Design and principle of operation of spark plugs

Spark plugs are simple in design; essentially they consist of a conductor in the center, a metal body to which a side electrode is welded, and an insulator. Despite the simplicity of their design, they play one of the most important roles in the operation of a car engine. Their duty is to ignite the combustible mixture, in any conditions and under any load on them.

At the moment when the piston reaches top dead center during the compression stroke, an electric spark is emitted, igniting the mixture of air and fuel. A spark occurs between the central and side electrodes. For it to occur, a voltage of at least 20 thousand volts is required. The ignition system is responsible for receiving it; it converts 12 volts received from the car battery into 25-35 thousand volts necessary for normal operation of the spark plug. The moment when high voltage should be applied is determined by a position sensor

There are three main types of spark plugs that are widely used today. They differ from each other in their design features and the metal from which they are made.

Main types of spark plugs:

- Two-electrode;

- Multielectrode;

- Candles made of precious metals.

What is its structure?

The basic design of a spark plug is approximately the same for any company that produces it. This is a metal body, electrodes, the number of which may vary depending on the brand, a ceramic insulator and a central contact rod passing through it. Then the differences begin.

The central contact rod, for example, may have a flat pad tip. But may have a U or V groove. It can be pointed - if it is made of iridium, like DENSO spark plugs. They even have a side electrode with a specially shaped profile. This company produces perhaps the most reliable spark plugs - iridium-platinum ones.

Some models may not have a side electrode at all - in particular, SAAB engineers have developed a motor in which the piston itself has a pointed protrusion, the function of which is the same as that of the side electrode. When the piston approaches top dead center as much as possible, a spark jumps between it and the central electrode, igniting the compressed fuel-air mixture.

The already mentioned two or more side electrodes also change the operating modes and parameters of the motor for the better. At the same time, the requirements for working gaps are increasing, which are generally not recommended to be changed or touched in any way by bending or unbending, but only strictly maintaining the factory parameters of their manufacture.

At the same time, the principle of operation of a spark plug with two or more electrodes is simple; no technical tricks are required for its stable operation: when, as the electrode is depleted and “eaten up” by the spark, spark failures begin, it automatically appears on the unused electrode, and the process of operation of the internal combustion engine continues without interruption.

The metal housing at the bottom with a thread for screwing into the cylinder head (cylinder head) has a flat or conical ring-shaped platform. Spark plugs with a flat platform are equipped with a crimp ring-washer made of soft metal, which prevents the compressed fuel-air mixture or combustion products from breaking out. For candles with a conical profile after threading, there is no need for such a ring; the conical profile itself reliably seals the top of the combustion chamber.

The central insulators in all models are made of heat-resistant ceramics. It is on this that markings are applied with the type, name of the manufacturing company, etc. Inside, between the contact for the wire and the rod with the central contact, there is a resistor, the main function of which is to suppress radio interference that occurs during the spark discharge. Taking into account the development of radio and telecommunications and their implementation in vehicle systems, including electronic injection control, the placement of such a resistor has become mandatory in the spark plug device.

In the part that is screwed into the cylinder head, the central insulator has the shape of a gradually tapering cone - this is done in order to more effectively remove heat, preventing overheating.

View of a modern candle

The variety of technical solutions in the development and production of gasoline internal combustion engines has also given rise to many models of spark plugs for them. Depending on the fuel used for the car, the compression ratio in the cylinder, and the method of ignition control (mechanical, using a distributor, or electronic), they can be divided into the following types.

CANDLE MANUFACTURERS, THEIR VARIETIES

Good candles are made by many companies around the world. Among the most famous and recognized leaders are Champion, NGK, Denso and Bosch. Today there are units on sale with a bimetallic central electrode. Champion went further and released cells with a side bimetallic electrode, which expanded the thermoelasticity of the unit.

In the mid-80s, products appeared whose central electrode was made of thin platinum wire. In terms of temperature characteristics, they surpassed all indicators of bimetallic electrodes. For sports and racing cars, analogues with silver electrodes are produced. The latest innovation in this area is NGK's patented best spark plugs today, in which the electrodes are made of an iridium alloy.

So which spark plugs are best? Working inside a cylinder, they must withstand very high temperatures (approx. 1000 °C), peak pressures (approx. 100 bar), extremely high voltages (approx. 40,000 V). The devices must also cope with the consequences of engine operation - aggressive combustion products of the air-fuel mixture, and all this while maintaining design parameters. When studying the question “Which spark plugs are good?”, you should remember that standard ones are designed for a service life of about 30 thousand km.

The following kits are available for sale: standard design; with increased strength. multi-electrode, with platinum tip electrodes, with iridium tip electrodes, yttrium.

Manufacturers and their serial releases

Today the following manufacturers are popular:

| Company/Country | Series | Series features | General qualities |

| Bosh/Germany | Super | Copper central electrode has chromium-nickel coating | Wear resistance, spark stability, improved fuel combustion, presence of a resistor to reduce interference, excellent starting in severe cold (platinum version) |

| Super plus | The central electrode is made of nickel-yttrium alloy, and the side electrode has a pointed shape | ||

| Super plus 4 | The production is based on the same components as Super plus, but there are 4 side electrodes | ||

| Platinum | The central electrode is made using a platinum alloy, and the insulator is made of ceramic | ||

| NGK/Japan | No separate episodes | The insulator is made of ceramic | High performance under conditions of peak loads and high temperatures, widely used as standard elements by many automakers |

| Denso/Japan | Standard | The electrodes are made of copper, nickel, chromium, and there is an interference suppression resistor | High fuel combustion efficiency, increased performance indicators, wear resistance |

| Platinum | There is a thin platinum electrode | ||

| Iridium | The central electrode is made of iridium alloy | ||

| Twin Tip | The electrodes are made of nickel using a special technology, which is designed for increased wear resistance | ||

| Brisk/Czech Republic | Classic | For carburetor type | The series are designed for a specific injection system and fuel used |

| Super | For injection engines of any manufacture | ||

| Forte | The central electrode is much thicker | ||

| Extra | Multiple side electrode components | ||

| Silver | Used on gas-powered vehicles | ||

| Platin | Platinum center electrode | ||

| Premium | Manufactured using special technology that provides increased spark power | ||

| A-line yttrium | Yttrium central electrode, spark plugs are designed for use in foreign-made cars | ||

| Champion/USA | Copper Core OE | Two-electrode version made using copper and zinc (frame) | Acceptable service life, improved heat transfer |

| Double Copper OE | The design has a copper central solid-drawn electrode | ||

| O.E. | Multi-electrode option | ||

| Platinum OE | There are platinum melts on the central electrode |

NGK spark plugs

company (Japan) is called the leader in the production of SZ . Its products are recognized as being of the highest quality and reliability. NGK spark plugs are marked as follows:

- domestic devices A 11 are an analogue of products B 4 H;

- And 17 DVRs are replaced by BPR 6 ES.

The marking of NGK products is quite simple to decipher. In particular, B4H:

- the letter symbol B specifies the diameter and pitch of the thread, in this case it is M14x1.25, other possible designations are A/C/D/J;

- digital symbol 4 indicates the heat value - this indicator varies in the range 2-11;

- the letter symbol H indicates the thread size (12.7mm).

Marking of NGK spark plugs The

designation BPR 6 ES indicates that this product is equipped with a standard thread, a projection insulator (P), a resistor (R), a heating coefficient of 6, a thread size of 17.5 mm (E), the symbol S indicates the individual properties of the product.

The presence of a number at the end (usually separated by a hyphen) indicates that the electrodes have a gap of this size.

Denso devices

This company labels its products as SK 16 PR-A 11, which stands for as follows:

- S – head electrode with a diameter of 0.7 mm made of iridium, the electrode on the side is equipped with a platinum plate;

- K - hexagon diameter;

- 16 - heat coefficient;

- P – head electrode protruding 1.5 mm;

- R – there is a resistor;

- A is a parameter specifically for this modification of the SZ;

- 11 - gap size.

Please note that letter designations on Denso devices may vary depending on the product series.

Denso spark plugs

Spark generators Bosch

Bosch products need no introduction . Let's say the article number WR 7DC has the following meaning:

- symbol W – thread with standard parameters (14);

- symbol R – the presence of a resistor that prevents interference;

- digital symbol 7—heat value;

- letter D—thread size (19mm);

- the letter C is a copper alloy electrode, other possible designations are O (regular alloy), S (silver element), P (platinum).

Products marked WR 7DC are an analogue of domestic spark plugs A 17 DVR, which work with engines of VAZ cars.

Bosch spark plug markings

Beru devices

The manufacturer Beru (Germany) produces candles and other components of premium quality. Products are marked, for example, as 14 R-7 DU, which stands for:

- 14 – thread size (14×1.25mm);

- R – there is a resistor;

- 7 – heat coefficient (interval 7-13);

- D – thread size (19mm) with gasket-seal under the cone;

- U – head electrode made of copper+nickel alloy.

Using another designation as an example - 14 F-7 DTUO - we will explain that the marking changes slightly: the values of SZ are standard, and the nut is smaller than the installation space (F), can only be used in “low-power” motors with a seal (T), the head element of the product strengthened (O).

Beru candles

Czech Brisk devices

Since the 35th year of the last century, the company has been producing SZ, which are in constant demand among our motorists.

The article number on the candles of this manufacturer, for example, DOR 15 YC, has the following decoding :

- the letter D denotes a “standard” size thread (1.25mm), oriented for wrench 14, with a body size of 19mm;

- the letter symbol O indicates a special design of the product, made in accordance with ISO regulations;

- the letter R indicates the presence of a resistor, and the symbol X indicates the ability of the electrode resistance to form carbon deposits;

- the number 15 is a heat indicator that can vary in the range 8-19 (in this case, the index 13 is not indicated by the manufacturer);

- the letter Y indicates a protruding arrester;

- symbol C indicates a head electrode made of copper;

- 1 (mm) - gap at the electrodes.

Brisk candles

Removal and installation

Removing the spark plug from the engine is carried out in the following sequence:

- remove the tip of the high voltage wire (it is unacceptable to pull the wire);

- unscrew the spark plug one turn with a special wrench, then clean the surface in the recess of the cylinder head around it with compressed air or a brush so that dirt particles do not get into the threads or combustion chamber;

- turn out the candle;

- check the presence of an o-ring (for spark plugs with a flat supporting surface);

- carefully inspect the spark plug for mechanical damage to the insulator, housing and electrodes.

Installation is carried out in the following sequence:

- new spark plugs coated with preservative lubricant must be wiped and washed in a solvent (gasoline). It is permissible to boil the candles in water and dry;

- carefully inspect the spark plug for mechanical damage, o-ring, contact nut;

- check and, if necessary, adjust the spark gap (bending the ground electrode) to the value specified in the vehicle operating instructions;

- The spark plug is wrapped by hand into the spark plug hole and tightened with a special wrench with a force of 2 kgm.

Precious metals in candle design

The gradation of species depends not only on the stated parameters. When describing the performance characteristics of a spark plug, you also need to take into account what material the electrode tips are made of.

The cheapest candles are nickel. The simplicity of the design also determines a short service life, so they are replaced often, after 15-18 thousand kilometers. Although in city conditions, taking into account the uneven operation (standing with the engine running in traffic jams, frequent alternation of acceleration and braking at traffic lights), this mileage can be safely divided into two, so the operating time of nickel spark plugs is normally no more than a year.

Platinum spark plugs are soldered with platinum, which increases their service life to 50,000 kilometers. Look at the cost of platinum in any exchanger and you will understand why these solderings make them so expensive.

Iridium spark plugs already contain two precious metals: iridium in the form of soldering on the tip of the central electrode and platinum on the side electrodes. Taking into account the cost of iridium, the price for them increases by 50-60% compared to nickel. But the technical characteristics of spark plugs with iridium are such that you can drive with them from 60 to 200 thousand kilometers.

Such candle parameters as: thread diameter; number of the key head for it; threaded skirt length; the gap between the electrodes also refers to their technical characteristics.

Checking the performance of spark plugs

To check the uninterrupted sparking, the spark plug is installed in a pressure chamber (at atmospheric pressure the spark plug behaves differently than in the combustion chamber), which provides gas pressure of up to 10 kg/cm2 and allows you to observe sparking between the electrodes. It must be uninterrupted after connecting a voltage of at least 22 kV to the spark plug.

To check the tightness of the connection, place the candle in a pressure chamber that creates a pressure of up to 20 kg/cm2, and measure the gas leak for at least 30 seconds. Its value should not exceed 5 cm3/min. In this case, leakage through the connections of the spark plug with the pressure chamber is not taken into account. It is allowed to carry out leak testing on spark plugs that are not equipped with O-rings. During vehicle maintenance, it is allowed to check gas leaks through the connections of spark plug parts under a pressure of 10 kg/cm2.

Determining the condition of the engine by carbon deposits on the spark plugs

Engine diagnostics using spark plugs should be performed on a warm engine. But in order to do this correctly, you need to go through several steps:

- Install new spark plugs.

- Drive them 150-200 km.

- Unscrew the spark plugs and pay attention to the color of the soot, which will tell you that it is not working correctly.

For every engine breakdown, a coating of a certain color forms on the spark plugs, by which it is possible to determine a defect in the engine’s operation.

Oily black soot

Oily black carbon deposits form in the threaded joint when excess oil enters the combustion chamber; it also appears when blue smoke comes out of the pipe at the start of engine operation. This happens for several reasons:

- The oil seals on the piston are already worn out.

- The piston rings on the valve are worn out.

- Valve guides are worn.

Thanks to this carbon deposit, it is clear that the parts of the cylinder-piston group are already worn out, and for high-quality engine operation they need to be replaced.

Dry black soot in the form of soot

This carbon deposit is called “velvety.” It has no oil leaks. It appears due to the fact that a fuel-air mixture enters the combustion chamber, which is excessively enriched with gasoline. This deposit appears during the following malfunctions:

- The spark plugs are not working correctly. This indicates that there is not enough energy to produce a spark of the required power.

- When such deposits appear, it is necessary to check the compression in the cylinders, because it is very low.

- If the carburetor is not working properly, there will always be such carbon deposits on the spark plugs, then it is recommended to adjust or replace the carburetor.

- In an injection engine, this means that there is a problem with the fuel pressure regulator; it greatly enriches the air mixture. This also leads to increased fuel consumption.

- It is also recommended to check the engine air filter; if it is clogged, its throughput is significantly reduced, there is not enough oxygen in the combustion chamber, which prevents the fuel from burning completely and this carbon deposits on the spark plug electrode.

This deposit settles on the spark plug electrode and does not reach the threaded connection.

Red carbon deposits on spark plugs

This is the color the spark plug becomes after using various fuel or oil additives. Chemical additives that are poured in large quantities burn out. With their constant use, it is necessary to reduce their concentration and constantly clean the electrode from carbon deposits, because over time the carbon layer will grow and the passage of the spark will deteriorate - engine operation will be unstable.

As soon as red carbon begins to appear on the spark plugs, it must be removed, and it is recommended to replace the fuel to which the additive was added.

White carbon deposits on spark plugs

White soot appears in different forms. Sometimes it has a glossy surface because it contains grains of metal or settles on the electrode in large white deposits.

Glossy white carbon

This soot color is very dangerous for the engine. This means that the spark plugs do not cool and the pistons heat up, causing cracks in the valve. The reason is simple - engine overheating. There may be other reasons for the appearance of this soot:

- A lean fuel mixture that enters the combustion chamber.

- The intake manifold sucks in excess air.

- Poorly tuned ignition - sparks very early or misfires.

- Wrong choice of spark plugs.

If white soot with grains of metal appears, it is not recommended to operate the machine. You need to take it to a service center or solve the problem yourself.

Mild white soot

When white carbon deposits appear, which evenly settles on the spark plugs, it is necessary to replace the fuel.

Spark plug life

Modern spark plugs, when operated on fully serviceable and adjusted engines, must, in accordance with OST 37.003 081, operate uninterruptedly for 30 thousand km for a classic and 20 thousand km for an electronic ignition system. The actual resource may be approximately twice as high, but is difficult to achieve in practice, like any spherical horse in a vacuum. Provided that all engine systems are in good working order and the fuel quality is normal, the service life of modern spark plugs averages 50 thousand km.

A peculiarity of Russia is the widespread use of banned ferrocene additives, which increase the octane number of “scorched” gasoline. Such additives contain iron, which during combustion settles on the spark plug and leads to a breakdown of the insulation between the electrodes and the inability to obtain a normal spark. As practice shows, you can run into such gasoline at any, no matter how “famous” gas station, and it is impossible to prove anything later. Spark plugs affected by such additives cannot be restored. Therefore, in Rus' there is no point in using expensive and “long-lasting” candles.

During operation, the gap between the electrodes increases on average by 0.015 mm for every 1000 km of run. Therefore, it is recommended to periodically (every 5 or 10 thousand km) inspect and maintain the spark plugs (in fact, adjust the gap to the required value). You can clean spark plugs using solvents and a brush (not a metal one). At service stations, spark plugs are cleaned using special sandblasting machines. It is also recommended to swap spark plugs, this is due to the fact that the middle cylinders operate at higher temperatures than the outer ones. Replacement, according to the recommendations of most manufacturers, is recommended after 30,000 km of vehicle mileage.

Types of candles

They are divided according to several characteristics:

- Heat number.

- Number of electrodes.

- Spark gap.

- Temperature range.

- Service life.

- Heat resistance characteristics.

In addition, some types of spark plugs from different years of production of the same company may differ in the length of the threaded skirt: early car models had thinner cylinder heads, which were made of cast iron and, accordingly, shorter threads were required. With the transition to cylinder heads made of aluminum alloys, their thickness increased, and therefore the length of the threads in it also became longer.

An experienced motorist will always pay attention to the heat number at the beginning, which shows at what pressure the heat effect can occur, that is, the continuation of engine operation after the ignition circuit is broken, when the engine continues to operate from contact with an electrode heated to critical values.

At the same time, it is still permissible to use a spark plug with a heat rating higher than recommended, but with a lower heat rating, engine operation is prohibited! Otherwise, the unlucky driver will quickly face the problem of burnt pistons, valves and a breakdown of the cylinder head gasket.

For high-quality and stable spark formation, spark plugs with two, three and even four side electrodes have been produced over the last two decades.

But stability of operation can be achieved in another way: by placing auxiliary elements that play the role of these electrodes on the spark plug insulator itself. Several circular electrical discharges appear around the central electrode, and thus the likelihood of engine failure is significantly reduced.

Brisk sports spark plug with intermediate electrodes on an insulator

Here are a few more important points in the characteristics of candles:

- Violation of such a parameter as the spark gap will also negatively affect the operation of the motor;

- No less important is heat resistance, its temperature range, which means heating of the part that is immersed in the space between the piston and the cylinder head. The temperature range inside the working part normally lies within 500-900⁰С. Going beyond this range means a decrease in resource. In particular, for all types of spark plugs, a decrease in temperature leads to a rapid increase in soot;

- In a normally adjusted engine, performance depends on mileage and is approximately 30,000 km for spark plugs operating on a classic ignition circuit, and 20,000 on an electronic one. However, the highest priced (but also the most reliable) DENSO spark plugs have a service life of up to 5-6 years. Or, in other words, they will provide mileage without replacement under standard operation for about 150,000 - 200,000 kilometers. True, the requirements for maintaining regimes according to instructions have been tightened. These requirements include the use of fuel with an octane number in no case lower than the recommended one, and their installation strictly according to the rules. In particular, it is not allowed to tighten them into the cylinder head with a force higher or lower than recommended, which may entail negating all their advantages;

- The thermal parameter shows the relationship between engine modes and the operating temperature of the spark plug. To increase it, the size of the thermal cone is increased, however, adhering to the recommended value of 900 degrees. Exceeding these limits increases the risk of glow ignition.

Cold and hot spark plugs

Spark plugs differ not only in type, but also in their characteristics and are selected individually depending on the engine design. Based on their characteristics, they are divided into three different groups: cold, medium and hot. To understand what this means and why they are needed, you need to understand what “heat number” and “heat ignition” are.

- The heat number is a value that shows the time after which the candle reaches the glow ignition. The higher its heat rating, the less it will heat up.

- Glow ignition is a negative effect when the ignition of the combustible mixture in the engine occurs not from the spark plug, but from heated engine elements, most often this is the spark plug itself. This effect occurs if a spark plug with the wrong heat value is installed in the car.

The operating conditions of spark plugs in summer and winter are different, so it is better to have a video in a set of spark plugs for different seasons.

For example, in hot weather, when driving at high speed, a spark plug with a low heat value will quickly lead to heat healing. Which leads to loss of power. In this situation, the spark plug must be replaced with a “colder” one. In the opposite situation, if at a low temperature, for example in a traffic jam, the spark weakens. In cold weather there will be problems starting the engine. If this problem occurs, it is necessary to install a “hotter” candle.

The choice is also influenced by the size of the engine; the larger it is, the “colder” the spark plug should be. Groups of candles by heat rating (Russian marking):

- The “hot” group includes candles with a heat number from 11 to 14.

- The “middle” group includes candles with a heat number from 17 to 19.

- The “cold” group includes candles with a heat rating from 20 to 26.

Diesel engines often use glow ignition, that is, self-ignition from a glowing plug, which makes it easier to start the engine at low temperatures.

Candle marking

The spark plug markings indicate its geometric and seating dimensions, design features and heat rating. Different manufacturers have their own designation system. Below are the markings used by Russian and leading foreign manufacturers, as well as a table of interchangeability of spark plugs of different brands (to view, click on the desired picture - the file will open in a new window).Options for replacing spark plugs

Options for replacing spark plugs

The heat rating is an indicator of the thermal properties of a spark plug (its ability to heat up under various engine thermal loads). It is proportional to the average pressure at which, during testing of a spark plug on a motor calibration unit, glow ignition begins to appear in its cylinder (an uncontrolled process of ignition of the working mixture from the hot elements of the spark plug). Candles with a low heat rating are called hot. Their heat cone heats up to a temperature of 900°C (ignition start temperature) with a relatively small heat load. Such spark plugs are used on low-boost engines with low compression ratios. With cold spark plugs, glow ignition occurs under high thermal loads, and they are used on highly accelerated engines.

Until the thermal cone heats up to 400°C, carbon deposits form on it, leading to current leakage and disruption of sparking. Upon reaching this temperature, it (carbon deposits) begins to burn, and the candle is cleaned (self-cleaning). The longer the heat cone, the larger its area, so it heats up to self-cleaning temperature with a lower thermal load. In addition, the protrusion of this part of the insulator from the housing increases the flow of gases over it, which further accelerates heating and improves the removal of carbon deposits. Increasing the length of the thermal cone leads to a decrease in the glow number (the candle becomes “hotter”).

Spark plug malfunctions, signs and causes

Without working spark plugs, normal operation of the car becomes impossible. Let's look at the signs of faulty spark plugs that require urgent driver intervention:

- Fuel consumption increases significantly;

- There is a drop in power and speed in the operation of the power unit;

- Difficulty starting the engine;

- The concentration of CO in the exhaust gases increases;

- You feel the car twitching while driving;

- Unpleasant noise coming from the engine at idle.

The reasons for such phenomena are naturally simple:

- The candle has simply exhausted its resource;

- Electrode melting or corrosion; The candle is not selected correctly;

- Contamination (deposits, carbon deposits, oil or fuel on the electrodes);

- Damage or contamination of the insulator.

Terminal rod and center electrode

The terminal rod is made of steel and protrudes from the spark plug housing. It is used to connect a high voltage wire or a directly mounted ignition coil rod. The electrical connection between the terminal rod and the central electrode is made using molten glass located between them. Filler is added to the glass melt to improve the degree of burning and interference resistance properties. Since the central electrode is located directly in the combustion chamber, it is exposed to very high temperatures and severe corrosion due to contact with exhaust gases, as well as residual combustion products of oil, fuel and impurities. High sparking temperatures lead to partial melting and evaporation of the electrode material, so the central electrodes are made of a nickel alloy with additions of chromium, manganese and silicon. Along with nickel alloys, silver and platinum alloys are also used, since they burn slightly and dissipate heat well. The central electrode and the terminal rod are hermetically sealed in the insulator.

When to change spark plugs on a car

Faulty spark plugs can lead to serious consequences, such as damage to the fuel system and engine, and this can lead to much greater costs. The safety of the vehicle’s power unit depends on their timely replacement.

When should you change spark plugs? Let's try to figure this issue out. Signs such as:

- Signs of wear on the spark plug itself are visible to the naked eye. These are melting, chipping and corrosion.

- Adjustment when driving;

- Startup problems;

- Decrease in engine power and thrust;

- Increased fuel consumption;

- Regular formation of carbon deposits on spark plugs (every 20-30 kilometers).

May indicate the need to replace spark plugs. On average, spark plugs should be changed every 25-30 thousand vehicle miles.

Candle device

The product design includes:

- Ceramic insulator.

- Metal glass with thread (skirts).

- Electrodes - 2 or more. The central one penetrates the insulator and ends with a contact for connecting the wire.

- Noise suppression resistor (some models).

Less common are laser versions that do not have electrodes. The fuel is ignited by a concentrated light beam.

General concepts, purpose

The purpose of a spark plug is to create a spark (electrical discharge) that ignites the fuel-air mixture in the combustion chamber of the engine cylinder. That is, it must operate on time and with the proper power on every full engine cycle. Normal (standard) operation of the engine depends on the quality of the spark: the better the fuel is ignited in the combustion chamber, the higher the engine power will be. Poor quality work of the SZ leads to problems: increased fuel consumption, incomplete combustion (increased CO emissions), loss of power, and rapid wear. So monitoring the condition and timely replacement of spark plugs is one of the important components of regular maintenance.

The principle of operation of a spark plug is quite simple: a voltage of 25-30 thousand volts is applied to the central electrode (cathode), as a result of which an electric discharge occurs between it and the negative electrode (anode) - a high-voltage arc that ignites the fuel in the engine cylinder. All modifications and new products that exist on the market today are designed to improve certain characteristics, but the very essence of how candles work does not change.

Spark plugs with V-cut core

Quite an interesting development and, I’m sure, quite effective. As can be seen in the figure, on a spark plug with a cut, the spark jumps at the edge of the electrode, where more of the fuel mixture accumulates. This fact indicates that the mixture will ignite faster, which will improve the quality of engine operation and reduce fuel consumption.

What should you be wary of?

In order to change spark plugs in a timely manner, thereby minimizing all sorts of troubles, you need to know the main signs of bad spark plugs. A car owner should be wary if:

- it is difficult to start the engine - the starter is activated, but the engine does not start or starts after several starts of the starter;

- the engine begins to “trouble” - “twitches” while driving (this is especially pronounced at idle), power/traction decreases;

- fuel consumption increases;

- the CO level in the exhaust increases;

- The engine dynamics have deteriorated (it picks up speed poorly, which means the power drops).

The owner can determine the wear of the spark plugs (SZ) by visual inspection. To do this, you need to extract and see what the SZ looks like. During normal operation of the power unit, carbon deposits on the SZ have a light gray-brown color. If you find one of the following deviations from the norm, the spark plugs need to be replaced.

Signs of replacing spark plugs and the reasons for their appearance:

- The spark plug body has mechanical damage, the electrodes or sealing washers have a changed shape. The presence of these symptoms indicates the need to replace the SZ. The reasons may be as follows:

- discrepancy between the heat index of the SZ and the type of motor;

- the cooling system is malfunctioning;

- high ignition timing.

- Black carbon deposits are a sign of excessively enriched fuel, which, when burned incompletely, forms excess soot, or the ignition spark does not have sufficient strength.

- The SZ acquired a shiny glassy appearance. This symptom is a sign of overheating of the spark plugs, which occurs when a lean fuel mixture is used or the car is operated on a gas-air mixture.

- The formation of oily deposits indicates the presence of motor fluid inside the combustion chamber due to the leakage of lubricants through the oil-removable valve caps of the cylinder head, or the piston system is worn out.

- On the SZ there is brown-yellow scale, formed due to soot on the dielectric of the tip of the spark plug.

- A chip/break of SZ insulators indicates sudden overheating/cooling.

- The occurrence of erosion on spark plug contacts is due to the presence of lead oxidative reactions. The reason is an increased spark plug gap.

- The melted SZ contact is a consequence of overheating.

- Scale of a reddish hue is a clear sign of excess metal-containing additives in the fuel mixture.

A common mistake when inspecting SZ

The SZ study is carried out after a long period of operation of the power unit. A misconception among motorists is that during a cold start of the power unit at temperatures below zero and instability in engine operation, the spark plugs are unscrewed. Seeing black soot on the NW, a hasty conclusion is made

However, this can happen when operating the engine during a cold start; at this moment the mixture becomes richer under duress, and instability of operation is caused, for example, by poor electrical condition (pay attention to high-voltage wires, etc.)

Faulty spark plugs almost always lead to various kinds of problems in the operation of the car engine. For example, unstable idling (the engine “troits”, the speed fluctuates), dips, jerking, twitching, loss of power and throttle response, difficult starting (both cold and hot) are often a consequence of the use of defective spark plugs.

First of all, we check for the presence of a spark at the electrodes of the spark plugs. Then you need to unscrew them from the engine and carefully inspect them. At the same time, this procedure will be a diagnostic of the operation of your car’s engine, since their appearance is an indicator of what is happening inside it.

Below is a list of the main, ubiquitous spark plug faults.

Cracks on the insulator

Visually visible cracks and chips on the spark plug insulator are a reason to immediately replace it. They can appear either on the top of the spark plug insulator or on the heat cone around the central electrode. The reasons for their appearance are natural wear and tear as a result of long-term use, poor quality of the insulator material, non-compliance with the technology of its manufacture (for example, with a noticeable longitudinal seam from the connection of its two halves), detonation as a result of an incorrectly set ignition timing, low-quality fuel or mismatch in heat rating required for a given engine.

How to extend the life of candles?

There are several simple recommendations that will help these parts work stably throughout their entire service life:

- Use high-quality gasoline recommended by the manufacturer. This information is indicated in the data sheet.

- Constantly monitor the ignition system. It must be in good working order and work stably.

- Spark plugs need to be screwed in carefully, selected taking into account the parameters of the car and changed in a timely manner.

Proper care of spark plugs is of great importance. To change them less often, follow these rules:

- take into account the heat rating, do not install too “hot” or “cold” spark plugs, so that this does not lead to serious engine damage and expensive repairs;

- help the spark plugs self-clean - run the engine at maximum speed to increase the temperature to 500°C and clean the parts from carbon deposits;

- for cars with gas equipment, buy special spark plugs with a thin central electrode and specially designed solders;

- Do not under any circumstances replace spark plugs with mechanical seals with parts with conical seals, as this will reduce operating efficiency and the degree of cooling;

- change spark plugs strictly according to the manufacturer's recommendations, focus on a mileage of 15-20 thousand km, trust diagnostics and repairs only to service station specialists.

Remember: untimely replacement of the spark plug can provoke breakdown of the insulator under pressure at high speeds and elevated temperatures. This will lead to loss of engine power, excessive fuel consumption and other malfunctions.

Spark gap and electrode material: classic, platinum and iridium spark plugs

The smaller the distance between the electrodes, the easier the discharge, which means less energy is needed to create a spark. It would seem that setting a smaller gap and saving battery life is the right decision.

But the task of the spark plug is to ignite the fuel mixture so that the volume of combustion is maximum, and for this you need... a larger spark gap, giving more space for ignition and a more powerful spark.

This contradiction can be resolved by reducing the thickness of the central electrode: the thinner it is, the less energy is needed to cover a greater distance. Pure steel or a nickel alloy with a copper core is not suitable for this purpose: the thin electrode quickly burns out, rendering the spark plug inoperable. Therefore, the latest designs use alloys of inert metals: platinum, gold, silver, iridium, palladium. This innovation has led to the introduction of spark plugs with a particularly thin center electrode on the market: for example, NGK spark plugs (manufactured by the Japanese company NGK Spark Plug Co. Ltd) have a center electrode thickness of only 0.4 mm. Many are made of precious alloy on the side electrode, which allows you to increase the spark gap by 3.5 times while maintaining the same level of energy consumption.

Car enthusiasts, deciding to purchase high-quality and durable spark plugs, make a choice between platinum and iridium.

Advantages of platinum candles:

- very long service life (up to 100,000 km), allowing you not to worry about replacing spark plugs;

- a thin electrode produces a larger spark, which means it improves the quality of ignition of the fuel mixture;

- the electrodes do not burn out, the gap between them does not change;

- less voltage is applied to the main electrode, which means it operates more stably for a long time;

- the spark temperature is higher, which makes it possible to ignite even a lean air-fuel mixture and can be used in engines with air superchargers.

The advantages of iridium spark plugs are almost completely duplicated by platinum spark plugs, plus a few more points:

- even greater resistance of the material to oxidation and burnout;

- the strength of iridium is higher than that of other metals;

- melting point is significantly higher than that of platinum;

- An iridium spark plug can operate stably over a wide range of loads.

Some companies (for example, the Japanese spark plug manufacturer DENSO) continue to develop various alloy additives that improve performance. One of the latest innovations is an iridium-rhodium alloy used in patented products.

The use of high-tech spark plugs not only allows you to forget about the problem of replacement for a long time, but is also one of the factors for saving fuel in the near future and increasing engine life in the long term.

However, in some cases, it will be more appropriate to use simple nickel spark plugs: if the engine wears out a lot, oil will settle on the spark plugs, which means that even expensive spark plugs will not serve their intended service life. Also, the use of low-quality gasoline makes the purchase of expensive spark plugs simply useless: even on the iridium electrode, carbon deposits will form, destabilizing the work of the spark plug.

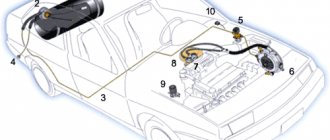

Ignition system

A car's ignition system is a rather complex set of devices that is responsible for the appearance of a spark at the moment that corresponds to the operating mode of the power plant. This system is part of electrical equipment. The very first engines, such as the Daimler unit, used a glow head as an ignition system - this was the first ignition system device that was not without its drawbacks. Their essence was that ignition took place at the very end of the stroke, since the chamber was heated to a fairly high temperature.

Before starting, it was always necessary to warm up the glow head itself and only then start the engine. Subsequently, the head was heated by maintaining the temperature from the burned fuel. In modern conditions, this principle of the ignition system can only be used in micromotors used in car models and other equipment used by internal combustion engines. This design makes it possible to reduce overall dimensions, but the entire structure may be more expensive. In small models this is hardly noticeable, but in a full-size car it can greatly affect the price. In all cars, the ignition system circuit is almost the same. Some differences are dictated only by the type of execution.