Device

Gasoline engines belong to the class of internal combustion engines. Inside the combustion chambers, the pre-compressed fuel-air mixture is ignited by a spark. A throttle valve is used to control engine power. It allows you to regulate the amount of air entering the combustion chamber.

Let's take a closer look at the structure of all the main components of any internal combustion engine. Each power unit consists of a cylinder block, a crank mechanism, parts of the cylinder-piston group, a gas distribution mechanism, a lubrication and cooling system, and a power supply system. Also, the engine will not be able to operate without electrical equipment. All these systems and components interact with each other during engine operation.

Design of internal combustion engines

The “heart” of any car consists of two parts - the cylinder block and the cylinder head (cylinder head). The first is a cast body made of cast iron or aluminum with channels for lubricant and coolant. Large diameter holes are made along the axis of the block - cylinders (4 or 6 pieces) with steel liners, inside which the pistons move.

The internal combustion engine design cannot be called too complex. If you thoroughly understand the location and role of the main parts, much becomes clear. The cylinder block serves as the basis for mounting the following elements:

Note. For simplicity, a gasoline power unit with an in-line cylinder arrangement is considered here. Other types of engines will be discussed below.

An aluminum cylinder head is screwed to the top of the block; this connection is sealed with a special gasket. On the lower plane of the part there are recesses - combustion chambers - with holes for valves and spark plugs. The structure of the engine cylinder head includes the following elements:

The gas distribution mechanism includes valves, hydraulic compensators and a camshaft with a chain (belt) drive.

Engine cylinder block

The cylinder block is the main part of any engine. This is a cast iron or aluminum cast one-piece part. The block has cylinders and a lot of different threaded holes for mounting attachments and other equipment. The element has mechanically processed planes for mounting the cylinder head and other parts.

The design of the block greatly depends on the number of cylinders, the location of the combustion chambers, and the cooling method. One block can combine from 1 to 16 cylinders. At the same time, blocks with an odd number of cylinders are less common. Of the models that are produced now, you can find 3-cylinder internal combustion engines. Most blocks have 2, 4, 8, 12 and sometimes even 16 cylinders.

Engines with a number of cylinders from 1 to 4 differ in the arrangement of the combustion chambers in a row. They are called in-line engines. If there are more cylinders, then they are located in the block in two rows at a certain angle. This made it possible to reduce overall dimensions, but the manufacturing technology of such blocks is more complex.

One more type of block can be distinguished. In them, the combustion chambers are located in two rows at an angle of 180 degrees. These are the so-called boxer engines. The operating principle of a gasoline engine of this type is no different from traditional internal combustion engines. They can often be found on motorcycles, but there are also cars equipped with them.

As for cooling, two types of systems can be distinguished. This is liquid and air cooling. The design features of the cylinder block depend on which cooling system is chosen. A unit with an air cooling system is much simpler compared to the same one with water cooling. The combustion chambers in this case do not belong to the block.

The liquid-cooled unit is much more complex. The design already includes combustion chambers. A cooling jacket is laid on top of the metal cylinder block, inside which coolant is forced to circulate, which serves to remove heat from the parts. The block and cooling jacket in the internal combustion engine are one.

The top of the cylinder block is covered with a head. It forms a closed space where the fuel combustion process takes place. The cylinder head can have a simple design or a more complex one.

Gasoline engines and their design

The gas expanding in the combustion chamber presses on the piston (M), which, using a connecting rod (N), rotates the crankshaft (P).

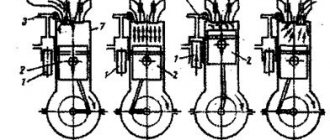

The operating cycle of a gasoline engine consists of the following stages:

• Intake stroke. At this moment, the piston begins to move downward, and the intake valve opens. The air-fuel mixture enters the cylinder.

• Compression. The piston begins to move upward, thereby compressing the mixture in the cylinders, which is necessary to release more energy during the subsequent explosion.

• Working stroke. When the piston rises to top dead center in the cylinder, the spark plug comes into operation and ignites the fuel mixture. After the explosion, the piston moves downwards.

• Release stroke. After the piston reaches the lowest point, the exhaust valve opens, through which the combustion products leave the chamber.

After the combustion products exit, a new cycle of internal combustion engine operation begins.

The result of the operation of the power unit is the production of rotational motion, which is optimally suited for turning the wheels of the car. This is achieved through the use of a crankshaft, which converts linear energy into rotation.

Design and main parts of gasoline internal combustion engines

The cylinder is the most important part of a gasoline engine, in which the piston moves due to the explosion of the fuel mixture. In the example described above we are talking about one cylinder. Such a device may have a motor boat or mower engine. Car engines have more cylinders - three, four, five, six, eight, twelve or more.

The arrangement of cylinders in an internal combustion engine can be as follows:

— in-line:

— V-shaped:

— opposed (the cylinders are horizontally located opposite each other):

Each cylinder arrangement has its own pros and cons, which determine the characteristics of certain engines and the costs of their production.

Piston (M). This part is made in the form of a metal cylinder, it moves up and down inside the cylinder of the engine.

Valves. Can be inlet (A) or outlet (J). They open at different engine strokes. The air-fuel mixture is supplied through the intake, and exhaust gases exit through the exhaust. During the moments of compression and combustion of fuel, all valves are closed.

Spark plugs (K). With their help, a spark is supplied, which is necessary to ignite the fuel. Correct engine operation implies the exact timing of the spark (early or late ignition - malfunctions). There is at least one spark plug for each engine cylinder.

Piston rings (M). They are a sliding seal between the piston and the cylinder wall.

With their help, the following functions are performed:

• the air-fuel mixture does not penetrate from the combustion chamber into the crankcase during engine operation;

• prevent the penetration of engine oil from the crankcase into the combustion chambers.

Carter (G). It contains the crankshaft and some engine oil.

Connecting rod (N). Serves to connect the crankshaft and piston to each other.

Camshaft (I). Its task is to timely open and close the exhaust and intake valves.

Hydraulic compensators (not indicated on the diagram). Not used on all engines, they are used to automatically adjust the gap between the camshaft and valves. If they are absent, the gap is adjusted using special washers, and this procedure must be carried out at a service station at a certain engine mileage.

Cylinder block (F). The largest part of the engine is its base. It can be either cast iron or aluminum. The top of the block contains the head (D) and valve cover (B). The working holes of the block are the engine cylinders.

Attachments.

It is not indicated in the above diagram, but it is worth describing it in a little more detail. All attachments consist of separate independent devices or elements of various systems. This is, first of all:

Generator. Serves to convert mechanical energy into electrical energy necessary to power the vehicle's on-board network and charge the battery. A running car powers its electronics from the generator.

Starter. The car is started with its help.

Injector or carburetor. These devices are used to prepare the air-fuel mixture. The carburetor is no longer used on relatively new cars. Now manufacturers use a fuel rail with nozzles and an injector.

Injection pump. A high pressure fuel pump is also used on some gasoline engines. Its task is to pump a certain amount of fuel under pressure and regulate the moment and quantity of its supply.

crank mechanism

This unit, which is also an integral part of the engine, is necessary to convert the reciprocating movements of the pistons into rotational movements of the crankshaft. The main part here is the crankshaft. It is movably connected to the engine block. Due to this mobility, the shaft can rotate around its axis.

A flywheel is attached to one end of the crankshaft. It is necessary in order to transmit torque from the crankshaft to the transmission. The operating principle of a four-stroke gasoline engine provides for two revolutions of the crankshaft per half revolution with useful work. The remaining strokes require reverse actions - this is what the flywheel provides. Since it has a fairly large weight, when rotating due to kinetic energy, it turns the crankshaft at the stages of the preparatory strokes.

The flywheel has a special gear ring around its circumference. Using this unit, you can start the engine with a starter. On the other side of the crankshaft there is an oil pump gear and a timing gear. There is also a flange on the reverse side on which the pulley is attached.

The assembly also includes connecting rods. They allow the transmission of force from the pistons to the crankshaft and vice versa. The connecting rods are also movably mounted on the crankshaft. There is no direct contact between the surfaces of the cylinder block, the crankshaft and connecting rods - these parts operate through plain bearings.

Basic elements of a gasoline engine

The main working element of the internal combustion engine is the piston connected to the crankshaft by a special connecting rod. This forms a crank mechanism that converts the reciprocating movements of the pistons into the power stroke (rotation) of the crankshaft.

To ensure the required compression in the engine cylinders, the piston is equipped with sealing cast iron rings. On modern gasoline engines, narrow rings (no more than 2 mm high) and wide piston rings (up to 3 mm high) can be installed.

The element connecting the piston and crankshaft. Connecting rods are made of high-strength steel, less often - of aluminum. The working crank rotation is always two-way.

Translational piston movements are converted into rotational movements of the shaft, which is responsible for the rotation of car wheels.

The internal combustion engine is equipped with special valves - intake and exhaust. They are designed to admit air mass and remove exhaust gases produced during fuel combustion.

To ensure the ignition process of the vehicle in the chamber, gasoline engines are equipped with spark plugs. An electric spark plug ignites the vehicle at a certain moment when it is fed and passes through the piston.

Gasoline engine auxiliary operating systems

Source

Cylinder piston part

This part consists of cylinders or liners, pistons, piston rings and pins. It is on these parts that the operating principle of a gasoline engine is based. This is where all the work is done. Fuel burns in the cylinders, and the released energy is converted into rotation of the crankshaft. Combustion occurs inside the cylinders, which are closed on one side by the cylinder head and on the other by pistons. The piston moves freely inside the cylinder.

The operating principle of a gasoline engine is based not only on fuel combustion, but also on compression of the air-fuel mixture. To ensure this, tightness is needed. It is provided by piston rings. The latter prevent the fuel mixture and combustion products from getting between the piston and cylinder.

Why doesn't the engine work?

Let’s say you go out to your car in the morning and start to start it, but it won’t start. What could be wrong? Now that you know how an engine works, you can understand the basic things that can prevent the engine from starting. Three fundamental things can happen:

Yes, there are thousands of other minor things that can create problems, but these “big three” are most often the consequence or cause of one of them. From a simple understanding of engine performance, we can come up with a short list of how these problems affect the engine.

A poor fuel mixture may be due to one of the following reasons:

Lack of Compression – If the air and fuel charge cannot be compressed properly, the combustion process will not work as it should. Lack of compression can occur for the following reasons:

The lack of spark can be for a number of reasons:

And here are a number of other reasons why the engine may not work, and here we will touch on some parts outside the engine:

In a properly operating engine, all these factors are within tolerance. As you can see, the engine has a number of systems that help it do its job of converting fuel into propulsion flawlessly. We will look at the various subsystems used in engines in the following sections.

Most engine subsystems can be implemented using a variety of technologies, and the best technologies can significantly improve engine performance. This is why the development of the automotive industry continues at the highest pace, because competition among automakers is great enough to invest a lot of money in each additional horsepower squeezed out of an engine of the same volume. Let's look at the various subsystems used in modern engines, starting with the operation of the valves in the engine.

Timing belt of two-stroke engine

If we consider the principle of operation of a two-stroke gasoline engine, then it does not have a timing mechanism as such. Here, the injection of the fuel mixture and the exhaust gases are released through technological windows in the cylinder. There are three windows: inlet, outlet, and bypass.

When the piston moves, it thereby opens or closes one or another window. The cylinder is filled with fuel, and gases are also vented. With this gas distribution mechanism, no additional parts are needed. Therefore, the cylinder head in two-stroke engines is simple. Its functions are only to ensure maximum tightness.

Timing belt of a 4-stroke internal combustion engine

The 4-stroke engine is equipped with a full timing mechanism. In this case, the fuel is injected through holes in the cylinder head connected to the valves. When it is necessary to supply or remove exhaust gases, the corresponding valves open and close. The latter can be opened and closed via the camshaft. It has special cams.

Supply system

The main task of this system is to prepare the fuel mixture and ensure its further supply to the combustion chambers. The design is very dependent on the operating principle of the car's gasoline engine.

Gasoline engines can have two types of fuel systems - carburetor and injector. In the first case, a carburetor is used to prepare the mixture. It mixes, doses and delivers a mixture of fuel and air to the combustion chambers. The injector injects fuel under pressure into the fuel rail, from where gasoline enters the cylinders through the injectors.

In injection cars, the principle of operation of the gasoline engine power system is different, due to which the dosage is more accurate. In addition, the air in the injector is mixed with gasoline in the intake manifold. An injector, unlike a carburetor, atomizes fuel better.

The fuel system of diesel engines is different. Here injection is carried out separately for each cylinder. The timing belt supplies only air to the combustion chambers. The system includes a tank, filters, fuel pumps, and lines.

How does an internal combustion engine work?

The operating principle of a car engine is cyclic, each cycle consists of 4 strokes (hence the second name for power units - four-stroke):

- Intake - the piston moves from top dead center (TDC) to bottom, drawing in the combustible mixture. The latter is supplied through an open inlet valve.

- Compression. Both valves are closed, the piston has passed the lowest point and moves upward, squeezing the air-fuel mixture.

- Working progress. After the compressed mixture is ignited by a spark, expanding gases are released from the spark plug. The piston, having passed TDC, goes down again under gas pressure - useful work is done.

- Release. The exhaust valve opens and the piston pushes the exhaust gases out of the cylinder and combustion chamber.

As you might guess, the working fluid in the engine is a hot mixture of gases released when fuel is burned. It transfers combustion energy to the pistons, connecting rods and crankshaft, doing mechanical work. Moreover, different cycles occur in all cylinders: in one - compression, in another - exhaust, in the third - power stroke, in the fourth - suction.

In fact, the movement of the car is provided by only one cylinder, in which the power stroke cycle occurs. Then the baton is passed to the next cylinder - the pistons rotate the crankshaft alternately. To understand the role of the main engine parts, it is proposed to take a closer look at the internal combustion engine operating algorithm:

- During the intake cycle, the crankshaft, through a belt (chain), rotates the camshaft to such a position that the cam presses and opens the inlet valve of the corresponding cylinder.

- At this moment, the injector nozzle or carburetor supplies the finished fuel mixture into the chamber. At the same time, the valves in adjacent cylinders open or only the exhaust valve is open, depending on the ongoing cycle.

- Further rotation of the camshaft closes the valve and the fuel is compressed in a confined space.

- At maximum compression (the piston is at TDC), the ignition system sends an impulse to the spark plug electrodes. A spark ignites the mixture and the working stroke begins, the valves remain closed.

- When the useful work is done, another camshaft cam opens the second (exhaust) valve. Through it, the exhaust gases, pushed out by the piston, go into the exhaust pipe.

We recommend: EGR in a diesel engine: what is it

The gear drive of the oil pump constantly rotates from the crankshaft in the car engine, whose main task is to create pressure in the channels and uninterruptedly lubricate all the plain bearings (liners). The circulation of liquid in the cooling system is ensured by a pump rotated by the timing belt or generator.

Turbocharging

Modern cars are equipped with small, low-displacement engines, but many of them have sufficient power. It is obtained through the use of turbines. The operating principle of a turbine on a gasoline engine is based on the use of exhaust gases. The gases rotate the turbine impeller, which forces air under pressure into the combustion chambers. The more air, the more fuel will be supplied, hence the power.

Cooling system

During engine operation, it heats up significantly. The temperature in the cylinders can reach 800 degrees. To maintain optimal operating temperature, a cooling system is required. The main task is to remove excess heat from cylinders, pistons and other parts.

The air system consists of special surfaces on the block, which are cooled by blowing air over them. The liquid system includes a cooling jacket in which antifreeze circulates. It is in direct contact with the outer surface of the cylinders. The system consists of a pump, a thermostat, pipes for connecting the lines, an expansion tank and a thermostat.

How does cooling work?

The cooling system in most cars consists of a radiator and a water pump. Water circulates through passages (channels) around the cylinders and then passes through the radiator to cool it as much as possible. However, there are some car models (most notably the Volkswagen Beetle), as well as most motorcycles and lawn mowers, that have an air-cooled engine. You've probably seen those air-cooled engines that have fins on the side—a ridged surface that lines the outside of each cylinder to help dissipate heat.

We recommend: What is the difference between antifreeze and antifreeze and can they be mixed?

Air cooling makes the engine lighter but hotter, and generally reduces engine life and overall performance. So now you know how and why your engine stays cool.

Electrical equipment

This equipment supplies electricity to the vehicle's on-board network. Electricity is necessary to operate the ignition system, starter and other devices. Electrical equipment is a battery, generator, starter, sensors. Although the operating principles of gasoline and diesel engines are different, electrical equipment is also available on diesel internal combustion engines.