The procedure for mechanizing production and other activities has significantly increased the objectives. Mechanisms designed to transmit rotation and distribute the generated force have become quite widespread. There are quite a large number of different gearboxes, all of them are characterized by their specific performance characteristics. An example is a planetary gearbox, the design of which has a fairly large number of different features. Let's take a closer look at this mechanism.

Design and principle of operation

The mechanism under consideration is represented by a classic combination of gears with different diameters, which ensure the transmission of rotation with a change in the number of revolutions and transmitted force. The features of the mechanism determine the possibility of application in a wide variety of industries. Operation can only be ensured if the rotating shaft is connected to the driven part.

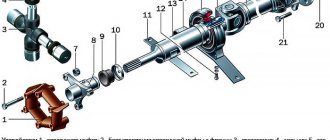

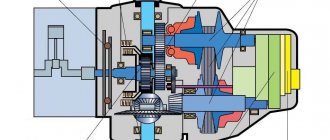

Considering the drawing of a classic device, it should be noted that it consists of the following elements:

- The main elements are represented by gear and worm pairs.

- To install and fix the main parts, centering bearings are installed.

- To lubricate the rubbing parts, the housing is filled with special oil. The possibility of leakage can be eliminated by using seals.

- Oil seals are also an important part of the design.

- The housing consists of two components, due to which it is possible to disassemble the structure during maintenance or repair.

The operating principle of a planetary gearbox provides that the lubrication of the main parts occurs due to the natural splashing of oil during operation of the device.

The diagram of a classic device looks like this:

- A motor is installed as a source of rotation.

- The other part is represented by a planetary gear. Other parts are located inside; the gearbox housing is attached to the motor using fixing elements.

- Next comes the shaft with bearing.

The structure is protected by the gearbox cover. It is fixed using bolts. In general, we can say that the device is quite complex, so repairing and maintaining it is not always easy.

The operating principle of the unit largely depends on the kinematic diagram of the drive. The calculation of the gear ratio is carried out using special formulas that can be found in the technical literature.

The main part of the structure consists of the following parts:

- Ring gear.

- Planetary or satellites.

- Carrier and sun gear.

The operating principle is calculated as follows:

- The sun gear is located in the central part of the structure. Often the main rotation is transmitted to it, for which the element has a mounting hole for the shaft.

- The central element is constantly in mesh with other similar gears, the axes of which are located around the circle.

- The satellites are meshed with a ring gear, which is represented by a large diameter gear wheel with an internal arrangement of the main parts.

- The carrier is required for rigid fixation of all parts relative to each other.

It is worth considering that for the mechanism to work, one of the parts must be fixed relative to the others. Depending on the choice of the driven or driving element, the gear ratio depends. It is quite difficult to calculate the number; the specific power also depends on this indicator.

The design features of the mechanism under consideration determine that it can be used to achieve a variety of goals.

Characteristics of the main varieties of this device

Various types of gears are used in the design of the planetary gear set of automatic transmissions. There are three main most common ones: cylindrical, conical and wave.

Cylindrical

Gear mechanisms transmit torque between parallel shafts. The design of a cylindrical gear includes two or more pairs of wheels. The shape of the gear teeth can be straight, oblique or chevron. The cylindrical circuit is simple to manufacture and operate. Used in gearboxes, final drives, drives. The gear ratio is limited by the size of the mechanism: for one wheel pair it reaches 12. Efficiency is 95%.

Read

Which automatic transmission is the most reliable and best, rating of automatic transmissions

Conical

Wheels in a conical design convert and transmit rotation between shafts located at an angle of 90 to 170 degrees. The teeth are loaded unevenly, which reduces their ultimate torque and strength. The presence of forces on the axes complicates the design of the supports. For smooth connection and greater endurance, a circular tooth shape is used.

The production of bevel gears requires high precision and is therefore expensive. Angular structures are used in gearboxes, valves, and milling machines. The gear ratio of bevel mechanisms for medium-duty equipment does not exceed 7. Efficiency is 98%.

Wave

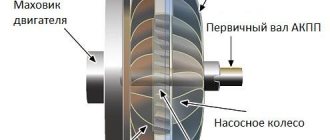

In wave transmission there are no sun and planetary gears. Inside the crown wheel there is a flexible oval-shaped gear. The carrier acts as a wave generator, and looks like an oval cam on a special bearing.

A flexible steel or plastic wheel is deformed under the action of the carrier. Along the major geometric axis, the teeth engage with the crown to the entire working height; along the minor axis there is no engagement. The movement is transmitted by a wave created by a flexible gear wheel.

In wave mechanisms, the efficiency increases along with the gear ratio exceeding 300. Wave transmission does not work in circuits with a kinematic characteristic below 20. The gearbox produces 85% efficiency, the multiplier - 65%. The design is used in industrial robots, manipulators, aviation and space technology.

Types of planetary gearboxes

There are quite a large number of varieties of reduction gearboxes. Classification is also carried out according to the number of steps:

- Single stage.

- Multi-stage.

The first version is much simpler, smaller in size and provides greater torque transmission capabilities. The creation of several stages determines a significant increase in the size of the structure, and the range of gear ratios decreases.

The classification is also carried out according to the complexity of the planetary gearbox. There are two main types:

- Simple.

- Differential.

Today, differential gearboxes have become very widespread, as they allow rotation to be transmitted in the required manner in a particular case.

Types are distinguished depending on the shape of the body, as well as the elements used inside. The classification is as follows:

- Wave.

- Conical.

- Worm-shaped.

- Cylindrical or wheel type.

Their use makes it possible to transmit rotation between intersecting, intersecting and parallel shafts. That is why the planetary gearbox has become widespread.

Two-stage planetary gearmotors are used when it is necessary to transmit rotation at different frequencies. Some versions are manufactured according to the 3k scheme, high-power planetary gearboxes are often large in size, and in the manufacture of the main parts, hardened steel is used, which is characterized by high wear resistance.

Operating principle of a single-stage gearbox

It's simple enough to understand. In such a mechanism, through a smaller sprocket located on one shaft to a larger one installed on another shaft, rotational motion is transmitted through the teeth. The effect of reducing the number of revolutions per minute is achieved due to the difference in the diameter of the sprockets. The length of the circle that the first one outlines during movement is significantly less than the one that the second one outlines, so the large asterisk rotates more slowly.

This type of gearbox is the simplest. It differs from others in that motion is transmitted through one link, and not through several, while the incoming and outgoing rotations have opposite directions.

Read also: Homemade stand for an angle grinder, do-it-yourself drawings

Torque can also be transmitted using a worm mechanism, but the gear ratio is affected by the diameter of the “worm”.

Application

Today, electric motors with planetary gearboxes have become very widespread and can be used in a wide variety of cases. The scope of application largely depends on the design features of the device and its characteristics. The following execution options are available:

- Cylindrical. This is due to the fact that the design features allow for an efficiency of about 95%. The purpose of a gearbox with a planetary gear is to transmit a sufficiently large force between parallel and coaxial shafts. Rotation transmission is carried out through spur, helical and chevron gears. The coefficient can vary from 1.5 to 600. The advantage of this design option is its compact size, as well as a high degree of protection from environmental influences.

- Conical ones are also quite common today. A design feature is that the gears have a conical shape. Due to this shape, smooth coupling is ensured, as well as a high degree of resistance to loads. In this case, the trees can be located vertically or horizontally.

- Wave devices can also be used. They are characterized by having a flexible intermediate number. The main structural elements include eccentrics and cams, which ensure tension of the flexible wheel. This design option is characterized by a high gear ratio, smooth running and an increased degree of tightness. There are several different types of this mechanism; for example, different types of bearings can be used.

Despite the rather complex design, it has become very widespread. An example is the engineering field, machine tool manufacturing and the production of various mechanisms. An example is a car gearbox, which is designed to transmit rotation and change the transmitted force or speed.

Quite a lot of attention should be paid to selecting the most suitable version. If the installed device does not have the required properties, then there is a possibility that the structure will fail when used.

The most important selection parameters include the following indicators:

- The type of gear used to transmit rotation.

- Maximum permissible axial and cantilever load. At the time of operation of the gearbox, the load arising during operation is distributed in a variety of ways.

- The size of the gearbox also matters. An indicator that is too high determines the inability to install in certain conditions. However, you need to pay attention to the fact that the increase in power is achieved solely by increasing the size of the device. Therefore, it is necessary to select a more optimal execution option.

- Temperature range at which the mechanism can be used. The type of material used in the manufacture of the housing and main elements determines the conditions under which the device can be operated. Too high a temperature causes an increase in ductility and a decrease in surface hardness, due to which there is a possibility of deformation and wear of the product. To ensure cooling, oil is added. Not all versions can be used for long-term operation; some can only be used periodically.

- The popularity of the manufacturer also matters. Some factories are characterized by producing high-quality and durable mechanisms.

Types of gearboxes

All types are designed according to a similar principle, the only difference is the type of gear transmission. The most common types are cylindrical, conical, globoid, combined, worm and planetary, but recently designers have resorted to combined designs, which allows them to combine the advantages of several types.

The design of different types allows you to transmit force between units that are located in different areas, whether they are perpendicular (bevel gear), parallel (cylindrical) or intersecting shafts (worm).

The gear ratio range can vary from a few units to several thousand, depending on the number of steps. Nowadays, the most common mechanisms are those that use several stages in their manufacture. This allows you to combine several types of gears and achieve maximum efficiency. Let's look at the main types.

Helical gearbox

Quite popular in the development and production of machines for various purposes. They effectively perform their functions when working with powerful installations, while showing high efficiency exceeding 90%. Most often used in parallel and drift shaft applications. It can be used with a different number of steps, on which the gear ratio depends; it can range from 1.5 to 400.

Worm gear

They have a fairly simple design, which is why they have gained wide popularity. One of the advantages is also the low cost in comparison with analogues. The number of steps is usually limited to one or two. In this case, the range of the gear ratio of the worm gearbox can be in the range from 5 to 10000, which can be calculated using a special formula. The disadvantage of this type is the low efficiency and limited power of the power plants with which it works. It consists of a gear wheel and a cylindrical, less often globoid, worm in the form of a screw.

Planetary reductor

A special type that compares favorably with analogues, having a number of advantages. Thanks to this, it has become widespread in heavy engineering. The design of this model allows you to achieve a high gear ratio when working with the most powerful power plants. Moreover, its dimensions can be significantly smaller than those of analogues. The mechanism is called planetary because of the specific arrangement of structural elements, which include: satellites, carrier, sun and ring gears.

The force is transmitted through the shaft to the sun gear, which is in mesh with all the satellites. At this time, the ring gear is in a static position. The model is characterized by high efficiency and operation in the gear ratio range from 6 to 450.

The choice of the type of unit is always based on the design requirements for the mechanism, and the choice of model should be made by a qualified designer. The first thing you need to determine is what type of transmission is needed, the optimal size of the mechanism, calculate the axial loads on the shafts and the temperature conditions of operation.

The gear ratio directly depends on the number of stages of the selected mechanism. Single stage ones are used to perform simple functions, usually of the worm type. Nowadays you can more often find combined types of gears, which allows you to significantly expand the functionality of the unit.

Standard straight shafts are used as input and output shafts, made in the form of bodies of revolution. The quality of the entire mechanism directly depends on their quality, since they are subject to many external loads of various types.

It is very important to change seals and oil in a timely manner. Constant preventative maintenance will ensure stable operation and protect against sudden breakdowns

To control the oil level, there is a special viewing window, which allows you to replenish the required volume in a timely manner.

In general, it is not difficult to independently calculate the gear ratio, select a suitable model and replace (repair) the gearbox. The main thing is to follow the recommendations of specialists and technical instructions specified by the manufacturer.

Advantages and disadvantages

The wide range of applications is primarily associated with the main advantages of the mechanism. Many of the properties are the same as the cylindrical version, since both use gears. The advantages are as follows:

- Compactness. Many models are small in size, making installation easier. Small overall dimensions also make it possible to create mechanisms with low mass. Due to this, the efficiency of the device in question is significantly increased.

- Reduced noise level. This property is achieved by installing bevel wheels with oblique teeth. Due to the use of a large number of teeth, the accuracy of the movement of the main elements is also ensured. Even with a heavy load and rotation speed of the main elements, a strong hum does not occur, which has become the reason for the widespread use of planetary gearboxes.

- Low load on supports. Conventional gearboxes are characterized by the fact that the load is placed on the shaft, which over time can break. The load also affects the bearings, increasing their wear. Over time, all of the above reasons lead to the need for maintenance.

- The load on the teeth is reduced. This is achieved due to its uniform distribution and the large number of teeth involved. A common problem is associated with abrasion of the working part of the teeth. Due to this, they begin to not fit tightly to each other, the consequences of this phenomenon are increased wear and the appearance of noise.

- Ensures uniform distribution of oil during operation. As with the operation of any other gearbox, in this case the degree of lubrication of the working surface is of great importance.

- Long service life. The peculiarities of the location of the satellites lead to mutual compensation of the exerted force.

- Increased gear ratio. This indicator is considered the main one. The gear ratio can vary over a fairly wide range.

In general, we can say that there are quite a large number of reasons why such a mechanism is used to transmit rotation. The efficiency of a planetary gearbox is relatively low, which can be called a significant drawback of this design option. In addition, the efficiency drops significantly when the device is used directly, as it wears out over time.

In addition, attention should be paid to the fact that the planetary gearbox is a complex structure, the manufacture and installation of which poses difficulties.

A slight deviation in size causes a decrease in basic properties, as well as the appearance of serious malfunctions.

Other news and promotions

Story. Description. New technical solutions for models

In the manufacture of reinforced concrete and concrete products for the purpose of prefabricated construction, as well as for compacting the concrete mixture when pouring it into a monolithic structure, high-quality hand-held internal vibrators are required.

Almost all mechanical inventions based on rotational motion can be historically correlated with the principle of the wheel and the time of its invention. Before this principle was understood, nothing like this could exist. Who and when first came up with the ability to connect several wheels using teeth and rotate them at the expense of each other is unknown, but this man created a small revolution.

This is how the first gear appeared. The principle of gear transmission of motion energy can be considered revolutionary in the development of industry.

Maintenance and repair

The complexity of the mechanism under consideration determines that there is a need for timely maintenance and repairs. To begin with, let us pay attention to how the calculation of a planetary gearbox is carried out. Among the features of this process, we note the following points:

- The required number of transmission stages is determined. For this, special formulas are used.

- The number of teeth and the calculation of the satellites are determined. Gears can have a wide variety of teeth. In the case under consideration, their number is quite large, which is the determining factor.

- Attention is paid to choosing the most suitable material, since the main operational characteristics of the device depend on its properties.

- The indicator of the interaxial distance is determined.

- A verification calculation is made. It eliminates the possibility of making mistakes at the initial design stage.

- Bearings are selected. They are designed to ensure smooth rotation of the main elements. When choosing a bearing, attention is paid to the load they are designed for. In addition, it is not recommended to use this element without lubrication, as this leads to significant wear.

- The optimal wheel thickness is determined. Too high an indicator causes an increase in the weight of the structure, as well as costs.

- A calculation is made of where exactly the gear axes should be located. This is done taking into account the size of the gears and some other points. As a rule, a drawing is used as a basis, which can be downloaded from the Internet. It is quite difficult to independently develop a project for the manufacture of a planetary gearbox, since you need to have the skills of an engineer to carry out the appropriate calculations and design.

It is quite difficult to make the design in question yourself, as is repairing planetary gearboxes. Among the features of this procedure, we note the following:

- The procedure is quite complex, since the mechanism consists of a large number of different elements. An example is that immediately after disassembly, all the needles can fall out almost instantly.

- Many experts recommend entrusting the work in question exclusively to professionals, since mistakes made cause rapid wear and failure of the mechanism.

- Repairs often involve replacing gears that wear out over time. An example is abrasion of the teeth, changes in the size of the seat and many other defects. It is almost impossible to make such products yourself, since this requires special equipment.

Gearbox - principle of design and operation

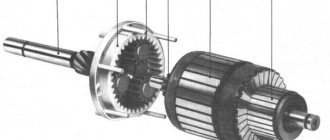

The planetary gear design has a set of gears on a rotating axis:

- The main element is the “sun” wheel located in the center.

- An important part of the system is the carrier; it fixes the axes of the remaining gears (satellites).

- Satellites are gears of the same size located around the central wheel.

- Ring gear - it combines all parts of the gearbox and is in contact with the satellites. This is the only part of the gearbox that is stationary.

The rotation of the central wheel sets in motion the satellites, which move around the perimeter of the ring gear. This process rotates the axes of the satellites, and they give movement to the carrier.

Pros and cons of planetary gearbox

The device is popular because it has a number of positive qualities:

- compactness - does not require much space and time for installation;

- has low weight;

- creates less noise during operation than conventional gearboxes;

- the load on the shafts and supports is small, this makes the supporting structure simpler, thereby reducing costs;

- has large gear ratios.

Differential transmission drives folded or unfolded movement in devices, which is used in metallurgical machines.

The planetary gearbox also has a number of disadvantages:

- The requirements for the manufacture of gearboxes are high. Precision is necessary because the teeth must fit tightly but move easily, so they are more difficult to assemble than other types of gears.

- The cost is higher than the price of other gearboxes.

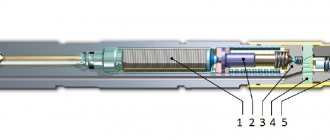

Input and output shafts of gearboxes

Gearboxes usually use conventional straight shafts in the shape of rotating bodies. The gearbox shafts are subject to external loads, cantilever loads and forces to overcome gears. The torque on the shaft is determined by the operating torque of the gearbox or the reactive torque of the drive. The cantilever load is determined by the way the gearbox is connected to the engine and depends on the radial or axial force on the shaft. In a number of machines that have special requirements regarding dimensions or weight, hollow shaft gearboxes are used. The hollow gearbox shaft allows the actuator shaft to be located inside the gearbox, thereby eliminating the need to use adapter coupling halves, etc.

Gear ratio

The gear ratio in a planetary gearbox is difficult to determine visually, since there are different ways to drive the system. In a planetary gear, one part is fixed, and the others act as drive and driven. The gear ratio depends on the teeth of all gears, their number, and the fixed element.

Gear ratios are:

- positive - when both gears are in the same direction;

- negative - if the gears move in different directions.

If the carrier is stationary, then the gear ratio is S/A, where S is the central wheel, A is the number of gear teeth.

When the ring gear is blocked, power is supplied to the carrier, and then the sun gear PO is less than 1 and will look like 1+A/S.

When the ring gear is fixed, and power passes through the central wheel, the software is equal to 1/(1 + A/S). It is the largest number that can be obtained with a planetary gear.

Selection of numbers of teeth of planetary gears

The number of wheel teeth is selected at the first stage of calculating the planetary scheme according to a predetermined gear ratio. The peculiarity of designing a planetary gear set is to comply with the requirements of proper assembly, alignment and proximity of the mechanism:

- the teeth of the satellites must coincide with the depressions of the sun and the epicycle;

- The planets should not touch each other with their teeth. In practice, more than 6 satellites are not used due to difficulties in uniformly distributing the load;

- The axles of the carrier, sun and crown wheels must coincide.

The basic ratio for selecting transmission teeth through the gear ratio looks like this:

i = 1+Zcorona/Zsun,

where i is the gear ratio;

Read

Owner's review of the automatic transmission installed on the Renault Kaptur

Zn is the number of teeth.

The coaxial condition is observed when the interaxial distances of the sun wheel, crown and carrier are equal. For a simple planetary gear train, the center distances between the central wheels and satellites are checked. Equality must satisfy the formula:

Zcorona=Zsun+2×Zsatellite.

In order for there to be a gap between the planets, the sum of the radii of adjacent gears should not exceed the axial distance between them. The condition of proximity to the sun wheel is checked using the formula:

sin (π/c)> (Zsatellite+2)/(Zsun+Zsatellite),

where c is the number of satellites.

Planetary wheels are placed evenly if the ratio of crown and sun teeth to the number of satellites is integer:

Zsun/s = Z;

Zcorona/s = Z,

where Z is an integer.

Types of planetary gearboxes

A distinctive feature of planetary gearboxes is the presence of two or more degrees of freedom. And the speed of a link is directly related to the angular speed of the remaining links.

There are several types of transmissions:

- Single-stage is the simplest option with small dimensions.

- Multi-stage - used to obtain a larger subordinate number.

Planetary gearboxes differ in the location of the shafts: vertical or horizontal.

In addition, planetary gears differ in the meshing of gears, there are:

- Direct (traditional method) - since installation of this design is the simplest. Used at low speeds and low loads.

- Helical - its use can reduce the noise of gearboxes, but axial loads complicate the selection of bearings. The tilt angle is 18 degrees, the stroke is smoother, used at medium and high speeds.

- Chevron - the teeth are directed in different directions. Recommended for transmissions with high loads. The advantages of this type are that there is virtually no axial load on the bearing, this extends the service life of the entire assembly. This type of transmission makes it possible to increase the inclined angle of the teeth up to 40 degrees. The disadvantage of this type is its high cost.

Failure

Wear is the main cause of planetary gear failure, which is mainly due to poor lubrication. Worn gears have increased gaps in the gears, which leads to increased noise, vibration and ultimately a decrease in tooth strength.

Jamming – breakdown of high-speed gears. Seizing occurs as the oil film is squeezed out between the teeth at high speeds.

Fracture – caused by bending stress. A fracture can destroy the shaft, bearings and the entire mechanism.

Planetary gearboxes are used where average precision is required and there is no need for a full shaft. The main industry for using planetary gearboxes is mechanical engineering; in addition, they are used in medical technology and measuring equipment.

To make an application, click on the button below: