Installation of gas equipment of any generation on a vehicle inevitably poses certain questions to the car owner. One of them is the question of how to connect the HBO button. Despite the apparent simplicity of the problem, connecting a device for converting from gas to gasoline causes, as practice shows, almost the greatest amount of controversy. This is common among both installers and the NGV equipment user community.

Do-it-yourself installation of HBO buttons

Operating principle and differences between buttons

The 1-2 generation button on the carburetor has two working positions and one neutral.

- I – the engine starts and runs only on gasoline (gas valve is closed, the red light is on).

- II – The internal combustion engine switches to gas, while the gasoline electric valve closes and the green lamp lights up.

- 0 (Neutral) – serves to burn gasoline from the carburetor float chamber.

Changing the fuel type should only occur through the neutral position. If you turn on the gas right away, two types of fuel will enter the combustion chambers and the engine will most likely stall.

Some copies have an indication of the fuel level in the cylinder, as well as an additional button for the pre-start supply of a portion of gas, which is needed to enrich the mixture when starting a warm engine on gas (for example, Lovato, Logo buttons for a vacuum reducer).

A key such as, for example, Stag 2-G already has a pre-start function built into it, with the ability to adjust by time.

In the injection version, instead of the middle position, there is an automatic mode (on some types, such as Stag 2-W, it can be extreme). In this position, the engine starts on gasoline, and when a certain engine speed is reached, the gas supply is automatically turned on.

The transition speed is regulated using a potentiometer on the side surface of the housing. This key can also come with a level indication.

The universal option involves installing a toggle switch on both the injector and the carburetor. The transition between modes is carried out using a jumper/jumper on the case (example SVG switch).

The 4th generation HBO button has an LED indication and 2 operating modes on/off. In the on position, the gas turns on automatically after the reducer-evaporator warms up to 35-45˚C. The temperature is programmed in the controller when setting up the equipment.

Button signals using Stag as an example:

- LED is on/off – the engine is running on gas/gasoline;

- blinks at intervals of 1 second. – the engine is not warmed up;

- flashes every 2 seconds – the system is ready to switch to gas;

- blinks every 4 seconds – the tank has run out of fuel;

- the buzzer beeps three times - the system switches from gas to gasoline due to lack of fuel;

- three short signals 1 long – ECU (control unit) error;

- two short beeps 1 long beep (with the ignition off) – maintenance of gas equipment is required.

In addition, the fourth version of the gas system has an emergency start on gas. The mode is activated as follows: hold the button with the ignition off until the LED lights up continuously. Then, without releasing the key, we start the engine. Deactivation occurs after stopping the internal combustion engine.

Types of buttons (video):

Selection table (with approximate prices):

| Name/labeling | injector/carburetor/generation | Level indication, +/- | Price in rubles |

| REG OMVL Dream XXI King | engineer/4 | + | 1020 |

| Logo 145 | engineer/4 | — | 280 |

| Logo 101 | carb./1.2 | — | 470 |

| Atiker (K01.003.000.020) | carb./1.2 | + | 600 |

| Stag 2-G | carb./1.2 | — | 550 |

| AEB 722 | carb./1.2 | + | 1050 |

| Tamona K-5 | carb./1.2 | — | 520 |

| Lovato | carb./1.2 | — | 590 |

| Torelli | carb./1.2 | + | 630 |

| Stag 2-W | engineer/2 | — | 600 |

| Tamona in-3 | engineer/2 | — | 540 |

| Stag LED-401 | engineer/4 | + | 750 |

| Stag LED-300 | engineer/4 | + | 580 |

amega267 › Blog › HBO OMVL (OMVL) Saver control description.

In general, I installed this kit on my car.

I've already driven 1100 km. So far the flight is normal and I haven’t felt any difference between gas and gasoline. I created this topic because... After installation, the guys did not receive proper and complete information about what and what indicator means on the LPG control button, and they also did not explain what and how it works. Just in a nutshell. Also, this information is not available on the Internet. So I will get to know this system more deeply and at the same time post everything here. I'll start with a description of the control button.

My button is like this

Next, what do the indicators mean and the color of the indicators?

So we started: in the center there is a button to turn on/off the HBO. Each action is accompanied by a beeping buzzer. Its volume level can be adjusted programmatically. Next are the indicators (I’ll start out of order): 3. This is a photosensor. It determines the level of illumination in the interior and, based on its readings, the HBO system selects the brightness of the remaining diodes. 2. Three green diodes. Indicate the gas level in the cylinder when the system is working properly. When the gas tank is full, all three light up, then as the gas in the tank is consumed, they go out one at a time from right to left. 1. Red LED. Indicates the minimum gas level in the cylinder if it lights up continuously. If it flashes, it means that there is low gas pressure at the reducer. (occurs at the moment when the gas has already run out in the cylinder or the reducer is damaged) 4. Red diode. When it blinks, it means that the system is in emergency mode and the HBO is not working. Usually flashes together with one of diodes 1 and 2 indicating the error number of the HBO system malfunction. 5. Blue LED. Indicates that the car's engine runs on gas. Programmed by default. During this time it glows continuously. If it blinks, then read on.

During a cold start of an engine (ICE) running on gasoline, the LPG starts and begins to wait for the gearbox to warm up to the set coolant temperature to switch from gasoline to gas. As a rule, the transition temperature is 35-45 degrees Celsius. At the same time, blue indicator 5 and indicators 1, 2 begin to pulsate. During warming up, as the transition temperature is reached, indicators 1 and 2 will not all flash at once, but will be added in turn from left to right, and as soon as all four (1 and 2) flash together with the blue indicator, this means that the coolant temperature for transition to operation on gas achieved and the system will automatically switch the internal combustion engine to gas operation.

Next, you can programmatically select which of indicators 4 or 5 will indicate operation on gas. Or you can turn off both indicators.

The emergency start procedure on gas is carried out as follows: 1. The temperature of the gearbox must be greater than 0 ˚ C 2. Turn on the ignition 3. Set the switch to the gasoline position 4. Turn off the ignition 5. Turn on the ignition 6. Press and hold the button on the switch for approximately 10 seconds The LED will flash and a continuous beep will sound. The gas ECU will open the gas valve and the LED on the switch will be on continuously. (If you hold the button for another 5-10 seconds, you will enter the fuel level sensor calibration mode and diodes 1,2 will start blinking alternately.) 7. Turn the key to start and start the engine. The maximum number of emergency starts is 50. You can check the number of emergency starts performed in the diagnostics.

Gas level sensor calibration mode. The gas cylinder must be empty for calibration. Next, carry out steps 2 to 6 as during an emergency start on gas. When the diodes begin to blink alternately, turn off the ignition and remove the key. Let's go fill the tank until it's full. 7. After refueling, insert the key and turn it to the ON position, but do not start the engine. The LEDs will start blinking again for about five seconds. All calibration is completed and the engine can be started.

LIST OF ERROR CODES Each error has its own individual digital code, which can be displayed on the switch using one red and three green LEDs. The corresponding function is activated in the configuration window.

Now I’ll touch the diagnostic connector.

Pinout and appearance as in the photo. (the photo is not mine. I was too lazy to take my own because it’s available on the Internet).

Colors of wires on the reverse side: +12V - red RX - white TX - green GND - black The only thing I will add is that there is no need to purchase an expensive cable for diagnostics for 1200 rubles. You can simply buy a ready-made assembly (100-200 rubles) or take a ready-made construction kit or even solder it yourself. In this case, the well-known PL2303HX or FTDI ft232rl are used. the price of their pennies. The firewood for them comes immediately sewn into the program for setting up the HBO. And upon completion of the installation of the program, it is possible to supply firewood for one or another chip. This is what the assembly looks like at a cost of about 100 rubles.

All you have to do is solder GND to its outputs; RX and TX three wires and plug them into the connector above as described. You can also configure other types of HBO.

Also, whoever has an ELM327 USB adapter uses the same chips in its depths. And accordingly, you can solder the wires where you need to adapt it to work on setting up and diagnosing the gas equipment and not have any costs other than the cost of three wires.

A program for diagnosing and configuring HBO is available on the Internet. Downloading it will not be difficult because... All stores selling gas equipment and spare parts for them offer it for download, so I won’t post links here. The file name looks like this: SAVER-4.0.7.0-setup

The only point: visits to HBO by third-party computers are recorded by HBO’s brains. There, computers are registered and an identification number is assigned to them. If your installation is still under warranty and you want to maintain this warranty, then you should not connect.

If there is no guarantee or you are going to set everything up yourself, then go ahead. A description of the settings is available directly in the program itself in PDF format. That's all for now, but I think I'll continue.

It's already been a year and 33,000 runs under my belt. Everything works fine so far except for one small thing. The thermistor in the pressure reducer, which shows the temperature of the reducer, has died. I didn’t buy a new one like this (for 250 rubles) because... there is an ordinary small-sized thermistor at 2.2; 4.7 or 10Kom. I bought three pieces on the radio market for 10 rubles 10 k. I picked out the body of the old one, cleaned everything, added a little KTP8 thermal paste to the beginning and filled the rest with epoxy. It began to work much faster and in the summer the car switches to gas after just 5 minutes of engine operation. And before the replacement it switched to about 75 °C.

And now three years have passed. Replaced all low pressure gas hoses with new ones. The old ones were already a little frayed and saturated with odorant. This caused the smell of gas to appear from under the hood. Now everything is in a bundle again.

Source: www.drive2.ru

Connection diagram of the 2nd generation HBO button to the injector

Installing and connecting the 2nd generation HBO button with your own hands on a car with an injector sometimes causes difficulty.

In fact, everything is much simpler than it seems. The factory instructions for installing the switch indicate the following pinout:

- the white wire should go to the level sensor on the multivalve (if such an indicator is installed);

- yellow goes to the positive of the gasoline valve (if there is emulation of gasoline injectors, this wire is not connected);

- blue connects to the positive terminals of the gas valves of the reducer and the additional remote valve with filter. The injector emulator also cuts into this circuit;

- red goes to the positive terminal of the ignition coil (necessarily with a fuse);

- black - mass;

- brown to the negative terminal of the coil.

It’s hard to disagree with the first three points. But for the rest we will make recommendations:

- The red wire is best connected to the positive side of the ignition switch. Because the coils may have voltage surges. In order not to disassemble the panel, the contact can be found on the fuse block.

- The black wire should only be attached to the car body, like all negative equipment cables.

- Brown, must be wound onto the central high voltage wire of the coil.

It is advisable to do 10-15 turns, without using electrical tape. The electrical tape dries out over time and falls off; it is better to make a knot similar to tying a fish hook.

If the ignition system consists of separate coils, it is necessary to wind the wire onto the first two armor wires (for a more accurate signal), without breaking the brown one, i.e. first to the first then to the second.

After connecting the button, it must be adjusted. Periodically increasing the engine speed with the accelerator, it is necessary to smoothly turn the potentiometer screw clockwise and back. It is necessary to ensure that the gas supply is turned on in the “automatic” mode when the tachometer reading is 2000-2500 rpm.

Installation process of gas equipment

When installing a cylinder, it is extremely important to carry out calculations, according to which the hole with the multivalve should be located on the side of the car, namely, towards the fuel filler cap. The multivalve is installed directly to the LPG cylinders using bolts, after which the level sensor should be installed. It is installed directly on the multivalve, depending on the specific configuration of the kit.

Next, you should install a solenoid valve, which will open when an impulse is supplied from the “brain” of the installation. After this, it is necessary to install the fuel line and the device for filling gas into the cylinders. In most cases, the 4th generation LPG equipment includes two lines: the main one and the refueling line. To ensure them, copper tubes should be used, the fastening of which is ensured by barrels and copper bolts. It is advisable to secure the VZU in close proximity to the filling neck.

Having installed the lines, it is worth checking for their tightness using a compressor. You need to pass a pressure of 5-6 atmospheres through the system, checking for etching from the installed tubes.

A gearbox should be installed under the hood, the unit of which in most cases is located near the car radiator. The outlet of the gearbox should be at the top and directed forward. The gearbox itself should be placed slightly below the level at which the coolant is installed for more convenient access to the cooling system.

Having mounted the injectors and cut them into the manifold, you should start assembling the low-pressure line, and then connect the injectors and the reducer using hoses from the standard LPG kit. Pressure testing should only be carried out with the tank filled.

Installation of control systems and connection of the wiring of the central distributor can be done before and after crimping. Next, you should check the operation of the engine in various modes and configure the operation of the LPG system.

Installation of gas equipment, especially the 4th generation, is a complex and labor-intensive process. It must be carried out in accordance with all the standards and requirements presented in the instructions, and also follow the recommendations from the brain disk. Installation of such an installation by a novice may take several weeks, but an experienced technician will be able to switch the car to gas in a matter of days.

Connection diagram of the 2nd generation HBO button to the carburetor

For a carburetor engine, the connection looks similar:

- Red - through the fuse to the ignition coil/switch.

- Light blue (blue) – gas valve positive.

- Yellow – positive of the gasoline valve.

- Black – minus (car body).

- The brown one goes to the ignition coil armored wire. It is needed to transmit an impulse to the key, which determines whether the motor is running or not.

If you still have questions about connecting or selecting buttons on the HBO, ask them in the comments. We will be happy to answer them.

Source

How to connect a HBO button

Installation of gas equipment of any generation on a vehicle inevitably poses certain questions to the car owner. One of them is the question of how to connect the HBO button. Despite the apparent simplicity of the problem, connecting a device for converting from gas to gasoline causes, as practice shows, almost the greatest amount of controversy. This is common among both installers and the NGV equipment user community.

Do-it-yourself installation of HBO buttons

Types of buttons

The LPG button is exactly the element that is equipped with any gas equipment when it is sold. Despite this, loss and damage to the fuel switch happens quite often, as a result of which the question regarding the choice of new buttons is always relevant among gas motorists. There are no particular difficulties in selecting a new HBO component, except for the fact that you need to purchase the type of button specifically for a specific car.

Based on the last point, it is worth noting that there is a classification of HBO buttons, which is carried out according to:

- The type of available equipment (it is not surprising that completely different types of switches are used for HBO 2 and HBO 4);

- Type of main fuel system. It is worth understanding that the LPG buttons for carburetors and injectors are made differently, because the electronic control of these mechanisms differs significantly. It’s also stupid to be surprised by anything here, since the injector nozzles and carburetor valves are completely different mechanisms.

HBO options: from mechanical to electronic

Propane and methane as motor fuels have their adherents as well as their opponents. Both give a lot of arguments confirming the correctness of their point of view. One thing is indisputable - gas kits allow you to spend your car budget more economically when installed on any power unit: gasoline and diesel, carburetor or injector, equipped with turbine or compressor supercharging. The modern gas equipment market offers an assortment of gas installation kits that is difficult to describe.

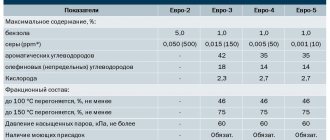

Gas motor fuel for refueling cars

Gas engine fuel began to be used to refuel cars at a time when the carburetor was the only unit supplying the fuel mixture to the engine, and such an innovation as an injector was just beginning to be mentioned as an innovative alternative to the traditional method of powering an internal combustion engine. Since then, several generations of gas equipment have changed, each of which represents a logical follow-up to the development of fuel supply systems in automobile power units.

- HBO of the 1st generation was used on cars whose engines had a carburetor as a power supply. This earliest version was not equipped with any instruments and systems of electrical, much less electronic control. All adjustments and settings were made mechanically: using screw jets. Currently, this early generation of HBO is not used.

1st generation HBO is suitable for everyone

- Installation complexes of equipment of the 2nd generation received an oxidizer in their composition. The inclusion of such a sensor in the equipment initiated communication during the operation of the power plant. The oxidation sensor is mounted on a carburetor or injector and is equipped with a fairly simple electronic control system. Gas engine fuel is supplied by a dispenser, the adjustment parameters and settings of which are set and carried out through communication with electronic devices designed to monitor the degree of enrichment of the fuel mixture. The equipment model with an oxidizer works more economically, which significantly reduces the cost of purchasing liquid and gas fuel.

How to install 2nd generation HBO

- The third generation of equipment occupies a transitional position between the second and fourth generations. It works on vehicles whose engines are powered by an injector, although some craftsmen have managed to equip a carburetor with this circuit. The scheme meets more stringent environmental requirements, but its construction is quite complex, and it does not work completely reliably.

- 4th generation gas complexes are the most common scheme of the gas equipment systems used. Installation kits require integration into power plants with separate injection. This model works with the same system that controls the injector. The supply of the fuel mixture to the internal combustion engine is carried out by gas injectors, which are regulated, configured and controlled by the computer. Switching to operate on gas engine fuel or on a gasoline-air mixture can occur not only with a manual button, but also in automatic mode - depending on the degree of temperature heating and the engine crankshaft speed.

4th generation gas complexes

- The fifth generation of gas cylinder kits works with power plants of cars with a direct fuel injection system. The main difference between the 5th and 4th generations is the physical state of gas engine fuel - gas is supplied by injectors in the liquid phase. The low distribution in Russia is explained by the low quality of gas motor fuel.

List of equipment for installing gas equipment with your own hands

1

.

HBO kit. The choice of kit directly depends on the make of the car. The main set consists of wires, a computer, harnesses, hoses, valves, injectors, gas temperature sensors, pressure sensors and a reducer. In some cases, the equipment may differ. 2

.

Gas cylinder. When installing gas equipment, most motorists try to achieve compactness. To do this, you should use cylinders in the form of a torus. One of the most popular on the modern market is the Atiker cylinder, measuring 630 by 255 mm, holding 54 liters of blue fuel. 3

.

Multivalve. The package of modern multivalves includes the device itself, a remote system for refilling cylinders and tubes. 4

.

Gas level sensor. A device that connects to the computer of a gas cylinder installation. The main task of the sensor is to display the remaining fuel in the cylinders. 5

.

Universal programmer. Used to debug and configure the computer. 6

.

Computer and disk with setup instructions. On the disk you will find firmware, instructions and diagrams. 7

.

Injectors, harnesses. 8

. Set of tools.

This is a minimum list of equipment that will be enough to install gas equipment with your own hands. Depending on the vehicle, the cost of equipment may vary. In most cases, the amount depends on the brand, type, manufacturer, configuration and model of the cylinder. Installation of 4th generation gas equipment will cost approximately 20 thousand rubles.

In some cases, the standard equipment of HBO is not enough and the motorist has to purchase:

✓ 2 copper hoses (6 and 8 mm in diameter, 1.5 and 8 m long; ✓ pressure sensor; ✓ connector for connecting the sensor to the LPG computer.

Functionality and emergency modification of the HBO button

There are many modifications of gas-gasoline switches for gas-cylinder automotive equipment. But regardless of the manufacturer and layout of the device, their essence is the same: when position 1 is on, the internal combustion engine runs on gas engine fuel, in the second position gasoline is used as fuel, and the third position involves automatic switching to use either gas or gasoline. It is clear that automatic switching occurs when the physical parameters of the power plant change: temperature, crankshaft speed, load. Automotive practice shows that the HBO switch is one of the most quickly failing components of the installation kit. Moreover, breakdowns, as usually happen, occur at the most inopportune moment.

Many motorists wonder: what does the button do? Upon reasonable reflection, the conclusion suggests itself - absolutely nothing special. By and large, the gas-gasoline switch from almost any installation package differs from a conventional three-position toggle switch only in the presence of automation, which allows you to read the peripheral speed of the crankshaft and the temperature indicators of the power plant. Some modifications suggest the possibility of fixing a critically small supply of gas engine fuel in a gas vessel. Although this function works on 2-3% of cars equipped with a gas installation. In purely practical terms, according to operators, such automation in most cases is completely unnecessary and is in no way worth the money for which it is sold. That is why it is quite possible to replace the standard HBO button with a regular switch with three fixed positions. The price will be an order of magnitude lower, and the functionality of the switch will be completely similar to the button from the branded package. The only thing that needs to be done in this case is to change the connection block.

DON'T WASTE MONEY ON REPAINTING! Now you can remove any scratch from the body of your car in just 5 seconds.

It is quite possible to replace the HBO button with a regular switch

In practice, things may happen somewhat differently. The HBO switch may fail in conditions where replacement is simply impossible, or the owner does not want to redo the block through which the connection is made, or he likes the appearance of the standard switch and does not want to disturb the usual design. In such cases, you can easily “restyle” the old button. In this case, nothing will be lost: the device works just as efficiently, and its reliability has only increased.

Maintenance of fourth generation gas equipment

1. Required to be performed weekly:

- external inspection of the system tightness, absence of gas leaks. A leak can be detected by the characteristic smell of an odorant and using a soap solution. Leakage can occur through cracks in the tubes, worn seals or loose tube clamps;

- removal of accumulated condensate in the gearbox through a special bottom plug. Untimely draining of condensate can lead to its coking and clogging of the drain hole, which subsequently, when condensate accumulates, leads to disruption of the normal operation of the evaporator reducer.

2. Required to be performed monthly: cleaning or replacing the filter. To do this, you need to disconnect the inlet tube from the filter and dismantle the filter. Clean or replace the filter element. There is a small magnet inside which should be replaced after cleaning the filter. 3. The gearbox should be disassembled and cleaned once every two years. In this case, care must be taken not to dent or tear the membrane. After cleaning and assembling the gearbox, be sure to check for leaks.

Increasing fuel prices are forcing most ordinary motorists and experienced motorists to think about finding an alternative that allows them to save on fuel in order to save money. One of the most profitable, economically feasible and simple options for saving money on fuel is the installation of a gas cylinder installation.

Today you will learn: how to install LPG on a car with your own hands, what parts and spare parts are needed, reviews from car owners after installing LPG.

Today, such a service is offered at almost every service station, however, having certain knowledge, minimal experience and direct hands will help you save money and install LPG yourself, without resorting to the help of specialists. Today, one of the most stable installations is 4th generation gas equipment. Most experts advise installing this particular installation.

Integration of 2nd generation of gas equipment on engines

The second generation was developed for installation on power plants, the power supply and dosing unit of which is a carburetor. Although this does not at all mean that it cannot be installed on an injector. Cases in which the 2nd generation complex becomes the best option for an engine with separate injection, of course, cannot be called a rule, but they do occur. In carburetor-type power plants, dosing and injection of gas occurs according to the same scheme as the gasoline-air mixture - through the carburetor. On power plants equipped with an injector, gasoline is supplied through a nozzle.

Second generation of equipment for gas engines

It is clear that it is impossible to supply gas engine fuel with the same nozzles. When power plants equipped with such a novelty as an injector appeared, gas equipment that operates on the principle of separate injection did not exist. The choice remained clear: supply gas engine fuel up to the throttle valve. However, such a change automatically turns the injection engine into an internal combustion engine, in which the carburetor is responsible for supplying fuel mixtures.

Intake manifolds in injection engines have an increased volume due to vessels for storing air reserves - receivers. During periods when the vehicle's power plant runs on gas engine fuel, the receivers are filled with an explosive mixture of air with propane or methane. This feature imposes certain conditions for the installation of the second generation injector. Thus, it is necessary to provide protection against ignition of the mixture in the intake manifold.

Intake manifolds in fuel-injected internal combustion engines

To do this, the gas engine fuel mixer must be preceded by a special valve designed to prevent the explosion of the air-gas mixture. This protects the air flow meter, filter housing and corrugated duct. For this purpose, mixers with a valve structurally built into them are usually used, although there are options with differentiated designs of components.

The supply of gasoline mixture to an internal combustion engine with an integrated injector unit is controlled by the computer. It is fair to assume that shutting off the liquid fuel supply when operating on gas engine power is possible using an electronic device. If the standard ECU is not equipped with a self-diagnosis function, then when the gasoline supply is turned off, a conventional EMR works well. However, connecting the diagnostic function can activate an emergency operating status, which sometimes leads to a complete blocking of the internal combustion engine. To level the situation, it is necessary to connect an electronic device that emulates an injector. The device creates the illusion for the ECU that the injector is operating in the normal normal mode for each situation.

Controlling the supply of gasoline mixture to the internal combustion engine

An electronic novelty for the 2nd generation when mounted on an injector, which is not installed on the carburetor, was a device that emulates the operation of a lambda probe. This is an information type sensor that shows the degree of enrichment of the mixture. When the internal combustion engine is supplied with gas, the device breaks the electrical circuit connecting the probe to the computer. The control electronics believes that the lambda probe is operating in nominal mode and does not provide the driver with emergency warnings. The signal coming from the emulator to the controller allows you to change the degree of enrichment of the gas mixture.

Features of the operation of 4th generation gas equipment

The equipment allows for combined power supply of the engine with gasoline and gas. Switching from one power mode to another can be done from the cabin manually, as well as automatically. The small control panel contains an LED gas level indicator and a fuel switch. The usual location of the control panel is under the steering column on the left near the headlight adjustment control.

The gas indicator contains four green LEDs and one red, located in one row. When one green LED lights up, it indicates the presence of 10 liters of gas. Usually this reserve is enough for 100-120 km. The red LED lights up to indicate the presence of emergency fuel remaining, which may be enough for 50-80 km. It warns you about the need to refill gas at a gas filling station.

A separate red LED, located in the upper corner of the remote control and operating in a flashing mode, signals that the engine is currently running on gasoline, but the system is preparing to switch to gas fuel. This happens every time the engine is started until it reaches normal temperature and warms up well.

Button for switching engine power mode and gas quantity indicators

Since the engine has both a gasoline and gas power supply system, such duplication doubles the reliability of its operation. In addition, the mileage on one refueling with gasoline and gas fuel increases significantly. This is beneficial on long trips through sparsely populated areas, where the network of gas stations is sparse and of poor quality. Also adding the ability to increase protection against car theft is an easily removed and installed switch, the removal of which blocks the supply of gasoline and gas to the injectors.

The 4th generation LPG is especially beneficial for car owners whose engines are equipped with an expensive fuel injection system for exhaust gas purification. It not only provides significant savings on expensive high-octane AI-98 fuel, but also saves resources. This equipment is intended for vehicles that meet environmental requirements Euro-3 and higher. It has a pulsed gas-air mixture injection system, which operates under the control of a separate control unit interfaced with a microprocessor. processes microprocessor commands and generates control signals that open electromagnetic gas injection injectors and block gasoline mixture supply injectors.

The concentration of the supplied fuel mixture is controlled by a system of sensors that determine:

- gas pressure;

- reducer temperature;

- gas temperature.

If the supply gas pressure drops below a threshold value, the electronic unit automatically turns off the gas injectors and opens the gasoline injectors, switching the engine to gasoline power.

Gas-gasoline switching device

The difference between a gas complex mounted on a carburetor and equipment intended for installation on an injector lies initially in the fact that in power plants with separate injection, the supply of the gasoline mixture is turned off almost instantly. The fuel type switch on direct injection engines is equipped with three fixed positions: 1st position – operation on a gasoline mixture; 2 position – operation on gas engine fuel; 0 position – operation in automatic fuel type switching mode. The mode in position 0 creates additional convenience when operating and driving the car. When this mode is activated, the electronics, based on sensor readings, decide when to change the type of fuel supplied to the engine.

Gas-gasoline switching device

Before parking the car for a long time, the carburetor must be filled with gasoline, so you should switch the engine to a gasoline-air mixture in advance. There is no need to do this for an injection power plant, so manual switching is not required; the automation independently makes the necessary switches.

Source

Gas equipment Lovato

Lovato's 4th generation HBO is represented by SMART ExR, C-OBD II and E-Go products:

- Lovato Smart ExR - inherited the main points of systems for cars with direct injection. But now installers have an effective tool for setting up gas equipment. A change in the light signal on the switch indicates that the car has switched to gas. That is, you don’t even need to press a button, human intervention is no longer required. On propane-butane and methane, the car drives just as easily and smoothly as on standard fuel. The ECU keeps under control the entire operation of the power plant and, if necessary, replaces the algorithm of the gas injector.

- SMART ExR is designed for 3-4 cylinder engines with sequential gasoline injection. There is a built-in auto-calibration tool at any engine speed to simplify system setup and ultimately reduce fuel consumption.

- EASY FAST C-obd II for 8-cylinder cars. It is considered the most functional and high-performance. The auto-correction option ensures accurate calculation of gas supply and optimization of internal combustion engine operation. Connects to standard vehicle diagnostics via OBD II protocol.

- E-go is a budget version of Lovato 4th generation for injection systems and engines up to 4 cylinders. Demonstrates innovative technical developments.

On a note! The Lovato 4th generation LPG kit, including electrical wiring, pipes, fittings and gas lines, meets all safety requirements and has the necessary certification. Easy to install, configure and easy to maintain. Adjusting the gas supply is simple and accessible to everyone.

Modern Lovato gas injectors are available in three types:

- Lovato KR (DP) - are the most reliable in their class, they are installed on cars that require special accuracy and speed.

- Lovato LP - nozzles for Smart systems, can be replaced with KP.

- Lovato EP (EP1) - nozzles designed for E-Go systems. They are proven, easy to install, and meet modern international standards.

Lovato gearboxes are in demand among car enthusiasts. Thus, the 4th generation Lovato gearbox is adapted for operation with any quality of fuel. The Lovato propane gas reducer rgv090 is considered one of the most reliable for carburetor cars.

On a note! In the case of gas-cylinder equipment, the principle that the most expensive is the best does not apply. Medium-priced Lovato LPG kits are much more effective in their capabilities than expensive analogues from other companies.

Connecting the 1st-2nd generation HBO button to the carburetor and injector

In the context of constantly rising prices for gasoline and diesel fuel, gas-cylinder equipment is becoming a real salvation for car owners who often use their cars.

HBO allows you to supply more affordable gas - methane and a propane-butane mixture - to the internal combustion engine instead of expensive traditional fuel.

The gas-cylinder equipment itself is quite reliable in operation and has a long service life, but it also has vulnerabilities that tend to break at the most inopportune moment.

One of these weak points is the HBO button - a device for switching the engine operating mode from gasoline to gas and/or vice versa.

As a result of intensive use, this important gas equipment control unit may begin to work incorrectly or even fail.

In this case, it is not necessary to contact a specialized technical center - you can replace the button yourself.

HBO Lovato (Lovato)

We all know that one of the first countries producing LPG is Italy. It was in this country that gas-cylinder equipment became widely known and began to spread throughout the world. HBO Lovato has been produced in Italy since 1958. During this time, the equipment of the Italian company has become widespread in more than 50 countries around the world. And every year the brand produces more than one million units of components for gas equipment. What is the reason for Lovato’s popularity all over the world, and in particular in our country? Let's figure it out.

How to connect a first-generation LPG button to a carburetor

The first generation of gas equipment is still widely used on cars with carburetor engines. The principle of its operation is based on mechanical regulation of the gas pressure coming from the reducer.

Such HBO systems are also suitable for injection (mono-injection) engines without a catalyst.

Switching from gas to gasoline and back is done by pressing the corresponding button switch, which is mounted in any convenient place inside the cabin.

to connect the first generation LPG button to a car with a carburetor engine if you follow the following order of connecting the wires:

- Red wire - goes through the fuse to the positive contact of the coil, where the ignition wire is also connected;

- Brown wire - 10 turns are wound onto the central armored wire from the coil;

- The yellow wire of the button goes to the positive contact of the gasoline valve;

- Black - to the “minus” of the gasoline valve;

- The red positive wire goes to the gas valve, the black wire goes to ground.

The diagram for connecting the LPG button to the carburetor is described more clearly in the video:

INSTRUCTIONS FOR REPAIR AND OPERATION OF SPECIAL TRUCKS.

Pages

Most Viewed

DS-11 instructions and connection diagram

Car engine operating modes

Gasoline mode. The engine starts on gasoline and runs on it, regardless of the presence or absence of gas fuel in the cylinder.

“Petrol – gas – petrol” mode. The engine starts on gasoline. After warming up, the engine switches to gas (carburetor - manually, injection - automatically) and runs on it until it stops completely.

The transition to gas fuel can be carried out both on the spot and while the vehicle is moving.

The next start of a car with an injection engine always occurs automatically on gasoline and does not require any additional actions from the driver. To start a car with a carburetor engine on gasoline, you must first move the operating mode switch from the “gas” position to the “petrol” position.

A gas-powered engine of any design can be manually switched to gasoline at the driver's request.

Gas mode. The engine starts, warms up and starts to move using gas.

For carburetor engines, this mode is used when the air temperature is at least 0°C or when the gasoline power system fails. On injection engines - only if the standard (gasoline) power system fails (forced manually switched on).

The driver selects any of these modes depending on the situation, desire, operating conditions of the vehicle, economic considerations, and in the event of a failure of the gasoline (standard) or gas (additional) power system.

For proper connection, a DS-11 connection diagram is posted on the website.