Signs of a bad input shaft bearing

You can determine the need to replace the bearing yourself based on special signs that appear during vehicle operation. A modern car has many bearings that periodically fail. Considering the fact that car mechanisms operate at high temperatures, high rotation speeds, under the influence of aggressive substances and large mechanical loads, bearings often fail. Timely, independent diagnostics of the operation of the input shaft bearings and, if necessary, their replacement can save car enthusiasts, prevent major repairs and ensure safe driving.

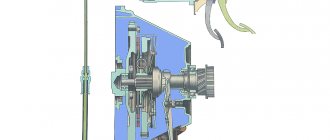

When diagnosing the performance of a bearing on the input shaft, its location should be taken into account. You can detect obvious symptoms of problems in its functioning even without dismantling and disassembling the gearbox. Considering the position of the bearing, which is located on the input shaft directly behind the oil seal, it becomes clear that this support unit bears one of the heaviest loads. Currently, roller bearings are most often used, the size of which depends on the make of the car.

The main sign of bearing failure may not be seen, but heard. When a bearing malfunctions, it makes a characteristic howling sound that can be heard at idle. When a knocking sound is heard while driving, this may indicate a bearing failure. In some cases, such a breakdown may make it impossible to engage the clutch. One of the reasons for this may be bearing jamming, which in the worst case scenario can lead to the need to repair the shaft.

Replacement of the input shaft bearing.

We dismantle the gearbox, having previously de-energized it and removed all attachments and disconnected the speedometer drive. We thoroughly clean the gearbox from accumulated dirt and oil stains. Using a screwdriver, we extract the retaining rings, which are the main fastening part of the bearings in most boxes. The next step is to press out the bearing, which is done either using special pullers or using a pry bar and a hammer (experience and an assistant are required). Then, after first checking the seat for defects or contamination, we press in a new bearing. Before installation, lubricate the shaft and bearing seat with a special lubricant.

Signs of a faulty input shaft bearing. learn this list

Car Citroen ZX 1.9i. If you press the clutch pedal in neutral, there is silence. I let go of the pedal and it starts to grunt and grunt. When driving you can't hear it over the noise of the engine. Is it the throwout bearing or the input shaft that's dying? How to determine. If, as they say, an autopsy will show, then what to look for during the autopsy.

esli vizatoe sceplenie i neslisno xrumkanie - slisno pri otpuscenoi pedalji - - eto u Vas pogib podsipnik pervicnogo vala. Pri vskritie smotretj podsipnik ilji vtulku ( nepomnju cto tam ) v maxovike i ljuft pervicnogo vala - xotja ego mozet i nebitj - potomu kak rassipalsja podsipnik i bivaet cto grimit i bez ljufta vala ( ilji ljuft nastoljko neznaciteljen cto rukoij nepocus tvovotj)

More like a throwout bearing. If you press the clutch pedal lightly, does the sound increase or decrease?

Looks like a main shaft bearing. The release bearing usually makes noise when you press the clutch pedal.

Of course, the most correct thing to do was to listen to these sounds (grunts and crunches) and then judge the reason. My statement is based on experience - in 9 out of 10 cases it is a squeeze.

Thank you all very much! I'll try to check when releasing the pedal. Let's say I remove the box (a LOT of work.), change the release lever ($14 - SKF). I'll put the box back in place. And it turns out to be the input shaft bearing!

As soon as you start it, you can’t hear it right away - you need to warm it up a little.

In any case, the box will have to be removed. Immediately check the release lever for rolling (it should turn easily, without any extraneous noise). Check the release bearing guide sleeve (the part along which it moves), sometimes the sound is caused by it. Rotate the input shaft and check its play (axial and radial). If possible, remove the input shaft and rotate the bearing.

Good luck.

The input shaft bearing makes more noise when the car is not warmed up. As it warms up the sound should become quieter. Just in case, check the oil level in the box.

Ops. It may not be a bearing. Try this, try to engage the gear (just try, without effort, just move the gearshift lever and press down a little) without squeezing the clutch. The sound is gone or not. Try reverse in all gears. And another question, when you turn off the engine, is there a knocking noise? Is it very audible, stronger than when it is set to XX?

The release lever will only make noise when the clutch is depressed. In general, it looks like your primary one is not in order.

Perhaps the Citroen ZX 1.9i is a unique car (I don’t know, I haven’t done it - XM doesn’t count), so I want to find out two questions for myself - 1. Colleague Frieman - tell me on which front-wheel drive car with a transverse engine a bearing (bushing) is installed in the flywheel primary shaft? 2.To Kluff - If we assume that on the specified car the release bearing is always in engagement with the basket, how will the sound change when the load on it increases (when you press the clutch pedal)? Best regards, Kenkel.

The release bearing is double-row, and when engaged it operates without load (rolling only) and is subject to minimal wear, but when pressed, the direction of forces changes and it is loaded in three directions, subject to maximum load and wear. That is. it has two states - idle and working. That's it, I'm done loading.

Perhaps double-row release bearings are installed on Citroens (it is not clear why) - the question is different. If we assume that this bearing did not jam and still retained its mobility, then the main reason for its failure should be fatigue spalling (pitting) of the treadmills. I would like to clarify - in this case, when will it make more noise under load or without it?

Signs of malfunction and diagnostics of the release bearing of the VAZ 2114 (how the bearing makes noise and hums)

Direct diagnosis consists of checking the functionality and presence of the following signs of failure. Signs of a malfunction of the VAZ 2114 clutch release bearing, if detected, will require its replacement:

- When you press the clutch pedal, you hear a noise, hum or knocking (rolling, internal vibrations occur due to damage to the tracks with rolling elements, deformation of the cage or the clutch itself).

- A whistle when the clutch is engaged makes it clear that the quantity or quality of lubricant is not enough;

- The speed does not change or the pedal moves hard (occurs when the clutch has fallen apart, as well as if the ear of the release bearing is broken).

- Watch a video example of how the release bearing of a VAZ 2114 makes noise and hums, as well as how the check is carried out. You can also hear the noise of the bearing after disassembling the transmission after removing the VP.

Main manual transmission malfunctions and their causes

The transmission is designed to change and transmit torque from the engine to the wheels, that is, it is one of the main systems of the car, determining its dynamic and speed characteristics. The key role in the transmission is played by the gearbox (gearbox, or simply gearbox, gearbox), when it fails the car loses its driving characteristics or cannot move at all.

As you know, today there are two main types of transmissions in the world - manual (mechanical) and automatic. These transmissions have different designs and operating principles, so they are characterized by different malfunctions. Here we will only talk about malfunctions of a manual transmission; read about problems with an automatic transmission in a separate article.

The following malfunctions are typical for a manual gearbox:

• Noise during operation and when changing gears; • Inability to engage any gear or all gears; • Difficulty shifting gears; • Spontaneous gear disengagement; • Oil leakage from the gearbox.

Self-diagnosis of a manual transmission

The problem with self-diagnosis of a manual transmission is that it is impossible to do without removing and disassembling it. The fact is that most mechanical malfunctions in one way or another occur due to wear of parts, and a worn gear or other part can be identified and replaced only after disassembling the entire box. And only problems with the gear shift drive can be solved without removing the gearbox - to do this, it is enough to conduct a visual inspection of the drive parts (levers, rods, cables, hinges, etc.), try their operation and, if necessary, replace them.

The procedure for removing a manual transmission is approximately the same for all cars:

• Jack up or suspend the car (its front part) and the gearbox - this will insure against falling and damage to the gearbox after it is disconnected from the engine; • Disconnect from the box all controls, wires and everything that interferes with its dismantling; • Drain the oil from the box; • On a rear-wheel drive car, disconnect the driveshaft; • On a front-wheel drive car - remove the wheels, disconnect the CV joints and some suspension parts; • Unscrew the bolts holding the gearbox to the engine; • Remove the fastenings of the hanging support pads; • Remove the gearbox; • Disassemble the gearbox and carry out diagnostics.

When disassembling the gearbox, the condition of gears, synchronizer couplings, splined shaft joints, bearings and other parts, the integrity of all seals, etc. are checked. If a faulty part is identified, it is replaced, after which the box is installed on the engine and filled with transmission oil.

Not every one of us can or has the desire to independently remove, disassemble and check the gearbox, so if you are unsure of your abilities, it is better to contact a service center. And, of course, owners of new cars whose warranty has not yet expired should definitely contact the service.

We independently change the release bearing on a VAZ 2114

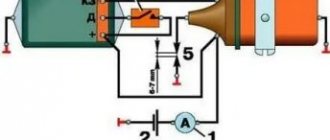

After removing the gearbox, it is important to inspect the discs, clutch basket, and also evaluate the condition of the gearbox housing from the inside. Remove dirt and excess used oil, make sure that the ear of the release bearing has not broken, then proceed to replacing the clutch. Below is a diagram of the clutch layout.

The principle of operation of the part is as follows: when you press the clutch pedal, the applied force is transmitted to the fork (4) through a cable (3), which moves the release lever along the guide sleeve of the input shaft (1), then the ball bearing housing transmits the force to the pressure plate (basket) (6), After this, the driven disk is disconnected, then the unit is disconnected from the engine to change speed.

Manual transmission malfunctions and their elimination

All gearbox malfunctions are characterized by certain external signs - it is from these manifestations that one can judge the nature of the breakdown. However, many malfunctions manifest themselves in the same way, so in the table presented here all manual transmission breakdowns are grouped according to their external signs.

This table does not indicate troubleshooting methods, since they, for the most part, require high qualifications and car repair skills. Only some operations can be carried out even by an unprepared car owner - this is replacing and filling oil, as well as replacing gear drive parts. If other manual transmission malfunctions are detected, it makes sense to contact a car service center.

Recommendations for manual transmission operation and maintenance

The durability and quality of the transmission largely depends on how the gearbox and clutch are operated. Extending the service life of the gearbox, and therefore increasing the comfort, controllability and safety of the car, is not difficult; all you need to do is follow a few simple recommendations.

The main thing in operating a manual transmission is smooth gear shifting with the clutch pedal fully depressed. Under no circumstances should gear shifting be allowed with the clutch not fully disengaged, as this leads to accelerated wear of the gears and increases the likelihood of their failure. It is also very important to move in the gear that best matches the current speed, and, if possible, switch to direct (usually fourth) gear - in this case, the torque transmission uses a minimum number of gears and two shafts (bypassing the intermediate one), therefore, wear of parts is reduced Checkpoint.

When switching to a lower gear, you should reduce the speed of the car, which is also necessary to reduce the load on the parts of the gearbox and the engine itself. Under no circumstances should you engage reverse gear even when the car is moving forward at a low speed - this will certainly lead to damage to the gearbox. And finally, if the first gear does not engage immediately, then you need to first depress the clutch (you can do it twice), and only then engage first gear again. Next, gear shifting must be done smoothly and with a mandatory pause between shifts.

A manual transmission also has operating features that many people are not even aware of. For example, in the winter season, especially at significant subzero temperatures, it is not recommended to park the car with the gear engaged - in this case, there is a high risk of the synchronizer ring freezing, and the next time you start the engine, even after the gear is turned off, the car may start moving. This is also fraught with some malfunctions.

Maintenance is also of great importance for the reliable operation of the gearbox. Firstly, periodically after long and active trips you need to inspect the gearbox for oil leaks. Typically, drips can appear in the area of the filler and drain plugs, along the perimeter of the junction of the box to the engine, between the crankcase and the gearbox cover, and also (in the case of a two-wheel drive vehicle) on the flange of the driveshaft coming out of the box.

Removing the VAZ 2107 gearbox

To remove the gearbox you will need a pit or a lift. The procedure is as follows:

- Disconnect (better remove) the battery.

- Engage neutral gear, disengage the handbrake, raise and hang the rear axle.

- Unscrew the bolts securing the cardan and the gearbox flange, and disconnect the cardan.

- Remove the exhaust manifold pipe by unscrewing the bolts.

- Disconnect the oxygen sensor.

- Remove the starter.

- Inside the car, remove the console and gearshift knob.

- Remove the gearbox protection.

- Unscrew the clamp connecting the catalyst to the exhaust pipe.

- Remove the clutch slave cylinder.

- Unscrew the speedometer cable, remove the boot and the reverse speed sensor wire.

- Remove the driveshaft.

- Unscrew the traverse while holding the gearbox.

- Unscrew and pull out the gearbox.

Input Shaft Bearing: Troubleshooting

The input shaft bearing is a part that is part of the vehicle’s gearbox (gearbox). The following symptoms will tell the motorist about its malfunction:

- while driving when the clutch is released, a foreign noise occurs;

- when the vehicle moves through the gearbox, knocking noises unusual for normal operation occur;

- spontaneous shutdown of gears is observed;

- Difficulty disengaging the clutch.

If such malfunctions are detected, you should begin repairing this unit as soon as possible. By postponing restoration work until later, the driver risks seriously damaging the gearbox, since a worn, skewed input shaft bearing destroys the clutch disc while driving. This leads to the car losing control and resulting in accidents. Replacing a unit when the first signs of a malfunction appear does not require significant costs, while eliminating the consequences of a breakdown is much more expensive.

Useful tips

If there is no oil on the bearing, but there is no damage to its surface, then you don’t have to replace it, but simply lubricate it and install it back. This is done if for some reason the required spare part is not on hand. Lubricate the gearbox input shaft bearing (including VAZ) in two ways. The first option involves boiling the part in lithol. It is best to carry out this operation in a water bath. But there is a safer option - lubrication using the injection method. To do this, lithol is drawn into a syringe and lubricant is filled into the bearing. But you need to take into account that such a process requires more time.

Simple repair of the input shaft support

You can purchase the parts required for this repair at the representative office. Here you will find bearings for all brands of cars. The products presented are original products produced by domestic and foreign manufacturers.

If this unit fails on your car, consider purchasing the materials that will be needed for this type of restoration work, namely:

Even though new bearings are supplied with factory grease, they must be further treated. This needs to be done for several reasons:

1. Over time, any lubricant loses some of its performance qualities;

2. The latest generation of sealants can significantly improve the performance of the unit, increase its working life, and protect the part from the influence of aggressive factors.

This type of bearing is not insulated with an oil seal. But, to remove it, the technician needs to partially dismantle the parts that make up the gearbox. The optimal solution would be to replace all rubber elements removed during repairs. This will allow you to postpone the period of preventive maintenance to prevent oil leaks from the gearbox.

Causes of breakdowns

Many different factors can influence an element to wear out and break down. Often the culprit is poor quality parts. When purchasing a product, you should not give preference to the cheapest options, but rather purchase a quality product. It is necessary to carefully inspect the unit and make sure that it is reliable and made of strong materials. Also one of the possible reasons is the way you drive the car. If the driver uses an overly aggressive style, literally pulling out the shift lever, then this does not add service life to the bearing, but seriously reduces its service life.

The conditions in which the car is operated are also important. If the car is constantly stored in a garage, if there are no overloads, then all this will have the best effect on the resource of each unit. And finally, the most popular reason why the VAZ input shaft bearing fails is ignoring the maintenance of the vehicle’s mechanisms and components. Owners of inexpensive cars who use them for work, as well as novice drivers who are just learning, can ignore maintenance.

Shaft bearing: features of part selection

The type and brand of bearing you will need for repairs can be found by consulting your vehicle manufacturer's information. In the future, you should inform the seller of its catalog number. The consultant will select the required part for you. When reinstalling, it is not necessary to use the brand recommended by the factory.

A wide range of products allows you to choose an analogue that is not inferior or superior in its performance qualities

. If you do not know the information about the catalog number of the unit installed on your car, you can search by make and year of manufacture of the car.

When purchasing, pay special attention to the date of manufacture of the sample. The shelf life of products should not exceed three years. In this case, the lubricant located inside the product retains its performance qualities. If this time is exceeded, the sealant thickens and does not work as effectively. It is permissible to use parts in a car after re-preservation - the date of the operation should be marked accordingly on the box. But at the same time, the product should not have signs of warping and rusting on its metal surfaces. It is undesirable to buy goods whose packaging has lost its integrity.

Briefly about gearboxes

First, let's look at what gearboxes are. In short, this is a unit that is built directly in the path of the main power flow from the car engine to the wheels. The job of the gearbox is to change the torque, i.e. traction on wheels. A change in thrust not only entails a change in speed, but also allows for more efficient use of engine energy. For example, in certain conditions it is better to drive in low gears. The gearboxes are as follows:

- Mechanical . Essentially, it is a set of gears arranged correctly. The system is also equipped with a clutch. This gearbox requires manual control, as a result of which it is considered the least convenient;

- Automatic . This is classic “mechanics”, supplemented by hydromechanical devices. Automatic boxes are easy to use, but they are heavy and expensive to manufacture;

- Robotic . May have several versions. The cheapest and simplest option: a manual transmission with attached electric drives that squeeze the clutch and also manipulate the control lever. More complex “robots” are 2 mechanical boxes and the same electric drives with a special electronic unit.

Separately, it is worth highlighting the variators, i.e. special continuously variable automatic transmission. Unlike classic gearboxes, CVTs use a pair of sliding pulleys with a metal belt. This is extremely convenient to use and allows you to reduce fuel consumption . The weak point of CVTs is metal belts, which quickly fail. Due to the low prevalence of such a transmission, I will not dwell on it in detail.

Signs of a faulty gearbox - manual transmission failure

Basic malfunctions of manual transmissions. Frequent manual transmission breakdowns. How to promptly identify a fault in the gearbox and prevent complete breakdown of the manual transmission. Regular transmission oil changes and manual transmission diagnostics will extend the life of your gearbox.

Possible reason: wear of the support bearings of the secondary shaft of the manual transmission.

Worn support bearings of the gearbox input shaft.

Wear of the lead-in splines of the gear and fifth synchronizer clutch or shift fork.

A possible cause of a manual transmission breakdown is a faulty differential or breakdown of the satellites.

Possible cause: the drive seal is damaged or the differential housing of the drive inlets is worn.

Possible cause: breakdown of the manual transmission gear or gear fork.

Possible reason: the manual transmission synchronization unit is faulty, the synchronizer blocking rings are worn out.

Possible cause: the oil seal is damaged or the gearbox input shaft bearing is worn.

Possible cause: clutch wear.

Possible cause: malfunction of the speed selection mechanism or the rocker.

Possible cause: worn differential bearings or differential housing.

Possible reason: breakdown of the reverse gear of the manual transmission.

Possible cause: wear of the synchronizer clutch.

Possible cause: clutch disc wear.

Possible cause: wear - broken gear fork

Types of gearbox bearings

Depending on the car manufacturer, the gearbox may use one or more types of bearings. Each type of bearing has its own advantages and disadvantages. For example, one type is characterized by high resistance to mechanical loads, but is characterized by large dimensions. Speaking about bearings, one cannot fail to mention two types of loads that they perceive: axial/thrust (along the axis of rotation) and radial (perpendicular to the axis of rotation). Both types of loads can be supported by a bearing at the same time, but in most cases one load is greater than the other. Gearbox bearings are divided into the following:

- Ball single row radial . These are the most versatile bearings. They are used in most passenger cars, although in some cases they serve as one of the supports in truck gearboxes;

- Ball single-row angular contact . Despite the obvious name, they can take both axial/thrust loads and radial loads. Structurally, they are an additional version of conventional radial bearings - their rings have special stops that prevent destruction of the bearing under heavy loads in different directions;

- Double-row angular contact balls . Due to their high resistance to loads, they act as a rear support for the gearbox input shaft. In rare cases, they also serve as support for the intermediate shaft. More expensive to produce than simpler single-row bearings;

- Roller needles . Can be single or double row. Extremely resistant to radial loads, because the bodies of rotation in them are needles of small diameter. Found application in secondary, less often in intermediate shafts;

- Roller single row radial . The bodies of rotation in such bearings are rollers. They have very high resistance to mechanical loads and are usually used in automotive technology;

- Single- and double-row conical rollers . They are used very widely. Good as supports for both primary and secondary shafts.

Car manufacturers carefully select bearings for the gearbox of each vehicle model. It all starts with dynamic calculations and ends with tests on special stands. Ultimately, the bearing is selected that ensures that the gears and shafts operate in the most efficient manner.