Repair and replacement of muffler corrugations are part of the basic services that are provided by almost all service stations. In reality, repairing the muffler corrugation is its replacement, since there is no point in restoring the part. During long-term use, the element burns out, its restoration is ineffective and labor-intensive. Only temporary repairs make sense. Violation of the integrity of the corrugation due to damage is rarely diagnosed; the way to solve the problem is replacement. Changing a part is easy; a welding installation is desirable, but not required.

Muffler corrugation - what is it?

The corrugation in the muffler is the most important element for removing exhaust gases from the combustion system. It has the form of a corrugated flexible element, alloy steel is used as the base, and a metal mesh is installed on top.

The corrugation in the muffler is the most important element for removing exhaust gases from the combustion system

Many have noticed that when the engine starts, a rattling sound appears from the power plant, which transmits vibration to the muffler. Such influences can seriously compromise the integrity of the gas removal system. The muffler is less susceptible to wear; if you install a corrugation, it dampens vibration shocks and protects the muffler.

On most modern cars, a corrugation is installed; it acts as an elastic connection between the power plant and the gas exhaust system.

Repairing the muffler and replacing the corrugation is most often carried out when elements fail or during regular maintenance, if the percentage of wear does not allow the car to be used until the next inspection. Sometimes they install a “glushak” on their car for tuning.

How does the muffler corrugation affect engine performance?

Strictly speaking, this connection has not been corrugated for a long time. Corrugation is created on sheet metal to give it anisotropic properties, that is, increasing rigidity in one direction of force application and decreasing it in the other.

In a modern car, corrugations (bellows) in their pure form are no longer used in the exhaust system. Here they place wicker welded inserts, called corrugations by inertia. But some of them actually have elements that operate on the principle of corrugation.

The emergence of such devices allows us to solve a number of problems:

- the flexible insert significantly reduces dynamic loads on the exhaust tract, reducing the likelihood of cracks;

- The corrugation allows some displacement of the inlet and outlet flanges in space, axial. radial and angular, which reduces the requirements for the accuracy of manufacturing large-sized parts, and therefore their cost;

- changes in the position of the engine, both as a result of vibrations or reactive moments, and long-term, due to wear of elastic fasteners, are compensated by deformation of the flexible connection, without causing further damage.

A serviceable flexible coupling has an extremely positive effect on engine operation, reducing the overall vibration load of the vehicle, while in no way interfering with the free exit of exhaust gases.

Troubles begin as the corrugation wears out and breaks down;

- exhaust resistance increases due to the appearance of foreign parts in the flow;

- external noise increases, a burnt out or torn coupling allows gas to pass out to the muffler and resonator;

- the fastening structure of the exhaust tract parts is distorted, they can begin to touch the road and break.

Flexible couplings are quite reliable, which is determined by the features of their design.

Why do you need corrugation?

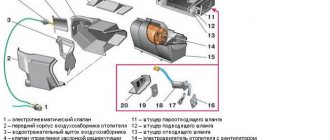

The unit is an auxiliary part of the car, acting as an elastic connecting link. Without it, the comfort of transport will suffer greatly, as it will not be able to meet even the basic conditions of reliability. Installation takes place on the exhaust pipe and the receiving part of the muffler pipe. There are exceptions; sometimes the first connection is installed immediately after the exhaust manifold, and the second after the catalyst.

The location and function of a part often leads to the need for premature work on the item. Wear occurs due to the suspension hitting large obstacles, the bottom clinging to the ground, or exhaustion of resources (number of heating and cooling cycles). The frequency of replacement depends on the operating conditions and the quality of the braid; it is better to buy with 2-3 layers.

The corrugation is an auxiliary part of the car

Role and functions of corrugation:

- combating vibrations transmitted from the engine to the muffler;

- facilitating longitudinal movements of the power unit in the engine niche;

- protection against premature destruction of exhaust system components.

The cost of replacing a muffler corrugation directly depends on the make of the car and design features. For a four-cylinder engine with in-line pistons, 1 corrugation will be required, and for a V-twin engine with 6 cylinders - 2.

Types of corrugation

The design of couplings is determined by the requirements placed on them. The corrugation should be:

- stainless;

- withstands high temperatures of exhaust gases;

- flexible, yet durable;

- sealed.

The manufacturing process uses stainless wire weaving technology and the use of elastic molded plates.

Double braid

The simplest corrugation is made of two layers, woven in a special way. The tightly packed wire allows gases to be retained, although it is difficult to talk about complete tightness.

On the subject: Why water drips from a car muffler

But such couplings are very inexpensive and they are the most flexible and absorb vibration loads well. But they do not last long, needing frequent replacement due to the rupture of the thin wire structure.

Triple braid

All high-quality corrugations have three or more layers. Among them can be either wicker or in the form of a metal sleeve. Couplings with sleeves have the trade name Interlock or Hydra, and those simply having a multi-layer weave are called Innerbraid.

The latter type is easy to identify by looking inside the pipe. There, instead of wicker, you can see sheet stainless steel, molded in various ways to give flexibility.

Multilayer corrugations are more expensive and have less flexibility, which does not prevent them from working normally, since the exhaust system fasteners are designed for this.

You just need to keep in mind that some repair inserts are limited in the nature of the mutual movement of the flanges, for example, torsion. This must be taken into account when selecting spare parts for repairs.

Consequences of corrugation damage

If the corrugation is damaged, gases will begin to leak before they enter the catalyst and resonator, that is, completely unpurified substances will enter the air. Atmospheric pollution increases many times over; if you stay nearby for a long time, you can feel a deterioration in your health.

The bigger problem is the penetration of gases into the car interior; no one would want to drive such a car. The corrugation is located slightly below the engine with an indent towards the center of the car. There are air intake ducts located near the unit, through which gases will likely enter the cabin. Poisoning is unlikely to occur, but comfort will be significantly reduced. If the failure occurs on the road, it is recommended to perform a temporary repair of the muffler corrugation at the nearest station, which will require welding.

Corrugation damage

Why do you need corrugation?

When the engine operates, vibration occurs in the exhaust system, which over time leads to the destruction of this system. The corrugation plays the role of a fuse , which absorbs all the vibrations that arise and prolongs the life of the car’s exhaust system. Therefore, it is the corrugation that fails first, replacing which will cost several times less than repairing the entire system.

Functions of the muffler corrugation

The elastic element of the exhaust system also allows the engine to move within a small range (in the longitudinal plane). Thanks to this, there is less pressure on other parts of the body, which is very important for the entire structure.

Why do you need a muffler corrugation?

What reasons?

There are few reasons why it is necessary to replace the muffler corrugation without welding: natural wear of the material, the passage of gases or mechanical damage. The following reasons can lead to such conditions:

- catalyst damage. If it becomes clogged, thermoregulation disturbances will occur, and during overheating, increased pressure is created in the corrugation;

- significant wear of the shock absorber pads on the power unit. The fasteners of the muffler itself are not able to provide sufficient movement of the unit;

- deformations due to impacts on the surface;

- incorrect installation of the device;

- the destructive effects of chemicals that are sprinkled on roads in winter;

- use of additives to increase the octane number in gasoline.

Replacing the muffler corrugation with your own hands will be required after preliminary diagnosis of the condition of the unit. Initially, failure is determined by the presence of noise during movement. If the element is completely destroyed, there is a risk of a strong deafening sound. Indirect evidence that the corrugated connection needs to be replaced is the presence of a characteristic odor from gases inside the cabin.

If you have enough driving experience, you can determine the malfunction by a significant decrease in the car’s power. The greatest reduction is observed in modern vehicles. The reason for the drop in performance is a malfunction of the oxygen sensor, which is included in the exhaust system.

In each case, you will need to replace the muffler corrugation with your own hands without welding or with it, this will help prevent further damage.

Do-it-yourself muffler corrugation replacement

What it is

The corrugation, or, as it is also called, a vibration compensator, is a key element of a car exhaust system, installed on almost all modern models. The purpose of the corrugation is to protect the exhaust system from resulting vibration. Externally, the part looks like an elastic tube made of metal. The vibration compensator acts as an intermediary between the exhaust pipe of the muffler and the exhaust pipe.

What is a muffler corrugation

Note! The corrugation consists of a multilayer metal mesh, thanks to which the part is quite flexible.

Exhaust system corrugation

The disadvantage of the corrugation is its location. The fact is that the compensator is located at the bottom of the car, so when hitting any obstacle there is a high risk of damage to the part. In such cases, the element must be replaced.

Choosing the right corrugation

The muffler corrugation is often replaced and sold at a service station, but you can buy the component at a car dealership. If the owner has the time or desire to carry out repairs on his own, he should initially purchase corrugation. The part is not unified; it is developed individually for most cars. The differences are the dimensions. Before going for the unit, you will need to clarify the size of the element; it is better to find out experimentally - from the pit. Before replacement, it is worth restoring the corrugation and doing the work within the next few days.

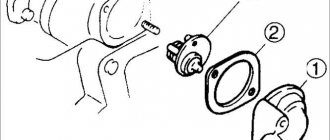

When taking measurements, it should be taken into account that you will have to cut the corrugation somewhat further than the weld on which it is fixed. New elements are sold with a slightly reduced diameter for stronger fixation and easier scalding. The corrugation is inserted 3 cm into the pipe, this facilitates repeated replacement of the element on the car without structural changes.

After measuring the length, the diameter is measured. Accurate numbers can only be obtained with a caliper. With known parameters, go to the store or market.

Advantages of SVS Exhaust car service

Our car service has a wide range of corrugations for various brands of cars, so we can choose for you the optimal part option that guarantees long-term operation of the vehicle. Among the main advantages of the car service it is worth noting:

- We have been working in the market for more than 10 years;

- Experienced craftsmen and professional equipment;

- Reliable materials, high-quality spare parts;

- Individual form of work;

- Free diagnostics and affordable prices;

- 3 year quality guarantee for all types of services.

Spare part price

The cost directly depends on the size, model of the car and corrugation parameters. For many low-price cars, the price will be 200–400 rubles. The cost of a unit for more expensive cars reaches 1200, and sometimes exceeds 1500 rubles. During the purchasing process, you should buy 2 gaskets; they are useful for connecting the flange parts to the corrugation. When dismantling the old structure, it is impossible to maintain sufficient quality of the old gaskets; it is better to replace them.

Muffler corrugations

Malfunctions that require changing the corrugation

These include the following:

- Crack in the accordion. It may not be visible behind the braid. The problem is indicated by a characteristic cutting sound and the appearance of exhaust gases in the area of the elastic connection.

- The muffler corrugation burned out. The symptoms are the same, only the sound will be louder, and there will be a noticeable stain from the exhaust gases on the outer braid. Such a malfunction is especially dangerous, since pieces of corrugation can get into the catalyst or resonator, which will lead to additional breakdowns.

- The muffler corrugation was torn. Complete element failure. The malfunction is noticeable to the naked eye - the exhaust system pipes are displaced, the protective braid is skewed. The exhaust sound is sharp and loud.

Reasons for corrugation failure:

- Use of fuel additives.

- Worn engine mounts.

- Clogged catalyst.

- Mechanical contact with the ground.

Replacing corrugations with your own hands

Previously, corrugation was a hard-to-find element that was sold separately only for foreign cars; today the market offers spare parts for all types of cars and manufacturers. More often, installation is carried out by specialists using a professional welding machine and other tools. The difficulty lies in the need to determine and select the temperature regime.

If the hand is “stuffed” and the person knows how to work with a power tool, the replacement is carried out in several stages:

- Dismantling. Using a grinder, the worn corrugation is cut off.

- Installation. Installation of a new part.

- Cleaning seams.

Incorrect installation will only temporarily help get rid of problems; the service life of the corrugation will be significantly reduced. It is preferable to leave the operation to specialists, but the task can also be done manually.

Preparation

There are a number of recommendations for quality preparation:

- The work will be somewhat easier if you completely dismantle the muffler pipe with corrugation;

- “grinder” cut off the knot at the weld or near it;

- Trying on the part will help identify possible difficulties in installation and determine that the part really fits. A preliminary assessment will prevent distortions in the structure and protect the spare part from excessive load and premature failure. There is no need to install a corrugated connection at the fitting stage;

- After selecting the location, the parts are grabbed at several points to the inlet pipe. Now the whole pipe is removed.

Replacing corrugations with your own hands

Welding

If there is a semi-automatic welding device, there is no need for a service station at all. When there is no equipment, an inverter type is suitable; 1.6–2 mm electrodes are installed in it.

Basic advice from professionals on stages:

- Before work is carried out, the pipe, especially the seam area, is thoroughly cleaned.

- Welding is carried out with a minimum current. The value is selected taking into account the electrode. During operation, the slag is removed.

- Once completed, the welded areas are treated with a protective coating or sealant to prevent corrosion.

The manufacturer does not provide for the use of a standard welding device during the procedure, and given the thinness of the sheet, there is a high risk of burning through the metal. It is recommended to practice in advance on a metal sheet of this thickness. Often a tin can is used as a test; it makes it easy to determine the tightness of the created seam. If the test result is positive, you should start working. Otherwise, it is better to continue training until a high-quality seam is created.

Replacing corrugations using welding

Despite the complexity of working with an inverter device, the task is feasible, but it will require skills. At the end of the work, the pipe is put back in place, and the flanges are changed during the installation process.

No welding

An attractive option for owners is to repair the muffler corrugation with your own hands without welding. It is not always an appropriate installation option, but sometimes it is recommended to eliminate welding. An effective and reliable method without the use of welding has become widespread among the people - the method of creating threads.

The process is carried out in steps:

- The cut is made using a grinder.

- A new corrugation is installed in place of the old unit.

- In the place of the rings and pipes, holes with a diameter of up to 6 mm are drilled. The number of bolts is 6–8 pieces for a standard car, depending on the diameter of the pipe.

- Using a tap, apply the thread.

- All collapsible parts are covered with sealant: bolts and joints between the corrugation and the pipe.

- Install corrugation.

The connection is quite reliable and completely sealed.

Temporary repairs

There is an old method to temporarily repair corrugation using a bandage. To defer for 1 month, you will need a thick elastic bandage. The work is carried out from the pit, since it will be necessary to heat the epoxy resin and treat the element with it. The damaged area is covered with a bandage, and resin is poured over the bandage.

This procedure will last for 1 month or less, then even greater damage will appear. It is preferable to replace the corrugation within a few days or weeks.

Welding corrugations into a car muffler

The most labor-intensive and reliable process of replacing the vibration compensator of the exhaust system.

Let us immediately note that only professionals are allowed to carry out welding work, so we do not recommend taking on such a complex task on your own. But if you have the proper experience and want to learn the nuances of the process, then our video will be very useful for you. From the video you will learn what mistake should never be made, how to install the corrugation correctly and which products are more reliable.