(viscous coupling) was invented back in 1917 by Melvin Severn, but at that time, his invention was not appreciated. The viscous coupling was only remembered in the mid-60s, during the creation of a car with good cross-country ability, handling and stability.

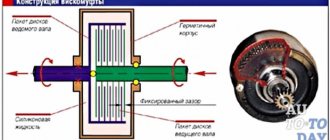

At its core, a viscous clutch is a multi-disc clutch, the characteristic feature of which is discs that do not have surfaces in contact with each other. It is known that the clutch is the most common clutch in a car. In it, the friction forces between the disks (steel plates, 0.25 - 1.0 mm thick) transmit torque. One half of the disks, installed with a minimum clearance in the range of 0.15 - 0.2 mm, is connected to a cylindrical body, and the second half is connected to the drive shaft of any of the axles, or to one axle shaft. The sealed cylindrical case is approximately 75 - 90% filled with silicone liquid, which in this case acts as a connecting link between the disks. Silicone liquid has high kinematic viscosity. If ordinary liquids reduce their viscosity when heated, then this one, on the contrary, became thicker, up to the state of a solid.

When a car moves on the road surface with the same coefficient of adhesion on all wheels, the latter rotate at the same angular speed. At the same time, the clutch discs rotate equally, without affecting each other.

But if one of the wheels, or the wheels of one bridge, hits the road surface with a lower coefficient of adhesion (dirt, ice), they, and this means that the clutch discs begin to rotate at different angular speeds. The viscous coupling is activated and blocks the rotation of these disks.

The process occurs as follows: during operation of the coupling, the silicone liquid is heated. And the greater the difference in rotation of the disks, the more the volume of the coupling is filled with this liquid, which in turn increases the friction between the disks of the device. Due to this, the transmission of torque changes proportionally depending on the difference in wheel rotation, that is, the required degree of blocking is achieved.

Operating principle of a viscous coupling

The principle of operation of the viscous coupling is to change the number of fan revolutions, depending on the temperature of the air flow after it passes through the radiator. The viscous fan coupling significantly improves the efficiency of the cooling system by more efficiently utilizing the fan impeller's performance. The clutch sets the fan the optimal speed, which allows the entire air control system to operate efficiently. This helps warm up a cold engine and maintains the desired engine thermal conditions within operating limits. The fan operating mode changes smoothly, which increases the wear resistance of not only the fan drive belts, but also other parts of the unit. During operation of the coupling, there is no friction between the parts, which significantly increases the service life of the viscous coupling.

The use of a viscous fan coupling means that:

- Engine life is increased and engine power losses are reduced

- Reduced fuel consumption

- Virtually silent operation of the viscous coupling

- The labor intensity of replacing generator and pneumatic compressor drive belts has been significantly reduced

- Due to the smooth running, the service life of the fan drive belts is increased

- Low cost of the entire re-equipment set with high quality products

Such a device operates autonomously, using the principle of changing the viscosity of the clutch working fluid.

The viscous coupling operates depending on the air temperature after the radiator of the engine cooling system. It is regulated by a bimetallic thermoplate, that is, it turns on at 61°C - 67°C, when the antifreeze temperature reaches 84°C - 92°C.

Most models with a longitudinally mounted power unit are usually equipped with a belt-driven fan combined with a coolant pump. If the fan impeller were rigidly connected to the drive pulley, and its rotation frequency was directly proportional to the crankshaft speed, then such cooling would not be effective, especially at high speeds and low air temperatures. Therefore, a viscous coupling is installed between the pulley and the impeller, which regulates the intensity of the flow of air passing through the radiator.

A nine-blade fan with a diameter of 710 mm is installed on the KamAZ engine. The material from which it is made is glass-filled polyamide, the fan hub is made of metal.

To drive such a fan, a viscous KAMAZ fan coupling is used, which is attached to the fan hub.

The operating principle of the KAMAZ viscous clutch is based on a change in the viscosity of the fluid during friction in small gaps between the clutch discs. High-viscosity silicone fluid is used as the working fluid.

Such a coupling, by its design, is non-separable and therefore does not require maintenance during operation.

The viscous clutch of the KAMAZ fan is turned on by a bimetallic spiral when the air temperature after the radiator reaches 61° C - 67° C.

The fan is installed in a fixed annular shell, which is rigidly attached to the engine. The fan shell and its casing help increase the air flow rate, which is pumped by the fan through the radiator.

Recently, crossovers, or so-called SUVs, have become increasingly popular. These cars differ from real SUVs not only in the absence of a supporting frame (here this function is performed by the body), but also in “dishonest” all-wheel drive with electronic locks. Moreover, it connects automatically. To connect the two axles together, a viscous coupling is used. Not every motorist knows what this element is. In today's article we will look at this mechanism in more detail.

Clutch repair

No matter how correctly and competently the driver operates his car, the all-wheel drive clutch can still fail. Dealership centers replace the clutch assembly, since finding spare parts is very problematic. The most common failure is the clutch jamming when turned on. This happens more often due to overheating.

When repairing, you need to disassemble the mechanism and visually inspect all parts for wear. If the parts are in satisfactory condition, rinse everything thoroughly and blow with compressed air. Check the bearing for play and noise when rotating by hand. If the bearing has play or makes noise when rotating, it should be replaced. An analogue can be selected according to size.

If the car has a high mileage, it is advisable to change the seals. Their service life is quite decent, but still not worth the risk. Oil seals can be selected according to size and markings. It is necessary to change the sealing ring of the coupling cover, lubricate it during installation and make sure that the edges do not lift up.

The same applies to the internal oil seal, which is installed on the GP side. Before installing the cover, add new oil. Insert the assembled coupling into the housing and adjust the gap between the movable plate and the housing. It is important that when the electromagnet is turned on, the plate does not touch the coupling body.

Another common breakdown is a hum while driving. It's usually the clutch bearing that hums. When replacing it, you should carefully inspect all parts of the coupling for wear. It is advisable to change the oil at each disassembly to prevent wear products from entering the mechanism.

Also interesting: How does all-wheel drive work in Duster - Dustershop77

Rarely does an electromagnet winding fail. You can check its operation directly on the car. Apply 12 V voltage to the connector contacts, and a click should be heard. And if you hold the clutch with your hand, then at the moment of switching on you can feel a slightly noticeable knock inside the clutch. This indicates that the electromagnet is working properly.

The all-wheel drive clutches of Hyundai Tucson and KIA Sportage are identical. They differ only in the outer casing depending on the year of manufacture of the car. They also differ in catalog numbers. If damaged, it must be completely replaced. But if desired, it is possible to repair the coupling on your own and at a lower cost. The most pressing issue during self-repair will be the search for spare parts.

Good roads and good luck with the repairs!

Design and principle of operation

The viscous clutch operates on the same principle as a torque converter in an automatic transmission. In both cases, torque is transmitted through a fluid. However, the clutch is designed a little differently than the torque converter. It is a hermetically sealed enclosure. Driver and driven impellers (two turbines) rotate inside it. When the wheel shafts rotate synchronously, the composition inside is in a liquid state. As soon as one axle slips, the torque of one turbine is transferred to the other. The liquid mixes and becomes solid. Thus, the transmission of torque to the axle is resumed. As soon as the car has overcome the obstacle, the mixing stops. The torque is again transmitted to one axle.

But this is not a single design diagram for a viscous coupling. Some have driving and driven friction discs instead of turbines (see photo below).

They work on the same principle. Dilatant liquid is also poured inside. When the shafts rotate at different speeds, it mixes and becomes dense (and expands). So, the torque is equalized, and both wheels (front and rear) rotate equally. Due to the expansion of the fluid, the driven and driving disks are pressed against each other.

As you can see, the mechanism is quite simple. The element lasts quite a long time, so repair of the viscous coupling may not be necessary soon.

Where is it used?

There are two main areas where viscous coupling is used. What are these spheres? Below we will look at them:

- Cooling system. The viscous coupling is used for forced cooling of the radiator. The mechanism is mounted on a rod and driven from the crankshaft using a belt drive. A multi-blade fan is installed on top of the part. How it works? The more the pulley rotates, the faster the fluid thickens in the clutch. Thus, at medium and high speeds, the engine radiator is forced to cool. As the speed drops, the heat exchanger cools naturally. The fan stops working. Nowadays this cooling method is practically not used. The viscous coupling was replaced by electric fans. They are driven by the engine temperature sensor. The element is not connected to the engine crankshaft and is more technologically advanced.

- All-wheel drive connection. And if in the first case the problem could be solved electronically, then it will not be possible to transfer torque to the second axis in this way. Therefore, the main application area for viscous couplings is crossovers.

Advantages

What are the advantages of this mechanism? Let's look at a few of them:

- Simplicity of design. The device contains liquid and two turbines (or disks) tightly closed in a housing.

- Strength. The housing in the coupling is able to withstand pressure up to 20 atmospheres. Therefore, you should not be afraid that the liquid will one day leak out from the outside.

- Practicality. It can work both on a dirt road and on asphalt (for example, if you start with a slip). Does not require any electronics. The drive is connected and disconnected automatically.

Flaws

Despite such significant advantages, it is worth noting the disadvantages of the viscous coupling:

- Low maintainability. In case of failure, the viscous coupling is replaced entirely with a new one. The cost of such a part is quite high. The viscous coupling is not repaired.

- Low efficiency of all-wheel drive. Both wheels will rotate at the same speed only when the car is slipping heavily. There is no question of rigid interaxle blocking here.

- Inability to force connection. For example, you need to cross a ford. To do this, it is desirable to have permanent all-wheel drive. However, a viscous coupling will prevent you from doing this. The wheels will rotate fully only after you have stalled.

- Reduced ground clearance. The mechanism body is quite large, which calls into question the off-road characteristics of the crossover.

- Low resistance to overheating. The element cannot operate in all-wheel drive mode for a long time (the properties of the fluid change, the viscous coupling bearing wears out). Otherwise it will fail. Therefore, you should not skid off-road for a long time.

Basic malfunctions of Viscous coupling

It is immediately worth noting that manufacturers of cars equipped with viscous couplings indicate in the technical documentation that this unit cannot be repaired, and in case of interruptions in its operation, it must be replaced with a new one.

There are two main malfunctions that may occur during the operation of a VM:

- The seal of the product body is broken, resulting in silicone oil leaking out of it. In this case, the viscous coupling simply stops working and does not “turn on” the temporary all-wheel drive mode or block the differential.

- Hardening of the silicone liquid and, as a result, loss of its “unique” properties (this can happen due to frequent overheating of the unit, for example, during constant off-road driving). This type of malfunction results in both shafts being in constant engagement. But transmission elements (drive axle gearbox, gearbox, etc.) of cars with temporarily connected all-wheel drive are not initially designed for such constant increased loads and can quickly fail. Therefore, at the first sign that the liquid has “turned” into a solid state, the viscous coupling must be urgently replaced. Inaction can lead to very expensive repairs.

Removing the UAZ viscous coupling with your own hands

Let's look at how to remove this part along with the fan, using cars from the Ulyanovsk Automobile Plant as an example. So, for convenience, you need to remove the radiator and fan casing (blinds). Next, using a 12mm wrench, unscrew the two mounting bolts of the pump pulley. Please note: the viscous coupling nut has a left-hand thread. Therefore, you need to unscrew it clockwise, and screw it in the opposite direction. After this, use a 32mm wrench to unscrew the coupling securing nut. Keep the crankshaft pulley from turning. If the nut is difficult to move, you can use a hammer. Gently strike the key in the direction it is facing away. Next, the coupling is successfully removed from the pump shaft. Using a 13 key, unscrew the 4 mounting screws. We take the mechanism out and install a new one.

Installation of the element is carried out in reverse order. The bolt rods are screwed into place using fine-nose pliers. Next, the coupling is installed and the fastening nuts are tightened by hand. There is no need to tighten the bolt on the coupling itself. It self-tightens when the engine starts.

So, we found out what a viscous coupling is.

The viscous coupling device is as simple as it is ingenious. It's hard to believe that more than 100 years have passed since its invention. It became widespread only 50 years later, when it began to be installed on sports cars. Manufacturers of all-wheel drive vehicles appreciated the fundamentally new system, and since then it has been widely used in the drive of SUVs. Today, viscous coupling is an element of a self-locking differential and all-wheel drive.

Selecting a new device

Now let's answer the question of how to choose a viscous coupling for a cooling fan. The easiest way to search is in online stores, because here you can, if not buy a new device, then at least find out the code of the original and the codes of all possible analogues. We'll talk about the latter shortly. You can search by:

- VIN code;

- Vehicle data. We are talking about the make, model, year of manufacture and engine parameters. Typically, this search method is the main one in online auto parts stores.

Of course, an important search parameter is the manufacturer of the final product. Many car enthusiasts justifiably do not trust the products of packaging companies. In the case of viscous couplings, you can even take products from such companies, since, in fact, they are produced by a limited number of companies, which are also suppliers to the conveyors of large automobile concerns and whose products are even sold by packers

. It is worth paying attention to the products of these companies:

- Behr-Hella (Germany);

- Nissens (Denmark);

- Mobis (South Korea);

- Beru (Germany).

Very good solutions can be found in the catalogs of Meyle and Febi (Germany). The Polish and Turkish analogs that appeared relatively recently did not perform so well. As a rule, reputable manufacturers of viscous couplings simultaneously produce radiators, fasteners and some pipeline elements. If you are confident in a certain radiator manufacturer, it is worth looking in its catalogs for the viscous coupling you need.

What is a viscous coupling and why is it needed?

A viscous coupling (as it is officially called) is a transmission element that transfers torque from one shaft to another. As a rule, it is used as a center differential, where it can work independently or in tandem with a free differential.

Viscous coupling device

The “working fluid” of a viscous coupling is a liquid with special qualities, so there is almost no mechanical friction in the mechanism. The operation of the viscous coupling does not require the participation of the driver; it operates at the right time itself, without any control.

The purpose of the viscous coupling is to automatically synchronize the rotation speed of the shafts on the front and rear axles. It comes into operation when one or both wheels on one axle hang out (slip), and their rotation speed sharply increases relative to the other axle. The work of a viscous coupling is to equalize angular velocities by fully or partially blocking the “problem” axis and transferring torque to the one with better surface grip.

Breakdowns

If used incorrectly, the coupling cannot cope with the increased load and fails. In automatic mode, a variable voltage is supplied to the electromagnet winding. The control unit, depending on the conditions, supplies a pulse current. The more torque is required to be transmitted, the longer the current pulses are supplied to the winding.

In this case, the unit that compresses the second clutch package takes up variable loads and also wears out. The second clutch pack acts as a damper, smoothing out sudden engagements of the clutch due to the slipping of the friction discs. This is necessary for a longer service life of the GP gearbox itself.

The seals begin to snot. Also, when the pressure increases, the control clutch package (which is activated by an electromagnet) is compressed without electricity, and the clutch does not disengage. In straight-line motion of the car, this is almost unnoticeable. But when the car turns, the friction disc packs cannot cope with the increased load, and the discs begin to slip, making a sound similar to a grinding sound. There is intense wear and tear on both packages.

And also interesting: Crossover clearance comparison table - TOP 10 most popular and reliable crossovers in Russia for 2020. These are the best crossovers that our drivers choose

With very high heating, an interturn short circuit in the electromagnet winding is possible. If the driver follows all operating rules, it is enough to monitor the seals to avoid oil leakage. If there is an oil leak, the coupling will remain without lubrication and will heat up. The result of overheating is described above.

Application of viscous couplings

The viscous coupling has proven itself excellent on off-road vehicles used for difficult terrain. It has been installed on off-road vehicles for a long time as a self-locking center differential. At the same time, viscous couplings were almost never used as an axial differential; other devices were used for this purpose.

Low price and excellent reliability have made viscous couplings in demand among most off-road sports enthusiasts. And even more modern types of transmission have not forced fans to abandon the convenient and simple mechanism.

To understand why this part is needed, you need to remember the operating principle of the plug-in all-wheel drive: it is activated when problems begin.

How to check a viscous coupling?

To test the device, place the vehicle on a level surface. Pre-warm the engine. Turn the steering wheel all the way in either direction and release the brake.

The viscous coupling is working properly if the car is moving slowly without pressing the gas pedal.

It is faulty if the car does not move away without pressing the gas pedal.

There is a radical way to check. The knot will have to be removed. It is placed in a container with boiling water. Then you need to try to twist it. Free rotation should not occur - it will indicate a breakdown.

Indirect evidence is checked as follows:

- Try cranking the cold engine by hand. The blades should rotate with force, there should be no inertial motion.

- When the engine starts, the movement of its blades is synchronous with the engine speed. At the same time, a strong noise is heard, which completely disappears after about a minute.

- Warm up the engine. Take a newspaper and roll it into a tube. Try using a newspaper to stop the blades of a running motor. The blades should stop with force.

These signs indicate that the viscous coupling is working properly.

Design and principle of operation

The operating principle of a viscous coupling is based on the transmission of rotation using the viscous properties of the fluid. This makes a viscous coupling fundamentally different from, for example, a torque converter, which uses the movement of fluid, that is, its dynamic properties.

A viscous coupling is a housing with a pack of disks inside. The disks are rigidly connected to the shafts and are placed alternately: one disk of the first shaft, the second - of the second, the third - again of the first, etc. The distances between the disks are minimal. This entire structure is filled with a special silicone-based liquid, which has an interesting property: with active stirring or heating, it becomes more viscous. With very fast movement, when the force of hydrodynamic resistance increases, it acquires the properties of a solid body; when it slows down, it immediately becomes more liquid. The principle of operation is clearly shown in the video below.

The viscous coupling process looks something like this:

- The car is driving on a flat, good road. Both axes rotate at the same speed. Inside the viscous coupling, packages of disks, mounted alternately on one and the second shaft, also rotate at the same speed, without rotating relative to each other. In this case, the viscous coupling is “turned off”, that is, the torque from the drive axle is not transmitted through it to the driven one (with the exception of approximately 12-15%, which will flow to the second axis due to the viscosity of the working fluid);

- The wheels on the leading axle begin to slip, but on the second axle they stop or almost stop. In this case, the plates of one shaft stand still, and the second one rotates very quickly. In this “blender” the liquid begins to move, heats up and thickens. The thickened liquid interlocks the plates of the two shafts with each other, and the greater the difference in their speed, the faster this happens;

- When the clutch is activated, the torque from the drive axle (which is slipping and spinning quickly) is transferred to the driven axle, and its wheels begin to move. If necessary, almost 100% of the torque is supplied to the driven axle, that is, the drive changes;

- When driving onto a normal road, the rotation of the plates in the clutch relative to each other stops, the fluid becomes less viscous, and the all-wheel drive is turned off.

The viscous coupling operates quickly but gently: 0.2 seconds is enough to completely block one axle. In this case, no jerks occur, and the device does not put extra stress on the transmission.

Advantages and disadvantages, pros and cons

Viscous coupling has many advantages:

- A very simple design that does not require any configuration or modification. There is no mechanical friction, and therefore no special wear;

- Possibility to make a durable sealed case;

- Does not require regular maintenance: no adding oil, monitoring fluid levels, etc. The viscous coupling works for a very long time;

- If it breaks, it is easy to replace: its cost is low and the work itself is not too complicated.

However, there are also disadvantages that have forced modern automakers to abandon the use of viscous couplings in favor of the new Haldex coupling:

- There is no way to block it manually. This is a rather unpleasant situation for jeepers who are accustomed to the full controllability of their vehicles;

- As a result, it is impossible to control the drive;

- Automatic blocking is not 100%. This is explained by the properties of the liquid: in order for it to tightly block one axis, the difference in rotation speed must be quite large. In real conditions, this is not always the case, which means that part of the engine power is wasted;

- Relatively slow response. Even fractions of a second on the road are important;

- Incompatibility with the ABS system, and this is already serious. And so much so that viscous couplings began to become a thing of the past mainly for this reason;

- Overheating during prolonged active work;

- Clutches for powerful cars protrude too much under the floor due to their size. The actual ground clearance decreases and a weak point appears.

In general, the viscous coupling performed well in its time. For cars not stuffed with electronics from the wheels to the roof, such a device was truly convenient and functional. Today, almost no one installs viscous couplings on new SUVs. The designers preferred the electronically controlled Haldex clutch. It works great together with ABS, works instantly and is generally a more modern and technologically advanced device.

Every motorist was interested in the question: what is a viscous coupling? Let's try to answer it. A viscous coupling is a mechanism for transmitting and equalizing torque in the transmission of a Renault, Volkswagen, etc. car. Its other name is a viscous coupling. The principle of operation in it is completely different than in a torque converter or fluid coupling. Torque is transmitted due to the viscous properties of the fluid that fills the internal cavity of the viscous coupling. It is used for automatic differential locking.

Story

In the United States of America in 1917, Melvin Severn invented the viscous coupling. But his invention had no application. On the Interceptor FF car from the English company Jensen, it was used as an automatic locking mechanism for the center differential in 1964. On vehicles with permanent all-wheel drive, viscous coupling has found its niche since 1965.

Not very four-wheel drive: clutch or differential?

The price of security

Somehow it so happened that plug-in all-wheel drive is considered a solution that is not particularly reliable, incapable of transmitting large amounts of torque, and generally palliative, associated with saving money.

Moreover, 9 out of 10 of my friends who know about cars first-hand are sure of this. But you must admit: the words “savings” and “cheaper” sound somehow strange when we are talking about the latest X5, X6 and Cayenne, or about the “modest” 550Xi or Panamera. Apparently, the reason is completely different - it is hardly possible to “save” so much on a banal center differential. If differentials were so expensive, then instead of a cross-axle differential, they would probably also use something else? And the well-known Torsen is clearly not worth millions. Yes, it's not the price of the differential itself. Surprises came from the identified nuances in adjusting the handling and operation of various electronic “assistants”: ABS, ESP and other active safety enhancement systems. And all this is because the requirements for the active safety of cars have grown greatly over the past decades, and the handling of even simple cars is at a level that sports cars of the eighties never dreamed of.

What's good about permanent all-wheel drive? The fact that torque is constantly present on all wheels, distributed according to certain rules strictly defined by the design of the mechanism. It is impossible to directly set the distribution, but there are other ways to “teach” the machine to do what is needed. For example, by introducing a lock, using brake mechanisms or something else.

It seems that there is no particular need for such “subtleties” on paved roads, after all, we drove Audi Quattro, Alfa 155, Lancia Delta Integrale... In any book, in the description of all-wheel drive designs, it is sure to say that the reduction in torque on the wheels due to its distribution on all four wheels allows you to increase the lateral component of the load, which means faster cornering. In addition, engine thrust can be realized on any surface. In addition, the differential is a reliable thing, it is not so easy to break, they are made with a reserve, the service life of the differential is very long. In general, solid advantages.

1 / 3

2 / 3

3 / 3

Unfortunately, there were also disadvantages very quickly. Any change in traction on an all-wheel drive vehicle causes a redistribution of mass along the axles and wheels, and the complex transmission then distributes the torque. A share of the torque will go to all four wheels, but its amount will depend on many factors. From the clutch of each wheel, from the mass of transmission parts, from friction losses in the units, and so on. As a result, it turns out that it is difficult to predict exactly how the thrust on each axle will change. Taking into account the constant change in load, changes in the slip angles of the front and rear axles become almost unpredictable. Only a very experienced driver can feel all the nuances of the car’s reaction to control actions and be prepared for any development of events. We had to look for a way out of this situation.

How is this done?

The stability of the machine can be increased by special design measures. For example, by increasing the moment of inertia around the vertical axis, distributing the load in favor of one of the axles so that it is always greater on one than on the other, changing the thickness of the tires or installation angles. Doesn't remind you of anything? Of course, Audi cars. On them, permanent all-wheel drive became commonplace and had at least several features from this list.

Pictured: Audi A6 Allroad 3.0 TDI quattro '2012–14

The motor located in front of the axle provided a large moment of inertia around the vertical axis and guaranteed high load on the front axle. The multi-link front suspension provides the best traction on the front axle over a wide load range.

On the Porsche 911 Carrera4, a similar drive circuit is simply “turned” 180 degrees, but the layout features are the same. But this scheme somehow did not take root on cars of other brands - the only exceptions are rare cars for “racers” and a small number of crossovers.

In the photo: Porsche 911 Carrera 4 Coupe '2015–present.

Subaru's all-wheel drive design and layout are almost identical to that of Audi's, with the exception of simpler suspensions and a more compact engine. At the same time, due to the smaller size and less overload of the front axle, the handling is much more “sporty”.

Mitsubishi, Lancia and Alfa Romeo are not even worth remembering: their layout with a transverse engine, and even on very compact cars, was not originally intended for untrained drivers.

In the photo: Under the hood of Alfa Romeo 156 '2002–03

It turns out that, unless special design measures are taken, a car with permanent all-wheel drive has difficult controllability. It can demonstrate the habits of either a front-wheel drive or rear-wheel drive car, depending on traction, load and a thousand other reasons. To obtain a result acceptable for a production car, considerable effort will have to be spent on fine-tuning the handling, because the average driver does not like such surprises; he needs unambiguous behavior. Of course, this can be achieved by installing sophisticated electronic stability control systems, but this is a complex and expensive method. It will be much easier to simplify the transmission circuit by installing a coupling that connects the second axis only when necessary. Of course, you still can’t do without electronics, but in the case of a front-wheel drive car with a transverse engine, the transmission will become much simpler. For example, instead of a very complex and heavy transfer case, you can get by with a simple bevel gear.

Articles / Used Toyota RAV 4 XA20 crossover: the body is intact only on the outside, and the bearings are afraid of off-road I will say right away: the popularity of this model remains a mystery to me. I don’t really like “gray” cars and I know for sure that at one time there were more versatile, more driver-friendly and more passable... 19629 3 3 04/25/2017

On machines with a longitudinal engine and a classic layout, the advantages of installing a coupling are slightly less. You won’t be able to get a significant gain in weight, but you can almost not connect the front axle, getting rid of traction jerks on the steering. And you can also reduce fuel consumption, which is also important for a production car.

To connect or not to connect?

Permanent all-wheel drive isn't that complicated, and it's not that expensive either. And the first generations of crossovers were often equipped with permanent all-wheel drive. What about crossovers? Remember our Niva, which turned out to be cheap and cheerful at the same time.

For initially front-wheel drive cars, it turned out to be easier and cheaper to make the drive plug-in. A weight difference of 50 kg is already very serious, and the advantages of unambiguous controllability and the ability to easily configure ABS systems significantly reduced the cost of fine-tuning the model.

The viscous couplings initially used to connect the rear axle turned out to be not the best choice, and they were quickly replaced with electronically controlled designs. True, some manufacturers, for example, Honda, held on to their specific methods of connecting all-wheel drive (we are talking about the Dual-Pump-System). But after the mass introduction of even the simplest systems with controlled connection, it became obvious that such a drive is quite enough for the vast majority of drivers. Moreover, it is enough even in the case of powerful cars and increased requirements for handling and cross-country ability.

The all-wheel drive system also has disadvantages. First of all, they are due to the fact that there are many nodes here that are expensive. Therefore, they are constantly trying to make them cheaper and simpler. The results, however, are not always encouraging.

For example, the clutch may not hold all of the engine torque in first gear, but only part of it, or hold the torque only for a limited time. It may not provide the ability to work with slippage, and the connection speed may not be adjustable or adjustable too roughly. The clutch may not be designed for long-term operation, as a result of which it often overheats under load.

The electronics that support the connection system can also be simplified. In this case, the algorithms sometimes do not take into account some driving modes, reducing the ease of safe controllability.

In the end, the clutch always has wearable components - for example, the clutches themselves, and often also hydraulic or electrical components.

And yet, as the cost of electronics decreases and such systems are used on more and more expensive machines, the quality of such a connection mechanism is steadily increasing. Although in general the clutch is still much more expensive than a simple differential, and attempts to make it even cheaper do not stop.

I note that there are connection designs whose operating efficiency exceeds that of all permanent all-wheel drive systems. These include almost all of the latest generations of all-wheel drive transmissions with variable traction vectoring on Subaru and Mitsubishi and on premium German cars. They provide the ability to directly control torque on one or more wheels to choose from. This allows you to create cars with perfect handling and fantastic capabilities. While driving such a car, any curve on any surface will be “written out” almost perfectly, and with minimal effort on the part of the driver. Unfortunately, these are complex and expensive systems that are aimed at achieving fantastic performance on the race track. And they are designed without regard to operating costs.

Don't be afraid of simpler systems. For example, much more popular cars are endowed with excellent handling and cross-country ability by Haldex couplings of the last few generations. Younger models of Land Rover, Range Rover, VW, Audi, Seat and Volvo widely use designs from this brand. And in operation, such systems have proven to be quite reliable.

BMW all-wheel drive vehicles have excellent cross-country ability and impeccable behavior on asphalt. Since permanent all-wheel drive on the E53 was replaced by plug-in, the system has been continuously improved, and the results of progress are impressive. Even reliability was able to be increased to a completely acceptable level.

Today, even very inexpensive systems with purely electric drive from Asian brands do not give up on off-road conditions, and even on the highway, cars with them delight with excellent behavior.

What will happen next?

Another ten years - and besides jeepers, few people will remember about permanent all-wheel drive. And as cars with internal combustion engines are replaced by electric vehicles, complex transmissions will die out on their own, like mammoths. And I'm afraid it's time for everyone to reconsider their attitude towards permanent all-wheel drive. This is not an expensive or elite solution, but just a not particularly popular technology from the mid-eighties. From a time when the capabilities of motors far outstripped the capabilities of tires and electronics. It was then that the legend of the most complete and permanent drive appeared. Which, however, is still alive today.

Viscous coupling: device, principle of operation

Several round flat disks are installed inside the sealed housing. A certain number of drive disks are connected to the drive shaft, and a certain number of driven disks are connected to the driven shaft. Their surface has holes and protrusions. All disks are mounted so that when rotating, they are located at a very small distance from each other. Inside the coupling body there is a silicone-based dilatant liquid, which thickens when vigorously stirred. It also has a high expansion coefficient when heated. When stirring, pressure appears on the disks, and they are pressed against each other due to the expansion of this liquid.

How a viscous coupling works - video

If the movements of the shafts are uniform, then the disks rotate at the same speed. When there is no mixing of the liquid, there is no pressure on the discs. When one shaft rotates differently relative to the other, the disks begin to rotate relative to each other. The liquid is mixed, viscosity increases, and the angular velocities of the disks try to equalize due to the friction force. And with a huge difference in speeds, this liquid has the properties of a solid. At this moment, the viscous coupling is blocked, and the torque from the drive shaft to the driven shaft reaches its maximum.

Disadvantages and advantages

The viscosity of a liquid depends on the speed of its mixing. It is impossible to guess the braking coefficient of disks, because there is no linear dependence of the properties. Therefore, such differentials have low efficiency. Viscous couplings without a free gear differential are not used due to their large design and low efficiency. Since the efficiency of a viscous coupling is directly proportional to the volume of liquid and the diameter of the disks, such a device increases the size of the drive axles, which leads to a decrease in ground clearance.

The advantage is the simplicity of the design. The viscous coupling housing is capable of withstanding a pressure of fifteen atmospheres. It does not require attention during its entire service life. If it fails, it is simply replaced.

Advantages and disadvantages

Among the advantages of VM it should be noted:

- Simplicity of design. Indeed, the unit is automatically put into operation without the use of any special sensors (measuring wheel speed) or an electronic control unit.

- Low cost.

- Durability. If you follow the operating rules recommended by the manufacturer, the service life of the viscous coupling is designed for the entire “life” of the car.

- No need for periodic maintenance.

- High hull strength. Its design can withstand pressure of even 15÷20 atm (the increase occurs due to heating and expansion of the liquid).

And now about the disadvantages:

- Response delay. Before the viscous coupling automatically “engages” the all-wheel drive, a certain (albeit insignificant) time passes, which is necessary to increase the viscosity of the silicone fluid and “engage” the shafts.

- Maintainability (or rather the lack thereof). The product is disposable and must be replaced if broken.

- Dependence of the efficiency of the connected all-wheel drive on the intensity of slipping of the drive wheels.

- Impossibility of continuous long-term operation in off-road conditions.

Where are viscous couplings used?

On Lancia Thema and Lancia Dedra 2000 Turbo cars, viscous coupling was used as an automatic locking mechanism for a free gear differential. But the main application is the use on off-road vehicles as a center self-locking differential. For example, on jeeps and Range Rover HSE, the viscous coupling was used as a limited-slip differential. It can also serve as an auxiliary locking mechanism that works with a gear free differential.

Video

You can synchronize torque between axles in a simple and inexpensive way by using a viscous coupling. Under normal conditions, the difference in torque is small, the viscous coupling is enough to prevent the front wheels from slipping relative to the rear wheels. So, when driving on a dirt road, one pair of wheels goes around an obstacle, the second pair goes straight, and the visco clutch at this moment equalizes their speeds.

Video

But, since it is problematic to use viscous couplings with an anti-lock wheel system, almost all global automakers stop using them and install Haldex forced couplings on their cars.

The work of many products is based on the use, sometimes in unexpected ways, of a variety of properties of substances familiar to us. An example of this is a viscous coupling - a special device designed for selective transmission of torque, depending on external conditions. For such products, the operating principle is based on changing the viscosity of the liquid poured into it. This is not to say that they are used extremely widely, for example as a manual transmission, but it would be wrong to ignore their use.

Operating principle of viscous coupling

The appearance of the viscous coupling and its operating principle will allow you to understand the given figure.

As can be seen from it, the viscous coupling device is a sealed housing in which two rows of disks are located. Each of them is connected either to the driven or to the drive shaft. The driving and driven disks alternate with each other, each of them has special protrusions and holes, and the distance between their planes is minimal.

The space inside the case is filled with a viscous liquid, most often made from silicone.

.

Distinctive features of this liquid, allowing it to be used as part of a viscous coupling, are:

- increase in viscosity, thickening with intense stirring;

- significant expansion coefficient when heated.

When the car moves uniformly, the discs rotate at the same speed and the liquid between the discs does not mix. When differences appear in the speed of rotation of the shafts (driven and driven), the speed of rotation of the disks also begins to differ, due to which the viscosity of the fluid increases and it works to transmit torque to the driven shaft from the driving one.

With a significant difference in the speed of rotation of the disks, the viscosity of the liquid increases so much that the viscous coupling is blocked and acquires properties characteristic of a solid body. For more information on how a viscous coupling works, watch the video

Operating principle of viscous coupling

What is a viscous coupling? If you decipher the name viscous coupling, it turns out that it is based on the phrase “viscous coupling”.

In principle, it explains the whole essence of a viscous coupling - a special viscous liquid filling the unit is the very link that transmits torque from one shaft to another, but they themselves are not mechanically connected.

This liquid has one interesting property - it begins to thicken when actively mixed, due to which the transmission of torque between the shafts changes.

Viscous couplings began to be actively used by automotive engineers to create automatic center locks for all-wheel drive vehicles. We will consider the design and operating principle of a viscous coupling in more detail later, but for now let’s look into the past.

How does a viscous coupling work in a transmission?

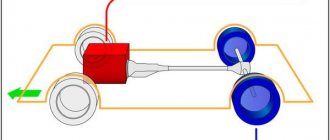

One of the main applications of viscous couplings is in all-wheel drive systems and transmissions in general. What it looks like - the picture explains

The all-wheel drive device using a viscous coupling is based on the fact that the rear axle is connected only when necessary. Under normal conditions, such a car is front-wheel drive, but when there is a difference in the angular speeds of rotation of the wheels of different axles, the viscous coupling is activated, and the torque begins to be distributed between the various axles.

In fact, this turns out to be a self-locking automatic center differential. In such a situation, when the wheels begin to slip, the driver does not need to take any action. However, it is worth keeping in mind that such plug-in all-wheel drive has limited use. It works well on bad roads, in icy conditions, in the city, but is not suitable for real off-road use.

The reason for this is the delay in the response of the viscous coupling during constant changes in the traction of the wheels with the coating, its overheating, and, ultimately, failure. In addition to providing all-wheel drive, such a device can be used to unload the wheel when cornering. A drawing will help you understand how this happens.

In this case, the viscous coupling is placed on one bridge between the differential and one of the axle shafts. When entering a turn at high speed, the grip of the inner wheel deteriorates and it begins to slip. Thanks to the viscous coupling, the torque is redistributed between the wheels, ensuring safe cornering.

Considering the important role that the viscous coupling plays in driving safety, and also that it operates in an all-wheel drive system, it is often necessary to check its current condition and performance. What actions need to be taken for this, as well as additional information about such products, you will receive from the video

What kind of oil to pour into the all-wheel drive clutch

The all-wheel drive viscous coupling, like other mechanisms, uses a lubricant in its operation, which is a special oil. All manufacturers claim that there is no need to change it throughout the entire period of operation of the vehicle. This statement does not always correspond to the actual state of affairs.

Also interesting: Isuzu SUVs in Moscow: model range - configurations and prices Filling the all-wheel drive clutch with oil

The need for an oil change may be indicated by small kicks in the rear of the car when pressing the gas pedal or making a turn. This behavior of the machine may indicate a damaged condition of the viscous coupling oil.

It is better to carry out the replacement at a service station, since this work is not the easiest. To replace it, you must choose the oil that is indicated in the instructions for the car. It often turns out that the specified lubricant cannot be found on sale - many motorists face this problem. We have to look for a replacement. A worthy option is Ravenol TF0870 lubricant.