The steering rack is a mechanism that transmits forces from the steering wheel to the rods. Simply put, with the help of this mechanism, the wheels are rotated synchronously where it is needed. The principle of operation is simple, but it is recommended to understand the nuances in order to understand how to make repairs. Therefore, it is worth studying the relationship between the steering rack and other adjacent components. This information will allow you to understand when there is a problem with this node or adjacent ones. If you have certain skills, you can diagnose the problem yourself. Moreover, today there are many applications that diagnose the car entirely automatically.

Steering rack device

This is a simple mechanism that has the following components:

- The steering wheel, which is located in the cockpit. Used to set the vehicle's direction of travel.

- Steering shaft. This is a metal rod that is equipped with special grooves. They are called splines. With their help, the steering wheel is attached on one side, and on the other, it is attached to the steering column.

- When creating a rack, a gear and the rack itself are used. A special lightweight alloy of increased strength is used in production.

- Tie rods are metal rods that have threads on one side and a threaded joint on the other.

- The steering tip is equipped with a threaded joint.

These are all components of the steering rack. True, it can also include a damper. This is a two-way shock absorber. Its purpose is to reduce vibration while driving. Thus, it is possible to reduce the negative impact on the entire mechanism. Not all cars have it, but SUVs have it installed by default. This is due to the fact that these cars often travel on bad roads.

steering rack with power steering

Causes and symptoms, and how to determine steering rack faults

The loads on this critical component of the vehicle structure depend on the quality of the roads. When operating a car on bad roads, the steering rack and the entire steering mechanism are subjected to high loads.

Knowing the signs and symptoms of steering rack failures, you can change the steering rack in time:

- If the steering wheel does not turn easily as before. It became noticeably harder to turn the steering wheel.

- If the steering wheel “beats”, that is, on bumps you can feel the beating of the steering column.

- If the noise of the power steering pump has become higher.

- If there is play in the steering wheel. When there is a lot of play, it is difficult to drive; you have to constantly turn the steering wheel, even on a flat road, to “catch” the wheels. Therefore, if the permitted permissible play of the steering wheel is exceeded, it is necessary to eliminate it as quickly as possible. This may also be due to heavily worn car tires. To choose the right tires for your wheels, you need to be able to decipher the tire speed and load indices.

- If oil comes out of the steering rack device. As the oil decreases, it becomes more difficult to turn the steering wheel and, also, extraneous noise may appear.

Since the steering rack is one of the most important elements of the car device, responsible for steering, if such signs of problems are detected, further operation is prohibited until the problem is eliminated.

Types of steering racks

There are three types of steering racks, namely:

- Mechanical is the simplest option, which is not equipped with additional functions. Turning occurs only thanks to the efforts of the driver himself. If you install a rack with a variable gear ratio, you can make the driver’s work easier. This model is practically not used, but remains on some old domestic cars.

- Hydraulic is considered the most popular. Its cost is affordable, and you also need to put in a minimum of effort to turn the steering wheel. The presence of a hydraulic booster reduces the driver's physical costs during the trip and increases the level of safety on the road. The point is that when an emergency occurs, you need to act quickly. When the steering wheel turns easily, the wheels will turn in the right direction faster. This will help avoid accidents or reduce negative consequences.

- Electric is considered the most modern. The work uses an electric motor. It is located in the steering column, on the steering shaft or included with the rack itself. The way this amplifier is integrated depends on the manufacturer itself. Electric booster is used in the most modern cars, which ensures maximum safety on the road.

These are all existing models. Modern steering racks are inexpensive, lightweight and do not require frequent maintenance. The control accuracy is quite high. Therefore, drivers can replace the steering rack, if necessary, with a more advanced one. You just need to make sure first that the particular car you are taking supports it.

steering wheel for car

Features of using slats

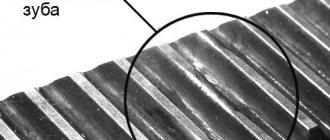

The rack itself is a sliding steel rod with a toothed notch. The drive gear is pressed against it from the teeth side. The steering column shaft has a spline connection with the drive gear shaft. Helical gearing is usually used as it is silent and capable of transmitting significant loads.

When the steering wheel rotates, the driver, acting in conjunction with the power steering, moves the rack in the desired direction. The ends of the rack act on the steering rods through ball joints. Threaded couplings for adjusting toe and steering ball joints are installed in the section of the rods. Ultimately, the moving force is transmitted through the swing arm to the knuckle, hub and steering wheel on each side. The configuration is designed in such a way that the rubber does not slip in the contact patch, and each wheel moves along an arc of the required radius.

Malfunctions and symptoms

There are several common problems that arise with steering racks. It is worth considering them in more detail. Here are some signs of problems:

- weighting the steering wheel in certain positions;

- the appearance of knocks;

- steering wheel vibration;

- leakage of power steering fluid;

- incomplete return of the steering wheel to its original position;

- The rotation of the steering wheel does not correspond to the rotation of the wheels.

Most often it all starts with the appearance of bitches. It is recommended to be alert immediately, because other signs will lead to more expensive repairs.

Now it’s worth considering the main malfunctions that you have to deal with.

- A knocking noise may occur due to damage to the anthers. Then the rod ends quickly become unusable, making themselves known by knocking. Repair is impossible; they must be replaced with new ones.

- Internal knocking often indicates problems with the piston or guide bushings. The rail needs to be disassembled to understand what the problem is. It is recommended to contact a service station for this.

- A knock also indicates the depletion of some components. In this case, you need to replace them or the entire mechanism completely.

- The hydraulic booster often develops a leak. In this case, it is necessary to replace the seals. It is also worth disassembling the rack to find the cause of the leak. If you do not have the appropriate skills, you should turn to specialists.

- When using electric power steering, it can be difficult to turn the steering wheel. This indicates the need to replace the electric power steering motor.

- When a similar problem occurs with the power steering, the problem lies in the pump.

It is necessary to distinguish between a problem in the steering rack and a problem with the power steering. Here are the symptoms of the latter:

- There is no power steering at all;

- there is no gain when the engine is idling;

- presence of extraneous noise when the engine is turned on;

- the appearance of foam in the working fluid.

Thus, it is not always necessary to immediately disassemble the steering rack. In some cases, it is worth first familiarizing yourself with the condition of the hydraulic booster.

Power steering pump

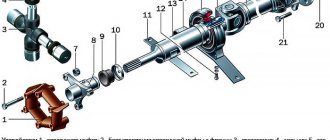

Composition of rack and pinion steering mechanism

A typical mechanism includes:

- a housing where all the parts are located, equipped with lugs for fastening to the engine shield or frame;

- rack;

- sleeve-type sliding bearings on which the rack rests when moving;

- input shaft, usually placed in roller (needle) bearings;

- a device for adjusting the gap in engagement from a spring-loaded block and an adjusting nut;

- steering rod boots.

Sometimes the mechanism is equipped with an external damper, designed to minimize one of the disadvantages of the rack and pinion mechanism - excessively strong transmission to the steering wheel of impacts from wheels hitting uneven surfaces. The damper is a horizontally located telescopic shock absorber, similar to that installed in suspensions. One end of it is connected to the rail, and the other to the subframe. All impacts are absorbed by the shock absorber hydraulics.

The simplest mechanisms used on the lightest cars do not have power steering. But most rails have it in their composition. The hydraulic booster actuator is integrated into the rack housing; only the fittings for connecting the hydraulic lines on the right and left sides of the piston come out.

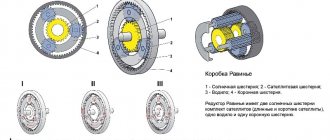

The distributor in the form of a spool valve and a section of torsion bar is built into the housing of the input shaft of the rack and pinion mechanism. Depending on the magnitude and direction of the force applied by the driver, twisting the torsion bar, the spool opens towards the left or right fittings of the hydraulic cylinder, creating pressure there and helping the driver move the rack.

Sometimes elements of an electric amplifier are also built into the rack and pinion mechanism, if it is not located on the steering column. Direct rack drive is preferable. In this case, the rack has an electric motor with a gearbox and a second drive gear. It works in parallel with the main one using a separate toothed notch on the rack. The direction and magnitude of the force are determined by the electronic control unit, which receives a signal from the input shaft torsion bar torque sensor and generates a power current to the electric motor.

Service Features

Servicing the steering rack is easy. This is an unpretentious element. However, it is important to periodically monitor its performance to avoid problems on the road. Without proper care, there is a risk that the car will no longer handle the road. Here's what you need to pay attention to:

- check the condition of the anthers and change them in a timely manner;

- if a defect is detected, components must be replaced;

- It is not recommended to keep the steering wheel turned all the way for more than 5 seconds;

- if the steering wheel does not return to its original position, you should contact a specialist;

- when starting to drive, it is necessary to turn the steering wheel with a minimum amplitude in order to extend the life of the mechanism;

- In winter, it’s worth turning the steering wheel in place several times to check its functionality.

If you do not have the necessary skills, then you should contact a service center at the first sign of a problem. Specialists will perform diagnostics and tell you if everything is in order. When repairs are required, they will complete them in a short time. At the same time, visiting a service station every 5–6 months will reduce the risk of serious problems. Most repairs will be superficial and inexpensive.

When choosing a new car, you should buy electric power steering. It will provide smooth rotation and easy control. It will be a little more expensive than hydraulics. But the result will be better.

Traction steering