Tie rod ends: why your safety depends on them

Failed tie rod ends not only reduce the ride comfort of your vehicle, but can also pose a real safety hazard. Let's take a look together at what surprises one of the simplest structures in a car can present, why, if a malfunction is identified, it is better to entrust its repair to professionals, how to identify a breakdown, and is it worth immediately changing the steering tip at the first sign of damage?

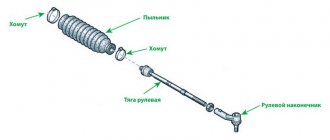

If we exaggerate, we can say that at least one axis of the car must be steerable so that the car can change direction, that is, steer. And since the car’s wheels also have springs, transferring force to the steering mechanism is not an entirely simple task, one of the most important links for solving which was such an element as the tie rod end:

Without this small but important element of traction, nothing will work.

Examination

Yes, in order to accurately determine that the limit switches are the culprit for the uncharacteristic behavior of the car, they should be checked. How to do it? Let's get a look.

- Examine the condition of the node visually. To do this, turn the steering wheel all the way to the right. This will allow you to look at the left tip. To visually inspect the right unit, you need to turn the steering wheel all the way to the left.

- Look at the rubber boot. It fits onto the tip. The presence of signs of rupture or cracks clearly indicates that the steering element needs to be replaced.

- If you do not do this, dirt will penetrate through the gaps and cracks in the boot, which will ultimately lead to very rapid wear of the part and can harm other components of your car.

- You can also lift the car with a jack by hanging the wheel in the air. Grasp the tip with your hands and shake it.

- If there is play, then the replacement will have to be performed on both sides simultaneously.

The defect is obvious

Experts strongly do not recommend changing tips individually. Even if the second element is intact, it is better to perform a double replacement.

What is a tie rod end used for?

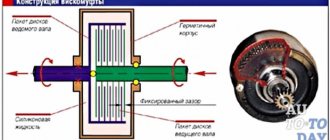

When the driver comfortably turns the steering wheel, he controls the steering mechanism, which converts this rotational motion into linear motion, turning the front wheels in the desired direction. The problem is that the steering mechanism is securely connected to the body, but the wheels are elastically suspended and spring on uneven surfaces, moving slightly not only up and down, but forward and backward, depending on the design of the chassis. So how do wheels that can move in three directions of space connect stably and accurately to the steering mechanism?

The answer to the question is provided by the human body, in particular the hip and shoulder joints. They work like a ball joint, consisting of a spherical part and its semicircular socket, between the bone formations of which there is a small amount of so-called synovial fluid, which acts as a lubricant that reduces friction.

An ingenious element of biomechanics was borrowed from nature by engineers

The tie rod end is built using exactly the same engineering principle, which consists of a metal rod with a thread cut on it and a hinge on the other side. The element is located on the link between the steering mechanism, steering rod and steering knuckle:

This ensures a constant distance between the steering guide and the steering arm of the steering axle and therefore precise rutting.

The following condition must be met: freedom of movement of the tie rod end.

This is what a rack and pinion steering mechanism looks like schematically:

Steering wheel (1); Steering shaft (2); Steering shaft rack and gear (3); Steering rod (4); Hub or steering knuckle (5)

Depending on the design, the tie rod may have tie rod ends at both ends or a threaded end on one side and a tie rod end on the other.

Quote (more details here: What is rack and pinion steering - in simple words https://1gai.ru/publ/521525-chto-takoe-reechnoe-rulevoe-upravlenie-prostymi-slovami.html):

“This is a simple but effective system that does not have the disadvantages inherent in the rack-and-pinion type of front wheel drive. In turn, the rack and pinion type usually adds more weight to the car, requires more effort to drive the car and often has a “dead zone” in the central part. These days, the latter type of steering is typically used on bulkier, slower vehicles such as trucks and buses.”

Sectional view of the tie rod end:

Ball pin (1); Splash cap (2); Hinge housing (3); Liner (4); Spring (5); Plug (6)

Replacement

Well, the symptoms of the problems and a direct check of the steering mechanism elements showed that it was the tips that were to blame. Therefore you will have to change them.

Is it difficult to do? If you have at least a little experience, you have already had to disassemble the steering system, then there should not be any difficulties. By doing everything yourself, you can save a lot on the cost of service stations.

Dismantling works

To illustrate the replacement example, we advise you to rely not only on the instructions presented in our article, but also on video materials. Detailed video lessons seriously help you master quite complex stages of work.

To work you will need a set of materials and tools. It includes:

- New high quality steering limit switches;

- The almighty WD40. If you don’t have the money to buy it, use plain brake fluid;

- A set of keys;

- Pliers;

- Brush with metal bristles;

- Puller (if you don’t have a puller, replace it with a small crowbar).

Assembly of the unit

Everything you need is ready, so you can safely get to work.

- Use a jack to jack up the side of the car where you plan to do the work to replace the tie rod ends.

- Unscrew the mounting bolts from the wheel and remove it.

- Use a wire brush to clean the joint between the tip and the steering knuckle.

- If this area is heavily contaminated, the simple force of a wire brush may not be enough. This is where WD40 comes in handy. We repeat, if it is not there, try washing off the dirt with brake fluid.

- Use pliers to remove the cotter pin. It performs the task of fixing a bolted connection. A kind of fixative.

- Unscrew the fastening nut.

- Now arm yourself with a crowbar and a small hammer. Although if you managed to find a puller, it would be much better.

- Using the selected tool, you need to remove the finger of your tip from the fist of the stand. In this way, the damaged element is removed from the retainer.

- The unit to be replaced should be carefully unscrewed.

- We recommend that you first measure the current distance between the squeegee and the center of the tip. When reinstalling, this information will be extremely useful.

- Now it's time for the new kit, which you purchased in a store or ordered online.

- Insert in place of the old unit, secure with traction.

- Return the hinge pin to its rightful place - into the steering knuckle.

- Next, you should screw the nut back, tighten it properly and secure the cotter pin in the correct place.

- This instruction fully corresponds to the features of replacing the tip on another wheel. Therefore, the manual is the same for the left and right front wheel of your VAZ 2110.

- The last stage of repair will still require you to visit a service station. This is necessary in order to check the wheel alignment. The probability of its violation is too high, so do not be lazy to spend a little time and money. They shouldn't charge you much for the check.

If you do everything correctly and consistently, it will take you about an hour to replace the steering limit switches. Experienced craftsmen can do it even in 30-40 minutes. But in any case, there is no need to rush.

Do not turn the wheels when the car is stationary!

In the past, when not every car had a hydraulic power steering system, none of the drivers even had the desire to turn the wheels while the car was stationary. Firstly, it is very difficult. And secondly, the steering wheel has to be turned with such force that it seems that some steering element is about to break.

But now everything has changed, power steering and electric amplifiers are found on Ladas, and on old Opels, Mercedes and other cars of the 90s and even 80s generation. Servos only require a little finger pressure to turn the wheels, which is the biggest problem with tie rod ends! At these moments, their joints are having a hard time!

Remember that the destructive forces in modern cars during such standing maneuvers are even greater than before, as cars have become heavier and tires have become wider.

In this case, forces arise corresponding to a weight of up to 1 ton (!) with each movement of the steering mechanism. Under such circumstances, it is almost a miracle that a relatively small link such as a terminal joint can withstand such overloads. But still, after about 100,000 km, it is better to check the joints - perhaps one of them has already failed and needs to be replaced.

Advice

Remember what you were taught in driving school: turn the steering wheel only when the car is moving.

Video “Checking car steering rods”

The recording shows how tie rods are diagnosed on a VAZ car, and also provides tips for identifying faulty tie rod ends.

Steering end

- This is a steering element in a car that provides mobility and rotation of the wheels to the desired angle. Its principle is based on a ball joint. On one side the tip is attached to the steering rod, and on the other it is connected to the steering knuckle. The main “enemies” of the steering tip are moisture, dirt and bad roads.

Check the boots on the tie rod ends!

The second, and on domestic cars the first, mortal enemy of the steering tips is torn boots. Dirt caps are designed to protect against dirt, water, sand and reagents. As soon as it breaks, depressurizes due to wear and tear on the inside, corrosion begins to progress rapidly, aggravated by increased wear due to the abrasive effect of sand and dirt. The lubricant is washed away by water, and very soon you will not recognize your car on the road.

What steering tips are on the UAZ Bukhanka? Steering tips UAZ Patriot

The steering mechanism is one of the most important systems of every car. On a UAZ Patriot SUV, the serviceability of the steering directly affects the safety of the driver and passengers. The design of the steering mechanism includes steering tips, which are directly responsible for the process of turning the wheels at the required angle.

Such devices allow maneuvering, which increases the level of vehicle safety. If the steering rod fails, the car becomes uncontrollable and cannot be used further.

In this material we will pay attention to the steering ends of the UAZ Patriot SUV and consider their purpose, designs, main types of faults, as well as the replacement process.

The tip performs the function of transmitting force from the steering column to the wheels. It is thanks to the presence of steering rods that a process such as turning the front wheels of a UAZ Patriot occurs.

The tip design is a part consisting of the following elements:

- frame;

- anther;

- ball pin;

- polymer bearing.

Below is a view of the steering rods of a UAZ Patriot.

The design of the UAZ Patriot, as well as some other similar cars, uses two steering rods. The rods are purchased as a set, and they must also be replaced as a set. Since an outdated part can simply fail while driving a car, which will entail a series of unforeseen circumstances.

Rod ends are parts that wear out quite quickly, which means that if a malfunction occurs, they require replacement. They cannot be repaired; moreover, sometimes problems arise with the dismantling process, so after they become unusable, the parts must be replaced with new ones. Let's look at how the replacement is made below.

What tips are best to install to replace old ones? For the UAZ Patriot SUV, products of the ADS brand are most often recommended, distinguished by their quality and structural strength. The cost of a set of products is approximately 2000 rubles.

Malfunctions and methods for identifying them

The steering rod has a much longer service life, which cannot be said about the tips. In the material about steering rods on this website you can find out more about the design and sequence of repair work. The faulty tips can be determined by the following signs:

- a car on the road floats left to right;

- steering play;

- observing a grinding noise while driving on uneven roads;

- knocking noises when turning the steering wheel;

- failures occur when setting wheel camber and toe angles.

The service life of the tie rod ends of a UAZ Patriot is influenced by the following factors: the quality of the roads on which the vehicle is driven, speed, driving style and the condition of the mechanism itself.

https://www.youtube.com/watch?v=gWmCjR1VFq8

Many craftsmen strive to repair products themselves, which often results in the products breaking down after a short period of time. Therefore, it is not recommended to try to repair the products using improvised means, since the safety of passengers, the driver and oncoming motorists depends on the serviceability of these devices.

The approximate or average service life of these mechanisms on an SUV is about 40-50 thousand km, after which, even if no product malfunctions are detected, it is still recommended to check them.

The main reason for the malfunction of these devices lies directly in the wear of the hinge structure. During operation, the boot tends to break the seal, resulting in the penetration of water and dust into the product.

An equally significant factor in the failure of this device is hitting a serious type of obstacle (a stone or falling into a hole).

As a result, there is a negative impact not only on the rod ends, but also on the entire suspension of the car as a whole.

Therefore, it is very important after each impact to carry out preventive technical inspections of suspension parts and more. How to replace rod ends is carried out, we will consider further.

Replacement

Replacing steering tips on a UAZ Patriot SUV is not a labor-intensive process and can be done at home if there is an inspection hole.

If a significant gap or play appears in the tie rod ends, the product must be replaced.

To replace tie rod ends, you will need the following tool:

- wrenches “8”, “22”, “27”;

- pliers;

- a special key for removing hinges, shown in the photo below.

After this, we begin to carry out the work, the sequence of which is as follows:

- Initially, the nut securing the ball joint pin is unpinned using pliers.

- The tie rod end locking nut is loosened.

- The nut securing the hinge pin is unscrewed.

- A special puller is installed to remove ball joints, as shown in the photo above.

- The hinge pin is pressed out of the steering knuckle.

- After this, it is necessary to unscrew the tip from the tie rod, being sure to count the number of revolutions around the axis. This is necessary so that there is no significant violation of the wheel toe angle.

- Make sure there is an oiler on the new tip, otherwise install it from the old product. Through it, using a technical syringe, Litol-24 lubricant is pressed into the housing.

All that remains is to install the new tip and the removed parts in the reverse order of removal.

After replacing the tie rod ends, you must

To summarize, it should be noted that even with the slightest suspicion of a malfunction of the products considered in the material, it is necessary to carry out a serviceability check and the necessary repair work, which will eliminate the possibility of an emergency situation developing on the road.

How often does your Patriot break down?

With steering column and steering wheel and steering gear. The steering drive consists of a bipod, longitudinal rod, transverse rod, steering knuckle lever and trapezoid arms.

Steering drive for cars of the UAZ-452 family, device

The longitudinal steering rod is a pipe with ends planted on both sides, into which special plugs are pressed. The ball heads of the bipod pins and the left steering knuckle lever enter the side holes of the rod ends, and are clamped between the crackers by springs.

The springs prevent the formation of play in the tie rod joints and soften the shock load on the steering mechanism. To protect the springs from breaking during strong impacts and the rod jumping off the pin, spring compression limiters are installed.

https://www.youtube.com/watch?v=oCEEpSUfA-g

The hinges are adjusted by screwing in the plugs all the way and unscrewing them 1/12-1/4 turn. After adjusting the gaps, the plugs are pinned. The steering rod joints are sealed with protective rubber linings with metal clips. To lubricate the hinges, grease fittings are installed at both ends of the rod.

On vehicles of the UAZ-452 family, the transverse steering rod is located in front of the front drive axle and is pivotally connected to the steering linkage arms, cast as one piece with the steering knuckle housings. In the area of the axle housing, the rod has a bend in the horizontal plane.

To prevent the rod from bending downwards, special support feet are installed in the hinges of the tips, which with their protrusions through spring washers rest against the end of the pin and limit its swing in a plane perpendicular to the axis of the rod.

From turning, the support heel is fixed with a tendril, which fits into the hole for the grease nipple. Right and left support heels are not interchangeable. When assembling, the support heel must be installed so that the protrusions of the heel are perpendicular to the thrust axis.

The left tip is welded to the rod by arc welding, and on the right side, between the rod and the tip, an adjusting fitting is installed with external left and internal right threads. The length of the rod is changed by rotating the adjusting fitting, which is locked with lock nuts.

Maintenance of the steering gear of vehicles of the UAZ-452 family

Performed during regular maintenance or as the need arises. During maintenance, the following work is performed.

— Checking the fastening of the steering rods and bipod. — Checking the condition of the steering rod joints. — Checking the condition of the steering rod heads, the serviceability of their seals. If necessary, undo the tie rod pin nuts and tighten them.

— Lubrication through four grease nipples of the steering rod joints.

Source: https://www.autoglim.ru/the-steering-of-the-car/what-are-the-steering-tips-on-the-loach-loaf-the-helmoasis-patriot/

Blow, more blow and bumps

The tip, and in particularly difficult cases, the steering rod can be destroyed by running over an obstacle. A stone on the road, a log or a hole - it doesn’t matter, there can be one outcome - a bent rod or a failed tip.

Techservice SPA expert Daniil Sevastyanov advises carrying out diagnostics more often:

“As a standard, our specialists carry out routine diagnostics of the suspension at each subsequent maintenance. It also includes checking the tie rods and ends. It doesn’t matter how much the car had driven at the time of servicing - 15 or 150 thousand km; in rare cases, the rod ends can be “killed” even on a new car with low mileage. It all depends on the driving style and operating conditions of the vehicle. A defective element cannot be ruled out. Especially in cases where non-original or low-quality parts were previously installed on the car."

Initial examination

It is very important to occasionally inspect not only the external condition of the car, but also look underneath it. Thus, it is possible to promptly prevent the breakdown of any part or assembly as a whole. Such a check will not take much time and effort, and you do not have to be an expert in cars to do this. To determine the malfunction, it is better to ask a friend to help you, since it takes two people to determine the presence of play. In addition, you can check the part for mechanical damage.

The rod fails much less often than the tips.

To perform an initial inspection of the steering ends, you need to do the following:

- The steering rod and ends are initially inaccessible, as they are located on the bottom of the car. For a more thorough inspection, you need to drive the car into the inspection hole. This will create more open access to all elements of the suspension, bottom and, among other things, will allow you to better check the steering tip. If it is not possible to use the hole, then you can use a jack, but only to lift the car. To increase safety, use stands (stumps).

- You need to use a rag to wipe the parts from any deposits, this will allow you to examine the surface for defects. You also need to pay attention to the fastening points, since it is in the connections that a malfunction can most often lurk.

- Basically, the first part that becomes unusable is the boot. Therefore, you should check it for cracks.

- To check the play, you need an assistant to turn the steering wheel in both directions, while you watch the work of the tips. If the tip moves along the axis of the pin by more than one and a half millimeters, then this indicates that the steering tip is faulty.

- The malfunction can be anywhere; when checking, you need to be as careful as possible. After examining one side, you need to check the other.

- If you wish, since you are under the car, perform diagnostics of other important components and parts. If necessary, some of them can be lubricated or urgently replaced.

How to independently identify broken tie rod ends

To do this, you need to take a close look at the car, noting its unusual behavior. First of all, pay attention to the fact that:

- the car may behave unpredictably in the traffic lane (yaw, pull to the side is noticeable)

— increased tire wear is noticeable (even with the wheel alignment set to normal)

- there is play in the steering wheel

- the steering wheel is more difficult to turn

- vibration may occur in the steering wheel

These symptoms may be accompanied in parallel by noise effects:

— a quiet, frequent knocking sound is heard when driving over small uneven roads or when overcoming a speed bump

- a similar knocking noise can be heard when turning the wheels (on one or both sides)

Important!

In fact, all of the above symptoms can also occur with other steering and suspension faults. But this does not mean that if they are identified, you should not go to a car service for diagnostics.

Symptoms of malfunctions

If you do not pay attention to the wear of the tie rod ends, the ball pin will become loose and jump out of its socket at the first decent bump. There is no need to explain for a long time what this entails: the wheel will become uncontrollable, and the driver will lose control of the car. How to determine that there are problems with the hinges and the car’s chassis needs to be checked:

- the first sign is a dull, frequent knocking sound when driving over small bumps, especially in turns;

- as a rule, extraneous sounds are heard from one side, but simultaneous wear of two tips also occurs;

- the free play of the steering wheel increases;

- when negotiating a turn on an uneven road, you can feel a tapping sound on the steering wheel;

- At the last stage of wear of the tips, the car has to be literally “caught” on the road, since due to the play of the ball pins, the wheels can deviate by 2–3° from the straight line.

Note. Unfortunately, such signs are observed not only as a result of problems with the steering rack, but also as a result of wear of the bearing of the rotary bipod and the pendulum. The exact result will be shown by a check performed by car service employees or independently in a garage.

If you find one of the listed symptoms in your own car, you should not delay diagnosis. Especially if the tips have served more than 40 thousand kilometers. To perform the check, you will need an inspection ditch; hanging the car on a jack will not allow you to swing the rod in the desired direction.

To check the tie rod ends yourself, use the step-by-step instructions:

- Drive the car exactly in the center of the inspection hole so that you can easily reach the hinges. If the ditch is too narrow, the car will have to be moved twice in different directions.

- Support the rear wheels with wheel chocks.

- Grab the rod with your hand as close to the tip as possible. Rock the hinge up and down to feel the play.

- A small elastic resistance indicates that the spring is working and there are no critical gaps. Significant play is felt immediately.

- Rotate the rod several times around its own axis. If it flows easily, literally dangling on the ball pin, the tip should be replaced.

Advice. When swinging the rod, do not confuse the hinge play with free play of the steering rack or a broken pendulum bearing.

To check the integrity of the anthers, an inspection hole is not needed. It is enough to turn the wheel and lift the car with a jack. The hole in the rubber boot is discovered thanks to thick lubricant, which is squeezed out from the inside through a gust.

Replacing the steering tip is also not a big problem; the only special tools you need are a puller to push the ball pin out of the steering knuckle eye. Please note an important nuance: after replacing the linkage, the camber angles of the wheels must be adjusted. You cannot make the adjustment yourself, so you will have to visit a car service center.

Owners of UAZ cars, like most owners of other car brands, sooner or later face the problem of replacing spare parts for their iron horses. In this topic, we will specifically talk about tie rod ends - one of the most important elements of the steering mechanism, about the selection, maintenance and replacement of which, as it turns out, many questions arise.

Self-diagnosis of tie rod end faults

To make sure that the problem is precisely in the above-mentioned part, you can use the “old-fashioned” proven method. For this you need an inspection hole and your car.

1. We go to the viewing hole

2. We grasp the rod with our hand close to the tip. We begin to swing the hinge up and down. A small “spring-loaded” resistance is normal, the spring works. But significant play is a bad sign. There shouldn't be any, just like there shouldn't be any gaps in the tip.

3. When you try to turn the rod around the axis, if it follows your fist easily, most likely the tip has already “ended”. It's definitely time to go to the workshop.

Signs of failure

Checking the steering tips should be performed immediately after a deterioration in the quality of vehicle control appears. If you find it harder to operate your car, it may be a sign that the tips or one of them is worn out or broken. Problems are also indicated by a dull sound at every turn, and noticeable feedback to the steering wheel of the slightest road irregularities.

The steering tip boot is designed to protect the ball joint from the external environment; therefore, its damage contributes to the failure of this part.

It should be noted that the initial inspection can be performed independently, which will at least help determine where the problem is. To do this, you should know how to check the tie rod ends yourself. This operation is performed by two people. The car must be driven into the inspection hole, the parking brake must be set and the ignition must be turned off. One person needs to sit in the cabin and turn the steering wheel in different directions, and the other at this time should be under the car and monitor the movement of the tip. The presence of play is very easily detected visually (by rocking the wheels). In addition to play, you also need to check the integrity of the protective boots and the reliability of fastening to the swing arms.