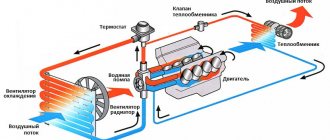

Cooling system pump design

Pump (pump) of the engine cooling system

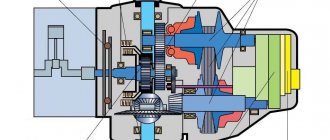

Structurally, the pump is a classic centrifugal pump for pumping water and non-aggressive liquids. It consists of the following parts:

- Sealed housing. It has a complex shape and is most often made of aluminum alloys. For connection to the system, two pipes are made in the housing - suction and pressure. The first is connected to the line coming from the radiator, and the second to the line of the engine cooling jacket.

- Shaft – transmits rotation from the drive to the pump impeller.

- Impeller or impeller. It has specially shaped blades with which it pumps coolant into the system.

- Drive pulley.

- Seals (oil seals) – prevent leakage of coolant at the points where the pump is attached to the lines.

- Bearings.

The pump is located in the engine cooling system between the radiator and the jacket. Most often this is the front part of the engine.

Initially, simply purified water was used as a coolant, and therefore such a pump is often called an engine water cooling pump. Now this term is irrelevant, since not pure water is used for cooling, but aqueous solutions with corrosion inhibitors (in warm climates) and antifreeze (in winter), which also contain ethylene glycol.

Centrifugal pump device

The pump is often installed in the front of a gasoline and diesel power unit. The solution is equipped with two types of drive. Mechanical drive is the most common. The mechanism is designed so that the force is transmitted from the crankshaft or camshaft of the power plant. A belt drive is used for this. The electric drive type is based on the use of an electric motor, which additionally has its own control system. The cooling system pump has a number of structural elements:

- frame;

- shaft;

- bearing;

- impeller (impeller);

- pump chamber seal;

- pad;

The coolant pump is a centrifugal type pump. During operation, the pump is capable of creating pressure in the cooling system at approximately 1 atmosphere. This pressure is quite enough for the boiling point of antifreeze in the system to move up by 20 degrees Celsius.

Structurally, the coolant pump consists of an impeller, which is mounted on a shaft with a pulley. This wheel may also be called an “impeller”. The entire structure is contained in a separate housing. The pump body is made of cast iron, and you can also find products made of cast aluminum or magnesium alloys. There are also cheaper versions, when individual pump elements are made of plastic. The pump body has special channels through which coolant is supplied and discharged to the impeller.

The pump housing is rigidly fixed to the engine cylinder block, and a special sealing gasket is placed between the internal combustion engine block and the pump housing. It is worth understanding that high-quality sealing of the pump and the best seal play an important role in the operation of the pump. It is this sealing gasket that prevents coolant from leaking out of the pump in the place where the pump connects to the engine cooling jacket. Where the shaft exits the pump housing, a pump seal is additionally installed. These solutions reliably seal the device and seal the joint between the pump housing and the block, thereby effectively preventing coolant leakage from the housing.

Article on the topic: Emulsion in oil: engine flushing

The impeller in the pump housing is responsible for the forced circulation of liquid in the system. The wheel is made in such a way that it has special blades of a special shape. It is for this reason that the wheel is called an impeller, which is fixed to the drive shaft.

The drive shaft is fixed in the housing on bearings, which are responsible for the rotation of the shaft. On the opposite side of the drive shaft there is a drive pulley, which is driven mechanically by the engine or by a separate electric motor.

Operating principle of the engine cooling pump

Location of the cooling system pump

The main task of the cooling system pump is to create excess pressure to ensure forced circulation of fluid in the circuits. On the practical side, this speeds up the process of heat exchange between engine components and coolant.

When the car engine starts, the pump drive transmits rotational motion to the impeller through a belt drive and shaft. At this moment, a vacuum is created at the inlet (suction pipe), which facilitates the absorption of liquid into the pump. The liquid is in a cooled state, as it comes from the radiator of the cooling system.

Entering the central part of the pump, the liquid moves along the impeller blades and, under the influence of centrifugal force, is forced through the outlet pipe into the jacket of the engine cooling system (to the cylinder head). Under the influence of high pressure, the coolant passes through the circuit through the main components and removes heat. After this, it returns to the radiator again, where it cools and is sucked in by the pump for a new cooling cycle.

Pump operating principle

When the engine is started and the liquid pump begins to operate, then the rotation of the impeller from the drive (in most cases provided by a belt from the crankshaft pulley) creates a vacuum at the pump inlet. Thanks to this, the coolant that is in the radiator and expansion tank is supplied to the pump. Next, the liquid ends up inside the pump and hits the impeller. After it passes over the impeller blades, centrifugal force will throw the coolant out of the pump. From there, the liquid will enter the cooling jacket of the power unit cylinder block. If we trace in more detail the path of coolant in the system after starting the internal combustion engine, we get the following:

- The liquid located in the lower radiator reservoir passes through a channel in the center of the liquid pump housing into the pump.

- The rotation of the impeller creates a centrifugal force that literally throws the coolant towards the walls of the pump housing. Since pressure created by the pump has appeared in the system, this pressure ensures that coolant is pumped through a special channel into the distribution tube, which is located in the cylinder head of the engine.

- Through the hole in this tube, the coolant will first end up in the pipes near the heated exhaust valves.

The specified pattern of fluid movement in this sequence ensures immediate and priority cooling of precisely those parts of the power unit that heat up the most. The liquid then follows along the engine jacket, cooling the remaining heat-loaded elements of the motor.

If the main thermostat valve is closed, then the coolant passes through the cooling jacket and enters the bypass channel, through which it is returned back to the centrifugal liquid pump. If the thermostat is open, then as the fluid moves in a large circle, it flows back into the pump from the lower radiator tank. The liquid supply is realized through the lower supply pipe.

Systems with additional pump

There are engine cooling systems in which two coolant pumps can be installed at once. If the main pump is responsible for the main function, then the additional pump can perform one of a number of functions depending on the design of the engine itself:

- Providing additional engine cooling, which is important for countries with high year-round outdoor temperatures.

- An additional centrifugal pump allows the operation of an autonomous heater, which can be included in the overall circuit of the power plant cooling system;

- Cooling of exhaust gases in the exhaust gas recirculation system;

- Another pump can be used to cool the turbocharger on engines that are equipped with supercharging;

- A second pump can be installed to pump coolant after the engine is stopped. This solution is used to avoid overheating of the power plant after stopping the engine and deactivating the main mechanical pump.

Related article: The engine is noisy or knocking after an oil change

In the vast majority of cases, the additional coolant pump is equipped with an electric drive. An additional pump is an element that is controlled by the internal combustion engine control system. The device is controlled by a command from the electronic control unit of the vehicle's power unit. It turns out that turning the pump on and off is controlled by the ECU.

Types of cooling system pumps

Types of cooling system pumps

Coolant pumps used in the modern automotive industry do not have any fundamental design differences. But they can be divided depending on the type of drive, purpose and housing design. The pump can be driven in two ways:

- Mechanical - the pump shaft is connected via a belt drive to the crankshaft or camshaft of the engine. In this case, it is set in motion synchronously with the engine starting.

- Electric - in this scheme, the pump shaft is driven by an additional electric motor, the operation of which is controlled by the electronic engine control unit (ECU).

According to its intended purpose, a car engine pump can be:

- Basic. Such a pump directly pumps liquid in the cooling system.

- Additional. It is not installed on all cars and can be intended for auxiliary cooling in regions with very hot climates, reducing exhaust gas temperatures, cooling the turbocharger in turbocharged engines, and additional cooling of the engine after stopping. Unlike the main pump, the additional one is driven by an individual electric motor.

The service life of a coolant pump depends on the type of construction of its housing. This parameter distinguishes between:

- Collapsible. This type is used in old and domestic cars. This design allows you to repair and flush the pump.

- Non-separable. In most countries, an engine pump is considered an inexpensive consumable spare part, and therefore many manufacturers have switched to producing non-separable pumps. They must be completely replaced every 60 thousand kilometers of the car. When installing a new pump, the drive belt must be replaced.

In addition to the designs described above, there are also switchable pumps. They allow you to turn off the flow of coolant until it warms up to a temperature of 30°C. This allows for faster engine warm-up and improved fuel consumption.

Possible malfunctions of the cooling system pump

A failure of the coolant pump can lead to the shutdown of the entire system. This can seriously affect the condition of the engine. The most common pump problems are:

- Wear of the seal (oil seal). In this case, a coolant leak occurs.

- Impeller failure. When the impeller is destroyed, fluid injection becomes worse (pressure drops) or stops altogether.

- Bearing jamming. If the pump's lubrication deteriorates, which can also be a consequence of leaking coolant, the pump begins to operate intermittently.

- Increased play between the impeller and the pump shaft. During operation, the impeller attached to the shaft may become loose, which leads to unstable operation of the pump and other breakdowns.

- Chemical corrosion. Most often, this problem affects the pump impeller and occurs if low-quality fluids are used.

- Destruction due to cavitation. Air bubbles that may arise during operation of the pump intensively destroy it from the inside, which leads to fragility of parts and their damage by corrosion.

- System contamination. Chemical deposits and simply dirt that gets inside the pump over time form a hard coating on its parts, which makes it difficult for the impeller to rotate and the passage of liquid.

- Bearing destruction. In this case, a characteristic whistle appears when the pump operates. It is difficult to replace such bearings, and therefore in this case the pump is simply replaced.

- Broken drive belt. If a low-quality belt is used or is not replaced in a timely manner, rupture or slippage may occur.

If the engine cooling system is stopped for just 5-6 minutes, the engine may overheat. The action of high temperatures disrupts the geometry of the cylinder head and leads to damage to the crank mechanism. You should not ignore minor malfunctions of the cooling system, as they can lead to serious repairs in the future.