Compositions such as lubricants for caliper pistons deserve a separate review. I know firsthand that problems with the brake system in many cars are extremely common. This is due to the lack of normal care, and often to the use of unsuitable or low-quality lubricant for the brake pistons.

You should not give up on this circumstance, since the performance and safety of the car depends on the condition of the brakes. To ensure these qualities, it is necessary not only to promptly change all spare parts that have expired, but also to lubricate them with a suitable, high-quality substance.

Working at a service station, I often come across the fact that drivers buy cheap lubricants, trying to save money, and as a result they get far from positive results. By lubricating the parts of the functional unit with a good lubricant, you can avoid friction problems and get rid of knocks and creaks that are uncharacteristic for this mechanism.

The use of poor lubrication can lead to uneven wear of the brake pads, and in especially difficult cases, to jamming of the mechanism. So, let's talk about which lubricants can perform all of the above tasks, and what to look for when choosing the right product.

Why is lubricant needed, and what are the requirements for it?

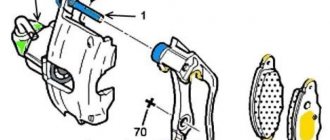

Every driver knows that lubrication is simply vital for caliper cylinders. Without a quality substance, the mechanism will not work fully and will quickly fall into disrepair. The substance is applied to the upper part of the piston, under the boot, due to which it perfectly protects the functional unit from corrosion and does not allow it to jam. Also, a special composition is used to treat the non-working and end surfaces of the pads to eliminate the appearance of squeaks and other unpleasant sounds.

If there is no lubricant in the mechanism, friction will occur “dry”. As a result, increased wear of the pad will occur, which will cause rapid failure of the part. It is worth mentioning separately that such products have certain requirements:

- resistance to low (-15, -20 degrees Celsius) and elevated temperatures - hundreds of degrees, since the parts of this mechanism can become very hot;

- neutral effect on rubber and plastic, since parts made of these materials are located next to lubricated surfaces;

- The pastes should be viscous and not wash out.

These requirements can be called basic, although there are several more criteria that are worth mentioning. This refers to providing protection against corrosion and stability when released into the aquatic environment. Mechanics often advise drivers to use ordinary lithol to lubricate the calipers and cylinders of the brake system, but I’ll tell you right away that listening to such advice is highly discouraged, since in the future this will lead to breakdown of the mechanism.

Xado Very Lube

The liquid material of the VeryLube series from the manufacturer Xado is supplied in an aerosol can with a capacity of 320 ml; the manufacturer allows operating temperatures in the range of -35...+400°C. Due to its increased fluidity, the liquid fills irregularities on the surface of the guides and does not have a negative effect on the rubber boots. When processing, several layers should be applied with intermediate drying of each layer for 1-2 minutes.

The protective layer has increased anti-friction characteristics and reduces abrasive wear of parts, reducing the likelihood of extraneous noise. The drug can be used both in passenger cars and light-duty trucks. Disadvantages include rapid leaching of the material with water; with prolonged exposure to elevated temperatures (for example, due to heating of the brakes when driving on mountain roads), degradation of additives is observed.

Types of lubricants suitable for the brake system

Not all lubricants are identical in composition and characteristics. There is even a small classification that allows you to divide all types of products into three large groups, taking into account their properties and capabilities. Many well-known and reliable companies produce lubricants of this type, but it is extremely difficult to choose a universal product, so you should focus on the requirements of a specific car and the capabilities of a specific substance. Let's look at them in more detail in the table.

| Options | Synthetics or mineral water with added metals | Mineral oil based lubricants | Synthetic oil based paste |

| general description | High-temperature lubricants with good extreme pressure properties. Particles of molybdenum or copper are added to the compositions. | Lubricants that include mineral oil and bentonite as a thickener. They do not have a dropping point. | The substances are compatible with polymers and rubber. They are made on a synthetic basis with the addition of additives and a thickener. They do not dissolve in water. |

| Features of application | You can lubricate the surface of the cylinder, springs and pad plates. | The lubricant is suitable for applying to the “fingers” of calipers. | Suitable for all disc brake caliper parts. |

| Most Popular Brands | Brands can be distinguished: |

- Huskey;

- Loctite;

- LIQUI MOLY;

- Mannol Kupfer;

- Valvoline Cooper.

How does ideal lubrication help the long-term operation of the brake unit?

The caliper is used in conditions close to extreme. This is also a constant temperature difference in the brake pad, which during sudden braking can heat up for a short time to a temperature of 600 degrees. The brake system suffers from contact with reagents used to treat roads, from dirt, dust, and from contact with brake fluid from worn piston rings.

For protection, you need to use lubricants that would protect against all these factors, but do not wash off, do not absorb dirt, and do not turn into coke at high temperatures. It is also important for the lubrication of the brake assembly that it be inert towards parts made of plastic, rubber or similar material, of which there are quite a lot now in the automotive industry.

It also should not react to brake fluid or other fluids that are present there, which can wash out any other lubricant such as lithol or nigrol; graphite lubricant will turn into elemental coke at high temperatures, which can damage the pistons. Litol and nigrol also destroy non-metallic parts.

When choosing, we also focus on temperature resistance: at heating temperatures of + 180 degrees and above, depending on the load, the lubricant should not leak out like olive oil, and at temperatures up to -35 it should not harden and become a lumpy substance.

Choosing a lubricant that will take into account all these factors and will be your ideal choice for your car and will protect it from breakdowns in this unit. Serviceable brakes mean a car that is obedient in your hands, has a short braking distance and does not wobble when you press the brakes.

Types of lubricants for brake cylinders

When choosing a lubricant for brake cylinders and calipers, you need to take into account that there are several types of it that are used for various elements of this unit. The caliper needs good lubrication, which is applied under the boot of the upper part of the brake cylinder, in order to protect it from corrosion and reduce the friction force that can jam it. If the correct lubricant is applied to the pistons of the brake cylinders, this will have a good effect on their operation and will make them more “obedient”.

Lubricants can be either specialized, intended for specific parts of an assembly, for example, there are separate types of lubricants for guides, or universal, used for parts of the entire assembly.

Manufacturers produce two types of lubricants: the first type is lubricants in the form of sprays, the second type is in the form of pastes. Both have their advantages and disadvantages.

Further, lubricants can be divided into the following groups:

- Pastes that have a synthetic, semi-synthetic or mineral base, to which various metals have been added, giving them certain properties. These are pastes such as:

- compound pastes, which contain a complex mixture of copper, aluminum and graphite powders, for example, HUSKEY 2000 Lubricating Paste and Compound, Wurth Al 1100;

- pastes containing copper and graphite in powder form, for example, HUSKEY 341 Copper Anti-Seize, LUQUI MOLY Kupfer-Paste, Marly Cooper Compound;

- non-metallic pastes containing magnesium salt and ceramic powder, for example, HUSKEY 400 Anti-Seize, LUQUI MOLY Bremsen-Anti-Quietsch-Paste, Textar Cera Tec;

- lubricants containing only copper;

- pastes containing only molybdenum compound in the form of disulfite, for example, HUSKEY MOLY Paste, Assembly Lubricant @ Anti Seize Compound and others.

They are not suitable for caliper guide pads, but for other high-load parts they are an excellent option.

Pastes based on mineral oil make up the second group of lubricants. They contain bentonite as a thickener. It also contains specially purified fatty acids and metal particles. These compounds are best used on parts exposed to temperature changes from -45 degrees to +180 degrees, and no changes in the form of clumping or dripping were observed in the lubricants in this temperature range. An example of such lubricants is Teroson VR500, Molykote and others.

The third group consists of lubricants based on synthetic oil. The most commonly used composition, considered universal, is suitable for lubricating all parts included in the brake assembly. The lubricant also works great for both front and rear brake cylinders, brake cylinder pistons, hydraulic brake cylinders, and brake cylinder boots.

The lubricant is made from highly purified synthetic oil with the addition of additives that give it various properties, for example, reducing wear of parts, protecting against corrosion, preventing oxidation during operation and a thickener.

These lubricants not only do not dissolve in water, but also do not react to brake fluid, which is always present there, alkali and acids. When heated, such lubricants do not evaporate and are good dielectrics. The operating temperature range, on average, is from -40 to +300 degrees. They can be produced in the form of sprays and lubricants. For example, it is better to use spray lubricant under the brake cylinder boot; it is better distributed and costs less.

Which lubricant to choose for car maintenance?

Of course, you can leave the car at a service station with authorized dealers. They will choose a lubricant at their own discretion, without consulting your wishes, and set a price for it at their own discretion, since everyone needs to survive, everyone is in a crisis. And the cleaning is not always carried out to the proper quality.

The job of lubricating a car's brake assembly is not at all difficult; you can watch a video of how this is done on the Internet. All that remains is to choose a lubricant so that this process is not repeated so often and the brakes do not let you down.

To buy lubricant for brake cylinders, it would be a good idea to inquire what metal the brake assembly parts are made of.

There are a number of excellent lubricants that contain fine copper powder and which work well at high temperatures, do not leak when heated, and protect against corrosion. But they are unacceptable for parts made of aluminum and alloys, as they react with each other, causing corrosion of the aluminum. An example of such a lubricant is the American product Molykote Cu 7439 Plus, which is based on a special semi-synthetic oil and finely ground copper powder.

An example of Molykote Cu 7439 Plus lubricant, which is not recommended for use on aluminum parts

But, being a lubricant used for high temperatures, it also has excellent characteristics in all other respects. It should be noted that its price corresponds to its quality and is quite high.

Of course, if you have a car in the mid-price category, there is no point in overpaying. You can choose domestic grease, but in no case lithium. Our industry, having purchased equipment, chemical additives and technologies, began to produce its product of fairly good quality. This is, for example, MC 1600 universal lubricant, which can be used as a lubricant for assembling brake cylinders.

Lubricant for calipers from a Russian manufacturer

The only disadvantage of this, by the way, high-temperature lubricant is that it cannot be used to lubricate the caliper guides. It is not compatible with DOT 5.0 brake fluid.

For the same purpose, you can choose PFG 110, Bremszylinder, UNIVERSAL copper grease from a Russian manufacturer.

You can use XADO VERYLube lubricant, which is relatively inexpensive, but comes in the form of a spray, and it must be applied in at least three layers, allowing it to dry after each application. Can be used to lubricate brake cylinder boots and seals, as it does not damage rubber seals.

By the way, for anthers we can separately recommend Toyota lubricant, which is called that and is produced by this concern. The price of the tube is quite high, but after using it the anthers are like new.

Much cheaper is the lubricant for the brake unit from the German manufacturer ATE, which is almost as good in quality as the previous one, but at a price 4 times lower.

ATE lubricant is today considered one of the highest quality and most popular among car enthusiasts.

The very popular LUQUI MOLY brand may not always be suitable, as it tends to destroy the rubber seals. It is more rational to use it as an anti-squeak lubricant.

If the question is what is the difference in lubrication of the front and rear brake cylinders, it is that the front cylinders have a higher load than the rear ones, so you need to be more careful in choosing a lubricant and change it more often, after about 500 km. .

| Attention Bearing Buyers Dear customers, send your questions and requests for the purchase of bearings and components by email or call now: Delivery of bearings throughout the Russian Federation and abroad. Bearing catalog on the website |

Attention Bearing Buyers

Dear customers, send your questions and requests for the purchase of bearings and components by mail or call now: tel: +7 (495) 646 00 12 [email protected] Delivery of bearings in the Russian Federation and abroad. Bearing catalog on the website

themechanic.ru

Which caliper lubricant is better, and which formulations will not give the desired effect?

The most correct option is to choose a quality product. It is important to remember that low-temperature lubricants dry out quickly and are then washed out, which leads to jamming and squeaking. For the “fingers” it is important to use a very flexible, preferably synthetic, lubricant that will not leak. The back side of the brake pads should be coated with special anti-squeak lubricants.

Experts advise you to abandon formulations that do not meet the technical parameters described above, otherwise the result will be a faulty mechanism and additional costs for replacing parts.

How often should calipers and pistons be lubricated?

People do not always know how often it is necessary to lubricate the described functional unit with a special paste. Personally, I do this every time they check the operation of the brake system, or rather, when replacing the pads. Sometimes the need for lubrication may be associated with the occurrence of squeaks and other foreign sounds.

As for the lubrication procedure, there is nothing complicated about it; just coat the parts. It is not necessary to apply the product in several layers. It is enough to use 2-3 grams of the substance.

Lubricating the caliper guides

Before moving directly to the cylinder, you need to understand its guides. The brake system generates a large amount of heat during operation. This leads to the fact that the connections often stick tightly. This also applies to guides that begin to jam. There is nothing good in this as it can lead to serious consequences. Wedging ensures that the pads are constantly pressed against the disc. This leads to significant overheating of the system. As a result, the pads burn and the discs become crooked. And a tire can easily catch fire in such conditions. That is why when servicing the caliper it is necessary to treat the guides with special lubricant. We will figure out which one exactly in this article.

Venwell Aluminum Spray

The lubricant works in the widest range from -60 to +1500 degrees. Experts note that when a critically low level is reached, the lubricant does not freeze, does not thicken, and loses its qualities.

- Characteristics

- Average price: 220 rub.

- Country Russia

- Base type: mineral

- Temperature range (C): -60 to +1500

- Specialization: extreme pressure, anti-friction, anti-corrosion

- Properties: waterproof, frost-resistant

It is known that car brakes can heat up to 600 degrees, and even more in case of emergency. The caliper lubricant must withstand such loads, and the higher its temperature spread, the better. Now we have the most stable lubricant, operating from -60 to +1500 degrees, and this is the most impressive result, which, moreover, is confirmed by independent experts. Of course, it is unlikely that such values will be achieved in reality, but it never hurts to have a margin of safety. In addition, the product has high anti-corrosion properties and is able to repel moisture without reacting to brake fluid and chemicals.

Copper grease for brake cylinders and calipers

It is the most common and popular among motorists. It is not afraid of high temperatures and is inexpensive, this is what makes it so popular. Most often used for processing discs, brake pads, as well as calipers and other elements of the brake system. It is worth noting that copper grease is applied to the reverse side of the product. If these are pads, then their front side should not be covered with any lubricant; this also applies to discs.

The process of applying the paste is also extremely simple. To do this, the surface to be treated is cleaned of dirt and corrosion. Next, lubricant is applied using a brush and distributed evenly over the entire surface. It is worth noting that it is also sold in cans, in which case it needs to be sprayed after reading the instructions for use.

Tips for choosing

It remains to discuss the question of which lubricant is better for the guide calipers of a particular car. The best way to determine the appropriate option is to look at the machine’s operating instructions and study the section on recommended lubricants. If you can find the necessary information in the technical data sheet or on the car manufacturer’s website, you definitely won’t go wrong with your choice.

If the information on the lubricants used may be incomplete, you will have to select the product yourself. The best option is to purchase one of the universal lubricants of the third group and kill several birds with one stone:

- Buying a separate composition for each element is too expensive and inconvenient, but a universal silicone composition fits everywhere.

- The paste tubes are large enough in volume, so one package will last until the end of the shelf life.

- Neutral silicone grease will extend the life of frequently changed elements - rubber boots and seals installed in the brake cylinders.

A universal lubricant will successfully work for the entire period until the next pad replacement if you completely remove the old lubricant and clean the surfaces before application. Cracked anthers should be replaced with new ones.

Basic base for high temperature grease

There is currently a huge selection on the shelves of auto stores. But if you look at it, there are only 3 broad groups:

- mineral based;

- synthetic base;

- mineral or synthetic base containing small amounts of metals.

If you figure out what kind of lubricant should be used under the brake cylinder boot, then the one that is made on a synthetic basis is best suited. This is due to the fact that it is neutral to rubber and plastic products. Consequently, the boots are not corroded and are ideal for machining brake piston or caliper guides. The base used provides a number of advantages, such as low volatility, high temperature threshold, and insolubility in water and other liquids. Overall, an excellent choice, although not always budget-friendly.

Mineral-based lubricant for brake cylinder pistons is much cheaper. But it is still better suited for guides, as it can withstand temperatures from -45 to +180 degrees Celsius.

ABRO Synthetic Brake & Caliper Grease

The cheapest lubricant with molybdenum and Teflon in our rating, costing 10% cheaper than its nearest competitor and almost 4 times cheaper than the top product.

- Characteristics

- Average price: 100 rub.

- Country: USA

- Base type: mineral

- Temperature range (C): -30 to +200

- Specialization: anti-corrosion, graphite

- Properties: heat-resistant, water-repellent

ABRO is a well-known manufacturer that often pleases car owners with quality products at an attractive price. In this case, he outdid himself by releasing a product with better characteristics and composition, while costing much less than its analogues. This is a synthetic lubricant that reliably protects your brakes from wear. It contains Teflon and molybdenum. All characteristics are at the highest level, but we know about them only from the manufacturer’s words. It is not possible to find reliable test results, hence the place in the ranking. The brand is clearly disingenuous with the description of the product, but it is unknown to what extent.

Lubricant with added ceramic particles

A relatively new development that has already gained popularity. It's not cheap, but the claimed benefits are very reassuring. Increased performance characteristics of the lubricant are achieved due to the presence of fine fractions in the ceramic composition. At the moment, this is one of the best methods of protecting brake cylinders and their seats from corrosion. In addition, the treated components eliminate the possibility of sudden temperature changes and the formation of dirt and dust on the surface.

Despite the high cost of such products, they are extremely popular among motorists. Can be used as a lubricant for rear brake cylinders, which are less loaded than the front ones. Among the most popular manufacturers it boasts high quality. Well, now let’s move on and consider a few more extremely important points.

TRW PFG110

This solution is one of the most popular among domestic motorists, who give their preference to this particular product. The product is universal; it has already proven itself on the positive side, as evidenced by the large number of positive reviews from motorists. The product is sold in tubes of twenty-five grams. Can be used in all mechanical components, including hydraulic ones made of rubber, that are in contact with brake fluid. It is not recommended to use this solution for aluminum elements that are under high dynamic load. This solution has excellent wear protection and resistance to high loads. You can also note the high adhesive characteristics of the product and its water resistance. In reviews, many motorists speak positively about the properties of the lubricant. In general, this solution has shown its highly effective properties, as evidenced by the large number of positive reviews from car owners.

pros

- Protective properties.

- Doesn't coke.

- Adequate cost.

Minuses

- Difficult to find on sale.

How is the brake system serviced?

Complex lubrication is often recommended when replacing brake pads or discs. There is nothing complicated here. First of all, we inspect the condition of the guides. We clean the fingers and seats from rust and treat them with a certain amount of lubricant. Copper, graphite, etc. are suitable. As for the piston, lubricant is needed to reduce friction and protect against corrosion. It is advisable to treat the surface of the part with a small amount of ceramic lubricant. It will effectively protect the surface from rust.

An extremely important detail is that it is worth checking the condition of the boot regularly. If it is torn, no amount of lubricant will help. First you need to replace the rubber seal and then add lubricant. In addition, there should not be too much of it, as it will begin to squeeze out through the anthers and cuffs, which is not good.

Which lubricant is better to use?

It is advisable to use different types of lubricant depending on the part being processed. For example, graphite lubricant is ideal for caliper guides. It is inexpensive and can withstand high temperatures. Protects metal products from corrosion and prevents sticking. One of the most affordable options is TRW products.

The optimal lubricant for brake cylinder pistons should be silicone or ceramic based. The best manufacturer in this regard is Febi. Cheap and cheerful. But anti-squeak Liqui Moly is not recommended for placing under the piston boot, as it can cause destruction of the rubber seal.

Anti-squeak paste is excellent for treating the brake pad plate and retaining bracket. Usually this is where its use ends. Remember that the brake cylinder seals should not be lubricated with pastes that corrode the rubber seals. This can lead to complete destruction of the piston and caliper.

RUSEFF

Lubricants from this manufacturer often become participants in various ratings and are included in expert reviews in such popular magazines as Behind the Wheel and Auto Vzglyad, as well as on the Drive portal.

- Characteristics

- Average price: 240 rub.

- Country Russia

- Base type: synthetic

- Temperature range (C): -50 to +200

- Specialization: anti-corrosion, anti-squeak, anti-scuff, anti-friction

- Properties: waterproof, frost-resistant

Judging by the number of mentions in specialized publications, the Russian brand RUSEFF can easily be called the most popular. Moreover, many experts say that this caliper lubricant is the best of its kind, at least for the money. This is a synthetic paste containing anti-friction and anti-squeak components. After application to the guide, the unpleasant grinding noise disappears from the module, and the service life of the parts is also extended. True, the drop threshold was set at only 205 degrees. That is, you should not apply lubricant to the piston cylinder or moving fingers. But the lower mark is as much as 50 degrees with a minus sign, which is a very good result.

Let's sum it up

As you can see, there is nothing difficult in servicing a car's brake system. But at the same time, it is extremely important to regularly lubricate all elements of the caliper, which operate at high temperatures every time. Pay attention to the guide pin anthers. They are also subject to wear, resulting in a rather unpleasant knocking noise on bumps. This happens due to the fact that the finger dangles freely in the seat and is not held by the plastic sleeve.

As for lubricants, there are simply a huge number of them nowadays. Any paste for lubricating brake cylinders, if it is intended for this purpose, will be suitable for use. It is not recommended to lubricate brake system parts with simple motor oil or grease, etc. All this will not lead to anything good.

Many parts of the brake system, with proper maintenance, can last 200-300 thousand kilometers or more, this applies to calipers, guides, pistons, etc. Pads and discs are more of a consumable item, but it is also advisable to look after them. All this will allow you to feel more confident behind the wheel and know for sure that the brakes will not let you down, because everything is lubricated and checked. Often the problem is with jamming of the guides and tight movement of the brake cylinder, which occurs in 90% of cases due to insufficient lubrication. If you use lubricant for the brake cylinder boots every time you replace the pads, then you will not have any problems with the car’s braking system.

Hi all! This is a very small part of what is there, I think it will be useful for many to know what it’s for)) there are people who pour some kind of oil from a pharmacy under the piston boot, someone smears copper and graphite paste on the guides, and some are simply fooled by salespeople in stores! thanks to all!

Lubricants for guide pins:

TRW/Lucas — PFG110 Febi 31942 Swag 30931942 Dow Corning/Molykote G-3407 Brake Anti-Fretting Caliper Pin grease Niglube RM (p/n MZ101616EX, 100 g) Slipkote 220-R DBC SEIKEN CF301 If the caliper is Ate, then we don’t lubricate the fingers at all there they work dry!

lubricants only for brake cylinders:

VAG B 000 100 Motorcraft XG 3-A Ate 03.9902-0501.2 (BMW83 19 9 407 854) Febi31942

lubricants/pastes for pads (anti-creaking pastes)

83192158852 (100 g), 83192152323 - CRC metal free paste (100 g), 83229400794 - CRC Copper paste (100 g). small packaging: 83192158851, 83122296187, 83230140233, 83120154346, 81229407103, 81229407627, 812294076028 88862478 (AC Delco-227g) Anti-seize lubricant 04796269 (1.76 oz) Ford p/n 1143321 (tube 80 g)

| It is worth noting the pastes: | The following brands produce lubricants: |

SLIPKOTE 220-R DBC

SLIPKOTE 220-R DBC

Quite a high-quality solution for cars. SLIPKOTE 220-R DBC can be used in the following temperature range: from minus forty-six to almost plus three hundred degrees. The basis of this solution is synthetics (oil), and various additives that make this product anti-corrosion. One of the significant disadvantages of this solution is its high cost. One way or another, this product collects a large number of positive reviews among motorists, many note its high efficiency and versatility.

pros

- Wide temperature range.

- Universal application.

- Protective properties.

- Anti-corrosion.

Minuses

- High price.