Technical progress does not stand still and is constantly evolving. Every year new technologies emerge, allowing engineers to improve or create completely new parts. This also applies to mechanical engineering. Hundreds of thousands of modern cars are sold in Russia every year. Each of them contains the latest technologies. We will talk about such a small unit as a starter, and we will figure out which starter is better: a gearbox or a regular one.

General information

The first starter used on a car had a number of significant shortcomings. Over time, the design was gradually improved and significantly transformed. The starter is a 4-band electric motor, which is necessary to rotate the crankshaft when starting the engine. It takes energy from the battery and increases the starting current several times. Due to this, any internal combustion engine starts. The principle of operation of the starter has not changed over the years.

Nevertheless, its design has been constantly improved. The weight of the part was reduced, the service life was increased due to the use of higher quality and new materials, etc. All this led to the fact that the starter was transformed quite significantly and even a new type appeared - gearbox. This is exactly what we will talk about now.

Principle of operation

How does a starter work? It refers to converters of electrical energy from a battery into mechanical energy to rotate the crankshaft. For the engine to start, the following processes are needed:

- After turning on the ignition, electricity from the battery enters the relay coil.

- The anchor engages with the bendix. The retractor relay provokes the clutch of the crankshaft and bendix.

- When the anchor reaches the highest point, the contexts are closed. Voltage enters the relay winding and the electric motor.

- The crankshaft moves and the engine starts.

- After turning the key, the process ends.

The operating principle and design of the car starter allows it to be diagnosed at all stages, so repair or replacement does not cause problems for drivers.

Classic starter: operating principle and design

The key feature of such a device is that there is no such intermediate unit as a gearbox. This allows rotation to be transmitted directly from the starter to the crankshaft. Consequently, the device is simpler to manufacture and much easier to repair. Another feature of such a starter is that the electric current supplied to the switch allows you to instantly engage the gear and flywheel. This helps the car to start, as drivers say, in a snap.

Currently, they are trying to replace such starters with reduction ones. However, most cars used to have a classic starter. The operating principle and design made this unit extremely durable. Such units almost never fail due to electrical influence, but much more often they need to be repaired due to low temperatures.

Differences between starters, advantages and disadvantages of operation

After a brief overview of what a gear starter is and how it differs from a classic one, we can conclude that this model is definitely preferable for cars operated within the city, as well as in regions with frosty winters. It is these starters that are installed on modern cars and trucks: VAZ, GAZelle, as well as foreign cars assembled in Russia.

Be sure to read: Description of the Rhodonite chicken breed

However, in conditions of shortage of spare parts and access to qualified repairs, it is safer to give preference to a simpler and more reliable option. It is no coincidence that old-style starting devices are still installed by car owners on classics used outside the city and for long trips, especially in warm climates. Such a spare part can be easily repaired “on the knee” if desired, and it fails noticeably less often than its modern counterpart. Another advantage of the classic starter is its low price. It is not recommended to save on geared models.

Construction and something else

During operation, the internal combustion engine produces a fairly large amount of energy. It is enough for lighting devices, music, wipers, etc. In general, while driving, the main load goes to the generator. In a static position, the motor does not produce anything, so it needs to be started somehow. For this purpose, various types of starters are used along with batteries.

The electric motor itself, that is, the housing, is made in a cylindrical shape. It houses the cores and exciting windings. It is clear that there is an anchor - one of the most important and expensive parts. The collector springs and cores are pressed onto it. It has an axial shape. There is also a starter solenoid relay. The price of this spare part is relatively small, although the part performs extremely important functions. First, it supplies energy from the ignition switch to the electric motor. Secondly, it pushes out the overrunning clutch.

Most often, it is the starter solenoid relay that fails. Its price is fortunately affordable and starts from 500 rubles and ends in several thousand. In addition, the design includes a bendix with a drive gear and brushes.

Starter operation stages

This node works as follows:

- connection of the gear to the flywheel;

- starting the starter;

- disconnecting the gear and flywheel.

Naturally, the starter only works when the engine starts, and then turns off. If this does not happen, then one of the mechanisms is faulty.

After the driver inserts the key into the ignition and turns it to the operating position, current is supplied from the battery to the traction relay. Thanks to this, the bendix of the gear starter engages the gears, at the same time, due to the supply of voltage to the electric motor, the circuit is closed and the car starts. Once the engine speed exceeds the speed of our starter, it turns off. It turns on only the next time the engine is started. Well, now let's look at how a gear starter differs from a regular one. There are some interesting details here.

How to install a gear starter on a VAZ 2107?

Fortunately for car enthusiasts, the domestic car plant made a new part that is completely interchangeable with the old one. Thus, the gearbox starter mounts have the same holes as a conventional starter.

Procedure:

- Before starting work, it is necessary to place the car on a flat surface and, if necessary, raise it slightly. This requirement is determined by the fact that on many Zhiguli cars it is better to unscrew the starter mounting bolts from the bottom. In addition, disconnect the battery terminal to prevent any accidental shorts that may occur when the electrical plugs are disconnected from the starter.

- Unscrew the ground wire from the old starter and pull out the red wire plug.

- Remove the two bolts that secure the starter to the gearbox. It's best to do this with small wrenches, since getting to these bolts, especially on a fuel-injected car, is quite difficult. After you unscrew them, remove the old starter by pulling it away from the box and lifting it up.

- Install a gear-type starting device in place of the old starter. Let us remind you once again that the gear starter has the same mounting as a conventional one and should not cause any difficulties during installation. Secure it with the same bolts and tighten them.

- Connect the electrical component to the new type of starter. First, screw in the ground wire, then insert the plug with the positive wire. After this, you can connect the battery terminal and start the engine using a new starting device.

Attention! If you have any problems with the electrical equipment of your car, then it is highly not recommended to connect a new type of starter until the relevant faults are eliminated.

That's all you need to know about the gear starter. This device is suitable for all domestically assembled Zhiguli models and will significantly improve the starting characteristics of the engine. Feel free to install a gear starter and forget about problems with starting the engine. We wish you good luck on the roads!

Gear starter

The general principle of operation is no different. Electrical energy is also converted into mechanical energy. The only difference is the presence of a gearbox. In addition, this starter also has permanent magnets in the winding, which makes it possible to slightly increase the reliability of the electric motor as a whole. Of course, there are some peculiarities here. In particular, many are interested in how much a starter of this type costs. In most cases, a little more expensive than classic ones, but not much. On average by 10-15%. But its service life is an order of magnitude longer, and this is definitely worth taking into account.

The service life of such a starter directly depends on the quality of the gearbox. The better the steel used when casting the gears, the less chance that the teeth will stick together after the hundredth start. In general, the design is popular today, and more and more gear starters are appearing.

Advantages and disadvantages of the classic version

So we are actually gradually approaching the answer to the question of which starter is better: gear or conventional. To do this, let's look at the strengths of the classic version. They are as follows:

- low cost;

- high maintainability;

- You can find spare parts almost everywhere.

But there are also some disadvantages, which are expressed in the following:

- high base current required;

- rapid wear of parts;

- does not work well at low temperatures;

- large weight and size.

In general, this is a fairly reliable design with proper maintenance. But development does not stand still, and this has led to more advanced gear starters. Let's look at their strengths and weaknesses.

A starter with a gearbox: what is good and what are its disadvantages

We have already figured out how this device works and what its fundamental differences are. It is no longer difficult to guess which starter is better, gearbox or conventional. The fact is that the first option has the following strengths:

- small size and weight;

- long service life regardless of ambient temperature;

- low energy consumption (40% less than the classic version).

As for the disadvantages, they are there too and are as follows:

- complexity of repair work;

- lack of spare parts in stores;

- high cost of the product;

- low quality gearbox.

Often the main reason for the breakdown of a starter with a gearbox is that low-quality components are installed. This leads to breakdowns and various types of malfunctions. In general, such a unit has more prospects in the future than a conventional starter. And this is not due to the fact that one is good and the other is bad, but due to scientific and technological progress.

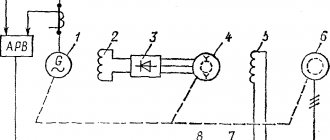

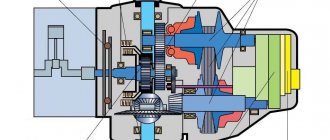

Design and operation diagram of a gear starter

A starter with gearbox consists of several main parts, which include:

- bendix (overrunning clutch);

- electric motor;

- solenoid relay;

- gearbox (usually planetary);

- mask;

- fork.

The main role in the operation of the element is played by the gearbox. It is through it that the Bendix interacts with the engine, successfully starting the internal combustion engine even when the battery charge is low.

The work of the starter with the gearbox occurs in several stages:

- current is supplied to the coils of the solenoid relay;

- the electric motor armature is retracted, the relay begins its work;

- Bendix comes into play;

- the pin contacts close and electrical voltage is supplied to them;

- the starter motor is switched on;

- The armature begins to rotate, the torque is transmitted to the bendix through the gearbox.

After this, the bendix acts on the engine flywheel, starting its rotation. Despite the fact that the operating mechanism is practically no different from a conventional starter, the transmission of torque through the gearbox ensures higher engine starting efficiency.

Let's sum it up

If you decide to replace this unit, then you first need to decide where the starter is located. This is usually the driver's side under or to the side of the engine. To remove it, you need to make room. Depending on the location, it may be necessary to remove the engine protection or the air filter with the box. Next, disconnect the wires and unscrew the bolts. Determining where the starter is located is not difficult. It has a cylindrical shape, and several wires come from it, secured with a nut. Everything is done quite simply and quickly.

So we answered the question about which starter is better: gear or conventional. Classic starters are good in their own way, but are gradually being phased out. But they also have their strengths, just as gearboxes have their weaknesses. For example, in the outback it will be difficult to find spare parts for a starter with a gearbox, but for a regular one - no problem. The same can be said about repairs - not everyone has encountered gearboxes on the starter and not everyone will undertake it. How much does a starter with gearbox cost? It all depends on the brand of the car; a normal one will cost 5-7 thousand rubles.