How to make a pressure gauge for measuring fuel pressure with your own hands

Many people have a problem with how to measure the fuel pressure in the fuel line. What they offer in diagnostic stores looks professional, but is also quite expensive, which is not acceptable for a beginner or for personal purposes. Someone suggests turning cunning adapters from turners, which is not possible for everyone. Since measuring fuel pressure is an important part of the diagnostic procedure, I will tell you how to make a simple and inexpensive fuel pressure gauge using simple and affordable tools. Most domestic cars have a fitting for connecting a pressure gauge. The thread on the fitting is standard. You will find the closest clone of such a thread in a hardware store in the compressors and hoses department. This miracle is called “Kit for refilling car air conditioners CH-135.” This set costs approximately 250 rubles. It looks something like this:

One of the adapters in this set is exactly what we need. Then we need a pressure gauge for the 6-10kg limit, and a piece of rubber hose. All this is in the same store. We measure out a rubber hose of the required length, coat the threads of the pressure gauge with autosealant and put the end of the hose on the thread. We secure the hose with a clamp. We do the same on the other side and install a threaded adapter. Another option is to sand down the threads and then install the hose. What should happen:

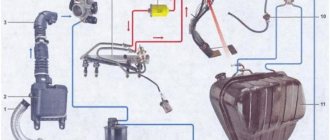

On the latest VAZ models, the fuel lines are mounted on plastic clips. The pressure regulator itself on such cars is located near the fuel pump in the tank. There is no return in such a fuel system, or rather it exists but is located directly in the fuel tank. To measure the pressure in such a line, you need to disconnect the fuel line from the fuel rail and connect a pressure gauge to it. To make an adapter for such a line, we will need an old fuel filter from which we will need to cut off the metal input. He will be our adapter. We take a hose of suitable diameter and secure our adapter with a clamp.

To work with one pressure gauge with two adapters, an additional disconnector is needed. There is a wide choice here, I used an air compressor and this is what it looks like:

Source

DIY fuel system diagnostics

Structure and design of the fuel supply system VAZ 2113-2114-2115

Without the correct pressure in the power system, the car engine simply will not work.

First of all, the fuel system will attract attention with malfunctions and failures. They cannot be ignored, because the first symptom of a non-working system is that the engine simply does not start

Smart car enthusiasts first check the spark and the presence of fuel in the system. In injection engines, when the ignition is turned on, the pump must start and, having raised the pressure in the system to the required value, it freezes and waits for further instructions. Therefore, we have the first stage of checking the pressure - checking the pre-start pressure. This is an important parameter because it speaks about the life of the pump, its ability to maintain minimum pressure in the system and, oddly enough, the condition of the fuel filter. The filter may be clogged, then the pump will puff up to no avail. Frankly speaking, this is the most common malfunction, knowing the quality of our gasoline.

Further, after starting the engine and while driving, various kinds of failures may occur in transient modes, at high speeds and heavy loads on the engine, when the electronic control unit requests an amount of fuel that the pump cannot supply. The result of this may be a lean mixture, jerking while driving, unstable engine operation and other similar unpleasant symptoms. The fuel supply system should not be blamed for all sins, but it needs to be checked. And here comes the need for a second pressure check - checking the pressure under load. If it is lower than nominal, then the pump or filter is again to blame, but without measuring the fuel pressure we cannot prove anything and can only be at a loss. Because both the ignition and the gas distribution mechanism can exhibit similar symptoms.

Video tutorial on measuring pressure in the fuel system

The residual pressure in the injection system or diesel engine is also important. After the engine is turned off and fuel is not consumed, it should not simply flow down the return channel into the tank

There must be residual pressure, since subsequent starting of the engine will be difficult - gasoline will need to go all the way from the tank to the fuel rail again, and the pump will again need to create pressure. And these are extra resources and extra time. It is much more rational to keep the pressure in the system within 0.7-1 atmospheres. All that remains is to figure out how to measure the fuel pressure and what is the best way to do this. Of course, you can go to a service station and carry out diagnostics, but the price for the work will be at least 1000 rubles, you need to go somewhere and trust someone’s word. It is much easier and faster to check the fuel pressure in the garage with your own hands. To do this, you just need a pressure gauge, and now we’ll figure out what kind of thing this is.

↑ Features of measuring fuel pressure

First of all, you should pay attention to signs during transport operation that indicate the presence of any malfunctions. Such signs include interruptions during engine operation or its unstable state when turned on at idle. The engine may stall or stall, and also consume a large amount of fuel. In this case, the exhaust may contain large amounts of CO.

If at least one of the above symptoms is observed, then the car urgently needs in-depth diagnostics to detect the problem. Ignoring an unstable engine start can lead to even greater problems, costly repairs and, more importantly, an accident on the road.

↑ Selecting a pressure gauge for measuring fuel pressure

To diagnose the fuel rail, you will need a pressure gauge model with a maximum value of 7-10 atmospheres. Many car enthusiasts mistakenly prefer to use a device with a large margin (about 18 atmospheres). However, this can lead to large measurement errors, making it difficult to identify the real problem and correct it.

A suitable fuel pressure gauge for a VAZ or a passenger car must be equipped with a hose. Typically the internal diameter is 9 mm, and the hose itself is supplemented with plumbing tow or similar. This is necessary in order to ensure a tight connection between the pressure gauge tube and the hose itself. If the device is made independently, then the issue of sealing and sealing the tube should come first. Otherwise, this may also lead to errors.

↑ DIY fuel pressure gauge

Experienced car enthusiasts know how to make a pressure gauge for fuel pressure. For this purpose, you need to purchase a separate pressure gauge of a suitable model, a tube of the desired length and adapters for connecting to the fuel system. All elements are twisted and tightened with a clamp to create a strong and sealed structure.

If you don’t want to bother creating a homemade device, you can purchase it at the store. In addition, simple devices with basic equipment are not expensive.

↑ How to measure fuel pressure

- To check the pressure, first turn off the ignition and open the hood of the car.

- Then find the fuel rail of the injectors, unscrew the fitting plug and nipple. To facilitate this process, you can use a spool valve. In this case, it is important to have a container on hand, because when unscrewing the nipple, residual fuel may spill out.

- After the above steps, a pressure gauge for measuring fuel pressure, the price of which is affordable for every car enthusiast, is attached to the fitting and sealed with a clamp. However, many modern devices include appropriate adapters that simplify the measurement process by easily screwing in and creating a tight seal.

The measurement itself must be carried out in four different engine operating modes. It is important to compare the readings obtained at startup, when idling, as well as with the tube removed from the regulator and with the drain tube pressed down. However, before proceeding with the diagnosis, it is important to make sure that there are no holes.

Source

Checking the fuel rail pressure

Checking the pressure in the fuel rail is performed during a thorough diagnosis of the entire fuel supply system to detect all possible faults. We will talk about how this can be done further (see the video “How to measure the pressure in the fuel system of a car” below).

Signs indicating a malfunction in the fuel supply system:

- The engine begins to operate unevenly, “triple”;

- Unstable operation at idle;

- Gasoline consumption is increasing;

- The car stalls at idle;

- The CO levels in the exhaust are off the charts.

If any of these symptoms or a combination of them appears, provided that testing of the ECU does not show any malfunctions, it is highly likely that there is a malfunction in the fuel rail. To completely establish this fact, you need to determine the pressure in the fuel rail.

However, all the pressure indicators in the fuel rail given below will be correct only in one case: if the fuel rail is not damaged, so you must first ensure its integrity. This is done as follows:

- After filling the fuel system with fuel, you need to turn on the ignition and evaluate the behavior of the pressure gauge. If the ramp is intact, the pressure readings should decrease to 0.7 bar (this is about 0.69 atmospheres) and stop at this level. If the pressure instantly drops to zero, there is a malfunction in the fuel pressure regulation system. The pressure regulator, in this case, must be removed and replaced. The check valve on the fuel pump motor could also be broken; the valve also needs to be replaced with a new one.

- Then you need to step on the gas, raising the engine speed to 3000, and monitor the pressure gauge readings. If the readings begin to decrease, then there is some kind of malfunction in the fuel pump.

- At the same time, if, when the engine is running, the fuel pump cannot reach the level of normal pressure, then most likely the fuel filter or the fuel pump mesh is dirty.

How to check the pressure in the fuel supply system

To check the pressure in the fuel rail, you will need to use a pressure gauge designed for a pressure of at least 7-10 atm. Pressure gauges with smaller indicators will not be suitable, since during the testing process they may fail, and with larger ones they will give a significant error, which is also unacceptable.

You will also need a hose with an inner surface diameter of 9 mm. You also need to stock up on flax tow or its substitute (it will be needed to seal the hose with the pressure gauge connection). To tighten the connection as much as possible, you will also need a clamp.

RAIL PRESSURE CHECKING PROCESS:

- We start the engine;

- Open the hood;

- We find the fuel rail itself (all the injectors are located on it);

- Unscrew the plug located on the fuel pressure fitting;

- Using a spool valve, unscrew the nipple, having previously placed a rag or flat container under the fitting, since fuel may splash other engine parts;

- The pressure gauge hose is mounted on the fitting and secured with a clamp;

- Let's start checking the pressure in each of the modes: a) while starting the engine, b) at idle, c) by removing the tube from the fuel pressure regulator, d) and also by squeezing the tube to drain the fuel.

- When the ignition is turned on - at least 3 atmospheres, with an error of up to 0.1;

- At idle – about 2.5 atmospheres;

- When removing the tube from the fuel pressure regulator - at least 3.3 atmospheres, with an error of up to 0.1;

- When squeezing the return tube, the pressure should rise to 7 atmospheres;

- When you press the gas pedal, the pressure should rise to three atmospheres, and when you release the gas pedal, it should drop to 2.5 atm.

If all the test options presented above do not make it possible to determine why the pressure in the fuel rail is dropping, then you should check the serviceability of the following sensors: TPS, IAC and mass air flow sensor (how to check the mass air flow sensor). In addition, it is advisable to measure the compression in the cylinders (how to measure compression on an injection engine - described here, how to measure compression on a diesel engine - described here).

Video: How to measure pressure in the fuel system

All about the pressure gauge for measuring fuel pressure

The cause may lie in the very components of the fuel system, and in order to get rid of such a problem, breakdowns must be determined accurately. This is why there are pressure gauges - devices with which you can measure fuel pressure and, based on this indicator, look for a malfunction. This device has a fairly simple design, so experienced drivers prefer homemade pressure gauges rather than purchased ones.

1. What can measuring fuel pressure tell us?

It often happens that everything in the car seems to be functioning correctly and smoothly, but then inexplicable problems begin to appear.

Homemade fuel pressure gauge - diagnostics and repair of injection engines

- Pressure gauge for measuring fuel pressure: what is this thing

- 1. What can measuring fuel pressure tell us?

- 2. Let's go buy a pressure gauge to measure fuel pressure

- 3. What parts are needed to create a homemade fuel pressure gauge?

- 4. Detailed explanation of the instructions for assembling a homemade fuel pressure gauge.

- 5. Diagnosis of fuel pressure in a car: how to get the correct measurements?

A lot depends on the operation of a car’s fuel system, and first of all it is the safety of the driver and his passengers. If even the most minor problems arise in its operation, the machine will immediately begin to behave uncontrollably, twitch and disobey.

The reason may lie in a variety of components of the fuel system, and in order to get rid of such a problem, the breakdown must be determined accurately. This is why there are pressure gauges - devices with which you can measure fuel pressure and, based on this indicator, look for a malfunction.

This device has a fairly simple design, so experienced drivers prefer homemade pressure gauges rather than purchased ones. In the article below, we will also look into the features of creating a pressure gauge yourself, but we will also mention the rules for purchasing such a device, and in general terms we will get acquainted with the problems of the fuel system and how they can be corrected.

What can measuring fuel pressure tell us?

It often happens that everything in the car seems to be functioning correctly and smoothly, but then inexplicable problems begin to appear. At high speeds, your car begins to make dips, jerks from time to time when driving, and when accelerating, it stalls altogether or does not even budge. At first glance, it is very difficult to explain such problems and in the search for the truth one can go through the entire mechanism. However, first of all it is worth checking whether the fuel pressure in the rail is correct.

This parameter is not under the control of the vehicle's electronic control unit (ECU), so lowering this indicator necessarily leads to improper engine operation. There is no doubt that if the pressure drops very strongly, the ECU will be able to determine the presence of a malfunction using a sensor that transmits the presence of oxygen in the fuel system.

The control unit will react by increasing the fuel injection time. But it takes some time to adjust the intervals between fuel supplies, which leads to sharp jerking of the car when it starts. This is why there is a need to measure fuel pressure in the rail.

Optimal fuel pressure indicators or when to sound the alarm. When measuring pressure using a pressure gauge, its optimal indicator should be at the level of 2.5 atmospheres when the car is idling. If you add a little gas during this time, the needle should jump to a level of 3-3.2 atmospheres. This simulation is caused by the operation of the accelerator pump and is not evidence of a malfunction. In general, the following most important factors influence the fuel pressure indicator:

— a regulator that determines the pressure level in the ramp;

— level of performance of the vehicle’s fuel pump.

First of all, the drawback may be hidden in the operation of the fuel pump, since when it cannot provide the required level of pressure, it will drop in the ramp. As we have already mentioned, the ECU will be able to slightly compensate for this shortcoming, however, low pressure turns off the ability to simulate the accelerator pump, which as a result causes failures.

If there are absolutely no problems with the operation of the fuel pump, then it gives a pressure of 5-7 atmospheres. In order for this level in the ramp to drop to 2.5-3 atmospheres, a special pressure regulator is installed in it. Such a regulator is a special small spring-loaded bypass valve, which also has a connection to a vacuum membrane. It is located in the area of the fourth cylinder, on the rack.

The big advantage of this valve is that it is able to adjust the fuel pressure not only due to the spring, but also due to changes in the vacuum in the manifold. This may be due to the fact that a thin tube is also connected to this very regulator, which connects it to the intake manifold.

Thus, if a breakdown occurs on one of these parts, the pressure drops, and even the ECU cannot fully mitigate the breakdown with additional actions. But besides the fuel pressure regulator (FPR), there are other parts of the automobile mechanism, the incorrect operation of which can also cause changes in pressure readings. Among them:

-fuel pump filters, etc.

To make the “diagnosis” more accurate, you need to understand in more detail the operating features of the fuel system of a regular car. But if we talk about its optimal level, then experienced motorists claim that the higher it is, the better for the operation of the car.

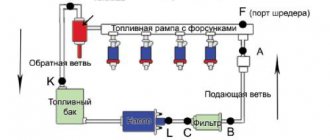

Fuel system operation diagram: what depends on what?

The fuel supply system in a car is not that complicated if you understand it without missing any details:

— engine operation is ensured by a gasoline pump that continuously pumps fuel; if the pump does not work, the engine does not work either;

— if too much gasoline is pumped in, it is discharged into the return line through the same fuel pressure regulator; — the pressure in the ramp will constantly increase/decrease depending on the vehicle speed and throttle input;

— when the engine is turned off, the pressure begins to drop, but in each car the rate of such a decrease will be different. It depends on how high quality the check valve is (it is located on the back side of the fuel pump motor).

Let's go buy a pressure gauge to measure fuel pressure

In order to be able to determine exactly what fuel pressure is in the car in the event of a problem, you can use a special device - a pressure gauge. There is no doubt that the easiest way to do this is at a technical service station (STS), but then you will have to pay for the work of specialists, and possibly a lot of money. And it’s not always possible to find time for such a trip.

Therefore, experienced motorists believe that, among other tools and devices for inspecting and repairing a car, they should have their own pressure gauge. Today, auto stores offer a wide selection of these devices, among which you can choose the appropriate model for measuring pressure in the fuel system of domestic and foreign cars. The advantage of such a purchase is as follows:

— when you purchase a pressure gauge complete with it, you will receive a large number of various adapters, with the help of which you can measure fuel pressure on a wide variety of car brands;

— purchased pressure gauges have an accurate scale that can very accurately display the pressure indicator;

— there are special testers that allow you to measure pressure in fuel systems with a bypass valve. At the same time, during the measurement process it is possible to release the residual pressure;

— professional pressure gauges allow you to obtain accurate fuel pressure readings in different vehicle operating modes, which homemade ones cannot always provide.

Today you can even purchase an electronic pressure gauge for measuring pressure in the fuel system. The data obtained thanks to this device is the most accurate, since it is very sensitive to even the smallest differences in pressure.

Many people, without going into detail, also try to measure the pressure in the fuel system using a conventional air pressure gauge, designed to measure air pressure in car tires. Of course, the principle of measuring pressure of both air and fuel is virtually the same. However, if for fuel pressure the measurement limit is 5-7 atmospheres, then for air it is much higher and amounts to 16-20 atmospheres.

For this reason, if you use an air pressure gauge to measure fuel pressure, you will experience a strong indicator error, since the needle will only be at the initial values of the device. But still, air pressure gauges are used to create homemade fuel meters.

Indeed, many craftsmen consider the purchase of a professional device to be an unnecessary waste of money, since you can create an accurate device for measuring fuel pressure with your own hands. There are a large number of similar instructions on the Internet that tell you how to make a pressure gauge with your own hands in a matter of minutes.

However, in order for a home-made device to show the clearest data possible, it must be crafted very carefully, without losing sight of a single detail. Also, you need to be able to correctly read and interpret the obtained indicators. Below we will try to teach you this simple task.

What parts are needed to create a homemade fuel pressure gauge?

And so, in order to make an accurate device for measuring pressure in the fuel system of a car yourself, you will need the following parts:

1. A regular pressure gauge for measuring air pressure in tires. It is much easier and cheaper to purchase than fuel. Many people recommend using a pressure gauge for VAZ cars, because if you tighten the gasoline fitting on it, you can also use it to measure oil pressure. To do this, the hose of the device we created is simply screwed on instead of the oil pressure sensor.

2. An adapter, the role of which can best be performed by a regular fitting. Its thread value should be 7/16-20 UNF.

3. Gasoline filter. We don't need it itself, we just cut off the fitting from it. It is recommended to slightly flare the ends of the cut fitting.

4. Connector for the fuel system, which is Y-shaped.

5. Clamps. You need to take four pieces.

6. Gasoline hose. To construct a pressure gauge, we need at least 1 meter.

After purchasing all the specified parts, we can move on to our immediate task - assembling the pressure gauge design.

A detailed explanation of the instructions for assembling a homemade fuel pressure gauge.

Assembling a homemade pressure gauge is one of the fastest steps for a person with skilled hands. To do this, you will need to connect a hose, previously cut into three parts, to the fuel system connector. Keep in mind that the joints must be tight and not allow air to pass through. Therefore, we secure them very tightly with clamps.

We attach our air pressure gauge to one end of the hose. It also needs to be secured as tightly as possible, for which we again use a fitting and a clamp. That's it - the fuel pressure gauge is created! To check the fuel pressure, you just need to connect one free end of the hose to the outlet of the fuel filter, and the other to the inlet of the fuel rail. However, the process of measuring pressure is not as simple as it might seem at first glance, so we will talk about this in more detail.

Diagnostics of fuel pressure in a car: how to get the correct measurements?

Pressure measurements can be done in completely different ways and under different vehicle operating modes. The most commonly obtained indicators are:

- when the car ignition is turned on. It is noted how much the needle jumped in comparison with the indicator at which it was before;

— measurements with a reset connection from the fuel pressure regulator (FPR);

— measurements with a compressed return line.

In general, if the slightest problem occurs that makes you suspect a malfunction of the fuel system, you should take a fuel pressure gauge and check as follows:

1. First of all, it is worth determining how the pressure regulator works. To understand this, you need to turn on the pump with the engine not running. If there are no breakdowns or malfunctions, the pressure gauge will show 3 ± 0.2 atmospheres. When the pressure drops below 2.8 atmospheres, you should think about replacing the RTD. After all, a malfunction of the regulator causes a decrease in vehicle controllability at high speeds. However, there is no need to rush; you still need to check the next point and only after that make a final verdict regarding the serviceability of the RTD.

2. The next important parameter for us is zero supply pressure. The pump raises this pressure without supplying fuel, so to speak, for testing. Its indicator indicates how well the pump works and how worn it is. If the indicator gradually decreases, this will indicate wear.

To measure it, you need to pinch the “return” using pliers. Let us immediately note that this must be done very abruptly. In this case, the pressure gauge needle should instantly jump to the limit value indicator. If everything happens as we described, there are no problems with the pump and its operation. If the arrow rises slowly, there may be two reasons for this:

— the fuel filter is clogged;

— the gas inlet grid is clogged.

But what will be the limiting value that the arrow points to will indicate some important facts. On new pumps the needle usually rises to 5-6 atmospheres. Drivers also note that the norm for Czech pumps is 7 atmospheres.

It is believed that the lower the maximum value, the lower the pump’s performance will be and the sooner it will have to be replaced. However, even if this indicator drops to 4 atmospheres, you can be sure that your car will drive for a very long time. But if the needle cannot rise higher than 3 atmospheres, then it is worth taking decisive measures to replace it.

3. Now we try to turn off the pump altogether. At this time, the pressure gauge needle should drop to 0.7 atmospheres and remain stable at this level. If it immediately drops to zero, the malfunction may be in the operation of the check valve or the RTD as a whole. Not very significant defects can be eliminated by simply squeezing the return line for a short period of time, since replacing the entire fuel pump due to one valve is not a very practical idea. However, if the RDT is to blame, this cannot be avoided.

4. Now you need to check how the fuel pressure changes when the engine is running. Running the engine causes the needle to twitch a little. The presence of malfunctions will be indicated by a needle “wandering” over a very wide range (the amplitude of its oscillations can be even 0.3 atmospheres). In this case, the gas inlet mesh is most often clogged.

5. The average fuel pressure with the engine running should be 2.3 atmospheres. If at this moment you remove the vacuum hose from the RTD, the needle should rise to 3 atmospheres (the limit that you measured in step 1). After this, you need to return the hose back and try to raise the speed of the car to 3 thousand. If the pressure drops, you can be sure that the reason for the “bad” behavior of the car is a faulty pump.

Thus, with the help of a simple, even homemade, pressure gauge, you can establish full-fledged operation of the car. This way, YOU can protect yourself and your family from unexpected situations on the road. You should also not forget that if one part malfunctions, the functioning of the vehicle mechanism as a whole is disrupted, so it is necessary to identify the breakdown and correct it in a timely manner.

And if, for example, while repairing your car you had to disassemble the gas tank, it wouldn’t hurt to look into it at the same time with a flashlight and clean it of sediment that usually accumulates at the bottom.

Subscribe to our feeds on Facebook, Vkontakte and Instagram: all the most interesting automotive events in one place.

- © 2021 Auto.Today

- This email address is being protected from spambots. You must have JavaScript enabled to view it.

- Confidentiality

- Advertising on the website

- Editorial

The use of any materials posted on the site is permitted provided there is a link to auto.today.

The portal's editors may not share the author's opinion and are not responsible for copyright materials, for the accuracy and content of advertising

Materials: https://auto.today/bok/1445-davlenie-v-toplivnoy-sisteme-pokupka-manometra-i-sozdanie-prisposobleniya-svoimi-rukami.html

Pressure gauge: studying the device, learning to choose and make it yourself

For a car to operate efficiently, all its systems and components need to work properly. One of the leading places is occupied by the fuel system. Not only the performance of the vehicle, but also the safety of the driver and passengers depends on the quality of its work. To avoid problems, you need to monitor its condition. The article discusses pressure gauges for measuring fuel pressure and their technical characteristics.

Technical parameters of the pressure gauge

From Greek, manometer is translated as “rarefied” and “meter”, that is, it is a device for measuring the pressure of non-dense substances: gases, liquids, etc. Pressure gauges are tools that can be used to diagnose the technical condition of a car. Modern devices can be mechanical, electronic and digital.

Measuring device with attachments

Purpose

Sometimes while driving the car starts to twitch, when you press the gas pedal it stalls, and sometimes it doesn’t start at all. There can be many reasons for this behavior of the machine. The first thing you should check is the fuel rail pressure. A decrease in pressure below the permissible level leads to improper operation of the power unit.

The electronic control unit (ECU) monitors the technical condition of a modern car, but control over the fuel pressure in the rail is not part of its functions. Naturally, with a significant decrease, the system will indicate the presence of a problem via a sensor that monitors the volume of oxygen in the fuel-air mixture. A pressure gauge for measuring fuel pressure makes it possible to assess the health of the fuel system.

With its help, such elements of the fuel system are checked as:

- gasoline pump;

- fuel lines;

- pressure regulator;

- injectors, etc.

The advantage of pressure gauges is that they are connected in parallel, so they do not interfere with the operation of the fuel system. Thus, readings can be taken while the engine is running (the author of the video is Dmitry Efimov).

Design and operating principle

The most widely used pressure measuring instruments are spring pressure gauges. Their advantage is the simplicity of the device, reliability, good technical characteristics and the ability to measure pressure in a wide range.

Spring pressure gauge design

The sensing element in a spring pressure gauge is a curved tube, hollow inside. It can have a cross-section in the form of an ellipsoid or an oval. Under pressure it becomes deformed. The tube is sealed at one end, and at the other there is a fitting with which the pressure in the medium is measured. The sealed end of the tube is connected to the transmission mechanism.

The design of the device includes:

- gear sector;

- leash;

- axis;

- gears;

- instrument arrows;

- frame.

To eliminate backlash, a special spring is installed between the teeth of the gear and sector. The measuring scale is graduated in pascals or bars. The arrow shows the value of the excess pressure of the medium in which the measurements are being taken.

The operating principle of the device is simple. Pressure from the medium being measured enters the tube. Under its action, the tube tries to straighten, since the areas of the inner and outer surfaces are different. The free end of the tube moves, and thanks to the transmission mechanism, the arrow rotates through a certain angle. The deformation of the tube and the measured pressure are in a linear relationship. Therefore, when the arrow deviates relative to the pressure gauge scale, it shows the pressure value.

Varieties

There are many types of pressure gauges for measuring both high and low pressure, with different technical characteristics. One of the parameters by which these devices differ is the accuracy class. The lower the value, the more accurate the pressure gauge. The most accurate are digital ones.

According to their purpose, pressure gauges are divided into the following types:

- General technical. They are intended to measure pressure in different media, including using them to measure vacuum and excess pressure.

- Electric contact. Equipped with an electrical alarm that allows adjustment of the measured medium. They are produced in two types: with micro switches and based on an electrical contact attachment.

- Special. Used to measure the pressure of various gases. Depending on the type of gas, they have a specific body color and marking letters: oxygen (K) - blue, acetylene (Ac) - white, ammonia (A) - yellow, for measuring non-flammable gases - black, for flammable gases - red.

Oxygen meter

- Reference. They have a high accuracy class, therefore they are used for checking, adjusting and testing other pressure measuring devices.

- Ship's. Used in river and sea transport.

- Railway. Used in railway transport.

- Recording: equipped with a mechanism that allows you to draw a graph of the operation of the device on chart paper.

Based on the principle of operation, there are the following types of pressure gauges:

- Piston. They consist of a cylinder and a piston inserted inside.

- Liquid. They are based on a tube filled with liquid. There can be two types: with one tube and with two. The latter are used to compare pressure in two environments.

- Deformation. They are based on the deformation of the sensitive element (spring, bellows, membrane, etc.), which, when deformed, affects the pointer of the device.

- Piezoelectric. They are based on the piezoelectric effect - when mechanical action occurs, an electric charge appears in a quartz crystal.

Various types of pressure gauges are widely used in industry, everyday life and other areas of the national economy, depending on the technical parameters.

Car won't start after DIY replacement

This is a fairly common problem. It must be said that the car should not start immediately after replacing the pump. The pump first needs to create operating pressure in the system. To do this, you need to turn on the ignition for a short time (a few seconds). The key must be inserted into the lock, but not turned. The lights on the dashboard should light up. Then you can rotate the engine with the starter for five to ten seconds. If nothing works out, then you should take a break for half a minute and repeat your actions.

We recommend: How to replace the air filter on a Ford Fusion?

If the engine does not start even after several cranks with the starter, this indicates that shortcomings were made during assembly and connection of the fuel pump. Another reason could be a malfunction of the new pump. There is also a possibility of a planned blocking or failure of the car’s security system.

When a car owner installs and connects a new unit, various failures may occur: sticking of valves on the pump, breakage of contacts, terminals and connectors. When such problems arise, you need to try to determine their nature. Did the breakdown occur in the mechanical or electrical part of the fuel pump? The easiest way to find out is if there is a problem with the power supply. You also need to remember that the fuel filter may become clogged.

In order to accurately determine the causes of the problems, you need to make sure that the fuel rail does not contain gasoline. After this, you need to re-remove and connect the pump directly from the battery or dimensions. This method of connecting the pump is the best for quickly checking it.

A car owner must take care of every part of the car. It is best to gain knowledge about its structure and repair yourself. It is important to acquire skills in diagnosing and solving problems in the operation of individual machine systems. This also applies to the functioning of the fuel pump.

Many drivers encounter breakdowns on the road, far from cities and service points. In such a situation, you can only rely on your own experience. Knowledge about the signs and causes of malfunctions in the fuel pump will help solve problems at the initial stage of their occurrence. It will also save effort, time and a significant part of personal funds.

What to look for when choosing?

To diagnose problems in the fuel system, you need to know what the fuel pressure is in different places in the system. The easiest way to get a technical inspection is at a service station where there are accurate digital devices. But for this you need to allocate time and money. Many drivers prefer to have this device in their tool kit, as well as a mechanical oil pressure gauge.

The car market and specialized stores offer a large selection of pressure gauges, with different technical characteristics, designed to carry out measurements on both domestic and imported cars.

Measuring kit

Factory pressure gauges have the following advantages:

Currently, the range of pressure gauges includes electronic and digital devices for measuring and adjusting fuel system pressure, which have high technical characteristics. Electronic and digital pressure gauges make it possible to obtain the most accurate readings, as they capture even the smallest changes in pressure readings.

It is better to buy a fuel measuring device that has a large, easy-to-read scale, with a measurement limit of 5-6 kgf/sq. see. Pay attention to the tightness of the connections, since during measurements if the tightness is insufficient, drops of fuel can fall on very hot engine parts, which can cause a fire.

Automotive fuel meter

Many car enthusiasts use air pressure gauges to measure and adjust the pressure in the fuel system, which measure the air pressure in car tires. Although the principles that underlie both devices are almost the same, however, the measurements differ in the range of values. For fuel, the limit of indicators is in the range from 5 to 7 atmospheres, for air - in the range from 16 to 20 atmospheres.

Therefore, when using an air gauge to measure fuel pressure, results will be obtained with a large error, since the needle will not rise above the very initial values. Adjustment with such indications is difficult to perform correctly. Despite this, homemade fuel measuring instruments are made from air pressure gauges.

Guide to making a homemade pressure gauge

Many handymen believe that it is not worth spending extra money on buying a factory pressure gauge, since you can make one yourself.

In order for a homemade device to provide the most accurate data possible, it must be collected extremely carefully, without missing a single detail.

Tools and materials

In order to construct your own device for measuring pressure in the fuel system, you need to prepare the following parts:

- An air pressure gauge used to measure the air pressure in car tires. It is preferable to fuel, as it is easier to buy and costs less. It is recommended to purchase a device designed for VAZ cars, since it can be used as an oil pressure gauge if you unscrew the gasoline fitting. To measure, you need to screw a hose from a self-made device into place of the oil sensor.

- Adapter. An ordinary fitting with a thread value of 7/16-20 UNF will successfully cope with this role.

- Gasoline filter, suitable for VAZ. You can take the old one. The filter itself is not needed, you only need a fitting from it. If you don’t have a used one, you can buy the cheapest one. The fitting needs to be cut off, and it is recommended to flare the ends a little. You can grind the fitting with your own hands.

- Fuel system connector shaped like a "Y".

- Four clamps.

- Gasoline hose. To make a measuring device, you need to buy a gas cord more than a meter long.

A set of parts for assembly

Having purchased all the necessary parts, you can begin making a homemade pressure gauge.

Algorithm of actions

Making a pressure gauge with your own hands is not difficult. Having all the parts, all that remains is to assemble everything correctly.

Assembly consists of the following steps:

- First, the fuel cord must be cut into three parts.

- Then you need to attach the fuel hose to the connector from the fuel system. For a reliable connection, the hoses are secured with clamps. The connections must be sealed and airtight, otherwise the readings will not be accurate.

- You need to attach an air measuring device to one end of the gas hose. It should also be secured as tightly as possible. To do this, as before, we use a clamp and fitting.

Homemade device assembled

The fuel pressure gauge is assembled; it can be used to measure the pressure in the fuel system. To do this, one of the free ends of the hose must be connected to the inlet of the fuel rail, and the second to the outlet of the fuel filter.

At the slightest suspicion of a malfunction in the fuel system, you need to:

- check the fuel pressure regulator with a pressure gauge, which is available;

- measure zero supply pressure;

- when turning off the pump, check the serviceability of the check valve and the RTD as a whole;

- A moving pressure gauge needle when the engine is on may indicate a clogged fuel pump strainer.

Checking the fuel-emulsion system

Thus, even with a homemade pressure gauge, you can monitor the health of the car, protecting yourself from unpleasant surprises on the road. Low and fuel pressure should be checked regularly. If the readings do not meet the norm, you need to look for the reason. If the slightest malfunction is detected, it must be corrected immediately.

When should measurements be taken?

The operation of the power system is structured as follows:

- An electric fuel pump located in the tank pumps fuel along the line into the fuel rail and further to the injectors.

- The regulator limits the gasoline pressure at a certain level, releasing excess into the tank through the return pipeline.

- The injector mixes fuel with air, then the mixture is directed to the nozzles, which open at the command of the controller.

When the wear of the regulator (abbreviated as RTD), pump or injectors reaches a critical level, the pressure in the gasoline circuit will change towards a decrease or increase. There are 2 possible scenarios: there is not enough fuel mixture for normal engine operation, or there is an excess of it - the spark plugs are literally flooded with fuel.

In both cases, checking the pressure in the fuel rail located next to the cylinder head will help identify the problem. The element is a manifold with branches for injectors, to which the main gasoline line is connected.

The fuel pressure in the manifold should be measured if the following symptoms occur:

- the car accelerates poorly, after sharply pressing the accelerator pedal, jerking and deceleration are felt;

- the engine of a loaded car “does not pull” and starts poorly when cold;

- shots are periodically heard in the exhaust manifold;

- a warm engine does not start after a short period of parking (especially in summer); the starter needs to be turned for 20–40 seconds.

The first two signs indicate a clear lack of gasoline, resulting from a drop in pressure in the ramp. The third case is unburnt fuel entering the exhaust manifold with subsequent combustion (a popping sound is heard). The fourth symptom indicates leaking injectors when the cylinders are filled with pure gasoline during parking. Until the pistons release excess fuel, the engine will not start.

We recommend: How to tighten a car armrest with your own hands (using the Priora as an example)?