The engine cooling system is designed to ensure that the power unit operates within a strictly defined temperature range. In other words, both overheating and too intense cooling of the motor, which does not allow the internal combustion engine to reach operating temperature, are allowed.

Next, we will talk about how to diagnose the engine cooling system, as well as what you should pay attention to if the engine does not reach operating temperature (remains cold) or overheats, there are coolant leaks, etc.

Read in this article

Engine cooling system diagnostics

It is not difficult to guess that the main task of the cooling system is first to ensure the speedy achievement of operating temperatures, after which further maintenance of this temperature and effective removal of excess heat into the atmosphere is realized.

At the same time, it is not allowed for the engine to remain too cold, since an engine that is not warmed up to operating temperatures wears out faster under load, and a very overheated internal combustion engine can seize.

The cooling system on modern cars is a combined type solution, that is, the engine is cooled by both liquid and air cooling. Taking into account the fact that this system includes a number of components, and that a special coolant (antifreeze or antifreeze) circulates in a closed circuit, malfunctions often occur during vehicle operation.

In practice, as part of diagnostics, it is necessary to check the entire system, and not just individual elements, for various defects or wear. It is also important to consider that modern cars often have very limited space under the hood.

This means that the cooling system hoses may have bends, several connection points, and differ in size and shape. Although the service life of hoses is quite long, even high-quality products wear out over time.

- So, let's get back to the diagnosis. First of all, you need to check the level and condition of the coolant in the expansion tank. It is recommended that the level be between the “min” and “max” marks on a warm internal combustion engine. On a cold engine, it is quite possible to reduce the level to o, since after the engine warms up, the level will increase as a result of the expansion of the hot coolant.

Also cloudiness of the coolant, presence of impurities, etc. usually indicates that antifreeze or antifreeze needs to be changed. As a rule, coolants are designed for 2-3 years of service, then a loss of useful properties occurs.

- Let's move on. If it is noticeable that the coolant level, even after being brought back to normal, is still dropping quite quickly, you should check the cooling system for leaks. All connections need to be inspected. As a rule, antifreeze leaks from:

- expansion tank;

- rubber hoses;

- pipes or pumps;

- thermostat;

- radiator;

The tank tends to crack, and its lid often becomes unusable. Also, leaks at the joints occur if the clamps become loose. The cooling radiator can also be damaged mechanically, cracks appear in it, etc. Coolant often leaks from under the thermostat housing; leaks can also be found in the area where the cooling system water pump is installed.

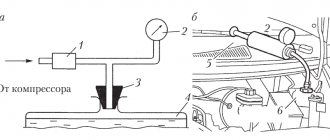

In any case, with the engine turned off, the tightness of the cooling system is determined by supplying air into the system. Also, instead of the radiator cap, a device is installed through which air is pumped to 100 kPa. A decrease in pressure will indicate depressurization.

- Now let's imagine that the system is sealed, the coolant condition is normal, the antifreeze does not leave, but the thermal operating conditions of the internal combustion engine are still disturbed. In such a situation, the motor may either overheat or not reach operating temperature.

Usually such problems are related to the thermostat. It can be quickly checked directly on the machine without removal. First, start the cold internal combustion engine, then let the engine run at idle. If the thermostat is normal, the lower radiator reservoir will also begin to heat up as the power plant warms up. This suggests that when the coolant heats up to 80–85 ºС, the thermostat is activated.

Problems also arise if the thermostat does not close when the coolant cools. This is manifested by a long warm-up of the internal combustion engine; the engine warms up, but only partially, or the engine remains cold all the time. These signs indicate that the thermostat is open all the time and the coolant is constantly circulating in a large circle through the radiator.

In both the first and second cases, the thermostat must either be changed immediately, or the device must be placed in a hot liquid, then its opening temperature must be measured and the operability of the element determined.

By the way, if the thermostat still turns out to be working, then the problem of overheating or underheating of the motor may lie in problems with the cooling system fan or temperature sensor (the radiator fan may not turn on or work constantly, operation may not occur in a timely manner, etc.).

- When diagnosing the cooling system, the water pump and the condition of this element deserve special attention. Problems with your pump are usually indicated by the following symptoms:

- Rapid increase in cold engine temperature after starting;

- The appearance of extraneous noise during operation of the internal combustion engine in the pump area;

- Noticeable axial and radial runout of the pump shaft when turning;

- A leak appears through the water pump seal.

Leaks in the area where the water pump is installed will indicate that the seal or seal has failed. One way or another, experts recommend regularly checking the condition of the water pump drive. It is also better to immediately replace the pump with a new one if any problems arise with the water pump of the cooling system.

Part 1. The engine is overheating.

The engine ALWAYS tries to warm up more if the compression is too low, if the ignition is too late, if the gas distribution mechanism is not adjusted (as a rule, the valve clearances are not adjusted). Despite these factors, the cooling system tries to maintain a stable engine temperature; the cooling system's capabilities are designed with a significant margin.

A very important element of the cooling system is the thermostat.

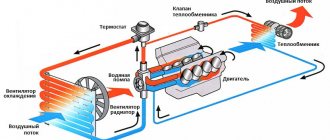

The thermostat switches the flow of coolant in the engine. The cooled fluid enters the lower part of the engine, heats up in the engine, the fluid goes up, and if this fluid is not heated to the desired temperature, the thermostat sends it bypassing the radiator back into the engine. If the fluid temperature is close to operating temperature, the thermostat directs fluid to the top of the radiator, the fluid passes from top to bottom of the radiator, cools and returns to the bottom of the engine. The pump ensures fast and uniform circulation of cooling liquid in the engine.

The thermostat is controlled by no electronics. No wise ECU (electronic control unit) sends any command signal to the thermostat. No amount of electronics can make an engine “warm up better” or “cool better.” The cooling mode is determined by the thermostat.

Possible problems with the thermostat: - the thermostat is always “open”. The engine does not heat up well, especially in winter. - The thermostat is always “closed”. The engine does not cool at all. It's just a disaster. — The thermostat is stuck in a certain “navigated” position. The engine does not heat up well and then quickly overheats. The names "open" and "closed" are just jargon. "Open" means the thermostat is directing coolant to the radiator. “Closed” is when the thermostat directs coolant bypassing the radiator. The pump in the cooling system rotates the same way, regardless of engine temperature. The radiator fan may stop. If the engine is not hot enough, there is no need to turn the fan. For this, there is a separate sensor that turns on the fan only at engine operating temperature.

The following symptoms of engine overheating are possible: - the engine does not heat up well, and then quickly overheats. The thermostat is not working well. We change the thermostat. — the engine heats up normally, the temperature is normal when driving slowly without frequent acceleration, but with frequent acceleration or fast driving, the engine overheats. You need to check if the radiator fan is spinning, which means the radiator is already completely clogged with scale. - the engine immediately overheats. Here are the options: Option 1. The thermostat is stuck in the “closed” position. If, when you tap on the thermostat with something wooden, it “becomes better,” this is not a solution, the thermostat must be changed. Especially those who are absent-minded should check that the belt that turns the pump is not broken, and in some designs this belt turns the pump and radiator fan. Option 2. Immediately check the amount of coolant (antifreeze) in the cooling system. This fluid doesn't necessarily leak anywhere. It can be “expelled” from the cooling system (such jargon) if you have a damaged cylinder head gasket, or there is a microcrack somewhere in the engine housing, and the coolant either boils away imperceptibly through this crack, or flows into the engine lubrication system (sometimes and so on). Option 3. Poorly adjusted valves can cause significant engine overheating. Also, the engine overheats if the ignition is too late, but late ignition is also characterized by additional symptoms, first of all, unstable engine operation during acceleration, loosening of the car when trying to accelerate.

We recommend: Car generator operation: where does it get electricity from?

Part 2, very short. The engine does not heat up well.

Thermostat. We just change the thermostat.

Part 3. Leaking. This part is more unpleasant than you might think.

It's good if it leaks where it drips down. Replace the rubber tube, install a new crimp clamp, and the problem will disappear. If the pump is leaking, replace the pump. If the radiator is leaking, you will have to have the radiator sealed at a service station, or you will have to replace the radiator. If the engine's water jacket is leaking, argon welding at a service station can sometimes save the engine. But if it flows from the cooling system to the lubrication system, or vice versa, it is much worse. There are the following options: - from time to time the amount of oil in the engine seems to increase, the amount of coolant decreases, and if you measure the oil level in the engine with a dipstick, you will notice that it foams when the engine is running. This is bad, your coolant gets into the lubrication system. — the coolant very quickly becomes almost black. This is also bad, the cylinder head gasket could have burned out, some of the exhaust gets into the coolant.

Useful tips

Please note that a decrease in the level of antifreeze or antifreeze does not always indicate problems with the cooling system. Coolant can go directly into the cylinders if there is damage to the cylinder head gasket, cracks in the head or block, etc.

In this situation, the engine often emits white smoke as the coolant escapes through the exhaust in the form of steam. In this case, the head or block must be removed; as part of the diagnosis, crimping of the block head is performed. Then a decision is made to repair the cylinder head or replace the element. Also, antifreeze or antifreeze may leak if problems arise with the engine block plugs. Leaks at the plugs will indicate that the engine plugs need to be replaced.

- It should also be added that with the onset of the cold season, it is very important not only to have coolant filled strictly to the level, but also to the density of the antifreeze. Remember, if you had to add distilled water during operation, the density of the solution decreases. In simple words, when the temperature drops, the liquid can freeze. Freezing often results in damage to both the cooling system elements and the internal combustion engine itself.

Thermostat operation:

When the coolant temperature is less than 75˚C , then the thermostat is closed, and the heat rotates in a “small circle”, bypassing the radiator. When the temperature increases to 95˚C , then the thermostat opens on its own and the circle of rotation increases. In this case, the heat passes into the opening of the radiator tube sheet and is quickly cooled there by the air pumped by the fan.

Everyone knows that the cooling system of a car's engine gets clogged after a while. Failure of the hydrodynamic functions of heat circulation causes significant overheating of the motor and a decrease in its operating parameters.

Cooling system malfunctions

The need to repair the cooling system arises in the event of constant overheating or undercooling of the coolant, a decrease in the level of coolant in the system as a result of a leak, the occurrence of electrolysis in the coolant, etc.

Overheating of the coolant causes engine detonation, which sharply increases wear on the cylinders and piston rings, leads to burnout of the pistons and reduced durability of the plain bearings (liners). Disruption of the combustion process of the fuel-air mixture during overheating and an increase in friction forces lead to an increase in fuel consumption and a decrease in engine power. A decrease in coolant temperature in the engine cooling jacket increases wear of CPG parts due to oil being washed away from the cylinder walls by fuel. The oil is diluted by fuel entering the oil sump, resulting in more intense formation of resin and varnish deposits on the pistons and piston rings.

A decrease in coolant temperature for every 10 °C from the nominal value reduces engine power by 1.5% and increases fuel consumption by 2%.

Engine overheating can be caused by: lack of coolant in the cooling system due to its leakage or boiling over, clogging of the system, breakage or slipping of the fan drive belt, failure of the electric or fluid coupling of the fan, jamming of the thermostat in the closed position or the blinds in the closed position, incorrect setting the ignition timing.

Engine overcooling is possible when the thermostat is stuck open or the thermostat itself is missing, or the hydraulic or electric fan drive is faulty.

One of the malfunctions of modern cooling systems with a radiator made of aluminum and a energized fan temperature sensor (thermal switch) is the occurrence of electrolysis.

Electrolysis is the reaction of decomposition of a solution of chemical substances when an electric current passes through them. Characteristic signs of electrolysis: clogging of the radiator tubes, the presence of white deposits near its leaky places and greenish deposits near the thermal switch. If such symptoms occur, you must carefully check the connections of the electrical devices of the cooling system.

For radiators made of aluminum, it is not recommended to use water as a coolant, as this will cause corrosion of the tubes.

Coolant leakage can be caused by leaking connections between cooling system hoses and fittings and pipes, leaking connections of pipe flanges, leaking drain plugs and heater taps, damage to hoses, cracks in tanks and the radiator core, and wear of the self-clamping seal of the liquid pump.

Car cooling system: device, diagnostics, repair

The cooling system in a car is designed to maintain optimal thermal conditions while the engine is running using a method of regulating heat from the parts that heat up the most. If the engine cooling process does not occur, then as a result of its overheating there will be a drop in power, and with a decrease in efficiency, fuel consumption will increase. There will also be an increase in wear of parts and the car may quickly break down. The engine may also heat up quickly and run poorly. In such a situation, it is worth repairing the car’s cooling system as quickly as possible.

Diagnosing the engine cooling system

General diagnostics of the technical condition of the cooling system consists of determining its tightness and heat balance.

A conclusion about the tightness of the system is made by visually verifying that there is no coolant leakage when the engine is running or not running, as well as by the rate at which liquid decreases from the expansion tank during vehicle operation.

The thermal balance of the system is judged by the time it takes for the engine to warm up and maintain its rated operating temperature under normal load. The check is carried out using a coolant temperature gauge.

The operation of the cooling system is considered satisfactory if the engine temperature is maintained within 85...95 °C when the loaded vehicle is moving at a speed of about 90 km/h.

You can check the general condition of the cooling system and find specific coolant leaks by supplying air under low pressure into the cooling system.

To check the tightness of the cooling system, you can use an air network (Fig. 1, a), and in case of its absence, an air pump (Fig. 1, b), which is connected to the plug of the expansion tank or radiator.

Design and operation of the cooling system

First, as they say, it wouldn’t hurt to “smoke the materiel” a little. After all, without knowing the structure and operating principle of the cooling system, trying to understand the cause of one or another malfunction is a thankless and practically useless task. Of course, you can always replace the thermostat, temperature sensor or fan switch without looking. Compared to other car spare parts, these parts are relatively inexpensive, and replacing them really helps eliminate almost all of the problems described above.

But if you don’t like such repairs, and you want to understand what and why you are doing, then you will have to study something. In the classic version, the cooling system of an internal combustion engine consists of the following components:

- small circuit;

- large outline;

- thermostat;

- coolant temperature sensor;

- main radiator;

- radiator fan and sensor for turning it on;

- stove;

- water pump;

- expansion tank.

Let's take a brief look at all these components and how they work together in a car.

Small and large outlines

The small circuit of the cooling system is considered to be that part that includes the engine water jacket, pump, temperature sensor and heater radiator in the cabin. The small circuit is separated from the large circuit by a thermostat. If the cooling system is working properly, then the liquid in it circulates only through a small counter until it reaches operating temperature. It takes heat from the engine cylinders, passes by the thermostat, and is pumped through the temperature sensor into the heater radiator. The cycle is then repeated in a circle.

This is how the cooling system works until the liquid warms up to operating temperature. When this moment comes, the thermostat starts to work. As the temperature rises, it opens slightly, allowing some of the coolant to flow into the large circuit. It consists of a main radiator, a fan, and a sensor that is responsible for turning it on.

Thermostat

Separates the small and large circuits of the cooling system. Essentially, it is a valve that smoothly opens or closes depending on the temperature of the coolant in the small circuit. Until the engine warms up, the thermostat is closed. Thanks to this, reaching operating temperature is accelerated - a cold engine warms up faster, and the heater in the cabin begins to warm up earlier.

When the engine temperature begins to exceed the normal value, the thermostat begins to open slightly. The liquid begins to be partially pumped through the large circuit by the pump. Passing through the main radiator, it cools down and returns to the small circuit. Thanks to this process, the operating temperature of the fluid in the engine jacket is maintained.

The thermostat has two main malfunctions - it gets stuck either in the closed or open position. In the first case, when a certain temperature threshold is reached, the coolant cannot pass to the radiator, which causes the engine to overheat. When the thermostat is always open, antifreeze is constantly circulating through a large circuit. As a result, the engine takes a long time to warm up, does not reach operating temperature when driving, and the heater in the cabin does not heat well.

Coolant temperature sensor

Installed in a small circuit. Measures coolant temperature and transmits readings to the dashboard. It is needed so that the driver has information about the current temperature of the engine - whether it has warmed up, whether it has reached operating temperature, whether it is overheating, and so on.

If the sensor is faulty (if everything else is working normally), nothing bad will happen to the engine. As a rule, there are two breakdowns. The first is complete failure. In this case, the arrow on the dashboard does not change its position, and the driver has no information about the engine temperature. The second breakdown is when the sensor “lies”. This means that the coolant temperature is in fact normal, and the arrow on the instrument panel is off the charts. And vice versa - the liquid is almost boiling, but the arrow shows the norm.

Main radiator

Needed for cooling antifreeze. During movement, it is blown by a counter flow of air, due to which heat is removed. After passing through the radiator, the cooled liquid returns back to the small circuit. There are two malfunctions. The first is a violation of tightness. The second is clogging of the honeycombs, resulting in poor cooling. Both malfunctions are determined visually without any instruments, and therefore do not need a detailed description.

Radiator fan and switch on sensor

When the car is stationary or driving slowly (for example, in a traffic jam, uphill or on a bad road), there is no natural airflow, or it is not enough. In this situation, the liquid is cooled using a fan. Its operation is controlled by a sensor, which sends appropriate signals to the relay. Some cars do not have such a sensor. The fan is connected to the motor through what is called a "viscous coupling", which causes it to rotate as the temperature increases.

There are also engines with radiators equipped with two fans with two independent sensors. The first one works, for example, at a temperature of 90-100°C, the second - already at 100-110°C.

As a rule, two failures of this unit occur most often. The first is the failure of the fan, as a result of which it does not turn on when the critical temperature is reached. The second breakdown is failure of the sensor or relay. The result is similar.

Stove

It is a small radiator located in the cabin under the front panel. It is blown by a separate fan, which takes air from the street and forces it through a radiator connected to a small circuit into the car interior. When heating is not needed, the air flow forced by the fan into the cabin is directed past this radiator. If the stove does not heat well, then either the coolant does not warm up to operating temperature, or the radiator in the cabin is dirty.

Cooling system maintenance

Currently, the cooling system is filled with special non-freezing liquids (antifreeze), which are a mixture of ethylene glycol and water (solution density 1067...1085 kg/m3) with the addition of anti-foam and anti-corrosion additives. It is also possible to use water, but in this case, deposits of calcium, magnesium and other metals contained in the water form on the internal surfaces of the cooling system elements.

Scale has low thermal conductivity and impedes heat exchange between water and cooling system elements, reduces the cross-section of radiator tubes, and impairs water circulation. For example, a layer of scale more than 1 mm thick increases fuel consumption by up to 20...25%, oil consumption by up to 25...30%, and reduces engine power by up to 10...20%. To reduce the scale layer, softened water with a low salt content, obtained by electromagnetic treatment of water, is poured into the cooling system (water is repeatedly pumped through a magnetic force field in the direction perpendicular to the power lines). As a result, the water acquires new properties: the salts it contains do not form scale and fall out in the form of sludge. In addition, it helps dissolve previously formed scale, turning it into an easily washable powder. You can also soften water: by boiling; adding soda, lime, ammonia; purification from salts by passing water through mineral, glauconite or sodium cation filters.

If scale still exists, it is removed using special substances, which are divided into alkaline and acidic.

The basis of alkaline compositions is caustic or soda ash (1 kg of soda and 0.15 kg of kerosene per 10 liters of water). Alkaline compounds are poured into the system for 5...10 hours, then the engine is started for 15...20 minutes and the solution is drained. After this, it is advisable to flush the cooling system with water, since alkaline solutions cause corrosion of non-ferrous metals (aluminum alloys of the cylinder head, brass radiator elements and their solder joints).

As acid compositions, a 5...10% aqueous solution of hydrochloric acid with the addition of 3...4 g/l of utropine is used to protect ferrous metals from corrosion. The sludge is washed off with water, passing it in the direction opposite to the circulation of the coolant.

After repairing or replacing elements of the cooling system, as well as every 60 thousand km, after three years, or according to the instructions of the vehicle manufacturer, the coolant should be replaced. The need for replacement is due to the fact that the anti-corrosion components contained in the system, during the process of filling it, are deposited on new or repaired and cleaned parts to form a persistent anti-corrosion layer.

Coolant replacement should be carried out on a cold engine or with heated liquid on a warm engine in order to avoid its damage due to sudden cooling of metal parts: set the heating regulator in the cabin to the maximum degree of heating so that the coolant fills the heater radiator, remove the cap from the expansion tank and open the tank taps radiator and cylinder block (if equipped).

When is cooling system diagnostics needed?

The most obvious malfunction that indicates a problem with the cooling system is engine overheating. This is logical, because this whole system is needed in order to avoid this. Frequent turning on of the fans will also indicate a breakdown, as will a long warm-up of the internal combustion engine.

The most common malfunctions in the cooling system are:

- Antifreeze leakage, for example, through loose pipe connections;

- Radiator malfunction, most often caused by blockages;

- Thermostat malfunction due to constant movement and work in an aggressive environment;

- A malfunction of the water pump, most often caused by bearing wear.

There can be many reasons for engine overheating: starting from old oil in the internal combustion engine and ending with banal damage to the valve in the expansion tank. In the case of a cooling system, overheating can result from the breakdown of any part of the entire system, and only professionals can detect and repair such a breakdown.

Experienced drivers know that on a long road trip in hot weather, additional cooling can be achieved by turning on the heater in the cabin. This will allow hot air to escape and speed up cooling. But it happens that there is overheating, and the air coming from the stove is cold. In this case, you can check the antifreeze level to see if there is a leak somewhere. And after such a trip you need to urgently go to the service center. There are also cases of unstable engine temperature. The cause of this is most likely a faulty thermostat.

It is important to note that the cooling systems in modern cars are very complex and not always the same. That is why it is better to refuse to repair yourself and entrust your car to professionals.

Car cooling system: device, diagnostics, repair

The cooling system in a car is designed to maintain optimal thermal conditions while the engine is running using a method of regulating heat from the parts that heat up the most. If the engine cooling process does not occur, then as a result of its overheating there will be a drop in power, and with a decrease in efficiency, fuel consumption will increase. There will also be an increase in wear of parts and the car may quickly break down. The engine may also heat up quickly and run poorly. In such a situation, it is worth repairing the car’s cooling system as quickly as possible.

How is the cooling system diagnosed?

First of all, the car is inspected for leaks. Antifreeze leakage is the most common cause of malfunction in the system, as the pipes lose their elasticity over time, and the clamps that tighten the connecting parts relax.

In addition to visual inspection, specialists check antifreeze for density using a special device. If the results of all checks turn out to be normal, then together with the owner of the car the problem is identified and a detailed inspection of each part of the system begins: first of all, the thermostat, pump and checking the general tightness.

At Svoy car service center, only professionals with extensive experience will work with you. This will help you, through joint efforts, quickly make a diagnosis and decide on repairs. And if you decide to leave your car for repairs at Svoye, then the service will pay for the diagnostics.