- We guarantee fast processing of your order during business hours (we work from 11-00 to 20-00, Saturday and Sunday are days off).

- We guarantee reliable packaging of your order (when sending it by Russian Post or transport company).

- We guarantee the fastest possible dispatch of your paid order (within 2-4 business days after receipt of payment).

- We guarantee a refund or exchange for another product (with recalculation) within 14 days from the date of receipt of the order (the product must be in good condition, without traces of installation, delivery costs are not reimbursed).

- We guarantee a free exchange of goods (transportation costs at our expense) if the purchased goods turn out to be defective.

Payment Methods

Delivery options

Pickup options

Product added to bookmarks!

- Description

- Reviews

APPLICABILITY: VAZ 2104, 2105, 2107 with a carburetor engine and an aluminum radiator.

Red reinforced silicone radiator hoses.

Three-layer hoses, wall thickness 4.5 mm.

Advantages:

– the silicone used in production makes the product resistant to wear and prevents the appearance of microcracks;

– thanks to 3-layer reinforcement, they can withstand operating pressures of up to 0.2 MPa;

– tensile strength and other impacts are 5 times higher compared to rubber pipes;

– silicone pipes remain elastic at low temperatures (up to -40°C) and can be used at high temperatures (up to +180°C);

– silicone pipes fit perfectly into the cooling system seats, requiring no modification.

Includes: 1 radiator inlet hose (upper), 1 radiator outlet hose (lower), 1 thermostat hose, 1 connecting hose.

The condition of the radiator determines the proper operation of the car. Failure of this spare part can cause engine failure. Therefore, it is important not to hesitate in purchasing a radiator device. To purchase such a part for a VAZ 2107 in Russia will cost 500-4000 rubles .

Design of cooling system radiators from LUZAR

LUZAR cooling radiators can be divided into three types:

- Tubular-plate, prefabricated, aluminum. It consists of aluminum plates through which aluminum tubes pass, inside which coolant runs. The tanks on such radiators are made of plastic. Cooling radiators of this type are used for small cubic capacity engines due to limited heat transfer; have the best rigidity and light weight, as well as the lowest cost.

- Tubular-tape, non-assembled (brazed), aluminum. The corrugated aluminum tape in such a radiator is located between aluminum flat-oval tubes. Radiator tanks of this type can be made of either plastic (most common) or metal (most often used for cargo cooling radiators). The design of non-assembled (brazed) aluminum cooling radiators is the most universal, allowing the creation of heat exchangers with any given characteristics. They have low weight and relatively high rigidity, as well as an optimal price.

Tubular-tape, non-assembled (soldered), copper-brass. The design is very close to type 2 - between the copper flat-oval tubes there are copper strips folded in the form of an “accordion”. At the same time, the tanks on such cooling radiators are made of brass - in order to increase the overall rigidity of the structure. Copper cooling radiators - due to the high specific heat capacity of copper - have excellent heat transfer performance. However, due to the high softness of copper, cooling radiators made of this metal are forced to have a narrow tube and a large interval (step) between the tubes, which imposes serious limitations on maximum efficiency. Also, copper cooling radiators have the highest prices and the lowest rigidity to torsion, fracture and internal pressure. In this regard, copper cooling radiators are “outdated” and are gradually falling out of use.

What is this?

A radiator is usually understood as a device that removes heat from the fluid circulating in the engine cylinders, thereby preventing overheating. The part is located in the front part of the hood space.

The autoradiator is represented by the following components:

- Top tank.

- Core.

- Bottom tank.

- Pipes.

- Coolant drain valve.

If the radiator fails, the power unit begins to overheat and individual parts expand. This leads to jamming of the pistons in the engine cylinders. Because of this, the motor becomes unusable.

Service station technicians say that you need to change the radiator on a VAZ 2107 when the following changes occur in the car’s operation:

- The motor is overheating.

- The engine will not start.

- The car stalls while driving.

- Increased consumption of antifreeze.

Failure of the car radiator can be caused by:

- Depressurization of tubes and tanks.

- Contamination of pipes.

- Natural wear and tear of device parts.

Factors affecting cost

The cost of an auto radiator for a VAZ 2107 is quite high. Therefore, for those motorists who want to save a little on their purchase, experts recommend searching thoroughly for the right spare part.

You should go through quite a few places of implementation in order to choose the appropriate option. When considering products at different points of purchase, you need to compare their cost and quality. The price of a radiator for a VAZ 2107 car depends on the following factors:

- Variety.

- Material of manufacture.

- State.

- Originality.

- Place of purchase.

- The need to order delivery of goods and the cost of such a service.

- Reputation of the selling company.

Approximate prices

Buying a new car radiator for a VAZ 2107 will cost from 1,400 to 4,000 rubles .

Approximate prices for radiators of different types:

- Aluminum - from 1400 to 2000 rubles .

- Copper - from 3500 to 4000 rubles .

Approximate prices for products from different companies:

- AvtoVAZ - from 1700 rubles .

- AT – about 1600 rubles .

- Kraft - about 1400 rubles .

- Hofer – from 1400 rubles .

- Bautler - about 1800 rubles .

- WEBER – from 1400 rubles .

- LUZAR – from 1500 rubles .

An old spare part can be purchased for 500-2000 rubles .

Where is the best place to buy?

Car mechanics are advised to install an original new radiator on the VAZ 2107. This spare part can be purchased at a specialized store or online store. The last place to buy may seem cheaper. But we must take into account that you will have to spend additional money on delivery of the product.

Old parts should be taken if there is a shortage of financial resources. They are sold at the car market, according to advertisements from private individuals, at car dismantling points. When choosing such spare parts, you should be careful and attentive: unscrupulous sellers may sell faulty car radiators.

The VAZ 2107 uses a water-type cooling system, consisting of many different elements. The main components of the system are the VAZ 2107 cooling radiator (which is also called a heat exchanger), as well as a pump and pump. A malfunction of the radiator leads to the engine starting to overheat, and at one point the temperature may exceed the norm, which will lead to big troubles.

Dismantling the cooling radiator VAZ 2107

The cooling radiator of the VAZ 2107 (injector) is similar to the radiator of the carburetor model. Therefore, their installation and installation are no different.

After draining the coolant, disconnect the expansion tank hose from the radiator, having first loosened the fastening clamp.

The further procedure is as follows:

- Loosen the clamp and remove the lower and upper inlet pipes.

- Disconnect the electric fan sensor connector.

- Disconnect the electric fan connector.

- Unscrew the three bolts securing the electric fan to the radiator (an 8 mm wrench is required).

- Remove the electric fan.

- Using a 10 mm wrench, unscrew a pair of radiator mounting bolts.

- Remove the cooling radiator (the radiator should be removed carefully, being careful not to damage it).

- Check the condition of the radiator rubber cushions. Replace them if necessary.

After dismantling, the radiator should be checked. The presence of deposits clogging the tubes is difficult to determine. If the reason for removing the radiator was to search for the causes of a coolant leak, you can carry out a simple check.

Checking the radiator tightness

You can check the radiator (brass or aluminum) in a bath of water. To do this, you need to plug the holes, immerse the radiator in water and supply air into it at a pressure of 0.1 MPa. If air bubbles appear, the radiator needs to be soldered and replaced. Aluminum radiators, which are equipped with most new VAZ classic models, should be checked at an air pressure of 0.2 MPa.

Minor damage to the brass radiator can be soldered. If the damage is extensive, or if the radiator is made of aluminum, it needs to be replaced.

Diagnosis of radiator faults

Antifreeze or antifreeze is used as the liquid that circulates through the system. The liquid removes heat from the engine, thereby heating it, and the radiator serves to ensure that the heated antifreeze or antifreeze is promptly cooled by the outside air and again flows to the internal combustion engine block. The radiator design includes a base and plates made of copper or aluminum. More common are aluminum heat exchanger models, which have advantages such as low cost and high cooling performance.

On VAZ 2107 cars, the injector and carburetor, the cooling radiator differs in the location of the upper pipe. On a carburetor car it is located on the side of the filler neck, and on an injection car it is located on the opposite side.

Like all car parts, the cooling radiator of the VAZ 2107 also becomes unusable. To identify a heat exchanger malfunction, there are appropriate methods:

- The engine does not cool well. The reasons for poor engine cooling are various factors, and heat exchanger failure is extremely rare. Initially, you need to make sure that the pump, thermostat are working properly and that there is no air lock in the system, and only then start checking the radiator. The reason for the failure of this device is the deposition of scale and other contaminants on the walls, which cause fluid obstruction. Not only does the throughput decrease, but the efficiency of heat transfer also decreases, so the car owner can detect engine overheating above an operating temperature of 90 degrees.

- Presence of signs of leakage - aluminum or copper radiator plates are very fragile, so the ingress of stones or branches can damage the integrity of the device. Depending on the size of the damage, fluid leakage will occur, a decrease in the amount of which will lead to an increase in engine temperatures.

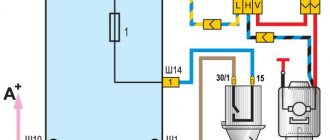

Functions and principle of operation of the VAZ-2107 cooling system

The engine cooling system of the VAZ-2107 belongs to the category of liquid, sealed, using forced circulation of coolant. To compensate for temperature fluctuations in the volume of antifreeze, an expansion tank is used in the system. The liquid heated in the engine is used in the interior heater, which is connected to the system by inlet and outlet hoses.

The cooling system includes the following elements.

- The tube through which coolant is discharged from the heater radiator.

- Hose supplying fluid to the interior heater.

- Thermostat bypass hose.

- Cooling jacket pipe.

- The hose through which fluid is supplied to the radiator.

- Expansion tank.

- Cooling jacket for the cylinder block and cylinder head.

- Radiator cap (plug).

- Radiator.

- Fan shroud.

- Radiator fan.

- Rubber lining for the radiator.

- Pump drive pulley.

- The hose through which fluid is removed from the radiator.

- Generator and pump drive belt.

- Pump (water pump).

- The hose through which coolant is supplied to the pump.

- Thermostat.

The cooling system of the VAZ-2107 belongs to the class of sealed ones with forced injection of coolant

The main function of the cooling system is to maintain the engine temperature within normal limits, i.e. in the range of 80–90 °C. The operating principle is based on the removal of excess heat into the atmosphere through an intermediate technological link - coolant. In other words, antifreeze or other liquid, heated to a high temperature in the cooling jacket, is sent to the radiator, where it is cooled under the influence of air flows and again supplied to the engine. Circulation is carried out using a pump driven by a belt from the crankshaft - the faster the crankshaft rotates, the faster the coolant circulates in the system.

More about the design of the VAZ 2107 engine: https://bumper.guru/klassicheskie-modeli-vaz/dvigatel/remont-dvigatelya-vaz-2107.html

Cooling system radiator

The cooling radiator of the VAZ-2107, which is a key element of the car’s cooling system, is usually made of copper or aluminum. The radiator design includes:

- upper and lower tanks;

- cover (or stopper);

- inlet and outlet pipes;

- safety pipe;

- tube-plate core;

- rubber cushions;

- fastening elements.

In addition, the radiator housing has a hole for the fan sensor, which is usually located on the lower tank, next to the drain hole.

The VAZ-2107 cooling radiator is made of copper or aluminum

The radiator dimensions are:

- length - 0.55 m;

- width - 0.445 m;

- height - 0.115 m.

Product weight - 6.85 kg. To ensure higher thermal conductivity, radiator tanks can be made of brass. The core is assembled from thin transverse plates, through which vertical tubes soldered to them pass: this design allows the liquid to be cooled more intensively. To connect to the cooling jacket, there are nozzles on the upper and lower tanks on which hoses are attached with clamps.

Find out more about diagnostics of the cooling system: https://bumper.guru/klassicheskie-modeli-vaz/sistema-ohdazhdeniya/sistema-ohlazhdeniya-vaz-2107.html

Initially, the manufacturer for the VAZ-2107 provided a copper single-row radiator, which many car owners replace with a double-row one (with 36 tubes) to increase the efficiency of the cooling system. In order to save money, you can install an aluminum radiator, which, however, is less durable and difficult to repair. If necessary, the “original” radiator on the “seven” can be replaced with a similar element from any “classic” by performing a certain reconstruction of the fastening elements.

I had several classic VAZs, and different radiators in the stoves and in the cooling system. Based on operating experience, I can say one thing: the heat transfer is almost the same. Due to metal tanks and an additional row of cassettes, brass is almost as good as an aluminum radiator in terms of heat transfer. But aluminum weighs less, is practically not subject to thermal expansion, and its heat transfer is better; when you open the heater tap, brass produces heat in almost a minute, and aluminum in a couple of seconds. The only negative is the strength, but in our country everyone is trying not to attract masters, but to do something themselves with crooked hands using a crowbar and a sledgehammer. And aluminum is a delicate metal, you need to be gentle with it, and then everything will be fine. And many say that the pressure in the cooling system vomits them. So if you monitor the valves of the expansion caps and the cooling radiator, then there will be no excess pressure.

Madzh

https://otzovik.com/review_2636026.html