Renault Logan muffler system

Exhaust system

: 1 — exhaust manifold; 2 — pressure plate for fastening the exhaust pipe to the exhaust manifold; 3 — exhaust gas catalytic converter; 4 - damper; 5 — additional muffler; 6 — main muffler; 7 — system suspension bracket

The exhaust system consists of an exhaust manifold, a exhaust pipe with a catalytic converter, additional and main mufflers and pipes connecting them. All elements of the system, except the exhaust manifold, are welded into a single unit. The exhaust manifold flange is connected by a ball joint to the exhaust pipe flange. A rubber-metal damper is attached to the pipe connecting the catalytic converter and the additional muffler to dampen resonant vibrations of the exhaust system. The exhaust system is suspended from the body on three rubber cushions. Heat shields are installed above the converter, additional and main mufflers and near the fuel tank. A metal gasket is installed between the exhaust manifold and the cylinder head. To seal the hinge joint of the exhaust manifold and the exhaust pipe, a ring made of composite material with a spherical outer surface is placed on the exhaust manifold flange, and an internal spherical surface is made in the exhaust pipe flange. The flange connection is tightened by a pressure plate through two conical springs placed on the exhaust manifold studs. The springs are tightened with nuts screwed onto the studs.

Location of the exhaust system on a Renault Logan car (power unit protection removed for clarity)

:

1 — rubber suspension cushion of the exhaust system; 2 - heat shield

The exhaust manifold is covered with a heat shield...

... and is secured with seven nuts to the cylinder head studs (the heat shield has been removed for clarity)

Connection of the exhaust pipe to the exhaust manifold

: 1 - spring; 2 — pressure plate; 3 - nut

Exhaust manifold with oxygen concentration sensor

: 1 — sealing ring connecting the manifold to the exhaust pipe; 2 — oxygen concentration sensor; 3 — exhaust manifold; 4 — sealing gasket connecting the manifold and cylinder head; 5 — exhaust manifold screen

An oxygen concentration sensor in the exhaust gases (lambda probe) is installed in the lower part of the exhaust manifold. The catalytic converter is designed to reduce emissions of carbon monoxide, nitrogen oxides and unburned hydrocarbons. For normal operation of the converter, the composition of the exhaust gases (in particular, the oxygen content in them) must be within strictly specified limits. This function is performed by the electronic engine control unit (ECU), which determines the amount of fuel supplied depending on the signals from the oxygen concentration sensor. If there are lead compounds in the exhaust gases, the catalytic converter and oxygen concentration sensor quickly fail. Therefore, operating a car on leaded gasoline is strictly prohibited, even for a short time. Also, the cause of failure of the converter may be a faulty ignition system or power supply system. If there is a misfire, unburned fuel enters the converter, burns out and sinteres the catalyst block in it, which can lead to clogging of the exhaust system and engine shutdown (or severe loss of power).

Location of marks on the pipe between the neutralizer and the additional muffler

Location of marks on the pipe between the additional and main mufflers

Connect the pipes of the new unit with the pipes of the exhaust system with a special clamp

Mufflers and catalytic converter are non-separable units; if they fail, they must be replaced with new ones. Spare parts include a neutralizer with a reception pipe, additional and main mufflers with pipes of a certain length, as well as special clamps for connecting pipes. To replace a separate element of an integral system, marks (cores) are applied in two places on its pipes, along which the pipes can be cut. Maintenance of the exhaust system consists of periodically inspecting it, checking for tightness of connections and the presence of through corrosion, including tightening loose connections and replacing rubber suspension cushions.

Source

Renault Logan muffler: purpose and principle of operation

Another key element of the exhaust system is the muffler. Already from the name you can understand that the device is designed to reduce noise levels, as well as convert exhaust energy. Structurally, the unit consists of 2 units, including the main muffler and the resonator (installed at the inlet). The noise level in the device is reduced due to multiple refraction of the exhaust gas sound flow with its subsequent absorption.

- Reducing the volume of pollutants. Here the catalyst works to a greater extent, but the filter elements of the muffler partially take on this option.

- Converting the energy of spent exhaust gases, reducing their temperature, reducing pulsations.

- Reducing noise levels. Thanks to the special design of the device, extraneous sounds are eliminated almost silently. Renault Logan car owners often complain about the loud operation of the muffler. If there is such a problem, we can talk about a malfunction of the exhaust system and the need for its repair.

The considered functions must be implemented in such a way that the Renault engine, if it loses power, does so only slightly.

The design of the muffler deserves special attention. There is an opinion that this is a simple knot in which there are no complex elements. This is wrong. The muffler is the most complex device in the exhaust system. There are two such units in a Renault Logan car:

- Auxiliary muffler (resonator) - designed to initially reduce noise and pulsation. Structurally, this is a tube with a large number of holes (perforation) and placed in another metal casing.

- The main silencer guarantees ultimate noise suppression. Unlike the preliminary unit, its design is more complex. Thus, a metal casing contains a group of tubes with holes, and the casing itself is conventionally divided into several chambers. Some of them are filled with special material that absorbs sounds. Noise suppression inside the device occurs due to multiple refraction of sounds.

Lately, more and more car owners are deciding to tune this unit and install direct-flow mufflers. The advantage of the latter is a “sporty” sound and a slight increase in power.

To ensure proper operation of the muffler, special attention should be paid to its configuration. As a rule, this work is entrusted to professionals at the service station.

When setting up yourself, the principle is as follows:

- All elements that cause gas to flow in the opposite direction are removed. If this work is not done, there is a high risk of the appearance of resonant frequencies with subsequent scattering of waves. As a result, the design of the exhaust pipe is made as straight as possible. If this task is not achieved, the distribution of gases will be uneven.

- The joints are treated with heat-insulating materials. To organize such thermal insulation, special materials are used.

- All joints are made flexible, which ensures resistance to the environment. If this is not done, there is a high risk of damage (deformation).

- During the diagnostic process, a special technique is used to measure the rotational torque of the crankshaft, as well as engine speed.

Renault Logan “Rouge LogRen” › Logbook › Replacing the muffler for Renault Logan

It happened on May 27, 2021, on the way to Voronezh on the M4 highway after racing on toll highways... Leaving the gas station, I suddenly heard that the voice of my car had become somehow bassy and hoarse, and when I got onto the highway, I felt some loss power. At first I thought that the gasoline I filled was bad...) Upon arrival in Voronezh, I, of course, became concerned about the problem. But an inspection showed that our long-corroded muffler had burned through holes, because the time had come. I’m not offended by Ruzhik, but I’m proud of him for not letting me down, but only giving a signal, speaking in a deep voice, that we must have a conscience and it’s time to change the muffler. On the advice of a friend, we went to the ShinPost car service center,

where, by the way, they are engaged in multi-brand, but they helped us to the fullest and really helped out the indigenous guests of the city.))) Thanks to them! They explained that it was useless to repair our muffler, that it was not the entire muffler that needed to be replaced, but only two parts that had become unusable - the middle and rear (the resonator and the muffler itself). But the exhaust pipe with the catalyst is still similar, since it has thicker walls. For your information, from the Logan factory the muffler comes in one piece - not dismountable, but on sale for replacement it is easier to find it in parts that are docked, inserted into one another, and secured with clamps. This is advisable, since in any case they do not last as long as the factory ones, and in the future these parts will be easier to change. While preparing for the renovation, I studied the following topic:

Renault Logan exhaust system

The Renault Logan exhaust system is a structural element of a car, consisting of a whole group of components. The general purpose of the device is to remove exhaust gases from the engine, reduce exhaust gas toxicity and protect against their penetration into the cabin. Beginners often think that only the muffler is part of the exhaust system. In practice, this includes a whole group of elements, each of which carries an individual functional load. What are the design features? What elements are included in the exhaust system, and what functions do they perform?

Why is an exhaust system needed?

Every driver knows that the exhaust system is an indispensable element of any car.

Therefore, they all pay a sufficient amount of attention to it, because it performs several important functions, without which the car would never be able to work properly:

- A muffler is necessary to reduce the content of pollutants in the exhaust gases. They can accumulate on pipe walls. The principle of this accumulation is reminiscent of the formation of scale in a kettle. And when it becomes too much, it stops working. The same thing happens with a car;

- Exhaust gases are removed through the muffler almost silently. Many people complain that the muffler is too loud. If this is the case, then the exhaust system in Renault Logan is faulty, so it needs to be repaired;

- The above functions are performed quite quickly, but the Renault Logan engine does not lose its power at all.

Design features

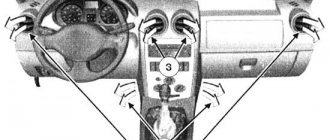

Fundamentally, the Renault Logan exhaust system is no different from the devices installed on other cars. At the outlet of the engine there is an exhaust manifold (1), from which a reception pipe extends, fixed with a pressure plate (2). A catalytic converter (3) is installed on the receiving pipe to clean the exhaust gas from harmful elements. The system is fixed using a group of brackets (7), thanks to which the entire group of devices is held on the bottom of the vehicle.

After the catalyst, a special damper (4) is mounted, which is based on metal and rubber. The first muffler (called additional) (5) is mounted in the immediate vicinity of it, and at the outlet the main muffler performs the main work.

The outer part of the front exhaust pipe has a ball joint, which ensures the mobility of the device. The very junction of the receiving tube and the exhaust manifold contains three elements - a spring (it is this that provides damping properties), a pressure plate and a nut holding the springs.

The rest of the Renault Logan car system, consisting of pipes and mufflers, is integral. If necessary, it can be replaced with individual elements. To solve the problem, the tube is cut in the right place after preliminary installation of marks. The latter are made in the form of dents, so it will be difficult not to notice them.

If elements are replaced, they are combined using special fasteners (clamps). Finding such devices on sale is not difficult. In this case, the entire exhaust system is fixed to the bottom at 3 points using special rubber “cushions”.

All system components are mounted in a horizontal plane. An invariable element of the mechanism are screens that filter out heat (installed in the area of the fuel tank). If you dismantle the thermal protection screen, you can see that a collector is installed under it.

Two more components of the system (catalyst and neutralizer) are installed in the complex and are also changed together. Finding original parts for Renault Logan is not a problem today.

Exhaust system Renault Logan 2004-2015

- Repair manuals

- Renault Logan 2004-2015

- Exhaust system

Design features

Replacing exhaust system suspension cushions

Replacing exhaust elements

Design features For Renault Logan cars, the manufacturer installs an exhaust gas system made of a single element, and supplies its individual parts as spare parts. Between the catalytic converter and the additional muffler......as well as between the additional and main mufflers...

Replacing exhaust system suspension cushions Rubber exhaust system suspension cushions are replaced if, due to their damage or excessive deformation, system elements begin to knock, coming into contact with the body or other components of the car. All cushions are changed using the same techniques, so the replacement process ...

Replacing exhaust elements To replace the exhaust pipe and catalytic converter you will need: a 10mm socket, an extension, a caliper, an angle grinder with a cutting wheel for metal. 1. Measure the distance between the marks (it should be 80 mm). NOTE The marks are located...

↓ Comments ↓

Section 1. Vehicle design

General information about the vehicle Vehicle registration data Vehicle keys Controls Heating (air conditioning) and interior ventilation Doors Seat belts Seats Rear view mirrors Interior lighting Hood Gearbox control lever

Section 2. Recommendations for use

Safety rules and recommendations What you need to have in your car Running in the car Operating the car during the warranty period Preparing the car for departure

Section 3. Problems along the way

The engine will not start Malfunction of the fuel injection system Idle has disappeared Interruptions in the engine The vehicle moves jerkily The vehicle does not accelerate well The engine stalls while driving The oil pressure has dropped The engine is overheating The battery is not recharging The engine is started from external power sources Faulty electrical equipment Extraneous knocking noises Problems with the brakes Punctured wheel

Section 4. Maintenance

General provisions Daily maintenance (EO) First maintenance (MOT-1) Second maintenance (MOT-2)

Section 5. Engine

Design features Removing and installing mudguards and engine crankcase protection Replacing the suspension mounts of the power unit Installing the piston of the first cylinder to the TDC position of the compression stroke Replacing and adjusting the belt tension, replacing the tension roller of the gas distribution mechanism drive Adjusting the clearances in the valve drive Removing, installing and troubleshooting the flywheel Replacement engine seal parts Cylinder head Removal and installation of the engine Engine lubrication system Engine cooling system Exhaust system Power supply system

Section 6. Transmission

Clutch Gearbox Front wheel drives

Section 7. Chassis

Front suspension Rear suspension Checking and adjusting wheel alignment angles

Section 8. Steering

Design features Possible malfunctions of steering without hydraulic booster, their causes and methods of elimination Possible malfunctions of steering with hydraulic booster, their causes and methods of elimination Steering column Steering rods Steering mechanism

Section 9. Brake system

Features of the device Possible malfunctions of the brake system, their causes and solutions Bleeding the hydraulic drive of the brake system Checking and adjusting the brake pedal Master brake cylinder Vacuum brake booster Brake force regulator in the hydraulic drive of the rear brakes Replacing hoses and pipelines of the hydraulic brake drive Brake mechanisms of the front wheels Brake mechanisms of the rear wheels Parking brake

Section 10. Electrical equipment

Design features Diagnostics of malfunctions of on-board electrical equipment Mounting blocks Battery Generator Starter Ignition switch (lock) Engine control system Lighting, light and sound alarm Windshield wiper Removal and installation of the windshield washer Removal and installation of the electric motor of the radiator fan of the engine cooling system Electric heating of the rear window Removal and installation cigarette lighter socket Instrument cluster Immobilizer Instrument panel switches Car audio system Replacement of sensors and switches

Section 11. Body

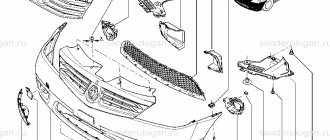

Design features Possible body malfunctions, their causes and solutions Removal and installation of bumpers Removal and installation of radiator lining Removal and installation of wheel mudguards and fender liners Removal and installation of the front wing Hood Removal and installation of the air intake box grille Doors Trunk lid Removal and installation of the fuel filler hatch cover tank Seats Removal and installation of floor tunnel lining Passive safety system (SRS) Rear view mirrors Instrument panel Heater and air conditioner Interior fittings Removal and installation of interior linings Removal and installation of trunk lining Replacement of fixed body glazing Body care

Section 12. Wheels and tires

Technical characteristics Marking of rims Marking of tires Replacing wheels Tire break-in Tire storage Wheel balancing Snow chains Spare wheel Checking tire pressure Checking tire profile Checking valve Checking radial and lateral runout of rims

Section 13. Purchase of spare parts

Engine oil Lubricants Coolants Brake fluid Fuel filter Air filter Engine oil filter Spark plugs

Section 14. A trip to the service station

Section 15. Winter operation of the vehicle

How to prepare a car for winter Recommendations for starting the engine in severe frost What is useful to buy for winter Useful winter tips

Section 16. Preparation for technical inspection

Recommendations List of malfunctions and conditions under which the operation of vehicles is prohibited Changes to state standards regulating the maximum permissible content of harmful substances in the exhaust gases of motor vehicles

Section 17. Tips for a novice auto mechanic

Safety precautions when carrying out repair work Tools Before starting work Restoring threaded connections Tips for body repair

Applications

Appendix 1. Tightening torques of critical threaded connections, N m Appendix 2. Lamps used on a car Appendix 3. Spark plugs used on a car Appendix 4. Air pressure in tires

Electrical circuit diagrams

Diagram 1. Battery charging circuit: 1 – starter; 2 – generator; 3 – electrical wiring connector for the engine compartment/interior (monoblock); 4 – instrument cluster Diagram 2. Fuel pump and fuel level sensor: 1 – instrument cluster; 2 – electrical wiring connector for the engine compartment/interior (monoblock); 3 – electrical wiring connector for the instrument panel/left rear part of the body; 4 – fuel pump and fuel level sensor; 5 Diagram 3. Engine control system: 1 – 597V fuse box in the engine compartment (see Fig. 10.2a and 10.2b); 2 – relay block 784 in the engine compartment, relay 700 (see Fig. 10.2a and 10.2b); 3 – injector of the 1st cylinder; 4 – fuse box in the passenger compartment (see fig. 4. Engine starting system: 1 – battery; 2 – starter; 3 – engine compartment/cabinet electrical wiring connector (monoblock); 4 – ignition switch (lock) Diagram 5. Turn indicators and alarm system: 1 – interior switching unit; 2 – electrical wiring connector for the instrument panel/left rear part of the body; 3 – right rear light; 4 – right front turn signal; 5 – right indicator repeater Diagram 6. Side light: 1 – fuse box in the cabin (see Fig. 10.1); 2 – electrical wiring connector for the instrument panel/left rear part of the body; 3 – side light of the left headlight; 4 – left rear lamp; 5 – license plate lamp; 6 – Diagram 7. High beam : 1 – fuse box 597A in the engine compartment (see Fig. 10.2a and 10.2b); 2 – switch lever for external lighting and direction indicators with a button for turning on the sound signal; 3 – fuse box in the passenger compartment (see Fig. 10.1); 4 Diagram 8. Electrically heated rear window: 1 – fuse box in the passenger compartment (see. rice. 10.1); 2 – instrument cluster; 3 – electric heating of the rear window; 4 – electrical wiring connector for the instrument panel/left rear part of the body; 5 – electric heating switch for Scheme 9. Electric fan of the heating and ventilation system of the cabin: 1 – fuse box in the cabin (see Fig. 10.1); 2 – relay 233 (see Fig. 10.2a and 10.2b); 3 – wiring connector for the electric fan of the cooling system/instrument panel; 4 – electric fan Diagram 10. Front fog lights: 1 – instrument cluster; 2 – switch lever for external lighting and direction indicators with a button for turning on the sound signal; 3 – fuse box in the passenger compartment (see Fig. 10.1); 4 – relay block 299 in the engine compartment Diagram 11. Electric mirror drive: 1 – fuse block in the passenger compartment (see Fig. 10.1); 2 – control unit for external rear view mirrors; 3 – electric drive of the left outside rear view mirror with heating; 4 – electric drive of the right outside rear mirror Diagram 12. Low beam: 1 – fuse block 597A in the engine compartment (see Fig. 10.2a and 10.2b); 2 – switch lever for external lighting and direction indicators with a button for turning on the sound signal; 3 – fuse box in the passenger compartment (see Fig. 10.1); 4 Diagram 13. Front door power windows: 1 – front passenger door power window switch; 2 – electric motor for window lift of the front passenger door; 3 – driver’s door window lift motor; 4 – block before Scheme 14. Electric fan of the heating (air conditioning) system and interior ventilation: 1 – fuse box in the passenger compartment (see Fig. 10.1); 2 – relay 233 (see Fig. 10.2a and 10.2b); 3 – electrical wiring connector for the engine compartment/interior (monoblock); 4 – electric fan Diagram 15. Sound signal: 1 – lever of the switch for external lighting and direction indicators with a button for turning on the sound signal; 2 – fuse box in the passenger compartment (see Fig. 10.1); 3 – sound signal; 4 – fuse block 597A in the engine compartment (see Diagram 16. Central locking system: 1 – interior switching unit; 2 – electrical wiring connector for the instrument panel/left rear part of the body; 3 – electric drive for the right rear door lock; 4 – electric drive for the left rear door lock doors; 5 – electric drive Diagram 17. ABS control system: 1 – fuse box in the passenger compartment (see Fig. 10.1); 2 – fuse box 597C in the engine compartment (see Fig. 10.2a and 10.2b); 3 – ABS ECU ; 4 – electrical wiring connector for the instrument panel/left rear part of the body; 5 – speed sensor Diagram 18. Windshield wiper and washer, headlight washer: 1 – windshield washer pump; 2 – instrument cluster; 3 – interior switching unit; 4 – electric motor windshield wiper; 5 – wiper and washer switch lever Diagram 19. Interior lamp: 1 – interior switching unit; 2 – electrical wiring connector for the instrument panel/left rear part of the body; 3 – interior lamp; 4 – driver’s door limit switch; 5 – limit switch of the right front door; Diagram 20. Connecting the speakers of the acoustic system: 1 – car radio; 2 – electrical wiring connector for the engine compartment/interior (monoblock); 3 – fuse box in the passenger compartment (see Fig. 10.1); 4 – cigarette lighter; 5 – vehicle speed sensor; 6 – right front Diagram 21. Rear fog lamp: 1 – fuse block 597A in the engine compartment (see Fig. 10.2a and 10.2b); 2 – switch lever for external lighting and direction indicators with a button for turning on the sound signal; 3 – fuse box in the passenger compartment (

Exhaust manifold for Renault Logan

As already noted, each of the components of the exhaust exhaust system has specific tasks. One of the most important components is the exhaust manifold - a device that ensures exhaust gas removal from the engine with subsequent purging of the engine cylinders. Not only the efficiency of gas removal, but also the power of the power unit, as well as its torque, largely depends on the design of the device. In this case, the oscillatory processes during exhaust gas exhaust must be coordinated with similar processes of supplying the combustible mixture to the intake system.

Due to the installation features, the intake manifold is forced to withstand elevated temperatures. That is why cast iron with a high level of heat resistance is used in the manufacture of the assembly.

Renault Logan muffler: purpose and principle of operation

Another key element of the exhaust system is the muffler. Already from the name you can understand that the device is designed to reduce noise levels, as well as convert exhaust energy. Structurally, the unit consists of 2 units, including the main muffler and the resonator (installed at the inlet). The noise level in the device is reduced due to multiple refraction of the exhaust gas sound flow with its subsequent absorption.

- Reducing the volume of pollutants. Here the catalyst works to a greater extent, but the filter elements of the muffler partially take on this option.

- Converting the energy of spent exhaust gases, reducing their temperature, reducing pulsations.

- Reducing noise levels. Thanks to the special design of the device, extraneous sounds are eliminated almost silently. Renault Logan car owners often complain about the loud operation of the muffler. If there is such a problem, we can talk about a malfunction of the exhaust system and the need for its repair.

The considered functions must be implemented in such a way that the Renault engine, if it loses power, does so only slightly.

The design of the muffler deserves special attention. There is an opinion that this is a simple knot in which there are no complex elements. This is wrong. The muffler is the most complex device in the exhaust system. There are two such units in a Renault Logan car:

- Auxiliary muffler (resonator) - designed to initially reduce noise and pulsation. Structurally, this is a tube with a large number of holes (perforation) and placed in another metal casing.

- The main silencer guarantees ultimate noise suppression. Unlike the preliminary unit, its design is more complex. Thus, a metal casing contains a group of tubes with holes, and the casing itself is conventionally divided into several chambers. Some of them are filled with special material that absorbs sounds. Noise suppression inside the device occurs due to multiple refraction of sounds.

Lately, more and more car owners are deciding to tune this unit and install direct-flow mufflers. The advantage of the latter is a “sporty” sound and a slight increase in power.

To ensure proper operation of the muffler, special attention should be paid to its configuration. As a rule, this work is entrusted to professionals at the service station.

When setting up yourself, the principle is as follows:

- All elements that cause gas to flow in the opposite direction are removed. If this work is not done, there is a high risk of the appearance of resonant frequencies with subsequent scattering of waves. As a result, the design of the exhaust pipe is made as straight as possible. If this task is not achieved, the distribution of gases will be uneven.

- The joints are treated with heat-insulating materials. To organize such thermal insulation, special materials are used.

- All joints are made flexible, which ensures resistance to the environment. If this is not done, there is a high risk of damage (deformation).

- During the diagnostic process, a special technique is used to measure the rotational torque of the crankshaft, as well as engine speed.

Experienced car enthusiasts know that by upgrading the muffler you can increase the power of the power unit. This parameter depends on two components - torque and crankshaft rotation speed. The calculation is made by multiplying these components together. The shaft rotation speed depends on the filling speed of the cylinder. If you close the outlet from the muffler, the pressure in the system will not decrease, and the release of gases will become impossible. As a result, the pressure in the system increases, and the cylinder stops being cleaned. The result is engine malfunctions.

The Renault exhaust system is designed in such a way that the volume of exhaust gas is combined with the total volume of the working mixture that enters here. Thanks to this, the exhaust system works with the greatest efficiency. To increase the power level, it is possible to tune the exhaust system and install a direct-flow muffler, which was mentioned above.

If it is necessary to replace the device, then the choice can be made taking into account the information in the table.

Catalyst Renault Logan: purpose, operating principle

The catalyst is an integral part of modern cars, ensuring a reduction in the concentration of environmentally hazardous elements in the exhaust gas. The Renault Logan catalytic converter is a 3-component one, which provides protection against several harmful substances, namely nitrogen and carbon oxides, as well as unburned hydrocarbons.

Externally, the device is somewhat similar to a muffler, but the principle of operation and tasks of the mentioned units are different. When the engine is not warmed up, the temperature of the catalytic converter and the environment are identical. As soon as the temperature reaches a certain limit, the device is activated. As a rule, the system enters operating mode within 1-2 minutes after the power unit is started. The hot exhaust coming out of the engine warms up the catalyst, which removes 50-80% of harmful substances in the exhaust gas.

Structurally, the catalytic converter consists of a group of elements, namely:

The principle of operation of the catalyst is designed to effectively remove hazardous elements from exhaust gases (they were mentioned above). After heating the converter, chemical reduction and oxidation reactions occur. This is possible due to the special porous structure of the device’s channels, as well as the precious metals contained in it. During the oxidation process, unsaturated hydrocarbons are “afterburned” with the subsequent formation of two elements - water and carbon dioxide.

As for the reduction process, it aims to reduce nitric oxide, releasing steam and pure nitrogen.

The catalyst operates normally after reaching a temperature of 300 degrees Celsius, and the optimal temperature regime (during normal operation) is 900 degrees Celsius. In this case, the activity of chemical processes directly depends on the mentioned parameter.

An equally important indicator for the catalyst is mileage. As soon as Renault Logan travels 16 thousand kilometers, the catalytic converter begins to work at its maximum capacity. It has already been proven that when such a mileage is reached, the catalyst provides better cleaning of exhaust gases from harmful elements.

What is exhaust?

If your power unit and adjacent systems are in good working order and operating normally, then the exhaust is nothing more than a combination of water vapor, nitrogen and carbon dioxide. They are practically colorless; when a working unit is operating, an invisible stream of these gases flows from the pipe; a catalyst , which removes various gases at the outlet of the exhaust manifold.

But why does white smoke sometimes come out of the muffler? Does this occur especially in the mornings in cold weather? It's not always a malfunction, it's simple physics.

How to determine whether a muffler is faulty on a Renault Logan

The structure of the exhaust system on Renault Logan cars is exactly the same as on any other economy class vehicles. All components of the system are designed to remove exhaust gases from the exhaust manifold and reduce their noise during the removal process.

In this case, the muffler quickly undergoes corrosion and depressurization, because it is precisely this that bears the main impact of the pulsation of gases and hot flows. The driver must be able to determine the performance of the jammer, since the safety of driving the car depends on this. It is very easy to determine whether a muffler is faulty - even a person who just got behind the wheel of a car yesterday can cope with this task.

The tube is designed to remove all exhaust gases outside the body

Procedure for diagnosing faults

First of all, it is recommended to drive the Renault Logan onto an inspection hole or overpass, or use a lift. Of course, if you have neither one nor the other, you can simply put the car on a jack. The main thing is to ensure your convenience and safety when inspecting the muffler:

When inspecting pipes, special attention must be paid to the condition of the resonator and the main muffler, since they are subject to wear more than other parts

If there is no visible damage to the pipes, then the muffler is in working condition. The first signs of a malfunction that the driver should pay attention to are a loud roar from the exhaust system and unpleasant odors in the cabin. Exhaust gases are colorless and odorless, but due to depressurization of the muffler they acquire a specific aroma that can be felt by humans.

Setting up the muffler

In Renault Logan, repair processes should be carried out by professionals, since at home you can damage the car. Of course, you can do something with your own hands, but this is not advisable.

One way or another, let's look at how the exhaust system is configured:

Any reflective elements that will cause gas to flow in the opposite direction should be removed. If this is not done, resonant frequencies may appear that dissipate the energy of the shock waves

Therefore, it is very important that the exhaust pipes are as straight as possible. Otherwise, the exhaust gases will be distributed unevenly; It is important that the pipes at the joints are thermally insulated

They can be insulated using special insulating materials; All connections must be flexible so that the pipes are resistant to the environment. If this is not ensured, they will constantly break down; When diagnosing a Renault Logan, you should use a special technique that can measure the crankshaft torque and engine speed.

Repair of Glushak on Logan

Before repairing, you need to make sure that it is advisable. Sometimes drivers try to save completely rotten mufflers, when welding large areas of burnout or corrosion is not able to restore the functionality of the pipe.

Repairing the bracket

Most often, due to driving on uneven roads, the bracket - the muffler mount - fails . The pipe loses its position under the bottom and begins to knock on the body. Accordingly, the bracket needs to be welded back. In this case, it is necessary to maintain the same dimensions and welding locations as before, because the performance of the muffler will depend on how correctly the bracket is welded.

However, not all drivers have experience working with a welding machine. Therefore, in garage conditions it is easier to repair the bracket in another way. Regardless of whether the fastening has completely fallen off or any of its elements have fallen off, you can cut out the remains of the old bracket with a grinder and put an iron clamp in its place. It will perfectly perform the functions of the previous fastening, and will cost several times less than welding work. However, it will be necessary to periodically check the condition of the clamp in order to promptly change it to a new one.

The easiest way to repair the bracket is to replace it with metal clamps

How much does it cost to change a gasket

On Renault Logan cars, one of the weak points of the exhaust system is the gasket between the exhaust manifold and the exhaust pipe. If while driving the driver hears extraneous squeaks and there is a burning smell in the cabin, then most likely the problem lies in the burnout of the gasket. In such a situation, it is urgent to replace it. Price: for self-repair up to 500 rubles, in a car service 2500–3000 rubles. The conclusion is obvious.

The gasket is made of heat-resistant materials to prevent rapid burnout of the muffler

It is recommended to immediately begin replacing this element:

Filters

You know, the last reason could be faulty (clogged) engine air filters. I also thought that this was not possible - but it is a fact! The thing is that there is less air (dirty filters do not allow it to pass), but there is more fuel, and the “smoke” increases. But here, not only white but also black exhaust can appear. But this is a topic for another article, be sure to follow our blog.

In the end, I want to say - if you have such a “whitish fog” effect in winter, the fluid level does not drop, then this is normal! You shouldn't even pay attention to this.

I hope you liked the article, if so, then tell us about us on social networks, this is the biggest reward for us.

How to repair a muffler

If your car's muffler requires repair or complete replacement, it is not recommended to do this work yourself, since there is a high risk that you will only worsen the condition of the exhaust system, and possibly the entire vehicle as a whole. In order to prevent such a situation, contact only specialized car services. In our car service center, qualified specialists with the necessary competence in the field of working with exhaust systems will competently diagnose the exhaust system of your car, and, if necessary, repair or install a new muffler in the shortest possible time.

Replacing the rear muffler for Renault Logan

To replace the Renault Logan muffler, you will need full access from below the car. This is done for ease of operation and correct installation of parts.

New clamps for installing the muffler

For reliable installation, purchase new clamps!

So let's get started with the process:

Dismantling the rubber bands that secure the muffler

This is how you can easily and simply change the muffler on a Renault Logan.

Replacing the middle part of the muffler

Middle section of muffler

Replacing the middle part of the Renault Logan muffler is slightly different. Since there are two versions of the exhaust system, we will consider both. In order to make repairs and replacements, you will have to get comfortable with a grinder and a welding machine.

So, let's proceed to the replacement process in the first option:

Take a grinder and cut the pipe

Option number two is a collapsible exhaust system. Consider the replacement process:

Clamps and special lubricant “glue”

We tighten the main and middle parts of the muffler

Regardless of which option you choose, we advise you to stock up on new muffler rubber bands, for example, FISCHER: 223-935 . That's all, now a new muffler has been installed, which will serve the owner its lifespan.

Muffler rubbers FISCHER: 223-935

Tuning and modification

Some car enthusiasts carry out tuning of Renault Logan, including the exhaust system. So, there are several options for mufflers. The simplest and most accessible is direct flow. It does not require modification of the fastenings and fits onto standard seats.

Direct-flow muffler PRO SPORT - cheap and cheerful

The second option is tuning for two pipes. So, in the middle part, instead of one branch, there are two. Accordingly, there will now be two mufflers. At the same time, there are fastenings for one, but for the second one will have to be made. More precisely, not the fastenings themselves, but the hooks for the rubber bands that hold the muffler.

Option three - installing a sports exhaust system. To do this, not one pipe comes out of the “pants,” but two. Accordingly, all fastenings will have to be redone for the new muffler. To do this, special “ears” are welded on, to which the exhaust system is bolted. It must be rigidly fixed, unlike a simple system.

How to replace a muffler on a Renault Logan

The muffler replacement procedure should not cause any difficulties. The only important nuance is the choice of a new high-quality muffler. In order for a new product to serve for a long time, it is necessary to find out in advance about the criteria for choosing “silencers” and their cost:

The criteria for selecting a muffler for a Renault car depend only on the financial capabilities of the owner: the more money, the better quality product you can buy.

Preparing tools for work

In order to replace the muffler as quickly as possible, you need to prepare a simple set of tools in advance. The set includes two 10-mm open-end wrenches and a flat-head screwdriver with a thin blade. You will need wrenches to unscrew the nuts, and a screwdriver can be useful if it is difficult to remove the muffler from the rubber bands with your hands.

Video: replacing the entire muffler

Do-it-yourself muffler dismantling

Once access to the bottom of the car has been prepared, you can begin to work.

Any work on the exhaust system elements is carried out only after the pipes and engine have completely cooled.

It is recommended to adhere to the following rules to safely remove the muffler:

That's all the work that will need to be done in order to remove the muffler from the Renault.

Old and new mufflers from Renault Logan - the difference is obvious

How to install Glushak on Logan

Before you begin installing the muffler, it is best to make sure that all rubber hangers are in working order. That is, they should not be stretched, have cracks or grooves. Otherwise, you need to immediately replace the rubber bands with new ones, because the reliability of fixing the muffler will depend on their condition.

Installation of exhaust system pipes is carried out in the reverse order:

Bolts must be changed every time pipes are replaced, as they quickly stick to the metal during long-term use.

Repairing muffler elements and replacing them are procedures that do not require special knowledge and skills. However, following simple recommendations will allow you to significantly save on service station services.