The exhaust gas recirculation (EGR) system, better known by the abbreviation EGR or EGR (from English: EGR - Exhaust Gas Recirculation), is designed to increase engine efficiency, reduce fuel consumption and make emissions more environmentally friendly.

Among other things, the USR reduces vibration on a diesel engine and prevents detonation on a gasoline engine. The system is not new and has been used for a long time, it could be found even on old domestic cars, however, due to an imperfect design and the lack of specialists capable of repairing the exhaust gas recirculation system in case of emergency, it was usually removed, that is, deactivated using various methods.

Purpose of the element

The name of the part comes from the English abbreviation Exhaust Gas Recirculation. Literally translated, this means “exhaust gas recirculation.” This part redirects part of the exhaust gases to the intake manifold. In practice, such recirculation has several positive effects in modern cars:

- the level of nitrogen oxide emissions is minimized;

- increasing the level of accuracy of exhaust gas control;

- reduction of engine detonation;

- accelerated heating of the tract, which is especially important in winter.

The EGR valve is installed on both gasoline and diesel engines. In cars produced before 2000, valve failure did not cause any specific inconvenience, and many motorists even deliberately turn it off. We'll talk about this later. It is worth noting that the EGR valve does not operate constantly. This part is in an inactive state when the engine is cold (unheated), at idle speed, when the damper is fully open. Now you know why the EGR valve is needed on diesel and gasoline .

Checking the USR system

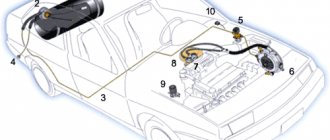

Naturally, the location of the EGR sensor will differ on different brands and models of cars, but in any case this unit will be located in close proximity to the intake manifold. Less commonly, it is located in the suction tract or on the throttle valve block.

In garage conditions, the inspection must begin with a visual inspection. By and large, there are two methods for diagnosing the EGR valve - with and without dismantling it. However, it is still better to carry out a more detailed check by dismantling the unit, since after checking, if the valve is clogged with deposits of burnt fuel, it can be cleaned before subsequent installation in place. First, let's look at testing methods without dismantling individual parts.

This is interesting: The central locking does not work: how to repair it yourself?

Please note that often when installing a new EGR valve, it needs to be adapted using special software in order for it to work properly with the electronic control unit.

How to check the functionality of the USR

First of all, before doing a full check, you need to make sure that the valve works at all. Such serviceability is done in an elementary way.

When you need to check the serviceability of a pneumatic valve, it is enough to observe the stroke of the rod when it is being throttled (one person is throttling, the other is watching). Or by pressing the membrane - the speed should drop. To check the EGR solenoid valve, you need to apply power directly from the battery to the plus and minus connectors, while listening for any clicks. Having completed these steps, you can proceed to a more detailed EGR check.

Pressing the valve

With the engine idling, apply a little pressure on the diaphragm. Depending on the specific structure of the valve, it can be located in different places. For example, in the popular Daewoo Lanos car, you need to press under the plate; under it there are cutouts in the body, through which you can press directly on the membrane. That is, the pressure does not occur on the membrane itself, since it is protected by the housing, but on that part of the housing that is located directly above it.

If, in the process of pressing the specified unit, the engine speed dropped and it began to “choke” (the speed began to drop), then this means that the valve seat is in good condition, and by and large, nothing needs to be repaired, except for preventive purposes ( To do this, you will need to dismantle the USR valve and, at the same time, perform additional comprehensive diagnostics of the unit). However, if after this pressing nothing happens and the engine does not lose speed, this means that the membrane is no longer sealed, that is, the EGR system practically does not work. Accordingly, it is necessary to dismantle the USR valve and perform additional diagnostics of the condition of both the valve itself and other elements of the system.

Valve check

As mentioned above, the location of the valve may differ in different cars, however, it is often installed in the area of the intake manifold. For example, on a Ford Escape 3.0 V6 it is installed on a metal pipe coming from the intake manifold. The valve opens due to the vacuum that comes from the solenoid. We will give an example of further testing using the engine of the specified car.

In order to check the functionality of the EGR valve, it is enough to disconnect the hose through which the vacuum (vacuum) is supplied from the valve while the engine is idling. If there is a vacuum pump within close reach, you can connect it to the valve opening and create a vacuum. If the valve is working properly, the engine will begin to “chop” and twitch, that is, its speed will begin to drop. Instead of a vacuum pump, you can simply connect another hose and create a vacuum simply by sucking in air with your mouth. The consequences should be the same. If the engine continues to operate normally, it means the valve is most likely faulty. It is advisable to dismantle it to perform detailed diagnostics. In any case, further repairs will need to be carried out not at its seat, but in a car repair shop (garage).

Solenoid check

A solenoid is an electrical resistance that allows current to pass through it. The solenoid changes the voltage passing through it using pulse width modulation (PWM). The voltage changes during operation, and this is a signal to apply vacuum to the EGR valve. The first thing to do when checking the solenoid is to make sure that the vacuum is at a good enough vacuum. We give an example of a test for the same Ford Escape 3.0 V6 car.

The first thing to do is to disconnect the small tubes at the bottom of the solenoid, after which you need to start the engine. Please note that the tubes must be removed carefully so as not to break the fittings to which they fit! If the vacuum on one of the tubes is in order, then it will be audible; in extreme cases, you can put your finger on the tube. If there is no vacuum, additional diagnostics are necessary. To do this, it will also be necessary to subsequently remove the USR valve from its seat for further comprehensive diagnostics.

After this, it is necessary to check the electrical part, namely, you need to check the power supply to the solenoid. To do this, you will need to disconnect the chip from the specified element. There are three wires - signal, power and ground. Using a multimeter switched to DC voltage measurement mode, you need to check the power supply. Here one probe of the multimeter is placed on the supply contact, the second - on the ground. If there is power, the multimeter will show a supply voltage value of about 12 Volts. At the same time, it makes sense to check the integrity of the impulse wire. This can also be done using a multimeter, but switched to the “testing” mode. On the Ford Escape 3.0 V6 shown, it has purple insulation, and at the ECU input it is number 47 and also has purple insulation. Ideally, all wires should be intact and with intact insulation. If the wires are broken, they must be replaced with new ones. If the insulation is damaged, you can try to insulate it with electrical tape or heat shrink tape. However, this option is only suitable if the damage is minor.

After this, it is necessary to check the integrity of the wiring of the solenoid itself. To do this, you can switch the multimeter to the continuity mode or measure electrical resistance. Next, use two probes to respectively connect to the two outputs of the solenoid wiring. The resistance value for different devices may be different, but in any case, it must differ from zero and from infinity. Otherwise, there is a short circuit or a winding break, respectively.

Checking the EGR sensor

The function of the sensor is to record the difference in pressure in one and the other part of the valve; accordingly, it simply transmits information to the ECU about the position of the valve - whether it is open or closed. First of all, you need to check whether there is power on it.

Switch the multimeter to DC voltage measurement mode. Connect one of the probes to wire No. 3 on the sensor, and the second probe to ground. Next you need to start the engine. If everything is normal, then the voltage between the two indicated probes should be equal to 5 Volts.

Next, you need to check the voltage on impulse wire No. 1. When the engine is not warmed up (the EGR system is not working), the voltage across it should be about 0.9 Volts. You can measure it in the same way as the supply wire. If you have a vacuum pump, you can apply a vacuum to the valve. If the sensor is working properly, and it will record this fact, then the output voltage on the pulse wire will gradually increase. At approximately 10 volts the valve should open. If during the test the voltage does not change or changes non-linearly, it means that the sensor is most likely faulty and additional diagnostics need to be performed.

This is interesting: Causes and solutions to error P0087 vw

If the car stalls after running the engine for a short time, you can unscrew the EGR valve and, leaning it and removing it again, look at the reaction of the engine - if, after removing the valve from the crankcase, a lot of smoke comes in and the engine starts to run smoother, the ventilation system or the valve itself is faulty. Additional checks are needed here.

Dismantling check

It is best to check the EGR valve when it is removed. This will make it possible to visually and using instruments assess its condition. The first thing to do is check its functionality. Essentially, the valve is a solenoid (coil) that needs to be supplied with 12 Volts of DC, just like in a car's electrical circuit.

Please note that the design of the valves may differ, and accordingly, the numbers of contacts to which voltage must be applied will also be different, accordingly, there is no universal solution here. For example, for a Volkswagen Golf 4 APE 1.4, there are three pins on the valve with numbers 2; 4; 6. Voltage must be applied to terminals numbered 2 and 6.

It is advisable to have an alternating voltage source on hand, since in practice (in a machine) the control voltage varies. So, in normal condition the valve begins to open at 10 Volts. If you remove 12 volts, it will automatically close (the rod will go inward). At the same time, it makes sense to check the electrical resistance of the sensor (potentiometer). With a working sensor on an open valve, the resistance between pins 2 and 6 should be about 4 kOhm, and between 4 and 6 - 1.7 kOhm. In the closed position of the valve, the corresponding resistance between pins 2 and 6 will be 1.4 kOhm, and between 4 and 6 - 3.2 kOhm. For other cars, of course, the values will be different, but the logic will remain the same.

Along with checking the functionality of the solenoid, it makes sense to check the technical condition of the valve. As mentioned above, soot (fuel combustion products) accumulates on its surface over time, depositing on its walls and on the rod. Because of this, the smooth movement of the valve and stem may be impaired. Even if there is not a lot of soot there, it is still recommended for preventive purposes to clean it inside and out using a cleaner.

Software check

One of the most complete and convenient methods for diagnosing the EGR system is the use of software installed on a laptop (tablet or other gadget). So, for cars produced by the VAG concern, one of the most popular diagnostic programs is VCDS or in Russian - “Vasya Diagnost”. Let's briefly look at the EGR testing algorithm with this software.

The first step is to connect the laptop to the electronic engine control unit and run the appropriate program. Next, you need to enter the group called “Engine Electronics” and the “Custom Groups” menu. Among others, at the very bottom of the channel list there are two channels with numbers 343 and 344. The first is called “EGR Vacuum Regulator Solenoid Valve; actuation", and the second - "EGR Solenoid Valve; actual value".

In practice, this means that channel 343 data can be used to judge at what relative value the ECU decides to open or close the EGR valve in theory. And channel 344 shows at what actual values the valve is triggered. Ideally, the difference between these indicators in dynamics should be minimal. Accordingly, if there is a significant discrepancy between the values in the two indicated channels, it means that the valve has partially failed. And the greater the difference in the corresponding readings, the more damaged the valve is. The reasons for this are still the same - a dirty valve, the membrane does not hold, and so on. Accordingly, using software, you can assess the condition of the EGR valve without removing it from its seat on the engine.

Types of valves

Initially, such devices were controlled according to the principle of vacuum in the intake manifold. With the development of technology, pneumoelectric models appeared (Euro-2 and Euro-3 standards). The most advanced are fully electronic valves that comply with Euro-4 and Euro-5 standards. Digital valves are controlled by an electronic control unit (ECU). The category of electronic devices is also divided into 2 groups: valves with 2 and 3 holes. The differences are in the recycling levels. In models with 2 holes, there are three such levels, and for a product with 3 holes, seven levels are characteristic. Smooth control of the gas supply is carried out thanks to a stepper electric motor, but this technology is installed only on the latest models. Some EGR models are additionally equipped with a gas cooling system.

Function of the EGR (exhaust gas) valve

When and in what quantities exhaust gases are sent to the external gas recirculation system is regulated and controlled through the exhaust gas recirculation valve - often called the exhaust gas recirculation valve (EGR) - or EGR.

The EGR valve usually consists of a poppet valve or a special gate valve. This valve releases or prevents the movement of exhaust gases into the engine intake tract.

Using sensors such as the mass air flow sensor and the oxygen sensor (lambda probe), the engine control unit calculates the ideal amount of exhaust gas recirculation and accordingly controls the exhaust gas recirculation valve (EGR valve).

The mechanical movement of the EGR valve device is usually performed electro-pneumatically or electrically using a servomotor.

On some vehicle models, the EGR valve is also equipped with a position sensor that monitors the correct opening and closing of the flap or pushrod. By the way, exhaust gas recirculation occurs only in the part-load region of the engine.

Valve operating principle

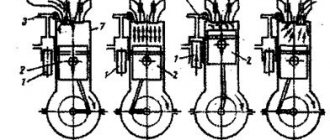

Regardless of the type of engine (diesel or gasoline), there are no fundamental differences in the operation of this device. The more air in the resulting mixture, the higher the combustion temperature will be. Accordingly, the rich mixture must be “leaned”, which is what the USR valve does. The operating principle of the EGR valve can be described by the following points:

- If the engine control unit, through data from sensors, observes an enriched mixture, the engine warms up (of course, provided that everything is working properly). The system sends a signal to the valve, and exhaust gases enter the inlet, leaving the mixture lean.

- If the ECU registers a uniform supply of the mixture over specific periods of time (normal driving on the highway), then the system opens the valve again, leaning the incoming mixture. By reducing the concentration of incoming oxygen, the combustion temperature decreases.

- Such equalization in both cases allows to reduce the concentration of nitrogen oxides in the exhaust gases.

If we go into the intricacies of how the USR valve works on each type of engine, we can highlight several points. In a diesel engine, the USR opens at idle, and it supplies up to 50 percent of the air volume to the intake. As the speed increases, the valve closes proportionally. When warmed up, it is completely closed.

Now let's find out the intricacies of how the EGR valve works on a gasoline engine. In engines, the valve, as mentioned earlier, does not turn on when cold, at maximum speed, or at idle. At low and medium load levels, up to 10 percent of the air supplied to the inlet is provided. This characteristic is a feature of the operation of the EGR valve on a gasoline engine.

Exhaust gas recirculation system - purpose

As I said above, EGR is necessary in order to reduce fuel consumption, make exhaust less toxic and improve the efficiency of the engine. But how does this happen?

You all know that in the combustion chamber during engine operation, the temperature reaches a high level, as a result of which oxygen reacts with nitrogen, resulting in the formation of nitrogen oxide. Due to the lack of oxygen, which is necessary for burning the fuel mixture, and an excess of nitrogen, the fuel is burned with less efficiency. As a result, engine efficiency (power) decreases, and fuel consumption increases. In addition, due to poor combustion of fuel assemblies, the environmental friendliness of emissions decreases and the level of harmful CO and HC in the exhaust gases increases.

Symptoms of a problem

Valve failure can lead to adverse consequences, so drivers should promptly determine if this part is faulty. Here are a few signs that will help you:

- unstable engine operation at idle speed;

- regular engine stops and detonation;

- jerky movement and noticeable misfires;

- The check light on the dashboard comes on.

Valve failure can be identified using the electronic control unit. The system will generate errors during diagnostics. If their code corresponds to P04XX (instead of XX, a number from 00 to 04), then the problem lies in the EGR valve. In the technical manual of the ECU you can see the decoding for each of these errors. If the above-described signs are detected, we recommend conducting computer diagnostics (either on your own or in a specialized technical center).

That's why you need to take the EGR valve seriously: it's small and clever.

If the EGR valve stops working correctly, then certain symptoms may appear in the car, clearly indicating to us that the exhaust gas recirculation system is faulty. Fortunately for you and me, most often this does not mean that it is time to change the valve itself. In many cases, we can easily fix everything ourselves.

Causes of malfunction

One of the main reasons for the incorrect operation of the USR is air leaks. If an air flow sensor is installed, then (due to its operation) the mixture will become leaner, and if there is a pressure sensor, for example, the mixture will be too rich. The presence of both sensors will make the car behave incorrectly, since at idle the engine will receive a rich mixture, and in other cases it will be too lean. The second reason is contamination of the valve itself. Here the way out of the situation is quite simple: it needs to be cleaned, which we will discuss later. Malfunctions are usually associated with either too much exhaust flow or too little. Depressurization of the housing also leads to problems. A malfunction of the USR system can be caused by the following breakdowns:

- external pipes are damaged;

- valve defect;

- valve solenoids failure;

- faulty pressure converters.

Indirect causes of valve failure include:

- use of low-quality fuel (after 10–20 thousand kilometers the consequences will be visible);

- wear of oil seals;

- problems with electrical equipment;

- wear of injectors;

- oil level too high;

- Incorrect ignition angle.

The valve itself becomes unusable after 60-80 thousand kilometers; accordingly, it requires complete replacement.

Restoring normal operation

Initially, the EGR system is designed for a vehicle mileage of no more than eighty to one hundred thousand kilometers. After this, it is necessary to replace all components of the system. In domestic conditions, a complete replacement after 50,000 km is optimal. However, in practice, this is not something everyone can afford. In this case, timely service can be recommended.

The seat and stem must be thoroughly cleaned to ensure tight closure and smooth operation. A special liquid sold in aerosol packaging, used to clean the carburetor, is effective in this case. In this case, this liquid must not be allowed to come into contact with the diaphragm.

If there is a solenoid, you need to clean the small filter located in it. This device is designed to protect the vacuum system from dirt. After cleaning this filter, in many cases the problem disappears.

Often, after a valve failure, car enthusiasts try to turn it off. This is usually done using a gasket cut from thin tin. There is no need to cut holes for the passage of gases. Only if the rod protrudes beyond the seating plane is it necessary to make a hole.

Thus, the EGR valve is of great importance in the normal functioning of the recirculation system.

Valve replacement

It is recommended to completely replace severely worn parts. Given the ease of access to the valve, its replacement can be done in a garage environment. Drivers will need:

- find the valve in the engine compartment (see the section “Where to find it”);

- dismantle the worn product;

- apply high-temperature sealant to the threads of the thermal valve;

- install a new gasket, and then install the newly purchased EGR valve.

When purchasing a new valve, follow the recommendations given by the car manufacturer.

Valve device

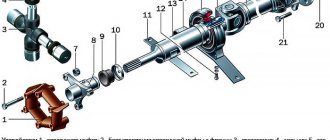

The valve consists of the following elements.

- Frame. It is a metal box with two tubes. One of them is connected to the inlet valve, and the second to the outlet valve. It is made of heat-resistant materials, since the temperature of the exhaust gases is very high (usually from special steel alloys).

- Damper. It is a metal disk with gaskets that blocks the access of exhaust gases to the intake valve.

- Electric motor. It is a spring-loaded electromagnet that opens the valve flap at the right time upon a command from the ECU.

- Cooler. It is an air radiator or washer connected to the vehicle cooling system. Necessary for the correct operation of the unit, as it reaches very high temperatures. Not used on all car models.

In addition, a whole complex of sensors works in conjunction with the USR. Some of them are not structural elements of the valve, but play an important role in its functioning. Perhaps the main one is the lambda probe. It is located in the exhaust manifold and determines the oxygen content in the exhaust (and therefore the degree of enrichment of the mixture). The following sensors are also used in the operation of the USR:

- valve position;

- exhaust temperatures;

- exhaust gas pressure.

The USR can also be installed on older model cars that do not have an ECU. They used a so-called vacuum valve. Its opening is controlled not by the ECU, but by a spring-loaded diaphragm, which is located in a special vacuum chamber and is rigidly connected to the damper. When a certain exhaust gas pressure is reached on the damper, the diaphragm bends and the valve opens slightly. Gases enter the cylinder and lean the fuel mixture.

car phone mount

Valve cleaning

If a relatively new valve is not working correctly, it is recommended to clean it. To do this, prepare a set of wrenches, a couple of carburetor cleaners (foam and spray), a Phillips screwdriver and a special lapping compound for valves. After dismantling the valve using wrenches, of course, the following steps must be performed:

- soak the insides of the part with carburetor cleaner;

- flush the channel in the manifold using a tube and foam cleaner;

- repeat the procedure several times (depending on the degree of contamination);

- unscrew the bolts and disassemble the valve;

- use paste to grind in;

- wash away all plaque and cleaners;

- dry thoroughly and install the part in place.

EGR valve, what is it and is it worth STUPLISHING it?!

This topic concerns directly the owners of diesel cars. The USR valve recirculates gases from the exhaust manifold, which reduces the emission of nitrogen oxide into the atmosphere. The USR valve does not affect the operation of the engine in any way; its direct task is to reduce the emission of harmful substances into the atmosphere. Disabling, dismantling, or flashing the USR sensor does not affect engine operation in any way!

On average, the USR valve serves its owner for 150,000 kilometers, approximately the same as a particulate filter. When an error occurs, many car owners are afraid to do any manipulations with the valve, and try to get by by replacing it.

Check for soot and oil on the throttle valve, before and after the EGR valve is plugged, after driving 5,000 -10,000 kilometers, and make sure that the valve does not become dirtier due to the absence of the valve! You need to turn off the valve correctly, both physically, by turning off all output channels, and programmatically.

Since 2006, in addition to the USR valve, particulate filters began to be installed on European cars. The particulate filter is killed during city driving over short distances, since the exhaust gases of a diesel engine do not reach the operating temperature to burn through the soot, thereby becoming clogged. When the filter is clogged, a pressure sensor installed on it signals its passability and signals the engine to increase the fuel supply in order to break through the clogged filter.

Having noticed fuel consumption and a particulate filter error on the instrument panel, I advise you not to delay, but to take action. Cleaning the filter is useless; it will lead to further rapid clogging! Replacing the filter with a new one will not be cheap! Way out; remove all the filler from the filter and muffle all sensors touching the exhaust tract and the engine will work like new! Remember, if the filter is clogged, exhaust gases cannot exit the system completely, thereby killing the engine! By the way, a used filter, or rather its internal filter element (it contains platinum group metals) can be handed over to special offices that recycle them and get 1000 or more rubles apiece!

Source

Removing (plug) valve

Plugging the EGR valve will be the cheapest solution to problems associated with it. It is worth noting that chip tuning only partially solves the problem. Disabling valve control in the ECU does not completely remove its influence, so drivers install a plug. It can be purchased on the market or made independently. It looks like a plate about 3 millimeters thick with a hole identical to the valve hole. It is necessary to dismantle the EGR valve, remove dirt from the channels, and replace the gasket with a plug. To prevent the computer from generating an error, be sure to make the appropriate adjustments in the electronic unit.

EGR valve malfunctions

The most popular problem that occurs with most motorists is carbon deposits that concentrate on the EGR valve seat or plate.

There may be several reasons for this unpleasant phenomenon:

- For example, this may be due to a poor-quality dirty intake mixture;

- Turbine malfunctions;

- Malfunctions in the operation of the air flow meter (MAF);

- The problem may also be clogged crankcase ventilation ducts;

- Ineffective combustion of fuel assemblies, as a result of which dirty residues along with carbon deposits circulate through the EGR valve and contaminate it;

- Engine oil level too high;

- Serious wear of the cylinder-piston group;

- Failure or critical wear of injectors, which disrupts the accuracy of fuel injection.

Consequences of jamming the USR

When installing a plug instead of a valve, drivers should take into account that such a move has a number of positive and negative consequences. The first include:

- the likelihood of carbon deposits forming in the collector is reduced;

- vehicle dynamics are improved;

- eliminates the need for regular valve replacement;

- The service life of the oil is slightly increased.

Adverse consequences include:

- accelerated wear of the catalyst (if present);

- the Check Engine light comes on, which prevents you from identifying other faults when they are registered by the system);

- fuel consumption increases;

- valve wear increases.

Now you are familiar with all the consequences of missing an EGR valve. Spending money on replacing it or installing a plug is a personal decision for each driver.

How to turn off the EGR valve with your own hands

Let's start with the fact that correctly disabling the exhaust gas recirculation system involves:

- mechanical valve damping;

- software shutdown in the control unit;

At the initial stage, a mechanical plug for the EGR valve is installed. Next, the EGR system is turned off using electronic equipment. It must be added that only on some models is it enough to physically shut off the EGR valve. Often, after the mechanical shutdown procedure, a software shutdown of the USR valve in the control unit is additionally required. Otherwise, the ECU will record an error in the operation of the exhaust gas recirculation system, “check” will be displayed on the instrument panel, and the engine will go into emergency mode with limited power output.

We also recommend reading the article on how to clean the diesel particulate filter yourself. In this article, you will learn about the various ways to clean the said filter element.

The most simplified option for installing the EGR valve plug generally suggests:

- Removing the valve. This element is most often located in the area of the intake manifold and is secured with several bolts.

- If necessary, the intake manifold is additionally removed and the intake manifold channels are cleaned of dirt.

- Next, you need to remove the gasket, which is located at the mounting location of the EGR valve.

- After removal, the gasket plays the role of a template, according to which you need to cut out a plug gasket similar in shape, but completely blind, from a steel sheet. The plug will only contain holes for mounting bolts. Please note that the plug will come into contact with hot exhaust gases under pressure during operation. For this reason, it is necessary to make the EGR gasket of appropriate thickness to eliminate the possibility of its rapid burnout. Let us add that a ready-made EGR valve plug is also available for free sale. To order a solution suitable for a specific model, you can use the search on specialized automotive forums.

- The next step is to reinstall the EGR valve. At the mounting point, the standard gasket and the new plug are combined. Be careful when tightening the bolts as they may become fragile.

- Upon completion, it is necessary to disconnect the vacuum hoses, since opening the valve via the vacuum system is no longer necessary.

- The final stage of the procedure for shutting down the recirculation system is making adjustments to the firmware of the engine control unit in order to programmatically disable the EGR error.

Why turn off the EGR valve?

Let's start with the fact that the EGR system is installed on a diesel engine to comply with the internal combustion engine stringent environmental regulations and standards that apply in developed countries. EGR is mainly designed to reduce the level of nitrogen oxides in engine exhaust gases.

The system partially redirects exhaust gases back to the intake manifold, due to which the amount of oxygen in the fuel-air mixture is reduced, the formation of nitrogen oxides becomes less intense and exhaust toxicity falls within the specified standards.

The EGR valve opens at the right time, allowing a portion of the total exhaust gas to flow back into the intake to be delivered to the engine cylinders. As practice shows, the exhaust gas recirculation valve often becomes clogged during operation. The need to suppress the EGR arises because soot and other exhaust components quickly damage this element; a clogged system prevents the supply of clean air for the most efficient combustion of diesel fuel.

This is interesting: Replacing the pump on a VAZ 2107 yourself - detailed instructions on how to change it yourself

On high-quality European diesel fuel, cleaning the EGR valve may be required once every 40 or even 60 thousand km. Driving on domestic diesel fuel requires you to perform this procedure every 20-30 thousand km.

Moreover, the relevance of equipping the engine with such a system is questioned by many experts. Disabling the USR naturally leads to an increase in the level of nitrogen oxide emissions. At the same time, emissions of soot, carbon dioxide and carbon monoxide are noticeably reduced. Also, after turning off the USR system, fuel consumption decreases, as the amount of oxygen in the intake increases and the mixture burns in the cylinders more efficiently.

In other words, the benefits of such an exhaust recirculation system are questionable. Environmental performance improves only slightly compared to the loss of engine power, increased fuel consumption and EGR service costs.

There are also individual statements that rapid contamination of the EGR valve and the supply of exhaust to the intake lead to increased carbon formation and coking of the combustion chamber. Malfunctions of the EGR system, which are often associated with incorrect operation of the EGR valve, lead to unstable engine operation and increased fuel consumption. Soot and resins enter the engine, and a process of accelerated oxidation of diesel engine oil occurs, which greatly affects the overall service life of the diesel engine.

The need to disable the USR system often occurs at mileages of about 80-120 thousand km. The fact is that after such a mileage the engine wears out a little. Exhaust gases that are redirected to the intake have a higher degree of contamination. Next, they mix with crankcase gases, and the result is the appearance of a thick layer of tarry deposits in the intake manifold, on the EGR valve, as well as on the valves of the engine itself.

The flow section in the intake becomes clogged with deposits, and the diesel engine gradually loses power. A clogged USR valve leads to errors and the car may unexpectedly go into emergency mode. It is quite obvious that in such a situation an urgent repair of the exhaust gas recirculation system is necessary or it can be turned off by shutting off the EGR valve.

Advantages and disadvantages of disabling the USR

The only drawback of removing the USR can be considered an increase in exhaust gas toxicity. There are many more advantages. After plugging the EGR valve on a diesel engine, owners note a sharper response to pressing the gas pedal in moderate load modes, and the so-called turbo lag effect on turbodiesels becomes less noticeable. When operating under load, the engine smokes less, the service life of the particulate filter increases, and the intervals between its cleaning increases. The service life of the engine oil is also extended, the engine is better cleaned, and is less susceptible to coking and wear.

It should be noted that although there is no noticeable increase in the power of a diesel engine after disabling the USR system, the engine becomes more responsive, and the car itself feels more dynamic when driving.

Finally, we would like to add that if you decide to perform power chip tuning of a diesel engine or install a tuning box on a diesel engine, then disabling the exhaust gas recirculation system is a highly recommended procedure.

How to properly remove the USR

Some car owners practice independently, “physically” turning off the EGR by installing a makeshift gasket that covers the valve openings. There are even original gaskets on sale, for example, from General Motors. But it is possible to get by with just installing a plug only on old diesel engines, where the operation of the EGR is regulated by vacuum (pneumatic-mechanical drive). Most modern cars have an electro-pneumatic or electronic control circuit - the signals to open and close the exhaust gas supply come from the electronic control unit.

To completely remove the EGR, you must simultaneously remove the valve and software disable the USR with flashing the controller. Some schemes require the additional installation of an emulator for the “correct” readings of the valve position sensors, flow meter and lambda probe. Only then will it be possible to avoid the recurrence of errors and frequent engine transitions to “emergency” mode.

Minuses

Now we get to the shortcomings of the system. It is because of them that many recommend removing it immediately, rather than rebuilding or purchasing a new valve.

The very first

– through it, soot, oil and other fuel combustion products, especially low quality ones, enter the intake. This is reflected in the intake valves. They become overgrown with carbon deposits. Unburnt oil, if there is an engine oil burn, “flies” into the cylinders and onto the same valves. The throttle valve is dirty. All this negatively affects the reliable and stable operation of the power unit.

Soot and oil fly into the intake through the USR system, which is deposited on the valves and throttle valve

Second.

Over time, after 100-150 thousand kilometers, and maybe earlier, depending on operation, the valve becomes overgrown with soot and soot.

It begins to wedge in different positions. This negatively affects the operation of the motor under load. He's losing momentum

.

EGR valve Skoda after 120 thousand kilometers

This is due to the fact that the USR system does not work in all modes of the power unit. In gasoline engines only at low and medium loads, at heavy loads it is turned off. On diesel engines - only at idle speed. If it gets stuck in the open position, the motor will not develop the required power and will not work correctly.

That is why many people drown out this system. They install a damper instead and recheck the engine control unit. This works out cheaper than buying a new EGR valve.