During operation, the internal combustion engine heats up to a high temperature. The engine cooling system must cope with the heat removal function. This is necessary for the efficient operation of the power unit. If there is no coolant circulation, the internal combustion engine will very quickly overheat with all the ensuing consequences. Let's talk about what the pressure in the cooling system should be and how to fix typical problems on your own.

Briefly about the main thing

The first step is to decide why there is pressure in the cooling system. It would seem that the banal circulation of coolant should be enough to remove heat. This used to happen when water was poured into the radiator. But it was also common to come across a car on the side of the road with steam pouring out from under the hood. This happened because the water did not have time to cool, and since its boiling point is 100 degrees, it boiled very quickly.

Modern antifreezes, most of which are alcohol-based, boil at approximately 115 degrees Celsius. But it’s worth remembering the school physics course, where you can learn that an increase in pressure leads to a shift in the boiling point of the liquid. This also applies to antifreeze that circulates through internal combustion engine systems.

Cooling system high pressure

VAZ engine Steering column VAZ engine cooling system

I was driving along the highway early on Monday morning to work, something made a noise in the engine and steam started pouring out of the air ducts in the cabin.

I stopped and opened the hood. In the area of the intake manifold everything was wet and steam was coming out. I decided to open the radiator. I threw on a rag and everything was as it should be. I turned it around, ran away and all the antifreeze flew out in a fairly good stream.

Then a tow truck, some kind of service in the “motor city” to which he took me, a lift, an inspection. No external damage was found, all pipes were inspected, everything seemed to be normal.

We filled it with water, started it up, everything was fine, no leaks or steam were found anywhere, but the mechanic (from the service department) said that exhaust gases get into the cooling system at high engine speeds. We checked the oil, it seems to be free of coolant impurities. It worked at idle and occasionally accelerating for almost an hour, and there were no symptoms of what happened. I sat down, drove to work (about 5 km), no overheating, nothing happened. In the evening I drove home about 45 km, got there without incident, nothing overheated or steamed anywhere.

This morning I went to work again, drove 5-6 km, zilch and steam from under the hood. Wet intake manifold again.

What could be the problem? Is it possible to somehow fix this?

Thank you in advance for your good advice.

Since the manifold is wet and steam is coming out, it means either hot coolant is escaping from somewhere, or hitting a hot engine, or all of the above

All that remains is to find what it comes from and where it comes from

1. We walked 200 km on Saturday night to avoid overheating. Just in case, I drove with the heater on, kept the speed in the region of 2000-2500, the movement from point “M” to point “K” passed without incident.

2. Upon arrival, I decided to check the operation of the expansion tank of the cooling system. This was prompted by the fact that when the coolant level in the radiator was changed, the liquid level in the tank remained unchanged. It turned out that the pipe connecting the tank and the radiator was completely clogged at the bend. Took it off and washed it.

3. The radiator was examined in more detail, which, as I assume, has not been cleaned for a long time. The water, compressor and Karcher did their job and the air finally flowed between the radiator honeycombs))

4. Next I started testing the operation of the cooling system with the radiator cap open. Initially, the liquid circulated in a small circle (bypassing the radiator), then the upper radiator pipe warmed up and the liquid gradually began to bulge out of the neck. At the same time, it seemed that the liquid was trying to boil, because... There were some small gurgles. Further heating showed that the liquid circulates normally in a large circle.

5. The main suspicion of the Autograd auto mechanics was that I had some kind of trouble with the cylinder block gasket (I changed a set of timing chains and gears 2 weeks ago). I arrived at the service center where they performed repairs on me. There the master said that if there were jambs with the gasket, then an almost instantaneous overheating of the engine would occur, or the oil would be of an unknown color and white smoke would pour out of the exhaust pipe. I took him at his word. Bubbles in the radiator haunt me. I was asked to drive around the city and beyond during the day so that the “zilch” that happened earlier would come out again. Having driven about 150 km in the heat in a mixed cycle (city + highway), no “zilch” happened. But some of the liquid left the expansion tank. It was poured to the “max” level and became approximately halfway between “max” and “min”. The fluid in the radiator was at the plug level.

6. On Monday morning I went to point “M” again for work. I covered 200 km normally. Upon arrival, I looked into the tank - it was empty, the liquid in the radiator was slightly covering the honeycombs. I drove around the city a little. I parked for about 5 minutes, I approached and a significant puddle of this kind had accumulated next to my “prime”. I tried to figure out where the leak was coming from but failed. But it was flowing from the intake manifold area, apparently below it. Last time, the service center removed the pipe passing in exactly that place, the only suspicion was about it. Now I have no desire to go to any service again. I will wait for Friday and try again to drive 200 km to my hometown. And then again the service and all that. Based on the results, if anyone is interested in the thread, I’ll post it, and if it’s not interesting, the topic can be closed.

What pressure in the engine cooling system is considered normal?

Much depends on the design features of the car. But usually it is 1.2-1.4 atm. for passenger cars. For example, on a VAZ-2110, 1.2 atmospheres can be considered normal. Critical pressure in the system is achieved when the antifreeze heats up and reaches its boiling point. At this time, the pressure in the system should be released. This is done so that the radiator or any other weakest point does not tear.

The expansion tank cap is responsible for releasing pressure. Its device is extremely simple. There is a metal case with two holes. Inside there is a ball with a diameter larger than the holes. When it reaches a certain temperature it rises. This results in air being vented into the atmosphere. On many cars 1.5 atm. is the pressure at which the release occurs.

How is pressure formed?

Let's try to figure out what causes increased pressure to be created and maintained in the engine cooling system. After you start your car's engine, it will begin to heat up and the coolant temperature will rise.

Accordingly, steam is formed, and due to it, the pressure level begins to increase. A valve is installed in the radiator cap or expansion tank that maintains it at the required level.

If we talk about digital parameters, then depending on the manufacturer it is from 1.2 to 2 bar. Typically, when the pressure rises above 1.5 bar, the safety valve is activated and the excess steam generated is released into the atmosphere.

Valve performance check

Until the antifreeze heats up, the ball inside the lid closes the bottom hole, while the top one remains open. This is necessary for the flow of air from the atmosphere and rapid heating of the coolant. I would like to note that it is periodically necessary to check the functionality of the lid. After all, it often happens that it gets wedged in one of the positions. Because of this, the engine either takes a long time to warm up or does not hold pressure.

Checking the cap of the expansion tank of the VAZ-2110 is extremely simple. To do this, just unscrew it and shake it. If you can hear the ball dangling inside the housing, then the system is working and it is not jammed. Excessive pressure in the engine cooling system, as noted above, can lead to fatal consequences. Therefore, on modern cars the cover has two valves: inlet and outlet. Nowadays you can find lids on sale that operate at a certain pressure. But it is strongly recommended not to change the parameters set by the manufacturer.

Blood pressure problems

Overpressure

The engine cooling system is also an indispensable thing in a car.

Excess pressure occurs when the air valve is faulty. This happens when the cap of the expansion tank or radiator becomes stuck. In this case, the part itself is in a closed state.

There is no other way than through the valve for excess air in the system to escape. Therefore, to prevent your engine from overheating, it is necessary to periodically check the performance of this part.

Unfortunately, the valve cannot be repaired. All that remains for the car owner in the event of a breakdown is a complete replacement. In this case, you also need to change the cover. Ideally, it should be changed at least once every few years.

However, many car enthusiasts often try to restore a damaged valve by using carburetor fluid. It copes well with various types of deposits that form in the valve as a result of long-term operation. However, this procedure does not provide a 100% guarantee that the part will be brought back to life.

No pressure

Every car owner faces a similar problem sooner or later. It is worth recognizing that long-term use of a car is always associated with wear and tear on the main components of the car.

Attention! Such a defect can only indicate one thing. The structure has lost its tightness.. But everything is simple in words, finding the damaged area is quite difficult

You should start by checking the air valve, since according to statistics, most problems occur precisely because of it

But everything is simple in words only; finding the damaged area is quite difficult. You should start by checking the air valve, since according to statistics, most problems occur precisely because of it.

If the valve is working properly, you need to focus your attention on possible leaks. They lead to the fact that the required number of atmospheres inside the part is missing

In addition, this reduces the level of antifreeze.

How to find a leak

First, it wouldn't hurt to find out why leaks form:

- rust;

- overheat;

- hose wear;

- problems with the cap or valve;

- damage to the plug;

- wear of important structural elements.

Finding a leak starts with looking under the car. The presence of fluid will indicate that you are moving in the right direction. After that, just feel the space under the hood. In a place where there is liquid there will be a leak.

A little more video about the engine cooling system:

As you can see, a lot depends on the correct pressure inside the system. Firstly, if there is a lack of it, antifreeze will boil much faster. Secondly, if the number of atmospheres exceeds the norm, the tank may explode.

- Why does the starter bendix skip?

- When and how to change the air filter

- What is a rear axle gearbox, operating principle

- What to do if the brake pads are frozen

High blood pressure and methods of control

The cooling system is designed in such a way that the expansion tank cap is responsible for the pressure in it. Although there are various design options. For example, on some American cars, the expansion tank serves as a sump, and the cap itself is installed on the radiator tee. However, the essence of the work remains the same.

The pressure in the VAZ-2110 engine cooling system should be in the range from 1.2 to 1.5 atm, while a drop or exceeding of these values can already be considered a serious deviation. Quite often, motorists are faced with high blood pressure. The reason will be the same lid, the valve of which is stuck in the closed position. In this case, the system will warm up, the pressure will increase, but it will not be released. Because of this, steam-air plugs form, preventing the normal circulation of coolant through the system.

How is internal pressure formed?

You can often come across statements that a working pressure is formed in the engine, which can be increased, that is, excessively strong, or insufficient.

But there is one thing to remember here.

No pressure is created specifically in the cooling system.

In fact, for an internal combustion engine, it does not matter at what pressure the cooling liquid will circulate through its internal cavities. The main question here is that the elements have time to cool.

Many people know from a physics course that almost all liquids begin to gradually expand when exposed to heat. This can be attributed to antifreeze and antifreeze. The average rate of expansion of liquids when heated is from 10 to 20% of their initial volume. That is, there will be exactly this amount of liquid in the system more after the engine stops running cold and reaches its standard operating temperature. And the cooling system acts as a closed loop. When starting the engine, it warms up, and at the same time the internal pressure begins to increase.

At the same time, the coolant puts pressure on the radiator walls, pipes and other internal components.

One of the key tasks in the operation of the cooling system is performed by the expansion tank cap. In fact, this is a low and high pressure valve capable of sucking in air or releasing excess pressure.

Replacing a failed unit

The cooling system cap can last longer than the car engine, or you can buy a new one, which will be defective. It's hard to guess here. But in any case, you should not try to repair it. It costs a penny for most models and is non-repairable. In case of malfunction, it is simply replaced with a new one.

At the same time, it is strongly recommended not to shorten the springs by changing the moment of operation of the cover. After all, many motorists do this, which in most cases does not lead to anything good. Of course, if you have tuned the cooling system and engine, then it is quite possible that you need to achieve more pressure in the system or, conversely, less. In other cases, it is worth buying only the original or a worthy analogue with the same parameters. Remember that high pressure in the engine cooling system can lead to local overheating of the internal combustion engine and failure of certain components.

System leakage

An even more popular problem among motorists is lack of pressure. This may happen due to:

- stuck air valve;

- presence of leaks in the cooling system.

Accordingly, identifying the problem will not be difficult. The first thing you can do is look at the antifreeze level on a cold engine. If it does not change from trip to trip, then there are no leaks in the system. The second step is to replace the air valve with a new one. After this, the pressure should normalize and the antifreeze will not overheat. Very often, increased pressure in the engine cooling system causes it to then drop. This is partly due to the wedging valve. Sometimes it works, sometimes it doesn't. As a result, pressure builds up, which can cause a leak to form in a weak spot, and then the seal disappears.

How to find a leak?

The first place to start is with a visual inspection. If you look under the car, it is likely that there is a puddle of antifreeze underneath. But even here you need to understand that often a gap appears only when a certain pressure is reached, so it will not be possible to find it when it is cold. However, there are special devices for pressurizing the system, and the engine must be cold to avoid burns.

As such a device, you can use a conventional pump and pressure gauge. Everything can be done in a garage. First of all, disconnect the upper pipe connecting to the expansion tank. It is advisable to insert a bolt of suitable diameter into the hole. Next, we connect a pump with a pressure gauge to the pipe and build up pressure. When reaching 1.5 atm. the air valve should operate. At the same time we are looking for a leak.

Nuances of the cooling system

Much also depends on the coolant used. For example, there is no need to pour water even into old cars; it is better to buy inexpensive antifreeze, there will be fewer problems. However, modern engines require high-quality cooling. The manufacturer indicates in the manual the recommended brands of coolant. It is advisable to follow these tips and not dilute the antifreeze if you do not have a concentrate.

Modern coolants have different service life and boiling points. For example, G12 boils later than G11, and G12++ has an increased resource, but it is also more expensive. In any case, to avoid engine boiling, it is recommended to fill only high-quality coolant.

Original spare parts

Very often, high pressure in the engine cooling system is formed due to a malfunction of the air valve, we have already dealt with this. Another thing is that this valve has an insufficient resource, or even a new one may not work. This also applies to other elements of the cooling system, such as a thermostat, water pump, pipes, sensors, radiators, etc. To sleep peacefully, it is better to get the original, the service life of which is often quite long. Of course, such spare parts cost several times more, but they almost 100% guarantee the proper operation of the unit as a whole. After all, the failure of such a seemingly insignificant element as a cover can lead to a major overhaul of the engine.

As for Chinese components, this is a lottery. Some of them can be quite high quality, while others do not travel even 100 kilometers. It’s better not to take risks, because the stingy pays twice.

General characteristics of the VAZ 2107 cooling system

The VAZ 2107 engine of all models has a sealed liquid cooling system with forced circulation of coolant (coolant).

Purpose of the cooling system

The cooling system is designed to maintain the optimal temperature of the power unit during its operation and timely, controlled removal of excess heat from heating components. Individual elements of the system are used to heat the interior during the cold season.

Cooling system parameters

The cooling system of the VAZ 2107 has a number of parameters that affect the operation and performance of the power unit, the main of which are:

- amount of coolant - regardless of the fuel supply method (carburetor or injection) and engine size, all VAZ 2107 use the same cooling system. According to the manufacturer's requirements, its operation (including interior heating) requires 9.85 liters of refrigerant. Therefore, when replacing antifreeze, you should immediately purchase a ten-liter container;

- engine operating temperature - The operating temperature of the engine depends on its type and volume, the type of fuel used, the number of crankshaft revolutions, etc. For the VAZ 2107 it is usually 80–950C. The engine heats up to operating condition, depending on the ambient temperature, within 4–7 minutes. If there is a deviation from these values, it is recommended to immediately diagnose the cooling system;

- coolant operating pressure - Since the cooling system of the VAZ 2107 is sealed, and antifreeze expands when heated, a pressure exceeding atmospheric pressure is created inside the system. This is necessary to increase the boiling point of the coolant. So, if under normal conditions water boils at 1000C, then when the pressure increases to 2 atm, the boiling point rises to 1200C. In the VAZ 2107 engine, the operating pressure is 1.2–1.5 atm. Thus, if the boiling point of modern coolants at atmospheric pressure is 120–1300C, then under operating conditions it will increase to 140–1450C.

Serious consequences

We have already discussed that pressure is created in the engine cooling system. It's quite normal. Another thing is that very often there is a malfunction that is extremely difficult to determine. For example, the antifreeze goes away, but there is no visible leak. In this case, it is quite possible for coolant to enter the engine crankcase. It is recommended to check the oil level regularly. If the coolant actually goes into the engine, the level will increase. Most likely, this indicates a broken cylinder head gasket, changing which is tantamount to rebuilding the power unit.

Any part has its own specific resource, upon reaching which there is no guarantee that it will continue to work properly. There are often cases when even a new expansion tank cap turns out to be inoperative. And now we are not talking about Chinese spare parts, but about original ones. Unfortunately, there is no escape from this.

Purpose, classification and principle of operation of the cooling system of a VAZ 2107 car

The engine cooling system is designed to maintain optimal engine thermal conditions through controlled heat removal from the hottest parts.

On a VAZ 2107 car it is liquid, closed type, filling volume: 8.65 l

On modern cars, the cooling system, in addition to its main function, performs a number of other functions, including:

* heating air in the heating, ventilation and air conditioning system;

* cooling the oil in the lubrication system;

* cooling of exhaust gases in the exhaust gas recirculation system;

* air cooling in the turbocharging system;

* cooling of working fluid in automatic transmission

The engine cooling system is liquid, sealed type, with forced circulation of coolant and an expansion tank.

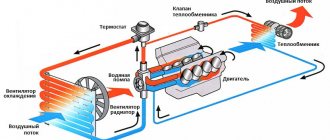

The principle of operation of the cooling system is that after starting the engine and until the coolant temperature reaches 80°C, it circulates from the cooling jacket of the cylinder block through the thermostat bypass valve to the pump, which again supplies liquid to the cooling jacket, bypassing the radiator (small circle) . This ensures quick warm-up of the engine. When the liquid is heated above 94°C, the main thermostat valve opens completely and the bypass valve closes. The fluid flows from the cooling jacket through the inlet hose to the radiator, where the fluid is cooled and passes through the outlet hose through the main thermostat valve to the pump, which again supplies fluid to the cooling jacket (large circle) Regardless of the position of the thermostat valves, when the heater valve is open, the fluid always circulates through the heater radiator. In addition, the fluid constantly circulates through the intake manifold heating unit or the throttle body (on an injection engine).

Let's sum it up

So we figured out why there is pressure in the engine cooling system, why it can be excessively high or, conversely, low. There is often nothing complicated about checking it yourself, although a lot depends on the car. For example, it happens that the coolant temperature sensor fails. It can provide incorrect data to control devices, thereby misleading the driver. It can show both a high temperature of the power unit and, conversely, a low one. But this will not mean that the system is not working correctly.

If there are any breakdowns in the cooling system, they must be repaired as soon as possible. It is advisable not to operate a vehicle with a stuck cover or thermostat. After all, for some engines overheating is fatal, and major repairs are not cheap at all. In general, it is worth regularly checking the coolant level in the system to ensure that there are no leaks or other defects. It is also recommended to periodically clean the radiators from dirt, as this can cause increased engine temperature.