Issues discussed in the material:

- What is a CVT on a car?

- How does a CVT work on a car?

- What are the types of CVTs on a car?

- What principles to follow when driving a car with a CVT

- How to check the variator when buying a car on the secondary market

Today, the CVT has numerous advantages, thanks to which it has earned the love of car owners. However, it also has shortcomings that cause disappointment. And although this type of transmission saw the light quite a long time ago, the system still remains not fully developed even by the leaders of the automotive market. From this article you will learn what a CVT is on a car, how it works, and we will also tell you how to properly drive a car with this type of gearbox.

CVT – continuously variable transmission

Among the types of transmissions, a continuously variable variator, which is responsible for transmitting torque, stands out. First, a little historical background.

CVT history

When it comes to the background of the CVT device, the personality of Leonardo da Vinci (1452–1519) is mentioned. In the works of the Italian artist and scientist one can find the first descriptions of a continuously variable transmission, which has seriously changed by the 21st century. The millers of the Middle Ages also knew the principle underlying the device. Using belt drives and cones, flour millers manually operated the millstones and changed the speed of their rotation.

Almost 400 years passed before the first patent for the invention appeared. We are talking about a toroidal variator patented in 1886 in Europe. The successful use of CVT transmissions on racing motorcycles led to the fact that at the beginning of the 20th century, as part of competitions, a ban was introduced on the participation of equipment equipped with CVTs. In order to maintain healthy competition, such bans made themselves felt throughout the last century.

The first use of an automobile variator dates back to 1928. Then, through the efforts of the developers of the British company Clyno Engineering, a car with a CVT transmission was produced. Due to the underdevelopment of technology, the machine was not reliable or highly efficient.

A new round of history took place in Holland. DAF owner Van Doorn developed and implemented the Variomatic design. The plant's products are the first option for mass use.

Today, world-famous companies from Japan, the USA, and Germany actively practice installing continuously variable transmissions on cars. To meet the conditions of the time, the device is constantly being improved.

What is CVT

The abbreviation CVT stands for Continuous Variable Transmission. Translated from English it means “continuously changing transmission”. In fact, continuity is manifested by the fact that the change in gear ratio is not felt by the driver in any way (there are no characteristic shocks). The transmission of torque from the motor to the drive wheels is realized without the use of a limited number of steps, which is why the transmission is called continuously variable. If the designation CVT is found in the marking of a car’s configuration, then we are talking about the fact that a variator is used.

Types of variators

The structural element responsible for transmitting torque from the drive shaft to the driven shaft can be a V-belt, chain or roller. If the specified design feature is chosen as the basis for classification, the following CVT options will be obtained:

- V-belt;

- wedge-chain;

- toroidal.

These types of transmissions are used primarily in the automotive industry, although there are many more options for devices responsible for smoothly changing the gear ratio.

Why is continuously variable transmission needed?

Thanks to the continuously variable transmission, the internal combustion engine will transmit torque without delay at any time during its operation. Such delays occur when the gear ratio changes. For example, when the driver moves the manual transmission lever to another position or the automatic transmission does its job. Due to continuous transmission, the car smoothly picks up speed, engine efficiency increases, and certain fuel savings are achieved.

New CVTs

Every year, more and more car companies are installing CVT on their models. At the same time, constantly improving their characteristics and introducing new technologies into units. One of the latest inventions is the common brainchild of Nissan and JATCO - a lightweight and smaller variator. It is made in the form of a V-belt type device combined with a new gearbox. This type is distinguished by its serious characteristics:

JATCO CVT

Now representatives confirm that they are developing developments to improve the variator. They improve ride comfort, acceleration and braking characteristics. Increase efficiency and reduce fuel consumption. They want to make a version of a continuously variable transmission in which the variator will become similar to an 8-speed automatic transmission.

The desire to improve the variator and the ongoing new developments of its types once again prove that it is the future. Perhaps soon it will completely replace the usual mechanized, robotic and automated gearboxes. Particular emphasis is placed on its hybrid types, in which the engine will operate in optimal mode, and the resulting energy will be stored in a storage device and then spent on driving the car.

Source

Design and principle of operation of the variator

Questions about what the structure of the variator is and what the principle of its operation is will be discussed in more detail. But first it is necessary to indicate what the main elements of the design are.

Main components

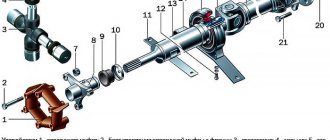

The CVT transmission includes drive and driven pulleys, a belt connecting them (chain or roller), and a control system. The pulleys are located on shafts and look like two halves of a conical shape, with the tops of the cones facing each other. The peculiarity of cones is that they can converge and diverge within a given range. More precisely, one cone moves, while the other remains motionless. The movement of the pulleys on the shafts is controlled by a control system that receives data from the vehicle's on-board computer.

Also the main components of a CVT are:

- torque converter (responsible for transmitting torque from the engine to the transmission input shaft);

- hydraulic unit (supplies oil to the rotating pulleys);

- filters for protection against metal production and deposits;

- radiators (remove heat from the box);

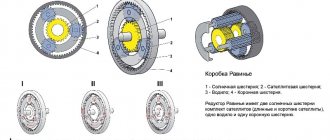

- planetary mechanism that ensures reverse movement of the car.

V-belt variator

The V-belt variator consists of two sliding and sliding pulleys connected by a metal belt. Due to a decrease in the diameter of the drive pulley, a simultaneous increase in the diameter of the driven pulley occurs, which indicates a reduction gear. Increasing the diameter of the drive pulley produces an overdrive.

Changing the pressure of the working fluid affects the movement of the drive pulley cone. The driven pulley changes diameter due to the tension of the belt and the return spring. Even a slight change in pressure in the transmission affects the gear ratio.

Belt device

A belt-shaped CVT belt is made up of metal cables or strips. Their number can reach up to 12 pieces. The strips are located one above the other and are fastened together using steel brackets. The complex shape of the brackets allows not only to fasten the strips, but also to ensure the contact with the pulleys necessary for the operation of the transmission.

Protection against rapid wear is provided by the coating. It also prevents the belt from slipping over the pulleys during operation. In modern cars, it is unprofitable to use leather or silicone belts due to the short service life of the part.

V-chain variator

A V-chain variator is similar to a V-belt, only the chain plays the role of a transmitter between the drive and driven shafts. The end of the chain, which touches the conical surface of the pulleys, is responsible for transmitting torque.

Due to greater flexibility, the V-chain version of the CVT has high efficiency.

Its operating principle is exactly the same as that of a belt drive transmission.

Circuit device

The chain consists of metal plates, each of which has connecting ears. Due to the movable connection between the plates in the chain design, they provide flexibility and maintain torque at a given level. Due to the staggered links, the chain has high strength.

The breaking force of a chain is higher than that of a belt. Plates with ears are made of alloys that resist rapid wear. They are closed using inserts, the shape of which is semi-cylindrical. The design feature of the chains is that they can stretch. This fact affects the operation of the continuously variable transmission, and therefore requires close attention during scheduled maintenance.

Toroidal variator

The toroidal type of CVT gearbox is less common. A notable feature of the device is that instead of a belt or chain, rotating rollers are used here (around its axis, in pendulum movements from the driving pulley to the driven one).

The principle of operation is the simultaneous movement of rollers along the surface of the pulley halves. The surface of the halves is shaped like a toroid, hence the name of the transmission. If contact with the driving disk is realized on the line of the largest radius, then the point of contact with the driven disk will lie on the line of the smallest radius. This position corresponds to the torque overdrive mode. When the rollers move towards the driven shaft, the gear decreases.

Design features

CVTs, conditionally, can be divided into two groups: with a steel belt and a chain. Continuously variable transmissions also have a torque converter. It is needed, first of all, for starting from a standing start. Remarkably, Multitronic does without it. These boxes use a clutch pack and a dual-mass flywheel.

The CVT transmission has a number of serious limitations that engineers have not yet been able to overcome. For example, for design reasons, neither a chain, nor, especially, a steel belt is able to transmit high torque. Because of this, the scope of application of CVT is currently limited to the maximum engine torque of 350-400 Nm. However, this threshold exceeds the performance of many modern engines. However, Audi is already beginning to abandon the use of continuously variable Multitronic gearboxes.

At the same time, other manufacturers are working hard to improve the design of the variator. This is how Subaru demonstrates all new models equipped with turbocharged gasoline engines, all-wheel drive and a continuously variable CVT gearbox (for example, Lineartronic for Levorg).

Pros and cons of a CVT gearbox

Like a manual or automatic transmission, a continuously variable transmission has its advantages and disadvantages. The advantages are:

- comfortable movement in a car (position “D” on the selector is set before starting to move, the engine accelerates and slows down the car without the shocks typical of manuals and automatics);

- uniform load on the engine, which is combined with precise operation of the transmission and helps save fuel;

- reduced emissions of harmful substances into the atmosphere;

- dynamic acceleration of the car;

- no wheel slip, which increases safety (especially when it comes to driving in icy conditions).

Of the disadvantages of a continuously variable transmission, noteworthy:

- design limitation on the combination of a CVT with a powerful internal combustion engine (so far we can only talk about a few examples of cars with such a tandem);

- limited resource even with regular maintenance;

- expensive repairs (purchase);

- high risks when buying a used car with CVT (from the “pig in a poke” series, since it is not known for certain how the previous owner operated the car being sold);

- a small number of service centers where technicians would undertake to repair the device (only a few know everything about CVTs);

- restrictions on towing and trailer use;

- dependence on monitoring sensors (the on-board computer, in the event of a malfunction, will provide incorrect data for operation);

- expensive gear oil and the requirement for constant monitoring of its level.

Variator: description, photo, principle of operation, device, types

The idea of changing gears without driver intervention has been around for a long time. It has existed since the first cars appeared on the assembly line. People modernized manual transmissions, created semi-automatic transmissions, automatic transmissions, but did not achieve the desired smoothness and complete feeling of calm shifting, because any transmission implied pushing and engaging, which was not always comfortable. And this increased fuel consumption, because the engine needs to be spun well enough to get the required acceleration, without damaging the unit. One of the ideas for the development of an automatic transmission was a continuously variable gearbox

CVT resource

The nuances of operation (road conditions, driving style) and the frequency of maintenance of a CVT transmission affect the service life of the device.

If the manufacturer's instructions are not followed or regular maintenance regulations are violated, it is useless to expect a long service life.

The service life is 150 thousand km; the transmission, as a rule, does not last longer. There are isolated cases when the CVT was changed as part of warranty repairs on cars that had not traveled 30 thousand km. But this is an exception to the rule. The main component that affects service life is the belt (chain). The part requires driver's attention, since if there is severe wear, the CVT gearbox can completely break.

CVT history

A car whose speed depended solely on the engine speed would be extremely inconvenient to use. Imagine that the car has only one gear, for example, first or third. In one case, you would be able to drive quite fast, but the car would take a long time to accelerate and slowly drive uphill. In another, everything would be exactly the opposite - an easy start, but an extremely slow speed. Because of such difficulties, the first manual transmission was developed.

conclusions

When it comes to cars with continuously variable torque transmission, there is reason for negative assessments. The reason is that the node requires regular maintenance, and its resource is short. Everyone decides for themselves whether to buy a car with CVT. The transmission has advantages and disadvantages. In conclusion, we can give a warning comment - when buying a used car that has a CVT gearbox, you need to be extremely careful. The owner of a used car can hide the operating features, and the variator in this regard is a sensitive version of a mechanical transmission.

Durability

Probably everyone who is even slightly interested in cars has heard about Audi's problems with Multitronic gearboxes produced by Luk. In the old type CVT (1999-2006), the control electronics constantly fail, the mechanical part fails and the circuit wears out prematurely. It is noteworthy that the chain was used precisely to transmit higher torque, but the engineers miscalculated its strength. Over time, the Germans have significantly improved their boxes, but problems still occur. Other German CVTs are also not credible, for example, ZF VT1-27T, used in the Mini R50/R53, and Mercedes 722.7/722.8 for A/B-class models.

Japanese designs cause much less trouble. Although, the Jatco variator, used in various Nissan models (for example, Qashqai), also belongs to the risk group. A common problem with CVT transmissions is the limited availability of spare parts and the reluctance of some mechanics to deal with CVTs. The undisputed leader in terms of reliability is Toyota (Lexus) CVTs.

A continuously variable automatic transmission, despite its relatively simple design, is quite complex and expensive to operate. In addition to electronics and belt/chain failures, premature flywheel wear can also occur. It is worth noting that the dual-mass flywheel is used only in some cars with CVT (Audi).

How does a CVT differ from other types of transmissions?

The most popular gearbox is manual. It consists of three shafts (drive, intermediate and dependent), if the car is rear-wheel drive and the engine is in a longitudinal position. In the case of front-wheel drive, the box has two shafts: incoming and outgoing.

In classics, switching is controlled by a valve body, and in modern versions - by electronics.

The automatic transmission has several movement options:

The classic has proven itself to be reliable. Such a gearbox can handle up to 400 thousand kilometers without problems. The condition is correct operation. As with other gearbox options, you need to fill the radiator with high-quality coolant. Among automatic transmissions, there is an option with manual shifting, which is so loved by many car enthusiasts.

The “Robot” checkpoint is a kind of hybrid. This is a mechanic where gears are switched electronically. There are two pedals and a clutch, but no torque converter. This gearbox is characterized by jerks when changing gears. This is especially noticeable against the backdrop of the variator, which has neither jerks nor shocks.

Recently, a new product has appeared on the market - a car with two clutches in the gearbox. One of them is responsible for even transmissions, the other for odd ones. This innovation eliminated temporary “sagging” of the robot when gear shifting lasted up to 3 seconds.

How CVTs are repaired

CVT repair is carried out in the same way as automatic transmission repair. They also do not like to be treated inappropriately and will go out of line. Owners of cars with a CVT should familiarize themselves with the rules for operating such a box, and not neglect them.

As for towing cars with a CVT, as in the case of an automatic transmission, it has its own characteristics. In particular, it will be possible to tow the car only by setting the shift lever to position N, and you will need to drive no more than 80 km at a speed of no more than 50 km/h. When towing over long distances, a tow truck is required.

On CVTs, as well as on automatic transmissions, routine diagnostics should be carried out at least once a year. If you notice unnatural noises or shocks in the box, then it is necessary to undergo diagnostics at a special service station. Diagnostics will help identify all existing noises, malfunctions and possible problems. And this way you can avoid costly repairs.

The variator belt , like the device itself, is often subject to repair. And you don’t need any sophisticated equipment to carry it out. For example, you can often change the belt on scooters equipped with a CVT with your own hands.

Video about the device and comparison of the variator:

And finally, I would like to summarize. Cars with a CVT are becoming more and more in demand. Their prices vary. For example, Chery Tiggo FL with all-wheel drive, equipped with a CVT, costs about 640,000 Russian rubles.

What is a variator

It may seem surprising, but the history of the appearance of CVTs goes back about 150 years.

They were popular in sewing machine drive mechanisms and were used in industrial equipment as early as the 19th century. Later, CVTs began to be installed on motorcycles, but as for automobile transport, CVT gearboxes did not take root here for a long time due to their low service life, as well as the difficulty of controlling when transmitting significant torque. In the second half of the twentieth century, specialists from DAF and Volvo were involved in the implementation of the variator for some time, but for a long time it was not possible to solve the problem of short service life. And only after engineers from several Japanese automakers began to work closely on improving this type of gearbox, did the CVT begin to gain popularity and be installed en masse on production cars. From a technical point of view, a CVT gearbox is a continuously variable transmission. Its other name is CVT (from the English Continuously Variable Transmission). Thanks to the special design and the use of external control, gear shifting in the variator is smooth, with a stepless change in the gear ratio. The selection of the optimal gear ratio occurs automatically by comparing the external load with the speed of the power unit. The operating principle of the variator allows you to use the power of the machine’s engine with maximum efficiency.

What is the difference between a variator and an “automatic” and a “robot”

When buying a car, even an experienced motorist will not always be able to figure out which gearbox is installed in it. Here are tips on how to distinguish automatic transmission, CVT and “robot” visually. We advise you to read about how a sequential gearbox works. It is impossible to find the differences between an automatic and a CVT transmission when getting into the car. Both look identical: one control lever, the same mode designation. There are 4 main features by which you can determine the type of gearbox: Number of modes. CVTs may contain a smaller number of modes - usually 4: “P”, “N”, “D”, “R”. Modern “automatic machines” also have additional ones. Indication of the gearbox type next to the vehicle make. To figure out what kind of gearbox is installed in the car, you should inspect it from the outside from the rear. Most manufacturers also indicate the type of transmission - "AT" or "CVT" - near the brand and model designation. The difference in the “behavior” of the vehicle while driving. A car with an automatic transmission will experience jerks and jolts. Vehicles with a CVT will not have them. In addition, the latter will have audible clicks in the box. Different “behavior” of the car when climbing a hill. If you brake and release the gas pedal when driving downhill, a car with an automatic transmission will move smoothly forward without rolling back. A car with a CVT will roll back and will not move forward at idle speed. If it is not possible to use the above methods, for information about the type of transmission, you should contact: a bona fide seller, an experienced car mechanic, or the accompanying documentation of the car.

Toroidal variator device

In contrast to the V-belt design, the toroidal type variator consists of two disks made in the form of concave curved surfaces. Rotation from the driving element to the driven element is transmitted using a special sliding roller. When it is tilted and moved towards the outer diameter of the driven disk, the gear ratio increases. Accordingly, when the roller is tilted in the opposite direction and shifted towards the center of the disk, the gear ratio of the variator decreases.

Diagram of the device and operating principle of a toroidal variator:

Basic requirements for toroidal variators: high efficiency, long service life. To ensure the fulfillment of the assigned tasks, expensive materials and modern technologies are used in the manufacture of variator elements.

Toroidal CVTs are relatively simple, however, such CVTs are rarely used in modern automobile production. This is due to the following factors:

Main advantages and disadvantages

Let's start with the pros and find out why the variator is better:

- Jerks and jumps are not typical for its design. At the same time, it accelerates faster, because the CVT transmission is continuously variable, and it is easier to control.

- A car equipped with a CVT will not stall at a traffic light in a traffic jam and will not stall on an uphill slope, because it moves off smoothly.

- Its features are 2 pedals and ease of control.

- Doesn't make noise or growl sounds.

- It is more economical on fuel and this is due to uniform acceleration and running.

- For drivers who care about the environment, a CVT is an excellent solution because it is an environmentally friendly transmission. It does not release as many toxic fumes into the air as a manual or automatic machine.

Why is a CVT on a car bad?

- High speeds at XO for a CVT gearbox are only permissible for a short period of time. It’s impossible to drive like this for a long time.

- Driving a CVT means purchasing a special fluid for the V-belt to work properly. This means that you will have to fork out for a liquid of this type, and finding it is also a problem.

- If you do not maintain the conditions in which the variator feels good, this will hasten the time of its death. And as a result - expensive and time-consuming repairs.

The harmful influence of the motorist can lead to breakdowns. If you do not undergo a scheduled technical inspection, this guarantees problems that will later result in waste of money.

The automobile variator and its pros and cons are highlighted in a video from the AUTOSALON channel.

Belt rupture and other damage is still No. 1 on the list of CVT failures.

To avoid trouble, you should always remember:

- Sudden pressing of the brake pedal to the floor almost always guarantees cracks in the belt.

- If you constantly initiate sudden braking, the belt will eventually wear out and burst.

- If the contacts in the terminals are broken, this will lead to errors in the operation of the node system, and as a result, will affect the variator.

- When the car is in neutral and suddenly rocks rhythmically, there may be a problem with the wiring. Even a microscopic rupture of the harness will lead to problems in the variator.

- A symptom of a failed CVT transmission is a burning smell in the cabin.

The disadvantages of the Mitsubishi CVT will be highlighted by the author of the video, Alexander Stepanov.

Operating principle of V-belt gearbox

In simple terms, the device works as follows. There are two pulleys: one driving, connected to the power unit, the other - driven, connected to the wheel drives. The shafts are connected by a belt or chain.

The pulleys are not cast, but made of two conical halves that can converge and diverge, changing the diameter of this structure.

The principle of operation is quite simple: let’s say our car is “moving away” and needs more power. To reduce the load on the motor, the cones on the drive shaft diverge, and it decreases in diameter. The driven pulley, on the contrary, must have a maximum diameter, so its cones are brought together. Thus, the engine makes the optimal number of revolutions in each specific case, which reduces the load on it.

As the speed increases, the diameters of the pulleys change accordingly - the driving one increases, and the driven one decreases. All this is necessary to stabilize the operation of the power unit, as well as to reduce traction effort.

Changing the diameters on each of the pulleys is carried out by an electronic system that receives data from the on-board computer and ECU.

The advantages of this option are its lower cost and simplicity of design, which is why the price of the transmission is slightly lower than for other types of CVTs.

CVT V-belt box device

Since the toroidal version is quite expensive to produce and is used only on premium cars, it makes sense to talk about only the V-belt type device.

Like the robot, the variator is installed either longitudinally or transversely. Its main components:

- Clutch system. The simplest device designed to connect the engine to the transmission and, if necessary, turn it off (the so-called “neutral”). A torque converter, also used in a conventional automatic transmission. Shafts with variable cones. A belt or chain to connect them. By the way, both components are made only from durable metals, since they bear a large load. Oil used to reduce friction between shafts, as well as to build up pressure. A pump that creates the same pressure. It is necessary for the correct operation of the cone parts. Sometimes it may be absent (in such cases, either hydraulics or a spring are responsible for changing the diameter of the pulleys). A hydraulic unit that performs the function of supplying oil through various channels to both pulleys. By the way, if various shocks or slipping occur during operation of the variator, most often this indicates a breakdown of the valve body. A filter system that prevents oil channels from becoming clogged with deposits and metal debris. Radiators that remove heat from the gearbox. Unfortunately, without them, such a transmission overheats quite quickly, especially when slipping or driving off-road. An electronic control system that receives commands from the ECU and changes the diameter of each shaft depending on speed and load. A device responsible for turning on reverse motion.

How does a toroidal variator work?

Looking at the diagram of a toroidal device, it may seem that it does not belong to CVT-type mechanisms. There is no belt drive here, the pulleys do not move relative to each other (they do not converge or diverge), the shafts stand still. But, if you analyze the operating principle of this mechanism, it turns out that it is very similar to a classic variator:

Thanks to two degrees of freedom, the variator rollers can rotate around their axis and also tilt in the vertical direction. As a result, they come into contact with the disks at various levels.