The idle speed sensor (regulator) is an executive part of the internal combustion engine and is installed in modern brands of cars. Inside injection-type systems (VAZ), idle air regulators are used, and in GAZ cars additional air regulators are installed. Carburetor systems are equipped with electromagnetic and electro-pneumatic valves. Today, vehicle manufacturers use sensors (IAC) with different numbers of contacts in the stepper (4 contacts), solenoid (2 contacts) and rotary (3 contacts) type connectors.

Purpose and principle of operation

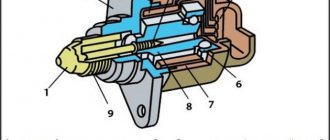

From a design point of view, a sensor is a device represented by several main functional elements:

- valve;

- body;

- stator winding;

- lead screw;

- plug output of the stator winding;

- ball bearing;

- stator winding housing;

- rotor;

- spring.

The main purpose of the sensor is to ensure the supply of a certain amount of air, which is necessary for stable engine operation. Air is supplied at idle speed, outside the throttle valve. In other words, the operation of the power unit during idle conditions is carried out with the throttle valve closed, and a special additional channel is responsible for the supply of air. The idle speed is adjusted by changing the cross-section of the channel blocked by the IAC needle.

When a car engine is idling, a certain amount of air enters inside to ensure smooth operation. The crankshaft position sensor takes into account the speed of the unit, and the data itself is transmitted to the control unit. It is from the unit that the sensor receives a command to reduce or, on the contrary, increase the air supply.

When the engine is warmed up to operating temperature, the controller automatically maintains idle speed. In the absence of the required temperature, it is the controller that increases the speed through a sensor and ensures sufficient heating of the power unit. Thanks to this design feature, you can start driving the vehicle even without preheating.

Purpose of the idle speed sensor

Purpose of IAC in vehicles equipped with an electronic ignition system:

- The microprocessor module determines the ratio of air and fuel when creating the air-fuel mixture in the injection power unit.

- The control unit measures a certain volume of gasoline or diesel fuel.

- The electronic type of systems is equipped with controllers for the crankshaft, throttle position, knock and flow meter. In accordance with the readings of these devices, the fuel pump is activated. The ignition is distributed to specific cylinders of the internal combustion engine.

- If the driver releases the gas pedal, the fuel valve closes completely. This leads to the fact that the proportions of the combustible mixture are violated. Combustion products move into the chamber when there is a difference in pressure between the exhaust and intake manifolds.

The idle speed sensor in electronic ignition systems performs the function of adjusting the composition of the combustible mixture during engine starting. Using the signals sent by the controller, the microprocessor module makes a decision about fuel enrichment. In doing so, it ignores the readings sent by the throttle control. The sensor transmits signals along the line. If necessary, a free channel opens in it through which air passes. This leads to equalization of engine speed while driving or idling.

User Roman Lozovoy presented a detailed review of the controller from the manufacturer General Motors for the Daewoo Lanos.

Symptoms of a problem

To choose the best option for correcting malfunctions of the idle speed sensor, you need to know the main signs that characterize the malfunction of such a device:

- the power unit does not hold idle speed;

- the speed jumps, then freezes, and returns to normal again;

- the engine shakes noticeably at idle;

- there is no compensation for increasing load;

- it is difficult to start the power unit without pressing the gas pedal;

- There are no sufficient warm-up speeds.

The most common problem that accompanies a breakdown of the sensor (IAC) is that the vehicle stalls at idle, when changing gears or releasing the gas.

It is quite possible to independently diagnose and replace the idle speed sensor if you know all the design features of such a device and take into account the rules for choosing an IAC.

Signs of a malfunctioning idle speed control on Lanos

The device in question has a fairly long service life, but the time comes when the regulator needs to be replaced. First, let's look at the question of how to understand that the sensor is faulty and needs to be diagnosed. The main signs when a driver should pay attention to IAC appear in the following ways:

The most common symptoms that force the car owner to check the serviceability of the IAC are when difficulties arise in starting the engine, as well as when the engine stalls when the speed is turned off. If all of the above symptoms occur, the sensor should be checked immediately. How to determine that the idle speed sensor on a Lanos is faulty will be discussed in the next section.

Possible causes of malfunction

There are several reasons that can provoke disturbances in the functioning of the IAC, but the most common include:

- problems with electrical wiring, represented by power failure and oxidation of the contact group;

- incorrect rod stroke as a result of contamination;

- failure of the electric motor;

- wear of the o-ring;

- rod breakage.

The shutter of the working IAC sensor moves without biting or slipping, but during constant operation, a significant amount of dirt deposits accumulates inside the channels of the throttle assembly, which disrupts the functioning of the IAC.

Verification activities

Self-diagnosis is conventionally divided into a couple of main parts designed to identify mechanical and electrical faults. To determine the problem, you need to use visual inspection and testing activities.

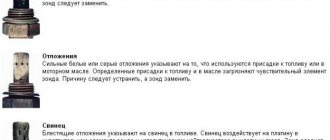

Sensor Inspection

A simple measure will help identify defects on the body and the degree of wear of the needle, and will also allow you to notice the presence of an excessive amount of carbon deposits. To remove all contaminants from the body and throttle assembly, you can use a standard product designed for cleaning carburetors.

Diagnostic programs

Special programs and a diagnostic adapter are used to identify relatively complex faults. The tandem of the ELM327 adapter and the OpenDiagMobile program has proven itself quite well. In the selected position of the IAC, all malfunctions in its operation are noted.

Wiring test

For this purpose, a household or professional multimeter is used. With the engine turned off, the regulatory connector is removed, after which the standard measurement limit “0-20” (constant voltage) is set on the device. The readings should be 12 V.

Checking resistance readings

You can verify the correct resistance values (terminals “A-B” and “CD”) using a multimeter. With the terminals disconnected, measurements are taken within the range of 0-200 Ohms. Normally, this indicator can fluctuate from 50 to 55 Ohms, and between the terminals - infinity.

Throttle assembly

One of the options for diagnosing the sensor involves dismantling the throttle assembly. With the valve connector connected, the procedure for turning the ignition on and off allows you to check the operation of the IAC (needle rubbing, evenness of movement, presence of suspicious sounds).

How does he work

The vehicle idle speed sensor performs a number of specific functions that are very important. If this part does not work well or fails, then it may be impossible not to turn off the car when you need to stop, for example, at a traffic light. Driving a car with a faulty idle speed sensor is not only uncomfortable, but also very dangerous. As soon as it is noticed that there is a problem with a given part, it may need to be repaired or replaced. The idle speed sensor is also called a regulator. On models such as the VAZ 2114 or other modifications of the Samara, this idle speed regulator is designed to stabilize idle speed. On the VAZ 2109 it performs a more complex function. The sensor is a small electric motor equipped with a conical needle.

Removed idle speed sensor

This part is located in cars of the VAZ family on the throttle body, next to the damper. The idle speed sensor itself, which we will call IAC, is attached here with two screws. But it also happens that dismantling this element sometimes causes difficulties. And all this is due to the fact that in addition to fixing with screws, the DXX is mounted on varnish. Let's look at what happens when the ignition is turned on:

- At this moment, the rod located on the idle speed control moves completely forward, resting against a special calibration hole located in the throttle pipe.

- After this, the sensor begins to work. He counts the steps and returns the valve back. And the position of this very valve depends on the time of year and engine warm-up. For example, this could be equal to 50 steps with the motor running.

- As the steps increase or decrease, the air passing through the calibration hole is under constant change. When the rod is extended, the steps increase. The reverse process occurs when the rod returns to its original position. The stroke of the rod itself on the vase is approximately 250 steps.

Injection system and DHH

- The idle speed is controlled by a sensor that is assisted by air. In other words, air entering the engine regulates idle speed.

- The mass flow sensor analyzes the incoming air based on its quantity. As for the controller, it supplies the required amount of gasoline or other fuel directly to the engine through the fuel injectors. Thus, the process of supplying the required volume of air occurs.

- As for a cold engine, the controller in this case increases the speed only due to the presence of the DXX. And this mode allows you to move away even without necessarily warming up the engine.

Replacing the sensor

If a complex malfunction is detected, the idle speed sensor cannot be repaired and requires complete replacement, followed by correct calibration of the installed new regulator. In this case, preference should be given to original products, which will allow you to forget for a long time about the need to perform an unscheduled replacement of the IAC. The service life of analog sensors is usually an order of magnitude shorter.

Step-by-step technology for replacing the XX sensor:

- disconnect the negative battery terminal;

- unscrew and remove the air filter;

- disconnect the plug from the sensor body;

- unscrew a couple of bolts;

- dismantle the XX regulator;

- install a new device;

- reassemble the dismantled elements.

The final step is to calibrate the new regulator by checking the distance from the mounting plate to the end of the rod. Normal values are within 23 mm.

Rules for self-calibration of IAC using the ECU algorithm:

- turn on the ignition for 8-10 seconds without starting the engine;

- start the power unit - sometimes there are jumps or an increase in speed;

- turn off the engine to install the rod in a different extreme position;

- repeat the above steps 2-3 times;

- run the engine for about five minutes.

It is important to remember that resetting the calibration data of a dismantled IAC occurs immediately after installing a new regulator and connecting the negative terminal to the battery. Correct calibration will allow the revolutions to “stand up” to the position necessary for stable operation of the system.

Required tools and replacement steps

To replace the sensor you will need:

- Two Phillips screwdrivers (PH2).

- Telescopic magnet.

If the latter is missing, no big deal. You can use screwdrivers with magnetic tips. This is required in order not to drop the fastening screws during the process of unscrewing and tightening them. Before you begin dismantling the old product, you must disconnect the battery by removing the negative terminal and disconnect the electrical harness that is connected to the sensor. Carefully bend the plastic clip and disconnect the wires from the regulator.

Replacing DXX

To do this, unscrew two screws and carefully remove the old sensor. Please note that it is more convenient to unscrew one screw with a short screwdriver, the other with a long one. And we emphasize once again, be extremely careful with the screws; when unscrewing, they can fall under the engine and onto the ground, where they can easily get lost in the grass or snow. New screws aren't a big deal, but they're a waste of your time.

Take a screwdriver and unscrew the two bolts securing the idle speed control of the VAZ 2110

The process of installing a new product is carried out in reverse order.

When purchasing a new regulator, pay attention to the serial number of the part. The ideal option is when the numbers of the old and new sensors match. Otherwise, ECM (Electronic Engine Control System) compatibility problems may occur.

Questions and answers

Determining the location of the engine idle stabilizer yourself is not too difficult. For this purpose, it is quite possible to focus on the installation location of the throttle position sensor.

Where is the idle speed sensor located on the VAZ 2114?

, The extremely inconvenient location of the IAC can somewhat complicate the diagnosis and replacement of the sensor installed on the throttle body.

Where is the idle speed sensor on the VAZ 2110?

In 8 and 16 valve cars of this series, the idle speed sensor is fixed next to the damper control mechanism and connected to them using bolts.

Where is the idle speed sensor located on the VAZ 2107?

The idle air control is located in the throttle body, attached to the rear of the intake manifold of the power unit.

How to replace idle air control

To replace the regulator, you can go in three ways:

- with complete disassembly of the throttle valve;

- partial;

- without removal.

I changed the regulator with complete disassembly, as I discovered clogged tubes, and a dropped plug rattled inside the receiver. When disassembling and cleaning I used carburetor cleaner. Although this is the same acetone and could have been saved.

Carburetor cleaner, if it is not needed under pressure, can be easily replaced with simple acetone

In the second option, the replacement is made without removing the tubes, but with removing the throttle. In this case, the air duct clamp is loosened, the throttle is unscrewed and, by moving it a little, removed from the studs. You need to turn it a little, this will give access to the sensor mounting bolt.

In the third option, you need a special screwdriver capable of unscrewing the sensor mounting screw. Typically, this is a flexible screwdriver for hard-to-reach places or an angled attachment for a screwdriver.

Necessary tool

To replace the sensor you will need:

- Flathead screwdriver.

- Crosshead screwdriver.

- Socket or open-end wrench size 13.

Replacing the idle speed sensor

To avoid getting burned, carry out the replacement on a cool or warm engine.

- disconnect the damper control cable;

- remove the block from the throttle position sensor;

- remove the block from the XX regulator;

- disconnect the coolant supply pipes from the throttle body;

- remove the crankcase ventilation pipe.

- disconnect the air supply pipe;

- pull the fuel supply hose to the throttle valve;

- unscrew the screws and remove the IAC.

Removed VAZ regulator

Removing the faulty regulator

Remove and replace the plug

Cleaned throttle body

Assembly is carried out in reverse order.

After replacing the regulator, do not start the engine immediately. Simply turn on the ignition, wait 10 - 30 seconds and turn off the ignition. After that you can start it. This time is necessary to calibrate the new idle air control ECU.

Ideally, when starting on a cold car, the speed should rise to 1500 rpm and drop to 800 as it warms up.