Multitronic device

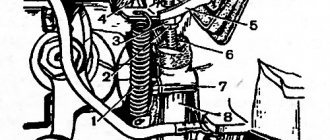

The structure of the Multitronic variator

The Multitronic variator consists of the following main elements:

- forward multi-plate friction clutch;

- multi-plate friction reverse clutch;

- planetary mechanism;

- chain variable transmission;

- intermediate gear;

- main gear;

- differential;

- electronic control system.

Multi-plate clutches

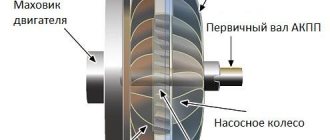

Multi-plate forward and reverse clutches technically act as a clutch, that is, through them the torque from the engine crankshaft (flywheel) is transmitted to the gearbox input shaft. Structurally and according to the principle of operation, they do not differ from gearshift clutches in an automatic transmission.

The clutches operate alternately: forward - when the CVT selector is set to position “D”, reverse - if the selector is in position “R”, i.e. when moving backwards. In the neutral position “N” and “P” the clutches are open.

The use of such couplings requires the presence of a flywheel with a built-in torsional vibration damper.

Planetary mechanism

Planetary mechanism

This element is used only when the vehicle is moving in reverse. As the vehicle moves forward, the forward clutch connects the transmission input shaft to the carrier, locking the planetary gear and rotating as a unit. The gear ratio is 1. And when the car moves backward, the ring gear is blocked on the gearbox housing. The blocking is performed by the reverse clutch. Due to this, the planetary gear transmits torque in the opposite direction. In this case, the reverse speed is regulated by the control system, and the gear ratio of the planetary mechanism is also equal to 1.

CVT transmission

A CVT transmission consists of two wedge-shaped pulleys (driver and driven) and a chain stretched between them. Each pulley consists of two disks with a conical surface. Through an intermediate gear, the drive pulley is connected to the engine crankshaft. And from the driven pulley the torque is transmitted to the main gear. During operation, the diameter of the contact between the chain and the conical surface of the pulley changes, resulting in a smooth change in the gear ratio and torque. This is possible due to the fact that one of the disks on each pulley is movable.

The drive of each pulley includes two hydraulic cylinders: pressing and adjusting. The first one presses the metal chain against the pulley discs. The second one regulates the gear ratio, i.e. affects the change in contact diameter. The metal chain links are used in different sizes, thereby reducing the noise level during its operation.

Control system

The Multitronic control system consists of the following elements:

- sensors;

- electronic control unit (ECU);

- hydraulic block.

Sensors record the position of the selector lever, the temperature and pressure of the working fluid, and estimate the number of revolutions at the input and output of the gearbox.

General cross-sectional view of the Multitronic gearbox

The ECU is responsible for choosing the optimal gear ratio, focusing on the driver's desire and driving conditions. Based on sensor signals, the ECU determines the pressure of the working fluid and the direction of flow using solenoid valves in the valve body.

The hydraulic control unit is responsible for controlling the forward and reverse clutches, pressure and adjusting cylinders of the pulleys. It also serves to regulate the pressure of the working fluid and cool the clutches.

The actuators of the hydraulic control unit include:

- manual control spool;

- hydraulic valves;

- pressure control solenoid valves.

A gear-type oil pump, driven by the input shaft of the box, circulates the working fluid in the system. The ejection pump serves to cool the clutches. Its action is based on the supply of working fluid due to vacuum. Cooling of the working fluid occurs in the heat exchanger.

The Multitronic variator is mechanically connected to the selector lever. The box has the same operating modes as a classic automatic. Tiptronic function, i.e. The ability to control the gearbox in manual mode is also available in the transmission.

Operating principle of Multitronic

The operation of the Multitronic transmission is almost identical to the classic CVT. The usual option has one feature that many motorists do not like. At constant speed, the transmission is quiet and the engine is almost inaudible. But when the driver presses the gas pedal to the floor, the engine speed jumps, and the car accelerates slowly. Of course, this applies to the work of the first CVTs that appeared in the 1980-90s.

To eliminate this effect, manufacturers began to introduce virtual gears into the transmission. Each of them has its own ratio of the diameters of the pulley axes. The simulated gear shift is controlled using a lever mounted on the gearbox selector or steering wheel paddles.

This principle of operation also applies to the multitronic from Audi, which was updated in 2005. When driving steadily, the box increases/decreases the speed of the vehicle in the same way as a conventional CVT. But for dynamic acceleration, the “Sport” mode is used, which simulates the operation of an automatic transmission (the gear ratio between the pulleys is not smooth, but fixed).

Multitronic box: its advantages and disadvantages

Multitronic from Audi

The Multitronic CVT has the following advantages:

- The gearbox ensures high smoothness and comfort when driving.

- High acceleration dynamics.

- High fuel efficiency of the engine.

- Fast response of the car when you press the accelerator pedal.

Along with the advantages, the Multitronic variator also has disadvantages. These include:

- It is not advisable to tow a car with Multitronic.

- Rolling a car backwards on a hill.

- Limited resource of box elements.

- Expensive repairs.

The advantage of a variator over other gearboxes is the ability to continuously change the gear ratio since it does not have fixed gears, as in a conventional automatic transmission. CVT gearboxes were made at one time by companies such as Toyota, Honda and some others. But Multitronic is much more complex in design and superior to all others in driving performance. If other automakers, due to their design, could install a variator on small-class cars with far from the most powerful engines, then Multitronic, capable of transmitting a sufficiently large torque to the wheels, is installed on cars with fairly powerful engines (an example of this is the Audi A8 with engine 3, 0 l with a torque of 300 Nm and transmission 01J). Audi is currently announcing a new generation of Multitronic gearbox, capable of transmitting up to 500 Nm. The main difference from competitors is that Audi abandoned the use of a multitronic belt drive in the box and used a metal chain that can withstand many times greater loads without changing its size.

Torque from the engine is transmitted via the input shaft to the input pulley; the change in gear ratio is controlled by a hydraulic unit with a pump and a Multitronic electronic control unit.

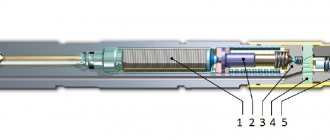

Multitronic works according to the following principle: torque is supplied to the input shaft from the engine using a gear through a 6 (models before 2006) or 7 (after 2006) disc clutch, which is controlled by an electronic control unit via a valve body. Next, the torque is transmitted through the chain to the output pulley and shaft, from where it goes through the drive to the wheels of the car. In this case, the transmission ratio through synchronously moving pulleys is constantly changing. This is again controlled by an electronic control unit. The electronic control unit (multitronic computer) is located directly in the gearbox and is mounted on the gasket, being, like all elements of the multitronic gearbox, in oil. This arrangement of the block made it possible to place all the sensors directly on it and get rid of a large number of wires. The control unit also contains a selector lever sensor (F125) for the gearbox selector. The selector, located in the cabin, is connected to the sensor purely mechanically, using a cable. The following sensors are mounted in the control unit:

-G182 - input shaft speed sensor

-G195 - output shaft speed sensor

-G196 - output shaft speed sensor -2-

-G93—transmission oil temperature sensor

-G193 — oil pressure sensor -1-, automatic transmission (pressure in the clutch line)

-G194 — oil pressure sensor -2-, automatic transmission (pressure pressure)

-N88-emergency pressure relief valve (see figure below).

Multitronic: Ingolstadt perfection

The design and principle of operation of an automatic transmission

Multitronics variator gearbox, which is considered one of the best in its class. Let's look at the mechanism of continuously variable torque transmission, how this system from Audi is designed and how it works. The main elements of the Ingolstadt variator are:

- planetary mechanism;

- intermediate and final drive;

- variator (the heart of the gearbox);

- differential;

- crankcase;

- hydraulic block;

- electronic control system unit.

The mediator between the Multitronic and the engine is two multi-disc clutches. They are so-called friction clutches or, more simply, friction clutches.

One clutch is for moving the car forward and the other is for reverse. The same mechanisms can be found in classic automatic transmissions, but there they are used to change gears. To prevent them from overheating, Audi engineers used forced cooling with a flow of working fluid.

The planetary mechanism in the “audyush” variator is needed exclusively for reverse gear, and to ensure that during such movement the speed does not increase indefinitely, an electronic limitation is provided.

The next element is the heart of the entire continuously variable transmission. Of course, we are talking about CVT transmission. To understand how it works, let's imagine two parallel axes of the same diameter, between which a belt is pulled.

If you start to rotate one axis, then the other will start to rotate and they will do it at the same speed. If the diameter of one of the axles is changed, their rotation speeds will be different. To change the diameter and, as a result, the gear ratio, in the real Multitronic design, two pulleys are used - a drive and a driven, connected by a specially designed chain (by the way, the chain is an original Audi solution).

Each pulley is two disks with a conical surface, which can move towards each other using hydraulic drives. As they come closer, the distance between the cones decreases, under the influence of which the chain seems to be squeezed outward (the diameter of the virtual axis increases); when they diverge, we observe the reverse process.

The drive pulley is connected to the motor shaft through an intermediate gear, and the driven pulley, in turn, is connected to the main gear and differential. Then the rotation from it goes to the wheels.

The electronic unit controls the operation of the entire system, relying on data from numerous sensors. They monitor a lot of parameters - the position of the gearbox selector, the speed at the input and output of the variator, the temperature in the mechanisms, as well as the pressure of the working fluid in the hydraulic system. The electronics also simulate the presence of gears familiar to the driver, although in reality the gear ratio changes smoothly.

The hydraulic unit drives the clutches and hydraulic pulley drives.

https://youtube.com/watch?v=HcuROau5FQM