Repost and the information will always be at hand ✅

The starter is an important device in any car that is necessary to start the engine. Before the creation of a mechanism that provided electric starting of the engine, the car was started using a crank, which was quite difficult even for men. Therefore, this part was once called “female”, since electric starting is hundreds of times easier than starting the engine with a handle using force.

To ensure the ignition of fuel, a number of conditions are necessary. One of which is to ensure the minimum rotation of the engine crankshaft required to start the ignition system. And for this to happen, you need an additional source of mechanical energy - an electric motor or starter. It looks like a DC motor, which is powered by a car battery, and contains such basic parts as a solenoid relay, drive gear, armature, and bendix.

Starter power varies and directly depends on the number and volume of engine cylinders. But to start a standard gasoline car, you need a starting device with a power of at least 3 kW. The mechanical part of it fails more often than the electrical part. As a rule, this happens after the device has been in operation for 5 years or more.

In the article I will tell you in detail what a car starter is, how it works, how it works, its types, what malfunctions there are, and how to carry out repairs.

History of the starter

A device similar to a modern starter was invented more than 100 years ago. Already at the end of the 19th century, inventors tried to come up with a mechanism that could start the engine automatically. As a result, car manufacturers settled on a starting handle, which was used until the mid-1970s. in addition to the starting device.

In the early 1900s. Electric engine starting was considered a fantastic idea because the prototype starter was larger than the car engine it started.

Serious development of the device began after one tragic incident. In July 1910, B. Carter, president of the Cartercar company and an old friend of the founder of the Cadillac automobile company, Henry Leland, died while trying to start the car. Once he was asked for help by a stranger whose Cadillac had stalled. It turns out that the girl forgot to adjust the ignition. And Carter, being a gentleman, did not consider it appropriate to check this. As a result of attempts to start the car, it began to “roar” and the starting handle flew out and hit Carter in the crown.

I would like to note the fact that he is not the first and not the last who was injured from such actions. Henry Leland vowed after this tragic incident that he would find a replacement for the manual starter. At the same time, a young automobile engineer, Charles Kettering, created an electric motor for National's cash register. His starter even appeared with the name World Wonder in an advertisement for the Model 30.

When they found out about this, Leland welcomed Kettering with open arms. After all, his small electric motor was a suitable prototype for creating a car starter, although it was underpowered and overheated. But there was no technical revolution here. It turns out that C. Kettering offered the company a different starter design than is currently used.

Charles Kettering

In 1912, he assembled a small engine and in Detroit it was first installed on a working car. The electric motor interacted with the teeth of the flywheel (and not the crankshaft) of the engine. Thanks to this, a low-power device could cope with such a task, and there was no overheating. Despite the distrust of the automaker General Motors, where the tests were carried out, the electric starter was introduced into production.

A small revolution in automobile production occurred in 1916, when V. G. Bendix came up with the idea of dividing the starter and generator into 2 different units. The starting device was connected here for a short time using an overrunning clutch or Bendix. Subsequently, an electromagnetic relay was invented, which automated the supply of starter gears to the engine flywheel. The next generations of starting devices differed from each other only in the materials used and the set of parts.

In Russia, a manual starter is popularly called a “crooked starter.” Until the beginning of the 21st century, UAZ models had the ability to start the engine using a handle.

The starter does not turn and does not start

If you turned the key, but the unit did not react in any way, you should analyze three possible factors:

Often, car owners are able to determine the cause of the breakdown in the following way: they need to try to connect the control element directly to the battery and make a short circuit with a piece of conductive wire. If the unit starts working properly, it means that the relay has not failed.

Sometimes drivers encounter unpleasant creaking and strange sounds when trying to start the car

. This can be explained by several phenomena:

If the signals are dubious, you should not try to start the car, because minor breakdowns can be eliminated in the early stages. If you let the problem go, it will only get worse.

What is a starter in a car?

The term starter comes from the English word starter or start, which translates as “to put into action.” The device plays the role of a mechanism - it spins the motor shaft to a frequency at which it starts. In general, a starter is designed to start some mechanism, for example, it is used to supply voltage to a glow discharge lamp or to start non-motorized models in aircraft modeling.

What does the starter look like? This is a cylinder that is housed in a metal casing. The average length of the device is 15 cm, diameter 7-10 cm. The design of the starting device includes 3 main parts: an electric motor, a drive gear with an overrunning clutch and a cylindrical retractor relay. The device is connected by a wire to the battery. The starter can reach 5000 rpm at idle.

What category does the starter belong to? My answer is this: any mechanism assembled from parts is an aggregate. This unit can also be a part in another unit. And a constituent element is something that does not contain components: housing, screw, wire, etc.

What is a recoil starter called? People call it this: crooked starter, handle, handle, kickstarter, starting lever, sniffer. And the term starter itself is also called starter or launcher.

Scientifically, the direct purpose of the starter is to convert electrical energy into mechanical energy. And it serves to start the internal combustion engine by acting on the crankshaft so that it starts moving.

Since the starter in a car is responsible for starting the engine, car manufacturers come up with many additional methods to increase safety when starting the engine and reduce the likelihood of theft. In some cars, the engine can only be started when the clutch is depressed, and in an automatic, when the lever is in parking mode.

Where is the starter located on the engine and where is it mounted? As a rule, the starter is located in the junction of the engine and the gearbox (not far from the engine crankcase), next to the flywheel . The starting device can be located either at the top or at the bottom in a horizontal position on a flange or support frame. If the device is installed at the top, then it can be accessed from under the hood, and if at the bottom, then only from under the bottom of the car. The device is fixed with 2-3 large bolts.

Let's take a closer look at what the starter is made of.

How to dismantle and replace the starter

The specifics of dismantling and replacing the starter on VAZ cars have one caveat - since the unit is located in the lower part of the vehicle, it is difficult to access it from above. For greater convenience, it is recommended to carry out work in a pit in a workshop.

The general sequence of actions for removing a part is as follows:

A new node is installed using the reverse algorithm:

Starter device

A car engine produces energy that is used to propel the vehicle. This occurs due to the revolutions of the flywheel and crankshaft. Also, the engine energy “powers” all the electronics of the car. But if the engine is stopped, it will not be able to generate energy and create torque. And in order for the motor to “wake up”, it must be spun up. And here the starter comes to his aid, drawing its energy from the car battery.

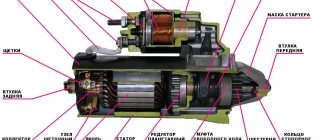

What's inside the starter? It consists of 5 main components:

- Housing (electric motor). This is a steel cylindrical shell. There are 4 magnetic cores (“shoes”) on the inner walls of the case. Previously, the device had an excitation winding (stator winding) wound into it, where current was supplied from the battery. But on new devices this role is performed by permanent magnets. There are only 4 of them and they are called the electric motor stator. All starter windings are in one circuit, and current is supplied to it from the central input of the device. The output from the windings is output to 2 positive copper-graphite brushes.

- Brushes and brush holder. The brush holders are located in the rear cover of the starter. They look like a clip with light springs that constantly press the brushes towards the commutator. The commutator is a part of the starter through which voltage flows to the brushes and armature plates. The contacts of the copper-graphite brushes are welded to the pole plates - the excitation windings. The brushes transmit operating voltage to the armature and plates and increase the peak power of the electric motor during the main operating cycle of the device.

- Anchor. What is an armature in a starter? This is a steel axle onto which its core and several plates are pressed. The armature is installed in the front cover of the starter, as well as in the rear cover using brass or copper bushings. I note that these bushings also play the role of bearings. In the grooves of the core there are frames, the ends of which are connected to the copper collector. And it, in turn, is connected to 4 brushes: 2 positive from the battery (a thick cable that passes a current of about 400 amperes) and 2 negative to ground. Thus, a magnetic field is created around the armature frame, which begins to rotate.

- Solenoid (traction) relay. This part is installed on the device body. The relay includes power contacts and a movable jumper. At the rear of the retractor relay housing there are power contacts (nickels) and a jumper. Nickels are copper bolts that are pressed into the relay cover; they provide contact immediately after current is applied. The wires from the battery and starter brushes (positive) are attached to the nickels using nuts. And the retractor relay core is connected to the bendix (overrunning clutch). The relay supplies power from the ignition and pushes out the bendix. Thus, the purpose of the relay is to control the switching on and off of the electric motor and the effect on the engine flywheel. Let me put it even simpler - the traction relay has the same function as a gearbox between the engine and the wheels. In new relay devices, in addition to the main winding, a holding winding is installed, which reduces the current consumption of the starter.

- Bendix (overrunning clutch or freewheel). This is a roller design with a drive gear, the purpose of which is to transmit torque to the flywheel. Bendix transmits torque using a gear, but only when the starter is started. The overrunning clutch also stops the reverse transmission of force that occurs when the engine starts, separating the flywheel crown and the Bendix gear. This helps prevent damage to the entire device. I'll say it more clearly. For the internal combustion engine to work, the flywheel and crankshaft must rotate at a minimum speed of 100 rpm. But the diameter of the starter gear is 10 times smaller than the flywheel. From this we conclude that the gear rotates 10 times slower than the flywheel. And when the flywheel starts to rotate at a speed of 100 rpm, then logically the starter gear should rotate 10 times faster - at a speed of 1000 rpm, which would lead to jamming of the device. Bendix transmits torque to the flywheel, but does not transmit it back to the starter. Due to the structure of the bendix (inner and outer races, rollers with springs), it does not spin more than it should and this prevents damage to the starter.

The starter consists of approximately 50 components.

Another good article: Car speedometer: what it is, types, structure and principle of operation. Errors and malfunctions

Many people are interested in how many contacts there are on the starter? I will answer: it has a central contact (positive terminal) and ground (negative battery terminal). How many windings are there in the starter? There are four of them: parallel, serial, retracting and holding.

Differences in the design of starters may be in the mechanism that separates the gears. And in a car with an automatic transmission, the device includes additional windings that prevent the engine from starting if the drive position is selected on the selector. Starters also differ in the presence of a gearbox, I will write about this later in the article.

Starter drawing

How does the starter start the engine, how does it work?

Starter operating principle

The starter works on the laws of physics that you were taught about in school. If you place a frame of wire with two ends between the 2 poles of a magnet and pass current through it, it will begin to rotate. This is the principle on which the simplest electric motor operates.

What does the starter do during starting? All his work is divided into 3 stages: starting the device, bringing the drive gear to the flywheel crown, disconnecting the drive and the flywheel. The starter itself rotates the armature inside its mechanism under the influence of a magnetic field, which sets the flywheel in motion.

The launcher's operating time is very short. After the engine is started, the starter is turned off and no longer takes any part in the operation of the car.

Let's take a closer look at the principle of operation of the starting device:

- The driver turns the key in the ignition. The electric current from the positive terminal of the battery is transmitted to the input contact of the starter, then to the field winding (or magnets), then to the positive brush with the commutator. After this, the current flows to the armature frame and the negative brush, which is connected to ground (the negative terminal of the battery). Magnetic fields arise that repel each other, causing the armature to rotate, which is pulled into the relay. The connection between the battery and the starter is short-lived, only at that second when the driver turns the key. This connection occurs due to the copper coin.

- The armature has a spline connection; a bendix with a gear is put on it. The spline connection allows these parts to move freely along the armature and at the same time transmit torque to the starter gear. The Bendix with the gear is moved by the fork. On what principle does the starter fork work? The plug is moved by a core, which in turn moves an electromagnet in the form of a coil, to which current is supplied from the battery through the ignition switch. I repeat once again: the power wire from the battery is connected to the input contact of the device using a coin; it is this that connects to the rod when the device is turned on. The core moves and pushes the rod, ensuring the closure of the 2 main contacts. And when the starter is turned off, everything returns to its original position.

- So, the traction relay is activated. The armature performs translational actions inside the device body and the bendix is pushed out. Because of this, the drive gear fits into the flywheel ring gear. The flywheel is a cast iron disc that is much larger than the starter drive gear on which the ring gear is mounted.

- The moment the gear engages the flywheel, voltage is applied to the electric motor and current is supplied to the electric motor. The flywheel begins to rotate, which in turn drives the engine crankshaft.

- That's it, the engine is started, the driver releases the ignition key. At the moment when the engine speed is higher than the starter speed, the bendix will move away from the clutch with the flywheel. All trigger mechanisms will return to their original position and it will turn off.

Watch the video, it explains very clearly how the device works.

Video: How the starter works

Now I’ll tell you about what kind of starters there are.

Scheme and principle of operation

The starter is one of the most conservative components of a car. Such an electrical device was first tested by Charles Cattering in 1912, that is, more than a hundred years ago. At first it also served as a generator.

But in the form in which the starter is used to start modern cars with internal combustion engines, it owes its name to the American inventor and auto industrialist Vincent Hugo Bendix, who immortalized his name in one of the main parts of the starting device.

A typical functional diagram of a starter is shown in the figure:

The principle of operation of the starter is almost the same for all car models with internal combustion engines. When the ignition switch is turned to the “Start” position, a starting current is supplied to the retractor winding.

This, in turn, drives the traction relay armature and the contact spring rod. The traction relay acts on a lever, usually called a yoke, which pushes the freewheel and gear (Bendix) into engagement with the flywheel. At the same time, the contact plate closes the coins, through which voltage is supplied to start the starter motor.

The typical functional diagram of a starter is so well thought out and tested that the difference between starting device models lies only in the design features and materials from which the components are made.

However, starters have their own vulnerabilities:

- solenoid relay;

- electric motor brushes;

- nickels;

- fork;

- freewheel;

- gear;

- armature collector;

- armature bushings;

- damper spring.

In fact, almost every component of this device can become unusable during operation. This is due, first of all, to the fact that when starting, especially in the cold season, the starter produces a lot of power, experiences extreme loads, and huge currents flow through it.

If the starter fails, it is important to diagnose it and determine which of its components is faulty. None of the modern computer diagnostic devices can do this. You should be guided by experience and your own knowledge.

Types and characteristics of starter

I described the classic starter design. In it, the bendix is located directly on the rotor shaft. Such a device requires an electric motor with a low rotation speed and high thrust, which leads to an increase in the mass and size of the device.

What kind of starters are installed on modern cars? These are starters with a gearbox. Let's take a closer look at each type of starting device, as well as what is their difference.

With gearbox

Such starters are called planetary. A standard gearbox has a sun (drive) gear, a carrier, and a ring gear. All these parts are engaged with each other. In a planetary gearbox, all components are used as a driven mechanism.

Another good article: Tachometer: what it is, types, what it measures, principle of operation and device, what it is needed for

A starter with a gearbox uses an additional shaft where the bendix is located. Thus, the bendix and the electric motor in the starting device operate only through the gearbox. But, despite the new part called a gearbox, the operating principle of such a starter differs little from the classic one.

The peculiarity of a planetary starter with a gearbox is that it consumes less energy for its efficient operation, thanks to which it can spin the crankshaft of the internal combustion engine many times in a row even with a very low battery charge. The gearbox reduces the speed of the electric motor, but improves its traction force. And the use of magnets in the design increases the service life of the stator winding and prevents possible malfunctions.

The gearbox converts rotation speed into thrust by changing the gear ratio, so you don’t have to use powerful and “gluttonous” electric motors in the starter.

Pros:

- Long service life.

- Small size and weight.

- Low cost of parts.

- You can start the car even in severe frost.

Minuses:

- There are problems finding spare parts.

- Low quality parts.

- More complex repairs compared to starters without a gearbox.

Devices with gearboxes and cylindrical gears are also used, but due to the complex mechanism they are not installed so often.

Without gearbox

Such devices are also called rotary starters. The design of this type of device does not include a gearbox, and rotation is transmitted directly to the starter gear. The most important advantage of the gearless mechanism is its very simple device, thanks to which even a beginner can perform repairs. In addition, such a mechanism is characterized by high reliability and endurance, which leads to an increase in the service life of the starter. Therefore, during operation, faults due to current supply occur infrequently.

In a gearless starter, the gear engages the flywheel instantly, so the engine starts very quickly. In addition, parts for the device can be easily purchased in most stores, although the price is quite high.

The disadvantages of starters without a gearbox are that at low temperatures its operation is extremely unstable due to the fact that the device requires a lot of energy. Also, such a starting device is heavier and bulkier compared to a gear type.

What is better: a gear starter or a regular one? For most vehicles, a geared starter is best.

Starter malfunctions

What is the approximate service life of a starter? The average value is 5 years or 120 thousand km. How long the starter lasts directly depends on the operating conditions. For example, if you drive short distances in urban areas and constantly start the engine, the starter will quickly fail.

I’ll tell you about the signs that accurately indicate a device malfunction. These are symptoms such as:

- A specific crackling sound is heard.

- There is a delay in starting the engine after the driver turns the ignition key.

- The starter motor can be heard starting, but there is no sound of the engine running.

- There is no action after turning the ignition key.

- The starter operates after the engine starts.

What possible malfunctions can occur with the starter?

- Poor contact . This is a common breakdown, and the driver can notice it when starting the engine. In this case, you should check the device's mounting and contacts.

- Magnets may fall off . This applies to modern devices. Here it is better to entrust repairs to experienced auto repairmen.

- Wear of support bushings . In this case, the armature will seem to “dangle” and there will be no full contact of the brushes with the commutator. In this case, there will be sparks, the brushes will burn and wear out. In this case, you need to replace the brushes and support bushings, and groove the commutator.

- Wear of rollers in Bendix . In this case, it is towed. The bendix needs to be completely replaced.

- Solenoid relay malfunction . Most often, nickels burn. The copper melts in them, and the nickels are soldered to the contacts. In this case, even after starting the engine, the starter will continue to work. All this drains the battery a lot. Therefore, here you should disconnect the wire from the battery as soon as possible, remove the device and replace the solenoid relay.

If the crankshaft rotates slowly , then the reasons for this are:

- High viscosity motor oil.

- Low battery charge.

- The wire contacts have oxidized.

If the starter runs too long , this is due to a stuck ignition switch or problems with the contacts.

If the starter does not start when you turn the key , then the reasons for this may be the following:

- The battery is discharged or broken.

- There is no contact of the ground wire with the battery or between the winding and the collector.

- The anchor is worn out.

- The brushes do not adhere to the commutator.

- Solenoid relay is faulty.

- The device control connector is disconnected.

- In automatic transmission, the selector is not in position N or P.

- The gearbox switch is faulty.

If the starter rotates very slowly , this is indicated by the following faults:

- The battery does not work or is low.

- Bushings are worn.

- The wire between the battery and the starter is faulty.

- Damage to the solenoid relay.

- The stator or armature winding is faulty. The mechanisms must be replaced.

- Poor contact of the armature or stator winding with ground.

- The brushes have poor contact with the commutator due to wear or incorrect position.

- Commutator burning.

The starter works, but the engine does not:

- Overrunning clutch worn.

- Parts in the gearbox are broken.

The starter rotates with the flywheel:

- Solenoid relay is broken.

- Failure in the contact group of the ignition switch.

There is no click of the solenoid relay:

- Low battery charge.

- Contacts or coil of the solenoid relay are burnt out.

- The contact on the positive terminal of the battery or starter has oxidized.

- There is a malfunction in the ignition switch component.

- Short circuit to ground in the coils of the solenoid relay. Here it is better to replace all the parts.

- The relay armature mechanism is stuck.

If the crankshaft does not rotate the starter armature , then the probable causes of the breakdown are:

- Towing the freewheel.

- Jamming when moving parts along the screw thread of the shaft.

- Broken clutch release lever.

- Malfunction of the clutch spring or drive ring.

If loud noises appear when starting the engine, you should check the fastening in the starter parts.

If a gear grinding noise occurs in the starter, you should check the switch contacts, the gear travel adjustment, the drive device spring, and the flywheel ring teeth. If the ring gear is damaged (it is often made of plastic), then it is better to replace it with a metal one. There is also a possibility that the solenoid relay is stuck.

Video: Checking a car starter, all methods and breakdowns

This video is suitable for beginners; an experienced mechanic talks very interestingly.

The most common reasons why the starter does not turn

Having ruled out the simplest and most banal reasons why the starter does not work, you need to remove it from the car, disassemble it, and try to diagnose it yourself. Here are some of the most common situations:

- Battery problems. If there are no problems with the charge, then you need to check the condition of the terminals and contacts.

The most insidious point is the negative wire connecting the gearbox and the car body. The contact may appear and disappear again. You need to completely disconnect it, clean it and put it back in place. If nothing has changed, then we continue to look for the cause of the breakdown further.

- There are situations when the solenoid relay makes appropriate sounds, but the motor does not start working. The reason for this situation is also a discharged battery. In this case, the lights on the instrument panel also go out. To solve the problem, simply charge the battery, but think about what could lead to its complete discharge.

- Security systems sometimes present surprises and surprises. It’s easy to identify breakdowns of this nature, but getting rid of them is quite difficult. The reason is the discrepancy between the characteristics of security systems and immobilizers of some cars. They do not appear immediately, but after some time. This problem was relevant for the second generation Ford Focus, released in 2008. The car ran exceptionally, but one day the starter stopped working. After a thorough check, it was possible to say for sure that everything was in order with the contacts and electronics of the car, but the part stubbornly did not perform its functions. The problem was solved by replacing the standard immobilizer. It turned out to be easy to identify the breakdown - bypassing all systems, the button simply sent power from the battery to the starter, and it worked perfectly. The case looks more like an exception, but still should not be discounted.

- Problems with the solenoid relay. Diagnosing it is extremely simple; just apply a charge directly from the battery to the relay terminal. If the engine starts to operate normally, then the problem is coming from the relay itself. You just need to clean the contacts, which are most likely burnt. But keep in mind that after such cleaning the relay will still not last long, because the manufacturer applied a special anti-corrosion layer to the terminal blocks, which disappears after cleaning. So be prepared to purchase a new part.

- Bendix is a gear that is located on the same shaft as the starter rotor. The main task of the Bendix is to transmit torque from the electric starter motor to the car engine. To determine that the culprit of the starter not working is Bendix, you just need to connect the two power terminals on the relay. This way we will allow current to bypass the relay, and we will be able to find out whether it works in this position.

Another problem associated with Bendix operation is wear of the gear teeth. In this case, the part is loosely connected to the flywheel, making idle speed. If there is such a problem, a characteristic noise and crackling noise is heard. To solve this problem, it is enough to replace the gear by completely disassembling the starter.

- Starter bushings. In front and behind the starter there are special bearings on which the shaft rotates. In this case, the relay makes a clicking sound but does not turn the starter, because the shaft can no longer perform this function, and the primary winding of the part closes with the secondary. In this case, you need to be extremely careful, because this situation leads to melting of the wires, which can cause a short circuit, a malfunction in the car’s electronics, and in the worst cases, a fire.

If, when starting the car, the relay clicks and the starter does not spin, then you cannot keep it turned on for a long time. After several attempts, the shaft often falls into place and the car starts as usual. But as soon as the first symptoms appear, you need to immediately seek qualified help or replace the bushings on the starter yourself. If you ignore this problem, the consequences can be very disastrous.

- Brush block. We penetrate deep into the starter; its electric motor operates only if there is a stable supply of electricity from the battery through the brushes to the primary winding. But the brushes have a limited service life, as they are made of graphite and wear out quickly. This option is easy to calculate by looking at the total mileage of the car. To eliminate the breakdown, you need to disassemble the starter, get to the brushes and visually objectively assess their condition. If they are worn out, you just need to replace them with new ones.

- Starter windings. The starter is a familiar electric motor, which is characterized by all the usual diseases for such devices. One of the most common is the problem of winding wear. If you smell a pungent odor when starting the engine, this is a clear sign that the winding will need to be replaced in the near future. Having disassembled a starter with a burnt winding, we will see that it has changed color, smells of burning, the protective varnish has burned out, and the color has changed to a darker one. This happens if the driver is overzealous in trying to start a broken starter.

Normally, the starter's operation should be limited to a few seconds, but inexperienced drivers may try to start the engine without leaving the starter alone for several minutes, thereby burning the winding of the part. After such an incident, you have to change the entire starter, since replacing the winding is a long, expensive and troublesome task. And in terms of money, often buying a new starter and replacing the winding cost the same. Therefore, do not try to squeeze all the juices out of the starter, take care of it.

How to prevent starter failure?

In order to increase the service life of the starter, it should be serviced from time to time. Let me draw your attention to the fact that it is recommended to always check the operation of the mechanism if, when you turn the key, the engine does not turn on within 5 seconds. But there is an exception here - high negative temperatures. If this happened because of this, then for a gasoline car you can use fluid to start a cold engine, and for a diesel car you can warm up the spark plugs.

I’ll tell you about how to operate the car, because it all directly depends on how long the starter runs.

- It is recommended to use automatic engine start to a limited extent . Remote engine starting “burns out” the starter and discharges the battery, especially if the signaling system “drives” the starter in an attempt to start the engine due to an error.

- When starting the engine, the ignition key must be released immediately . Otherwise, this will lead to rapid wear of the starter device. In this case, the anchor most often fails. Some models have a plate that indicates the maximum operating values and starting frequency.

- You cannot move with just one starter if there is no fuel . Drivers often do this when they suddenly run out of gas. As a result, the starter device quickly wears out and breaks, and the battery quickly runs out. Although using this method you can drive 2-3 meters relatively safely in first or reverse gear with a manual transmission.

- If you are unable to start the engine, you should repeat the next attempt after 30-60 seconds so that the starter has time to cool down, especially if there are more than 2 starting attempts in a row. In general, it is not recommended to leave the starter switched on for more than 10 seconds after starting the engine.

- From time to time, check the fastenings and contacts on the battery terminals. If there is oxidation, the parts should be replaced.

- Carry out regular vehicle maintenance to identify device problems at an early stage.

Another good article: Silent blocks: what are they in a car, how they work, what they are responsible for, types, cost, how to replace

Starter performance monitoring sequence

If, when turning the ignition key to the “Start” position, the starter does not show any signs of life, you must perform the following sequence of actions:

1. Measure the voltage at the battery terminals with a multimeter. There must be at least 12 volts to start the engine. If less, you should charge the battery.

2. Next, you need to measure the quality of the vehicle's ground tire. You should check the contacts of the “minus battery” bus - the car body and the “minus battery” bus - the engine body, actually the starter. This is best done by turning on the ignition and measuring the voltage between the battery negative, the metal elements of the engine body and the stripped elements of the engine body. Voltages must be strictly 0.0 Volts. If more, the connection contacts may be broken.

3. Before taking further actions, it is better. In many cars, the engine may be blocked by the immobilizer, which may require key binding. A malfunction of the automatic gearbox components can also introduce a prohibition mode for starting the car.

4. For further diagnostics of the starter, an electrical diagram of the vehicle and a diagram of the location of relays and fuses are required. The car's starting system can be organized in one of two ways. In cars of earlier years of production, voltage was supplied to the starter solenoid relay directly from the ignition switch contact group. A malfunction of the contact group leads to a lack of voltage supplied to the solenoid relay. In this case, it is necessary to check the presence of contacts according to the ignition switch connection diagram. Modern vehicles control starter activation using a starter relay, usually located in the relay and fuse box under the hood. It is necessary to check the serviceability of the relay, the presence of +12 Volts at its input contact. You can force the starter to turn on by closing the relay contacts.

In this case, be sure to move the manual gearbox to neutral (!).

5. Next, proceed directly to work with the starter. It is usually located in the flywheel area. A more convenient location is between the engine and the radiator of the cooling system. In this case, access to it is simplified. It is worse if the starter is located behind the engine under the exhaust manifold. In any case, it is necessary to trace the path of the wires coming from the starter. Two conductors extend from it: one thick (cross-section of at least 25 sq.mm.) for starting the electric motor and a thin one for controlling the solenoid relay.

6. First of all, it is necessary to strip the thin conductor in a convenient place and connect a wire with a cross-section of at least 2 sq. mm to it. and insulate the connection point. Then move the gearbox to neutral. After this, connect the connected conductor to the positive terminal. If there is no action from the starter, the following options are possible:

- malfunction of the solenoid relay winding (break);

- wear of the starter motor brushes;

- failure of the collector lamellas;

- armature winding break;

- lack of contact on the connector of a thin wire (often occurs when a thin wire comes into the connector “under the chip”, sometimes it’s enough just to move it);

- lack of grounding on the car engine body (to be more sure, you can connect the engine body to the battery negative with a powerful wire).

7. If the solenoid relay works reliably, but the starter motor does not rotate, you should check the presence of + 12 Volts at the output of the thick conductor. It usually has a “nut” connection, sometimes the contacts burn and char. In this case, the contact areas should be removed and cleaned. You should also check the connection of the thick conductor in the area of the positive terminal of the battery.

8. Using a multimeter, you can check the resistance of the coil of the solenoid relay (between the connected conductor and the motor housing, it should be in the range from 3 to 20 Ohms for different types of starters).

9. If the previous actions did not lead to a positive result, it is necessary to begin diagnosing the malfunction on the starter removed from the vehicle.

Video - how to close the starter directly if it does not turn:

Bad advice on how to quickly break the starter device

- Immediately after starting the engine, hold the ignition key in the Start position, and you can also press the accelerator pedal. In 5 minutes the bendix will jam, the brushes will wear out, the armature will overheat and the starter housing will burst.

- Engage 1st gear and turn the ignition key. There should be no fuel in the tank. After a couple of hundred meters of driving, the starter will break in exactly the same way as in the previous version.

- When using diesel fuel, you need to add a diluent - ether, for the sake of economy, so as not to buy winter diesel fuel. Detonation will occur during startup, the bendix, the front part of the starter and the armature will break.

- Drive through a cold puddle, soaking the starter, and then warm it up. After this, the starter begins to “sneeze”; it will jam due to rusting of the stator with the armature.

Video: How to remove, disassemble and reassemble the starter

Detailed video about disassembling and assembling a gear starter for VAZ cars! Removing and installing the solenoid relay, replacing the starter bushing, how to change the starter brushes, flywheel diagnostics, checking the bendix, and also checking the starter.

VAZ car starter - design and repair features

Features of the design and operation of a VAZ car starter: design, types, connection, dismantling and replacement, diagnostics and repair. Video about VAZ starter.

When the car engine is running, the movement of the car engine is supported by a flywheel, which provokes its rotation. The crankshaft has several counterweights. Both the flywheel and the components of this unit generate an inertial effect that prevents the motor from stopping at a “dead point”.

In terms of design and specifics of operation, starters for VAZ look almost the same as systems from other manufacturers. The only differences may be the power of the device. For example, a low-power starter is suitable for a gasoline engine, and a more powerful one for a diesel engine.

How to repair a starter yourself

I'll tell you how to sort out and restore the starter using a specific example. I came across a sample with the following breakdown: the starter turns the crankshaft slowly, even with a high battery charge.

Having dismantled and disassembled the device with the connected starting wires, when it starts, it rotates quite confidently. After some time, the device stopped and smoke appeared.

When the back cover of the starter was removed, black dust fell out of it. This means that the brushes are worn out. After removing the brush mechanism, remove the housing with magnets and rotor.

In order to better examine the cause of the problems, you need to sort out the starter, blow out all the mechanisms with a compressed air cylinder and wash them in gasoline. After these manipulations, it becomes clear that the brushes have practically worn out, the springs that pressed them have weakened, the brush holders have turned blue due to overheating, and the coils have melted.

How to resuscitate and repair the starter in this case? You need to take the brush mechanism (assembly) and bring it to a company that repairs automotive electrical equipment. Ask for an analogue. Approximately this will cost you 450-500 rubles. And if you compare it with the price of a starter (5,000 rubles on average, it all depends on the brand), it turns out to be quite cheap.

Then we thoroughly clean the rotor and inspect the commutator, which is in constant communication with the brushes. It turns out that the collector is also worn out (marked with arrows in the picture), but it will be able to work for some time without re-grooving it. Therefore, we simply clean the collector using fine sandpaper. As a rule, a commutator can easily work through a couple of sets of brushes. But if the collector fails, then most likely the entire starter will have to be replaced.

Go ahead. Let's carefully examine the Bendix (overrunning clutch). Let's try to rotate its gear manually. It should spin one way, but not the other. Also, the bendix should move easily along the shaft axis. In my case, everything is fine with him. If there were problems with the overrunning clutch, it would also be quite difficult to find it on the market. Most often, the rollers and springs wear out in the Bendix, which is why the gear does not lock but slips during reverse rotation. As a result, the starter works, but the engine does not. In this case, it is best to replace the bendix or the entire device.

Then he inspects the condition of the gearbox itself. We remove the gears, then wash them with gasoline. If everything is fine, then we apply just a little CV joint or high-quality bearing grease to the bearings and gears.

Additionally, let's inspect the contacts of the retractor relay. To open it you will need a soldering iron. You need to unscrew two screws and solder solder on two contacts (indicated by arrows).

The contacts were in perfect order. Clean them with a piece of sandpaper. Then you need to heat up the pistons that go on the lid and slam the lid on the table with a sharp movement. Extra pieces of solder will come out of the pistons and the holes will become free. Then the cover can be put on the wires without any problems and soldered everything in place.

Under no circumstances should the core of the solenoid relay be lubricated with anything, because in the cold this will cause it to jam. To calm your soul, you can lightly apply motor oil and wipe everything dry.

Then we assemble the starter device in the reverse order. Be sure to apply some grease to the rear rotor hub.

Some people ask how to rewind the starter? If there is a problem with the winding of the device, then re-winding is not entirely effective. Here it is better to replace the entire part or device.

Before installing the repaired starter on the car, grind the brushes to the commutator. To do this, connect the starter using battery cables. Let him work for a couple of minutes intermittently. Everything is ready, the starter can be installed on the engine and enjoy a confident start.

Video: How to make a starter with your own hands?

The author shows how you can make an UNREALLY COOL DIY product from a broken starter with your own hands. This is an impact screwdriver. Make yourself such a necessary tool!