What is included in the piston group of an engine?

Main menu

Marine engines

The piston group consists of a piston assembly, sealing and oil rings, and a piston pin.

Based on design features, pistons are distinguished as trunk pistons, for crosshead-type and double-acting engines. The trunk pistons are connected to the connecting rod by a piston pin. To ensure gas-tightness of the cylinder cavities, the piston is equipped with sealing rings, and to prevent oil from entering the combustion chamber, with oil scraper rings. The material for the pistons is cast iron of the SCh24-44 and SCh28-48 grades and steel. Small-diameter pistons of high-speed engines can be made from aluminum alloys (AL1, AL2, AK2, AK4). Such pistons have low weight and low thermal stresses in the bottom; The disadvantages of the pistons are low wear resistance and a high coefficient of thermal linear expansion.

The piston (Fig. 139) consists of a lower guide part - a three-piece or skirt 1 and an upper part - a piston head 3 with piston rings 2. The configuration of the engine combustion chamber, the type of purge, the location of the valves and nozzles in the cover determine the shape of the piston bottom 4. The piston bottom can have concave, biconcave, convex and other shapes. Some shapes of the piston heads are shown in Fig. 140. When the piston diameter is more than 400 mm, the piston head is removable. The split design makes it possible to reduce the cost of the piston, since only the head is made of expensive heat-resistant material, and makes it easier to repair the piston. The head is attached to the troika with bolts or studs.

In some piston designs, the inner surface of the bottom is covered with a membrane to prevent carbon formation and protect the head bearing from thermal radiation; To increase rigidity, the bottom is reinforced from below with ribs, which at the same time improve its cooling.

Piston pin 1 (Fig. 141) is placed in bosses (bosses) 2 and is secured against axial displacement by spring rings 3. The fingers are secured with a locking bolt 6 or rotate freely - the fingers are of a floating type. Floating type pins are more common on high speed engines. Bronze bushings 4, pressed into the bosses of the cast iron piston, are bearings for the floating piston pin. The pins are made from low-carbon steel 15 or 20, followed by carburization and grinding, or from alloy steel 15ХМА, 12МХ2А, 18ХНМА, 20Х, etc., followed by hardening. In some piston designs, mushroom-shaped aluminum plugs 5 are installed to prevent the finger from touching the cylinder mirror.

Piston rings are placed in grooves machined into the piston body. Piston rings are divided into sealing and oil scraper rings. O-rings 2 (see Fig. 139) ensure the tightness of the piston in the cylinder, prevent the breakthrough of gases into the engine crankcase and facilitate the removal of heat from the piston head through the cylinder liner to the cooling water. Oil scraper rings 6 and 7 (see Fig. 139) serve to remove excess oil from the cylinder mirror, which reduces carbon formation in the cylinder and prevents oil from penetrating into the combustion chamber. The material for making rings is SCh24-44 cast iron, less often steel. The rings are made self-springing with a locking cut, which ensures insertion of the ring into the piston groove and the possibility of thermal expansion of the ring. The number of sealing rings is six to three, oil scraper rings are three to one. Sealing rings, as a rule, have a rectangular cross-section; the working surface of the ring and the surface of the cylinder mirror are parallel.

Metallic knock in the engine

If you hear knocking noises in the engine that increase under load, it means there is a serious problem in the cylinders and piston group.

Car chemicals in such cases, as a rule, do not help. You should immediately contact a car repair professional. Often extraneous noise in the engine is the knock of the piston group. This sound indicates a discrepancy between the clearances between the piston and cylinder. This is a serious problem that needs to be fixed urgently.

It is important not to confuse the knocking of the piston skirt with such sounds from liners, hydraulic compensators, connecting rods and other engine parts. Experienced technicians determine the nature of extraneous noise by listening to a running engine using a phonendoscope.

Why does the piston skirt knock?

When the engine is running, the piston moves up and down in the cylinder, and the connecting rod describes circles with its lower part, fixed to the crankshaft.

Thus, as the connecting rod moves up and down, it pushes laterally on the cylinder through the piston. When at TDC, the piston shifts, that is, the lateral pressure of the connecting rod changes direction by 180 degrees. If the wear of the liner and piston rings exceeds the permissible values, the glass “dangles” and the piston skirt begins to hit the cylinder wall. Because of these impacts, an extraneous sound appears in the engine.

The knocking noise may weaken or disappear altogether after the engine warms up. This is explained simply. When the engine is not warmed up, the piston shifts to cold. The temperature of engine parts still differs little from the environment. Wear makes itself known.

When heated, the aluminum piston expands faster than the cast iron cylinder. Aluminum has a higher coefficient of thermal expansion than cast iron. Thus, the technological gap returns to normal (or approaches it), and the piston shifts without beating. The knocking becomes quieter or is not heard at all.

What to do if a knock is diagnosed when the piston is switched to cold

If the car mechanic is 100% sure that the extraneous noise is the knocking of the piston skirt when repositioning the connecting rod, get ready for an expensive repair.

You should not delay taking measures to restore engine performance - the situation will quickly worsen. When the engine operates with such a malfunction, scuff marks appear on the piston skirt, and the inner surface of the cylinder quickly wears out. If you continue to drive a car with such a problem, the degree of wear on the cylinder will reach such a level that you can “overshoot” the repair size. That is, wear or scuffing will be greater than the diameter of any piston designed to repair the engine of the required model.

Engine piston: design features

The engine piston is a cylindrical part that performs reciprocating movements inside the cylinder. It is one of the most characteristic engine parts, since the implementation of the thermodynamic process occurring in the internal combustion engine occurs precisely with its help. Piston:

- sensing gas pressure, transmits the resulting force to the connecting rod;

- seals the combustion chamber;

- removes excess heat from it.

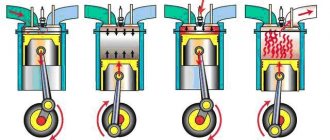

Operating principle and design of the engine

An internal combustion engine is so called because the fuel is ignited directly inside its working chamber, and not in additional external media. The operating principle of an internal combustion engine is based on the physical effect of thermal expansion of gases formed during the combustion of a fuel-air mixture under pressure inside the engine cylinders. The energy released in this process is converted into mechanical work.

In the process of internal combustion engine evolution, several types of engines, their classification and general structure have emerged:

Below, only piston engines are considered, since they are the only ones that are widely used in the automotive industry. The main reasons for this are: reliability, cost of production and maintenance, high productivity.

Extreme conditions determine the material used to make the pistons

The piston is operated under extreme conditions, characterized by high pressure, inertial loads and temperatures. That is why the main requirements for materials for its manufacture include:

- high mechanical strength;

- good thermal conductivity;

- low density;

- low coefficient of linear expansion, antifriction properties;

- good corrosion resistance.

The required parameters are met by special aluminum alloys, which are characterized by strength, heat resistance and lightness. Less commonly, gray cast iron and steel alloys are used in the manufacture of pistons.

Pistons can be:

- cast;

- forged.

In the first version, they are made by injection molding. Forged ones are made by stamping from an aluminum alloy with a small addition of silicon (on average, about 15%), which significantly increases their strength and reduces the degree of piston expansion in the operating temperature range.

Internal combustion engine structure

The first piston internal combustion engines had only one cylinder of small diameter. Subsequently, to increase power, the cylinder diameter was first increased, and then their number. Gradually, internal combustion engines took on the form we are familiar with. The “heart” of a modern car can have up to 12 cylinders.

The simplest is the engine with an in-line cylinder arrangement. However, as the number of cylinders increases, the linear size of the engine also increases. Therefore, a more compact arrangement option appeared - V-shaped. With this option, the cylinders are located at an angle to each other (within 180 degrees). Typically used for 6 cylinder engines and larger.

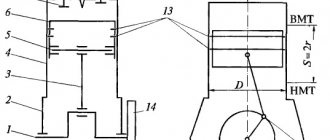

One of the main parts of the engine is the cylinder (6), which contains a piston (7) connected through a connecting rod (9) to the crankshaft (12). The straight up and down movement of the piston in the cylinder is converted by the connecting rod and crank into rotational movement of the crankshaft.

A flywheel (10) is attached to the end of the shaft, the purpose of which is to ensure uniform rotation of the shaft during engine operation. The top of the cylinder is tightly closed by the cylinder head (cylinder head), in which there are inlet (5) and outlet (4) valves that close the corresponding channels.

The valves open under the action of the camshaft cams (14) through transmission mechanisms (15). The camshaft is driven by gears (13) from the crankshaft. To reduce losses due to overcoming friction, removing heat, preventing scuffing and rapid wear, rubbing parts are lubricated with oil. In order to create normal thermal conditions in the cylinders, the engine must be cooled.

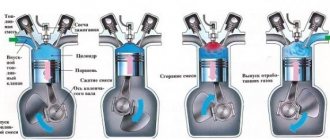

But the main task is to make the piston work, because it is the main driving force. To do this, the cylinders must be supplied with a combustible mixture in a certain proportion (for gasoline engines) or measured portions of fuel at a strictly defined moment under high pressure (for diesel engines). The fuel ignites in the combustion chamber, throwing the piston down with great force, thereby setting it in motion.

The design features of the piston are determined by its purpose

The main conditions that determine the design of the piston are the type of engine and the shape of the combustion chamber, the features of the combustion process taking place in it. Structurally, the piston is a solid element consisting of:

Is the piston of a gasoline engine different from that of a diesel engine? The surfaces of the piston heads of gasoline and diesel engines are structurally different. In a gasoline engine, the surface of the head is flat or close to it. Sometimes there are grooves in it to facilitate full opening of the valves. The pistons of engines equipped with a direct fuel injection system (DNFT) have a more complex shape. The piston head in a diesel engine is significantly different from a gasoline engine - thanks to the combustion chamber in it having a given shape, better swirl and mixture formation are ensured.

Engine operating principle

Due to the low performance and high fuel consumption of 2-stroke engines, almost all modern engines are produced with 4-stroke cycles:

The reference point is the position of the piston at the top (TDC - top dead center). At this moment, the inlet port is opened by a valve, the piston begins to move down and sucks the fuel mixture into the cylinder. This is the first beat of the cycle.

During the second stroke, the piston reaches its lowest point (BDC - bottom dead center), at the same time the inlet port closes, the piston begins to move upward, due to which the fuel mixture is compressed. When the piston reaches its maximum top point, the fuel mixture is compressed to its maximum.

Piston rings: types and composition

Piston rings are made mainly from special gray high-strength cast iron, which has:

- high stable indicators of strength and elasticity under operating temperatures throughout the entire service life of the ring;

- high wear resistance under conditions of intense friction;

- good anti-friction properties;

- the ability to quickly and effectively break in to the cylinder surface.

Thanks to alloying additives of chromium, molybdenum, nickel and tungsten, the heat resistance of the rings is significantly increased. By applying special coatings of porous chromium and molybdenum, tinning or phosphating the working surfaces of the rings, their wearability is improved, wear resistance and corrosion protection are increased.

What is it made from?

Let's consider the materials of the CPG parts. All materials for CPG must have high strength, excellent thermal conductivity, slightly expand when heated and have anti-friction properties. Have increased resistance to rust.

The sleeves are made of cast iron or special steel with additives so that the part can withstand high loads.

Pistons were initially made of cast iron, but with the development of technology, aluminum began to be produced. Modern engines use prefabricated steel pistons, especially diesel engines. In experimental engines, ceramic pistons are being tested, but so far in production, ceramics are used only as a coating on pistons.

Piston rings are made of high-strength gray cast iron with the addition of molybdenum, chromium, tungsten or nickel. Additives provide better “break-in” of parts, increasing their wear resistance and resistance to high heat.

The piston pins are made of alloy or carbon steel, carburized and hardened. If the file leaves scratches on the finger, these are defective (not hardened) fingers, they cannot be installed, this will lead to failure of the CPG.

To summarize, I’ll tell you which engines have a CPG. This group is present on all units operating on the principle of internal combustion. Regardless of whether the unit is diesel, petrol or gas. Due to their convenience and relative simplicity of execution, reliability and durability, as well as safety for humans (except for environmental friendliness), cylinder-piston gas engines are widely used all over the world, even in mowers and chainsaws. Electric motors do not have CPGs; they operate on a different principle.

Source

Composition of the piston group

A unit consisting of a piston, compression rings, oil scraper rings, and a piston pin is usually called a piston group. The function of its connection with the connecting rod is assigned to a steel piston pin, which has a tubular shape. The requirements are:

- minimal deformation during operation;

- high strength under variable load and wear resistance;

- good shock resistance;

- low mass.

According to the installation method, piston pins can be:

- fixed in the piston bosses, but rotates in the connecting rod head;

- secured in the connecting rod head and rotate in the piston bosses;

- freely rotating in the piston bosses and in the connecting rod head.

Fingers installed according to the third option are called floating. They are the most popular because they wear lightly and evenly along the length and circumference. When using them, the risk of jamming is minimized. In addition, they are easy to install.

How to extend the life of the CPG?

The service life of the cylinder-piston group depends on the type of engine, its operating mode, regularity of maintenance and many other factors. The service life of the CPG of domestic cars is, as a rule, shorter than that of foreign cars: about 200 thousand km versus 500 thousand km.

In order for the CPG parts to fully exhaust their service life, it is recommended:

- Use motor oil approved by the vehicle manufacturer

- Change oil and coolant strictly according to regulations

- Monitor the operating temperature of the engine, avoid overheating and cold starting

- Carry out vehicle diagnostics regularly

- Use special products to maintain automotive components that can protect them from increased wear and maximize their service life.

The car doesn't pull

A significant reduction in engine power leads to a deterioration in the dynamic characteristics of the car. “The car doesn’t pull” - drivers say in such cases

. There are many reasons for this malfunction: from low-quality fuel to problems in the transmission. One of these problems is wear of the elements of the cylinder-piston group: rings and inner cylinder walls.

The gap in the piston-cylinder friction pair must be strictly maintained.

Parts are manufactured with high precision. When rings or cylinders wear out, the gaps increase and the seal is compromised. Compression drops, which leads to incomplete combustion of fuel and power decreases. Expanding gases from the combustion chamber break into the crankcase, which increases the destruction of the oil and reduces its service life.

In addition, a worn oil scraper ring does not completely remove oil from the inner cylinder wall as the piston moves down. The lubricant is burned when the fuel is burned. Therefore, the exhaust smoke takes on a bluish tint. By the way, a changed color of the exhaust is one of the signs that allows you to identify problems with the cylinder-piston group at an early stage.

The increased gap in this friction pair causes another symptom - the smell of gasoline emanating from the oil. The fact is that gases from the combustion chamber, through the enlarged gaps that appear in the piston-cylinder pair, break into the crankcase. Thus, incompletely burned fuel vapors enter the engine oil, giving it a characteristic odor.

What to do if a drop in power is caused by wear of the CPG elements

So, engine power dropped by more than 10%. It turned out that the engine had low compression and there was reason to believe that worn piston rings or cylinders were to blame. What's next? There are two options.

If the cylinder rings are worn or damaged

The cost of replacing piston rings is the most insignificant among other types of CPG repairs. This operation can be performed without removing the engine from the vehicle. If you have the skills, you can replace the rings on the pistons yourself.

If the cylinder walls are worn

In this case, boring and honing of the cylinders will be required. Moreover, most modern car engines are beyond repair, i.e. are not subject to boring and do not have repair dimensions for the CPG. It is necessary to strictly maintain the dimensions so that the repair kit of pistons and rings fits in place with the required clearance. Tolerances are calculated in hundredths of millimeters: for example, in a VAZ 2106 engine, the mounting distance between the piston and cylinder must be maintained in the range of 0.05 - 0.07 mm.

The operation of boring and polishing (honing) of cylinders should be entrusted only to experienced specialists. It takes professional level skills and equipment to do this kind of work. Mistakes are not allowed. If the deviation from the specified dimensions exceeds the tolerance, the engine will quickly fail.

An easy way to solve CPG problems

Obviously, the cost of cylinder boring and polishing service is relatively high. If you take timely measures, you can significantly reduce costs by postponing the replacement of the piston group by tens of thousands of kilometers. If there is slight wear on the cylinders and piston rings, you can add the tribotechnical compound Suprotec Active Plus or similar products to the engine oil.

The additive partially restores worn surfaces, seals the gap and promotes better oil removal from the cylinder walls. In most cases, this allows you to restore the engine's life to acceptable parameters - the car's dynamics improve, and blue smoke disappears from the exhaust pipe.

Engine additive "Suprotek Active Standard"

For naturally aspirated petrol engines up to 1.6 litres. Restores and equalizes compression, reduces fuel and oil consumption due to waste, protects friction surfaces in the CPG and gas distribution mechanism from wear during startup and overheating.

more reviews

It is important to remember that if after using the tribotechnical composition “Suprotek” or a similar product there is no improvement, then repair is needed. You should not exceed the dose indicated on the package, hoping that everything will work out. The best solution is to immediately contact a reliable car service.

Blue or white smoke from the exhaust pipe

It was already said above that this is one of the first “alarm bells” signaling that not all is well in the cylinder-piston group. If you take action in time, you can get by with “little loss.” Pouring tribotechnical composition is a relatively inexpensive and simple operation. You can even replace piston rings yourself, saving several thousand rubles on the services of auto mechanics.

If you do not take action in time, considering that blue smoke from the exhaust pipe is not too big a problem, you can get a full-scale engine failure. Repairs in this case will cost tens of thousands of rubles. Therefore, as soon as you notice that the smoke from the exhaust pipe has turned bluish, use auto chemicals. If Suprotec or similar products do not help, contact a car service.

What problems may arise in the CPG

Worsened dynamics, knocking noises, white or bluish smoke and increased oil consumption are external manifestations. These are signals that the piston rings need to be replaced.

or a more complex type of engine repair. What's going on inside? Let's figure it out.

The following malfunctions may occur in the engine cylinder-piston group:

- wear and damage to piston rings;

- scuffs on the piston skirt;

- damage to the internal walls of the cylinders;

- wear of connecting rod and main bearing shells;

- wear of the inner walls of the cylinders.

Depending on the type of problem, CPG repairs of varying degrees of complexity and cost are required. Small malfunctions can lead to an avalanche-like increase in malfunctions, which will result in an accident. It is better to deal with problems in the early stages.

Engine systems

The above is a BC (cylinder block) and a crank mechanism (crank mechanism). In addition, a modern internal combustion engine also consists of other auxiliary systems, which, for ease of perception, are grouped as follows:

Timing - gas distribution mechanism

In order for the required amount of fuel and air to enter the cylinder, and combustion products to be removed from the working chamber in a timely manner, the internal combustion engine has a mechanism called a gas distribution mechanism. It is responsible for opening and closing the intake and exhaust valves, through which the fuel-air combustible mixture enters the cylinders and exhaust gases are removed. Timing gear parts include:

The timing belt is driven by the crankshaft of the car engine. Using a chain or belt, rotation is transmitted to the camshaft, which, using cams or rocker arms through pushers, presses on the intake or exhaust valve and opens and closes them in turn.

Lubrication system

Any engine has many rubbing parts that must be constantly lubricated to reduce power loss due to friction and avoid increased wear and jamming. There is a lubrication system for this. Along the way, it solves several other problems: protecting internal combustion engine parts from corrosion, additional cooling of engine parts, and removing wear products from the contact points of rubbing parts. The lubrication system of a car engine consists of:

Cooling system

While the engine is running, its parts come into contact with hot gases that are formed during the combustion of the fuel-air mixture. To prevent internal combustion engine parts from being destroyed due to excessive expansion when heated, they must be cooled. You can cool a car engine using air or liquid. Modern motors usually have a liquid cooling circuit, which is formed by the following parts:

Fuel supply system

The power supply systems for spark-ignition and compression-ignition internal combustion engines differ from each other, although they have a number of common elements. The common ones are:

Both systems have fuel pumps, fuel rails, fuel supply injectors, the supply principle itself is the same: fuel from the tank is supplied through filters by a pump to the fuel rail, from which it enters the injectors. But if in most gasoline internal combustion engines the injectors supply it to the intake manifold of the car engine, then in diesel engines it is supplied directly to the cylinder, and there it is mixed with air.

Exhaust system

The exhaust system is designed to remove exhaust gases from the cylinders of a car engine. Main details and components:

In modern internal combustion engines, the exhaust design is supplemented with devices for neutralizing harmful emissions. It consists of a catalytic converter and sensors communicating with the engine control unit. Exhaust gases from the exhaust manifold enter the catalytic converter through the exhaust pipe, then through the resonator into the muffler. Then they are released into the atmosphere through the exhaust pipe.

Source