Why does a diesel turbine practically last forever?

If you compare a turbine on a gasoline engine and take the average mileage of 90,000-120,000 km.

and a conventional turbine from a diesel engine with a mileage of 250,000 km, or even more. The operation of a turbine on gasoline and diesel is almost identical. The turbine has a hot part and a cold part. The hot part runs on the energy of the exhaust gases that come from the exhaust manifold and spins this part of the turbine. It is connected by a shaft to a cold compressor wheel which spins up to high speeds and forces air into the engine cylinders. Takes air from the environment. Due to this, we have more air-fuel mixture and the engine power increases. So why do diesel turbines last longer?

- This is the exhaust temperature.

For gasoline it is 800-900 degrees Celsius, and for diesel it is 500-600 degrees Celsius. (This is on average.) Because the efficiency of a diesel engine is much greater and the energy from the burnt mixture goes into work, while in a gasoline engine it goes into heating. The higher the temperature of the exhaust gases, the more the turbine heats up and the oil that lubricates the bearings (bushings) can burn both in the channels and in the bearings. Therefore, lubrication of the turbine will be much worse and the turbine may completely coke and the oil will stop flowing. Oil not only lubricates but also removes excess heat. Since the exhaust temperature of a gasoline engine is higher, the turbine fails prematurely. But on a diesel engine, the exhaust temperature is lower and the turbine feels better. - Engine speed.

For gasoline, the engine runs at an average of 4000-6000 rpm. min. And diesel is on average 1500-2000 rpm. min. Accordingly, when a gasoline engine exhausts, more exhaust gases pass through the turbine and the turbine spins up faster. A diesel engine has lower revs, the exhaust is not as intense, and the turbine does not spin up as quickly as with gasoline. Fewer revolutions increase the life of the turbine. In a gasoline unit, the turbine develops 100,000-150,000 rpm. min. And diesel performance is much lower. On gasoline, valves are installed to relieve pressure so that the turbine does not rupture. Diesel engines also have them, but diesel engines operate at lower speeds. - Oil.

The base of gasoline and diesel oil is almost the same. But diesel runs on heavy fuel and produces a lot of sulfur during combustion. Sulfur is a solid substance and, when deposited on parts, acts as an abrasive. Therefore, appropriate powerful additives are added to diesel oil to remove sulfur and prevent it from settling on rubbing parts. But gasoline oil does not have such additives. This means that diesel oil lubricates the turbine better, removes oxidation and sulfur, does not burn, and removes heat. - Oil change intervals.

Diesel engines need to change oil more often. Approximately 5000-7000 km. On gasoline 8000-10000 km. This means that the oil on a diesel engine is cleaner and lubricates the turbine much better, and therefore the turbine runs longer on a diesel engine.

Source

Necessary additions to the turbocharging system: valves, intercooler

It took engineers decades to create a truly efficient turbocharger. After all, it’s only in theory that everything looks smooth: by converting the energy of exhaust gases, you can “recover” the lost percentage of efficiency and significantly increase engine power (for example, from one hundred to one hundred and sixty horsepower). But for some reason this did not work out in practice.

In addition, when you pressed the accelerator sharply, you had to wait for the engine speed to increase. It happened only after a certain pause. The increase in exhaust gas pressure, the spin-up of the turbine and the injection of compressed air did not occur immediately, but gradually. This phenomenon, called “turbolag” (“turbo lag”), could not be tamed. And it was possible to cope with it by using two additional valves: one to bypass excess air into the compressor through a pipeline from the engine manifold. And the other valve is for exhaust gases. And in general, modern turbines with variable blade geometry, even in their shape, are already significantly different from the classical turbines of the second half of the twentieth century.

Bosch diesel turbocharger

Another problem that had to be addressed during the development of diesel turbine technology was excessive detonation. This detonation occurred due to a sharp increase in temperature in the working cavities of the cylinders when additional masses of compressed air were pumped into them, especially at the final stage of the stroke. The charge air intercooler (intercooler) is designed to solve this problem in the system.

An intercooler is nothing more than a radiator for cooling the charge air. In addition to reducing detonation, it also reduces the air temperature in order not to reduce its density. And this is inevitable during the heating process from compression, and from this the efficiency of the entire system drops significantly.

In addition, a modern engine turbocharging system cannot do without:

- control valve (wastegate). It serves to maintain optimal pressure in the system, and to release it, if necessary, into the exhaust pipe;

- bypass valve. Its purpose is to divert charge air back into the intake pipes up to the turbine, if it is necessary to reduce power and the throttle valve closes;

- and/or “blow-off-valve”. Which bleeds charge air into the atmosphere if the throttle is closed and there is no mass air flow sensor;

- exhaust manifold compatible with turbocharger;

- sealed pipes: air pipes for supplying air to the intake, and oil pipes for cooling and lubrication of the turbocharger.

What determines the service life of a turbocharger?

Why do some turbochargers fail after a short period of time, while others continue to work for years? At the same time, turbocharger manufacturers report that their products have the same service life as the engine on which they operate. This is due to the latest technologies at enterprises, automated lines, and strict multi-stage acceptance at the output of finished compressors. Then why do engine turbochargers break? For example, the average life of a turbine in diesel engines is up to 200 thousand km . A gasoline supercharger will last slightly longer due to its simpler design.

One of the reasons for this situation is the rapid development of turbocharging technologies. Corporations release new models with new technologies and new capabilities. Not only ordinary buyers, but also professionals who service turbochargers do not have time to monitor this. As a result, there are very few specialists who thoroughly understand the design and repair of turbochargers.

In addition, the service life of the turbine will correspond to the declared one only if all engine components are in good working order, its correct operation and maintenance. At the same time, you must always remember that even minor damage to the turbocharger leads to serious problems with the engine. This is why it is important to constantly ensure that the turbocharger is operating correctly.

Turbine failure and consequences

Malfunctions of a turbocharger, regardless of its type of design, require immediate repair. It is also necessary to eliminate the reasons that may lead to turbine failure. This is necessary so that after repair or installation of a new supercharger, the device does not fail again.

Most often, turbochargers suffer due to the fact that the efficiency of lubrication of the turbocharger rotor is greatly reduced. The fact is that special requirements are put forward for oil for turbocharged diesel or gasoline internal combustion engines. Turbo engine lubrication works under conditions of increased loads and high temperatures, and also acts as a working fluid for cooling.

During engine operation, a decrease in the performance of the oil pump is observed due to its wear; the capacity of the oil supply lines for supplying lubricant to the turbine is gradually clogged with deposits. Also, wear products from engine parts in the form of mechanical particles enter the engine oil and can lead to damage to the turbine rotor.

How to extend the life of a turbocharger?

Although buying a turbocharger for a car is not a problem, it is much easier to prevent its breakdown. To do this, experts advise:

- Operate the vehicle according to the manufacturer's recommendations. So, you should not sharply load the engine in the first minutes of driving, especially in cold weather. It is not recommended to turn off the engine immediately after stopping - you need to let it idle. You need to stop driving aggressively.

- Change oil and filters in a timely manner, and before changing the oil, be sure to flush

- Use only high quality oil recommended by the manufacturer.

- Avoid getting foreign objects on the blades of the compressor and turbine wheels. Parts of the combustion chamber, spark plugs, nuts, washers, and parts of pistons can get into the turbine wheel, and parts of the air filter, pieces of rubber, bolts, nuts, and washers can get into the compressor wheel.

- Change the air filter in a timely manner (not based on mileage, but based on condition), check the condition of the pipe connections and blow out the air path.

- Avoid thermal and stress loads on the turbine;

- Always fill your car with high-quality fuel and do not refuel at dubious gas stations.

- Ensure constant maintenance of the car engine and all car systems: ventilation, lubrication, fuel supply.

And yet, despite all your efforts, the turbine may fail.

When to change the turbine?

There are several signs of a failed turbine:

- the motor loses power;

- fuel consumption increases;

- exhaust gases smoke excessively;

- the temperature regime of the engine is violated.

will help replace the turbine!

You can contact us for any service, including turbocharger repair in Yekaterinburg. The turbine is a very complex mechanism, and after replacement or repair, the service life of the turbine depends on the qualifications of the specialist.

Even just to disassemble a turbocharger requires special tools and operating skills. Repairs will require even more serious professional training. ProTurbo service specialists install turbochargers on the engines of various vehicles - cars, trucks, and special equipment. All work is carried out on high-precision equipment using high-quality materials and with a subsequent guarantee.

Regular customers are given a discount. Our reasonable prices save you money!

In order to identify a turbocharger, it is necessary to correctly “read” the information plate that is installed on it.

Below are photographs of information plates of the most common turbochargers - Garrett, Mitsubishi, IHI, KKK, Holset with a description of the information printed on them.

Source

Turbocharged engine - what is its resource? Its pros and cons

Turbo engines are considered very weak and problematic. Partially this is true. Turbocharged engines have a much shorter resource (that is, service life) than their conventional, naturally aspirated brothers. The weak point is the turbine itself, which can “run out” several times throughout the life of the engine itself.

In this article I will try to tell you about the service life of turbocharged engines, their advantages and disadvantages, and also offer some tips for operating cars with such engines.

Oil

Well, probably the third reason is diesel engine oil . If you don’t go into the weeds now, the lubricant for the gasoline and diesel versions is different, but not critical. I will say more, they have the same base, but different additives (a diesel engine has more of them and they are slightly different).

When an engine runs on heavy fuel, a lot of sulfur is often formed (these are by-products during combustion). Sulfur is hard crystals that can cause excessive wear on cylinders, shafts, liners, etc. It needs to be removed from the power plant.

That's why these detergent additives exist inside diesel oil. Thus, the turbine is lubricated more efficiently than its opponent.

AND THE REPLACEMENT INTERVAL for a heavy fuel engine should be more frequent. For example, the recommended interval for gasoline is now 15,000 km, and for diesel it is 10,000 km. Lubrication is better and of higher quality, which has a positive effect on all components and assemblies.

Now we are watching the video version.

This is where I end, I think my materials were useful to you, SINCERELY YOUR AUTOBLOGGER

(

6 votes, average: 4.67 out of 5)

Similar news

Timing belt resource. We will analyze foreign cars, as well as PRIORA, KALINA and GR.

Car blanket, like AUTOHEAT - what if it makes sense? My review. Let's look at p.

Engine HYUNDAI SOLARIS and KIA RIO (GAMMA and KAPPA - G4FA, G4FC, .

Advantages

The very first thing that comes to any person’s mind if you ask him about the advantages of a turbo engine is that he will immediately say that it is power. Yes, due to the operation of the turbine, conventional engines can produce much more power, giving you more emotions and pleasure from driving a car.

Another advantage is fuel consumption. If we take into account the fuel consumption per unit of engine horsepower, then it will always be lower with a turbo engine.

Turbo engines are much more compact than naturally aspirated engines. A striking example of this is engines with two or three cylinders, but with a turbine. You can google – Fiat 0.9 TwinAir for 2 cylinders and Ford 1.0 EcoBoost for 3 cylinders.

Flaws

The first disadvantage comes from dignity, no matter how strange it may seem. A turbo engine will consume more fuel than an aspirated engine. There is one more drawback - such engines need good, high-quality fuel so as not to lose their service life.

There is one more drawback, although it is rather dubious - it only needs high-quality oil. Every car needs high-quality oil, but a turbo is more demanding. In fact, you just need to pour the oil that the manufacturer recommends. And the oil needs to be changed more often than on naturally aspirated engines.

The service life of an average turbine is 150 thousand km. Yes, some go for 250 thousand, but this is rare. Repairing or replacing a turbine is an expensive proposition.

The turbine must be cooled after each trip - here you cannot, as with a conventional aspirated engine, turn it off and go about your business. The turbine should run for about 5 minutes to cool down and clean itself.

Diesel engine turbine life

The question is probably rhetorical, but still. How long did the turbine last? And yet, at first, both in the service and friends advised me to install a turbo timer, as it seems to increase the resource. Now 130,000 of them, 5,000 of them were taken from my hands. So I think how many more. In fact, if you look at it, the Germans are practical people and if the turbo timer really increased the resource, then on newer versions they would have installed it anyway. he..no. So how much did the turbine spin? And how much will it cost to replace it? By the way, when replacing a turbine, do they change anything at the same time?

Now they will begin to intensively send you on a search. As I understand it, the turbine runs for 150-200 thousand. When replacing, you need to change a lot of other things (oil supply pipe, gaskets, N75 valve, etc.)

Turbo engine resource

And now about the myth that turbo engines have a shorter service life compared to the same naturally aspirated engines. In fact, this is not entirely true. The resource is almost the same, only the turbo engine is more demanding on the main components (fuel, oil, operation), and therefore it dies much more often.

If you take care of the turbo engine, it will travel the same 300 thousand km as the naturally aspirated one without any problems.

By the way, an important fact is that small-volume turbo engines require even more care than conventional ones. Such engines constantly operate under high load (after all, they produce a lot of power). That is, we change the oil not every 7500 km, but every 4-5 thousand km.

Revolutions

The higher the engine speed, the more exhaust gases, the more rotation of the turbine (I think this is understandable). BUT again, turbine wheels cannot spin indefinitely (yes, they can hold 100 - 150, even 200,000 revolutions), but there is a limit everywhere. In gasoline versions, engine speeds can reach up to 6–7000 (and normal operation is 2–4000), that is, the “exhaust flow” is very high, the turbine wheels spin very strongly—which does not add to their service life.

For a diesel engine, operating speeds range from 2 to 3000 (nowadays up to 4000 are found, but this is rare).

This means the flow of exhaust gases is much less. The rotation of the turbocharger shaft is much less, which adds to its resource compared to its opponent.

Useful tips

Here are 4 basic rules that, in my humble opinion, every owner of a turbocharged car should know.

Tip one - change the oil

Change your engine oil regularly and often. If the car is driven only in the city, reduce the oil change interval by a quarter of the recommended one. At the same time, the air filter must also be replaced.

Tip two - oil quality

Always buy REAL, quality oil that will do the job. If you really care about this, read the relevant resources (for example, oil club). Well, or stay on my channel - I will definitely release a series of articles about motor oil.

Tip three - extra load

Yes, you have a turbo engine, there is a lot of dope in it, you constantly want to rock it. But do not forget to drive not only in the cut-off mode, but also in quiet mode. This will have a positive effect on the life of the engine and the turbine itself, as well as on your wallet. But gas station chains may begin to cry due to loss of profit.

Tip four - let it cool

As I wrote above, the turbo engine must be allowed to cool after each trip. Do not turn off the engine immediately after stopping, but let it idle for at least 3-4-5 minutes. This will allow the turbine not only to cool down, but also to preserve its service life.

The rotor is also lubricated with oil, and if you turn off the car, it will continue to spin without slowing down, literally wearing itself out.

Well, the unspoken truth is that turbo engines definitely need warming up (and naturally aspirated ones too), since the oil channel is longer, which means more pressure is needed to pump the oil. This happens best with “warm” oil.

I hope you found it interesting and will take note of this. Subscribe to the channel and give it a thumbs up to see even more interesting articles on automotive topics in your feed every day.

Source

Turbine design

In principle, I already have an article on how a turbine works (it’s an educational read, by the way, there’s a video there). Here I will remind you, in simple words.

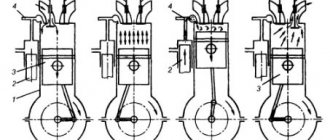

A turbocharger has two sides: one is hot and the other is cold. In both parts, there are two impellers (others call turbine wheels). They are rigidly connected by a shaft, which sits on bearings (usually bushings that are lubricated with oil). If one part (the impeller) begins to unwind, the other begins to rotate accordingly.

What is the point of the work: - exhaust gases that escape from the cylinder block enter the exhaust manifold , in which (to put it roughly) our turbine is installed. Exhaust gases spin the hot impeller (and it can rotate at crazy speeds, 100 - 150,000 rpm), and since there is only one shaft, the cold impeller also begins to rotate at the same rates. Only it works like a compressor, sucking in air from the environment and pumping it into the engine cylinders. Thanks to this, the air-fuel mixture inside becomes much larger, and the power increases.

This device is typical for both diesel and gasoline engines; there is practically no difference between them (the rest are special cases).

However, the difference in operating principles gives the diesel version more advantageous conditions.

Is a turbine really that scary? How to drive correctly with a turbo engine and how much repairs can cost

In our last publication, we already compared turbocharged and naturally aspirated engines, trying to understand what their differences are and which one is better to choose. Let's say that you have already purchased a car with a supercharged engine or are about to buy one.

How is the turbine constructed?

In general, a turbocharger is designed simply. The main part is the cartridge. A shaft is placed inside it, and turbine wheels are attached to this shaft at two opposite ends. In order for the shaft to rotate normally and not heat up, motor oil is supplied to it under pressure. There is also a tube with antifreeze attached to the cartridge for additional cooling.

Attached to the sides of the cartridge body are two “snails” - hot and cold, inside which turbine wheels rotate. The hot exhaust gases enter, spin the wheel, and then “fly away” into the exhaust pipe through the side hole of the cochlea. The turbo wheel in the cold scroll sucks in clean atmospheric air from the intake tract and drives it under strong pressure further into the intake tract to the engine cylinders.

This is the general design of the turbine, and we will not now go into the intricacies of the design and various layout options. However, it is worth mentioning the new generation of turbines, where the oil is supplied under lower pressure, and the shaft rotates in very expensive and heavy-duty ball bearings.

Will the turbine “eat” oil?

As we have already said, a turbine cannot operate without oil. Typically, rubber seals are used to seal rotating shafts (as in an engine and gearbox), but no seals can withstand the operating conditions of a turbine. The operating temperature in it reaches thousands of degrees, and the rotation speed of the shafts reaches hundreds of thousands of revolutions per minute. These are much harsher conditions than in a motor.

The shafts and bushings in the turbine are fitted to each other with very high precision, and due to this, oil should not leak through them if the turbine is working properly. But as soon as the gaps increase, oil is sucked through the “cold” part of the turbine into the engine intake manifold along with the forced air. In such cases they say that “the turbine drives oil.”

Why is this happening?

- Natural wear of the working surfaces of shafts and bushings.

- Reduced oil pressure in the engine: the turbine lacks lubrication and wears out more.

- Increased oil pressure in the engine: oil is simply squeezed out through the cracks between the bushings and shafts.

- Increased vacuum in the intake manifold - oil from the turbine is sucked there. As a result, in engines where the clearances in the cylinders are close to ideal, oil loss due to a faulty turbine can reach several liters per hundred kilometers. This is what supporters of naturally aspirated engines are afraid of.

What is the life of the turbine?

Everything here is very individual and depends on the driving style. On average, on gasoline engines, the turbine life is 150 thousand kilometers. On diesel engines - 250 thousand kilometers. However, if you drive fast, overclocking the engine and turbine, the service life can be reduced to 100 or 60 thousand.

Features of turbines for gasoline and diesel internal combustion engines

Modern turbodiesels often receive superchargers, which are designed to provide flexible control of the flow of exhaust gases. The solution is called a variable geometry turbine. This device has a rather high initial cost compared to its analogues. It is also worth adding that the maintainability of these turbines is quite low.

Gasoline turbo engines are commonly equipped with turbines whose geometry is fixed. Superchargers of this type are much easier to repair and can last quite a long time after professional restoration and subsequent balancing.

As for the restoration of variable geometry turbines, which are widely installed on diesel engines, the situation is different. Not every service accepts turbines with this design for operation. Also, after repair, there is no guarantee that a turbocharger of this type will be able to pump the required amount of air in strict accordance with engine speed.