fluctuations appeared after the internal combustion engine was repaired, then there is a low quality of the restoration work carried out. When the power plant is factory assembled or repaired at a high-quality car service center with the crankshaft dismantled, the crankshaft assembly with flywheel and clutch must be balanced before installation. Balancing work is carried out on a special balancing stand, where all beats are recorded and eliminated.

In general, the process is similar to the procedure for balancing wheels during tire fitting, with the difference that the specialist does not hang additional weights, but drills the necessary holes. When carrying out work in “field conditions”, balancing is not carried out and, as a result, the strength of vibration increases. When overhauling a power plant, before assembly it is necessary to weigh the CPG parts. Uneven weight placement of parts leads to increased twitching and a significant reduction in motor service life.

The shaking will certainly increase if the flywheel has been repeatedly overheated and subsequently not bored and balanced. But even with a strong decrease in the mass of the flywheel, its weight may be lower than the inertial one, smoothing out flaws in the balancing of the crankshaft and the difference in the weight of the CPG elements. As a result, unstable operation of the internal combustion engine at idle is observed.

Some car owners remove balancer shafts to reduce repair costs. This inevitably leads to imbalance, increased vibration and load on the crankshaft, thereby reducing the service life of the engine as a whole.

On vehicles with a manual transmission, strong vibrations at idle may be a consequence of a poor quality clutch.

Reason No. 3 - Engine tripping

ICE tripping is a process in which one or more cylinders do not work or function intermittently. Most often this occurs due to a failed spark plug. You can check this malfunction by sharply pressing the accelerator lever. The consequence of the action will be a shot in the exhaust system.

It is difficult for inexperienced drivers to notice a faulty spark plug. This is due to the fact that the spark plug rarely malfunctions all at once. This process follows the following scheme: at first a good spark is formed, then over time it weakens, then gaps in spark formation appear and in the end no spark is produced at all.

Over time, the problem intensifies, turning into strong vibrations that can even reverberate through the steering wheel and will be felt inside the car. In addition, when tripling occurs:

- reduction in traction and power characteristics of the vehicle;

- failures during acceleration;

- jerking of the car when driving uphill.

To determine a faulty spark plug, it is necessary to alternately remove the high-voltage wires from the spark plug with the engine running. When the working spark plug is turned off, the engine sharply loses speed and may stall. If the spark plug is not working, then when it is turned off, the nature of the operation of the power plant will not change.

Another way is to unscrew the spark plug from the block head and inspect it. There should be no cracks, soot, or traces of oil on it and it should be dry. If the spark plug is not working, then the electrode is wet, since it will be washed by the fuel mixture, which will not ignite due to the lack of a spark.

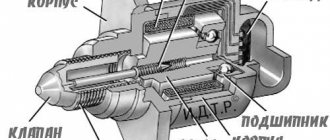

Idle air control valve or IAC

The IAC is a small electric motor in which a cone-shaped needle is placed on a spring. It is designed to supply air to the engine power system, which is necessary to form the proper quality of the air-fuel mixture, making it lean. It is connected to the mass air flow sensor and, receiving a signal from the ECU, opens, providing air flow without using the throttle valve, which changes position when the gas pedal is pressed.

Having rather fragile parts and being located in the engine intake manifold, the regulator is subject to the formation of various deposits on the needle, which impedes its movement, which leads to failure of this part.

Checking the performance of the IAC is quite simple; to do this, you need to use a tester and check its resistance readings on a warm engine. The operating resistance should be in the range from 40 to 80 ohms. If it is not, then it is faulty and needs to be replaced.

Another characteristic sign of a regulator failure is that when the engine is hot, it begins to stall as soon as the gearbox is switched off while driving.

The IAC cannot be repaired, so it is simply replaced with a new part. If the regulator resistance indicator is normal, then it is worth checking the mass air flow sensor.

It's time to service the carburetor - minor defects

The reason for the drop in speed during warming up can also be minor breakdowns in the carburetor system. These are torn membranes, dislodged cable fastenings or a sticking damper drive. Such troubles can be cured during an inspection of this device. In the old days, every second car driver could independently rebuild the carburetor, install a repair kit and drive on, listening to the contented rumbling of the unit. Today the repair principle is as follows:

- you should go to a car store or market to find a suitable repair kit for your type of carburetor; it is better to take original high-quality parts;

- Next, it is important to find a master who is well versed in carburetors and can help with troubleshooting problems in your device; there are fewer and fewer such masters in cities;

- In a few tens of minutes, a specialist will go through the equipment, find the problem and install new gaskets, membranes, seals and other products from the repair kit;

- Next, you need to check the equipment to make sure there are no unpleasant effects; often this can only be done the next day on a cooled car;

- the last step is regular visits to the technician once every 2 years for maintenance and inspection of the carburetor, this will keep the car in normal working condition for a long period.

Carburetor fuel injection has its advantages. You will have to pay a fortune for maintenance and cleaning of the injector. But carburetor repair, even with the replacement of certain parts, will not cost too much. But to get these benefits, you should find a technician who is well acquainted with the features of your particular car model. Such a specialist will help you fix all the problems and continue to operate the machine without problems.

The role of the mass air flow sensor (MAF)

This device is designed to measure air, a certain amount of which is supplied to the manifold for mixing with gasoline. In appearance, it is a metal mesh and a measuring element placed in it with a four-pin power connector. The measuring element is equipped with a platinum string, which acts as a heat exchanger. It is cooled by the air flow coming from the air filter, and heated by supplying electricity to it; the stronger the air flow, the more electricity is supplied to the platinum.

If the DMVR fails, the electronic unit does not receive a signal about the incoming air volume, and the unit is not able to provide the required engine operating mode.

It is not difficult to check it on a warm engine; to do this, you need to disconnect the power connector from the sensor and start the engine. With this option, the electronic unit will select emergency mode and increase the number of crankshaft revolutions to 1500 per minute. After driving a car for several kilometers and realizing that the car has become much more responsive, you can identify a malfunction of the mass air flow sensor and the need to replace it.

Sensor that regulates the throttle position (TPV) and its mechanism

This element, guided by a signal from the control unit, begins to open the throttle valve, which provides more gasoline and air to form the fuel mixture.

During idling, the throttle is completely closed, blocking the air flow. Any malfunction in this mechanism will cause the crankshaft speed to fluctuate sharply on a warm engine.

The breakdown of any part of this mechanism negatively affects the performance of the power unit. A malfunction in the throttle sensor manifests itself in its inability to control opening or closing, while the damper does not respond to the signal, remaining in one position. As a result, a large amount of oxygen enters the gasoline, which excessively leans the mixture, making it unsuitable for ignition in the combustion chamber of the engine. You can check the operation of the TPS with a tester. To do this, the car starts, and the black wire on the tester is connected to the car body, and the red wire is connected to the TPS contact number 1 or letter A. It should show a value from 4.8V to 5.2V. Any deviation from this norm indicates a malfunction in the power supply to the TPS.

Next, proceed to check the resistance with the throttle valve closed and open. To do this, close the remaining terminals with the multimeter wires and look at its value, which when closed is from 0.9 to 1.2 kOhm, and when open – no more than 2.7 kOhm. Any deviation means the TPS is broken and needs to be replaced.

The movement of the damper itself is also checked, which should be free. Any jamming of the damper must be eliminated by removing the resulting carbon deposits and other contaminants.

EGR system

This system is designed to return some of the exhaust gases back into the cylinders to improve ignition in the combustion chambers. On a warm engine, its malfunction can lead to sudden jumps in idle speed. The main purpose of EGR is to reduce toxic emissions into the atmosphere. Due to constant exposure to elevated temperatures, the EGR valve becomes clogged, which leads to floating crankshaft speeds. Fix the breakdown by simply cleaning the seat on the valve; if this does not help, then it needs to be replaced.

Engine speed fluctuates: symptoms and main causes

First of all, the tachometer helps to notice floating speed. Most often, the floating speed appears at idle. Normally, even on a slightly warmed-up engine, the tachometer needle should remain stable at about 800 rpm while idling.

The only exception is the warm-up speed XX, when the ECU on injection engines itself raises the speed to 1000-1100 rpm. In this case, after the engine temperature rises slightly, the control unit will lower the idle speed to the desired level of 750-800 rpm.

Also, jumps in speed can be observed if you increase the load on the engine (press the brake pedal, turn the steering wheel in a car with hydraulic booster, turn on the air conditioning or climate control, etc.). The revolutions may also fluctuate while driving in transition modes.

In this case, without additional load, the engine can keep the speed stable at idle, but as soon as the load appears, the speed drops, and the engine almost or completely stalls.

When releasing the gas, the speed is increased or “freezes”: common malfunctions

Let's start with the fact that on many cars with an injector, the ECU raises the speed while the internal combustion engine is warming up. This is necessary to ensure that the power unit operates stably after a cold start.

However, after the temperature rises, the control unit reduces the idle speed, bringing it to normal. On many cars with a carburetor, the driver independently increases the speed during warm-up, using the so-called “choke”.

Moreover, after the engine is warmed up, the normal idle speed is, on average, 650-950 rpm. If you press the gas and release the accelerator, the speed should increase, and then decrease again to the specified values.

- So, let's start with common carburetor problems. Often the engine speed does not drop due to problems with the throttle valve. For example, when the driver steps on the gas, the throttle must be opened wider to allow more air to enter the cylinders to burn fuel. After the gas pedal is released, the throttle closes and the speed decreases.

If the damper does not close completely, an over-enriched mixture enters the cylinders, and the speed is increased. The cause may be severe contamination of the throttle assembly or damage to the valve itself (deformation). First you need to clean the damper; carburetor cleaning liquid is suitable as a cleaner.

We also note that the damper does not close tightly even when the drive cable is worn out. In this case, the cable must be replaced. On carburetor cars, engine speed often does not drop even if the gasket between the carburetor and the cylinder head has failed. The culprit may also be an intake manifold that is damaged.

The main task is to find the correct ratio of fuel and air. Often, a high level of fuel in the carburetor float chamber also leads to increased speed. The check should begin with the needle valve.

- Now let's move on to the injector. Please note that on many injection cars, after cleaning the throttle valve, the assembly also needs to be additionally “trained”. As for problems, the injection system itself is more complex, that is, there are more reasons for high speeds compared to the carburetor.

Common causes of floating revolutions

So, we figured out the main symptoms. Now let's move on to the reasons. Let us immediately note that floating idle speed is often a problem with injection engines. The fact is that a complex ECM system is responsible for idling in this case.

This system assumes the presence of a controller, sensors and actuators. The control unit receives signals from sensors and transmits commands to actuators (for example, IAC), maintaining stable engine speeds at idle and other modes, regardless of the load on the internal combustion engine.

However, any failures that are associated with the supply of air, fuel, a violation of the composition of the working fuel-air mixture or its ignition, as well as various mechanical breakdowns will lead to floating speed.

If malfunctions occur in the operation of the device, the ECU is not able to correctly “select” the mixture composition at idle, as a result, the speed floats.

One way or another, the ECU does not receive correct data on air flow, which leads to disruption of mixture formation and jumps in engine speed.

To prevent such complications, it is necessary to periodically clean the throttle from dirt, and on many cars, additional training of the throttle is required after cleaning.

Let’s also add that if the speed of a diesel engine fluctuates, this is often caused by rust on the fuel injection pump blades. Corrosion occurs due to the presence of water in diesel fuel.

Let's sum it up

As you can see, in order to accurately determine why the engine speed is not reset, in many cases in-depth diagnostics may be necessary. For carburetor engines, cleaning and adjustment of the carburetor itself is often necessary, while the injector will require computer diagnostics.

If the problem is not on the surface (the throttle cable has become sour, after washing or dry cleaning, the carpet in the cabin is not installed correctly, which presses the gas pedal, etc.), then it is better to take the car to a service center.

The most complex situation is when the design of the power system involves the presence of a large number of sensors and actuators. In this case, even the use of diagnostic equipment does not always allow you to quickly and accurately determine the problem.

Finally, we note that timely detection of a problem allows you to save the life of the internal combustion engine and other components and assemblies. In other words, high idle speeds, floating speeds and jumps indicate that there are problems with the air/fuel supply or with mixture formation. Ignoring such problems negatively affects the engine and its service life.

Why the engine may have high idle speed. The main reasons for high idle speed on an injection engine and engines with a carburetor.

The engine twitches at idle: why does this happen? Engine jerking in idle mode, diagnostics of possible malfunctions, recommendations.

Why does the engine idle unevenly? There are jumps in idle speed. The main causes of unstable idling, diagnostics.

What symptoms indicate that the engine has started to stall: the main signs of engine stalling. Common causes of internal combustion engine tripping, diagnosis, repair.

At idle the speed “floats”: why does this happen? The main malfunctions associated with idle speed on gasoline and diesel engines.

Floating engine idle speed when cold. Basic malfunctions, symptoms and identification of breakdowns. Unstable idling of the diesel engine.

Many owners of injection cars could observe the effects when the speed suddenly drops at idle. This phenomenon occurs especially often when the engine is warmed up to operating temperatures. Sometimes the revs drop so low that the engine stalls. Let's figure out what can cause low idle speeds on a warm engine, and also find out why they drop. This information will be useful to everyone.

Tips and tricks

Let's look at how you can eliminate some of the malfunctions that lead to floating and speed jumps, and do it yourself.

The main thing is to disconnect the electrical contacts from the throttle valve. Let us add that on many cars where the damper was heavily dirty, you then need to additionally set the correct opening gap of the damper or “teach” the throttle using the appropriate equipment.

According to drivers, this helps protect the pump from corrosion and is a preventative measure. At the same time, we note that this method is suitable for construction equipment and it is highly not recommended to practice such solutions on modern diesel internal combustion engines.