It is quite obvious that we will be talking about a weapon with which you can make an unnoticed shot. Silent prototypes have been known around the world for more than 100 years. But the narrow range of applications and the secrecy of the project brings many tales about these mechanisms.

Any weapon equipped with a special device to reduce sound levels is called silent. Or, as they say in the modern world, with suppressed sound. Moreover, this term is conditional, since it is impossible to fire a shot completely without sound. How a weapon silencer works began to be studied back in the 19th century, after the advent of smokeless gunpowder. At the same time, two methods of sound suppression were immediately identified: cutting off the gases from the combustion of gunpowder and blocking them in the barrel, and pre-increasing and cooling the gases before release into the atmosphere.

Firearms appeared several centuries ago and sound was considered the norm until our century. The roar of firing was accompanied by thunderous noise, sparks and haze. And all this was considered an indicator of good weapons.

In the modern world, silencers are used not only by the military, but also by hunters and athletes. Over its long history, it has been modernized and optimized many times.

The history of the creation of “silent” weapons

The very first attempts to create a device to reduce shooting noise were made a couple of years after the invention of smokeless gunpowder. Since the appearance of the shot had disappeared, it became necessary to reduce the sound. The first suppressors came out at about the same time. Registered in Sweden in 1894. In 1898 it was invented by France. In 1899, Denmark patented its multi-chamber suppressor. But for mass production, a device was used that was patented by British gunsmiths at the beginning of the 20th century.

Is it possible to remove the resonator?

Not the most reasonable decision for a number of factors:

- the entire system will be much louder. Due to its level, the sound will become unpleasant to the human ear. This becomes especially noticeable at low frequencies;

- the level of fuel consumption will become higher, because the engine performance settings will be disrupted;

- jam it soon enough it will become unusable. The muffler and resonator are directly connected. And when the service of one element ceases, the temperature of the gases will increase greatly, which will lead to breakdown;

- the engine power will become significantly lower, as the gas shock waves will be distributed incorrectly.

If there is a desire to abandon the device, then in this case a comprehensive tuning is required with adjustment of the entire exhaust system and installation of new elements for the full functioning of the engine and muffler. Even taking into account the possible breakdown of the car, some drivers simply remove the part without any system upgrades.

History of development

In Russia, the first patented suppressor appeared in 1916, thanks to the developments of the gunsmith-engineer A. Ertel. But it couldn’t get much demand, since it was used preferably for an artillery gun. But the device gained its greatest popularity around 1920, due to its popularity not with the military, but with hunters. They were the very first to realize the importance of silent shooting. And literally 10 years later this device was banned for use by civilians. Due to high demand not only in hunting, but also in criminal cases of citizens.

In the modern world, many countries have allowed the use of a suppressor in hunting and sport shooting. This is what increases the demand for new models. All production is aimed at minimizing the sound of firing, while improving the quality of accuracy and speed of fire. But still, to purchase this device, you need a purchase permit with a medical examination.

How can you extend the life of a muffler in a car?

Even original high-quality elements of the resonator and muffler last on average about 3-6 years. It all depends on the frequency of use of the car, storage conditions and climate zone. In areas with very harsh winters and low temperatures, even one full year for a muffler is already an achievement. Therefore, it is important to consider several features before determining the optimal life and corrosion protection methods for your muffler. In fact, many tips for maintaining a muffler look stupid and will not help in reality improve the situation.

It is worth following these recommendations:

- Fewer trips over very short distances. The life of a muffler is calculated not in years, but in cycles. It doesn't matter whether you've driven 3 km or 300 km since you started the engine, the damage will be approximately the same.

- Fewer trips to unknown places. SUVs are designed for off-road use, but driving a comfortable sedan on a country road with rocks and other obstacles is very dangerous; you can damage the muffler elements.

- Always change the muffler mounts on time. If the rubber hangers fall apart, the device begins to jump and even drag on the ground, which can cause various damages.

- Do not pour oil into the engine crankcase. Too high an oil level has a very bad effect on the operation of the catalyst. This device begins to burn out, and other troubles appear in the operation of the exhaust system.

- Make sure the power unit is working properly. If the fuel does not burn out, the gases will burn it directly in the catalyst or resonator, this will cause big problems with the muffler.

- Do not install cheap muffler segments. Cheap spare parts can be the first cause of exhaust system failure. Therefore, it is better to buy original parts or give preference to more expensive analogues on the market.

Preventative treatments or other methods of protecting the muffler metal do not make any sense. The fact is that the paint or anticorrosive agent will fly off during the first trip. Due to extreme heat, these parts cannot be protected with any coatings. The only thing you will achieve in this case is a persistent unpleasant odor in the cabin. Only after a week of use will the smell disappear.

When purchasing exhaust system segments, you should also note that they require running-in. They are painted to protect them from rust while in transit and while waiting in storage.

We invite you to watch a video about problems with the car exhaust system:

Advantages and disadvantages

This device has very few disadvantages:

- price;

- difficulty of design;

- difficulty in obtaining permission to purchase (confirmation of use by type of activity is required.

- But there are many more advantages that can be identified:

- weapon balancing;

- high maneuverability;

- ergonomics;

- significant reduction in shot noise;

- muzzle brake compensator function

- increased strength;

- Style (a weapon equipped with a suppressor looks more powerful).

Types of mufflers - installation location

The exhaust system of a modern car has at least one muffler, but often there are two or more. Depending on the installation location, there are three types of mufflers:

- front, closest to the exhaust manifold;

- middle, usually installed after the catalytic converter;

- rear, in front of the exhaust pipes, almost at the very exit.

The front and middle mufflers are also called resonators. The front muffler is used almost everywhere, but not always, but the middle one is less common.

The rear muffler is also called the rear part, the main muffler, in automotive slang “samovar”, “can”, “barrel”. It is present in the design of any exhaust gas removal system, even direct-flow, without fail. Otherwise, engine operation will be accompanied by a deafening roar as exhaust gases are removed.

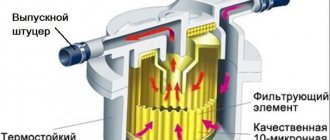

Muffler device

The standard version of the device has a classic look. This is a muzzle mechanism that is applied to various variations of firearms. It is fixed on the barrel or is a continuation of the design provided by the manufacturer. The main task of the device is to reduce the sound level and reduce the volume of fire from the combustion of gunpowder, to ensure the shooter's secrecy.

This feature is very important for military operations, because there is no particular need for a hunter in the forest or a shooter in the field to hide. And for a military man, it is very important not so much to reduce the noise of shooting as to hide sparks and flashes in the dark. With the help of flashes of light, the shooter is very easy to detect and will become an excellent target for the enemy. The suppressor also has a number of useful advantages, such as shooting intensity. There is also minimal gun recoil.

The suppressor looks like a cylinder made of metal materials: steel, copper, aluminum, a durable plastic mass can be used. Inside it there are cells in which the powder gas is removed. Most often, the device is attached to the end of the barrel using a special thread.

At the instant of the shot, gases penetrate the compartments and lose speed in them.

The chambers can also be filled with materials that absorb heat: aluminum mesh or shavings, copper wire. In this case, the gases cool themselves when the filler is heated and reduce their pressure. But such fillers are difficult to clean and are simply replaced. The noise level can also be affected by the material from which the partitions are made. If you replace steel parts with aluminum ones, the sound of shooting will be significantly lower. But such designs also have disadvantages. During a long series of shots, the pressure in the compartments increases, the cooling parts heat up and the productivity of the mechanism decreases. Subsequently, the main task and benefit of the device will be lost. Designers advise firing one salvo at a time with a large period of time between them so that the structure has time to cool down.

What role does a muffler perform in a car?

There are a number of tasks that the exhaust system performs. Previously, cars used simpler devices, which did not always provide sufficient reduction of noise and vibration. Today, devices are more effective, but expensive. Therefore, the repair and operation of such products turns out to be more expensive. But on the other hand, you get excellent operating capabilities and use the machine with minimal noise.

So, the main functions of a modern exhaust system:

- changing the cross-section of the exhaust flow - this becomes possible due to the implementation of chambers of various types and sizes in the system, as well as due to the constant narrowing/expansion of the exhaust flow;

- exhaust gas recovery - modern exhaust gas removal systems are equipped with EGR valves, which make the car more economical by burning gases in the combustion chamber;

- Sound wave interference is a simple and old technology that is implemented by perforating some tubes in the system, this effectively dampens noise of various frequencies;

- absorption of sound waves in the resonator - this device helps reduce rough noise and also simplifies the work of the muffler directly, which is installed next to the resonator;

- absorption of sound waves, thanks to the presence of special material in the chambers, such material absorbs sounds and creates comfortable operation of the car in any conditions.

Also, do not forget about catalytic neutralization of exhaust gases. Modern exhaust systems have a catalyst installed that reduces exhaust toxicity and allows the car to climb the ladder of environmental cleanliness levels. Recent changes in the design of the catalytic converter reduce the life of this device and also make it more expensive. But without this system, the car will not be able to meet modern environmental standards.

Silencer for various weapons

Every man is interested in how a pistol silencer works. The speed of a bullet leaving such a weapon is approximately 300 meters per second, which means that it does not exceed the speed of sound. It also has less energy, which means noise reduction is easier. But the big disadvantage is the reduction in the already low penetration ability. Most modern pistols are designed so that the entire bolt covers the barrel. To fit the suppressor, it was necessary to change the structure of the bolt and cut a special protrusion on the barrel. A standard example of such a pistol is the Chinese Type-64, in which the suppressor is integrated with the barrel, and the cells are located under and around it. Each compartment contains a mesh to absorb heat.

Reducing the noise of a firing revolver is much more difficult, since gases escape between the drum and the muzzle of the barrel. In the case of submachine guns, it’s a little easier. The forend and the damper are one piece. Suppressors for shotguns were developed specifically for bodyguards.

Why do mufflers fail?

Silencers fail due to condensation forming inside. When the exhaust system operates, it receives a hot flow of gases from the engine, and the catalyst often even comes into contact with the flame. This causes the system to heat up, which quickly cools down when the car is stopped. With daily use of the car and no downtime, the risk of developing corrosion processes in the muffler is minimal. However, with prolonged inactivity, rotting processes begin.

Metal breaks down for many reasons:

- Condensation accumulates in the lower part of the muffler elements, but it does not leave, so any protective coating of the metal is quickly destroyed, and aggressive corrosion processes begin.

- High temperatures destroy paint and any metal coatings provided by the manufacturer, so these parts cannot be reliably protected from rust.

- Prolonged downtime is the biggest enemy of a car muffler, as it starts the process of covering all parts with rust, and it is impossible to stop this process.

- Scratches and dents from stones and various obstacles along the way - this is important for cars that have low ground clearance, microcracks and mechanical damage.

- Small thickness and low quality of metal are factors in the rapid failure of exhaust system elements, which must be taken into account when choosing spare parts for repairs.

There are a lot of destructive factors, and even under ideal conditions, mufflers do not last long enough, since operation is carried out in extreme temperatures and in conditions of sudden temperature changes. Metals in such conditions fail quite quickly. A muffler failure requires replacement of exhaust system elements. Welding is not the most suitable restoration method, taking into account the operating conditions of the metal. In such conditions, welds behave unpredictably, so problems with the muffler may appear the very next day.

The principle of operation of the muffler

At a certain distance from the muzzle there is a wide rubberized membrane. Gases move between the cartridge and the walls of the barrel and are stopped by a membrane, from where they enter the compartments, and only after that they are released into the atmosphere with a significantly reduced pressure and temperature. Such a tool can last up to 200 volleys without replacing the washer. The shape of the washer can be either straight or curved. In the latter case, the powder waste is deflected towards the edge of the damper and does not advance ahead of the cartridge. The same effect is obtained when using a helical partition.

The suppressor is a fairly voluminous element that changes the balancing of the weapon and complicates the aiming process. This can be avoided through a peculiar arrangement.

Problems with the resonator

Any breakdown in this device can lead to serious problems with the car as a whole. The only way to solve this problem is to immediately replace the part to avoid even greater damage.

The most common breakdowns are considered to be:

- poor operation of the exhaust pipe due to a malfunction in the resonator. This problem is difficult to detect on your own;

- the presence of vibration during normal operation of the vehicle. This means that the internal part of the resonator is not working properly;

- low speeds at maximum engine operation.

If any sign is detected, urgent repair of the faulty spare part is recommended. But, unfortunately, repairs at a service station can cost a lot of money. In this case, the device can be replaced independently. If this happens for the first time or there is too little knowledge in this area, it is better to turn to specialists for quality repairs.

The reasons for the breakdown or malfunction of this device can be various factors. The spare part may simply become clogged. Since the holes in the core of the device are quite small, they easily trap tiny particles of soot and soot. As the period of operation increases, the build-up of foreign matter becomes larger and the device begins to work not at full capacity, thereby significantly increasing the sound of combustion of vapors.

Another reason is the elementary burnout of a spare part when using low-quality fuel or fuel entering the exhaust system. This part of the system is the very first to be hit by combustion temperatures. And in case of emergency operation, the internal part can burn out literally within a few weeks. The only solution in this situation is to replace all spare parts.

Rough driving and hard contact with the road may cause mechanical damage. With a small impact force, the structure can still be restored. And in case of a deep dent - only replacement.

With a sharp change in temperature climate and an increase in humidity, the internal parts of the device can quickly fail. If corrosion appears inside the pressure treatment valve, the patches will be useless. Only replacing the entire part will help.

In this article, you learned how the muffler resonator works inside, the principle of operation, possible malfunctions and ways to solve them. With proper maintenance, timely diagnosis and prevention, this part can last for many years without replacement.

More details about types

Different types were used at different times. Depending on the required functionality.

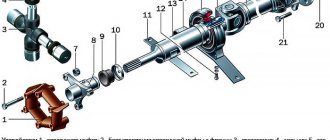

Multi-chamber

The first suppressors were muzzle-type and multi-chamber. They were constructed from an attachment to the gun barrel, in which partitions divided the cavity of the device into separate expansion compartments.

The extended device type has gained more popularity. They are based on reducing the temperature of the gas by reducing its pressure. Also, by increasing the number of cells, the main task of the device increases.

By separating the chambers with rubberized washers, efficiency increases significantly. But due to the process of breaking through the membrane, the speed of the bullet is significantly reduced. The intensity of shooting also decreases. Such washers have low wear resistance. When using a damper, the hum is practically inaudible and is barely audible in a quiet place. This remedy is also called “yelping puppies” because of their faint sound.

Some devices used two cells with a soft rubber gasket. In the first compartment there was a cut-off valve, and in each of the compartments there were valves for releasing gas. During a shot, the cartridge passes through these chambers in turn. Passing through the first cell, the powder combustion waste wastes pressure and slowly exits through the hole. Those who make it to the second exit into the atmosphere in the same way.

Integrated

Such dampers were a natural improvement to the classical mechanism - they were combined with the carrier into a single weapon. There are several holes in the barrel, through which gases pass into the damper located at the rear of the body. And in front there is the simplest chamber compartment.

Thanks to this design, the noise level is reduced even further. The length of the entire gun becomes significantly shorter, since there is no need to attach an additional device. But the biggest benefit is increased efficiency. If several principles are used simultaneously, maximum suppressor performance can be achieved.

The downside is the length does not correspond to the geometric dimensions. After all, to increase the speed of a bullet, you need sufficient space for acceleration.

Mechanical

This type is used very rarely. In it, noise is suppressed mechanically. But in them, energy is lost due to compression of springs or other elements, which greatly affects the speed and intensity of fire. One of the few advantages was the compactness of this device. But the disadvantages, unfortunately, greatly exceed the advantages.

Development and improvement

Today, the most important task in improving a suppressor is to further suppress sound, reduce dimensions, increase accuracy and intensity of fire, because every gunsmith knows how a silencer for a weapon works. Until now, suppressors are special-purpose items without the possibility of mass production. In recent years, to reduce the volume level, it has been recommended to purchase special cartridges.

The productivity of the devices is increased due to complex calculations of the rotation of the gas flow. This is possible through the use of complex profile partitions and turbulent eddies. Particles of powder elements collide with each other, quickly losing their energy.

What is a resonator for in the exhaust system?

When moving, any vehicle makes various sounds and noises. These sounds can be both quiet and loud. If the engine is gasoline, the noise will be especially loud. And it was precisely to reduce this roar that a muffler was invented, which became the main link in the entire chain of the exhaust system. The muffler actually includes only a few elements, one of which is the resonator. This entire chain solves the problem of reducing the sound of fuel burning in the engine. The noise level depends on the diameter of this part. Also a very important aspect is the shape of the spare part.