Every experienced driver always listens to various sounds while operating his car. The appearance of uncharacteristic knocking or humming may indicate the presence of some kind of malfunction. Prompt diagnostics in most cases helps to significantly save your money on further repairs.

In cars with front-wheel drive and all-wheel drive, problems often arise with the CV joint (constant velocity joint). Such parts are made from high-quality metal alloys, but even this does not prevent possible damage. The main sign of a malfunction in this component is the appearance of a specific crackling sound.

A little about the nature of the problem

A CV joint is necessary to transmit rotation between the axle shafts with a constant change in the angle between them. The part is used in front-wheel drive and all-wheel drive vehicles. The drive wheel in such cars must not only rotate, but also turn, and also lower and rise on a spring. Such hinges allow you to do all this.

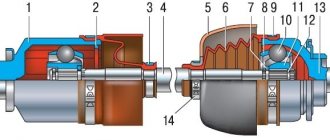

The design of this unit consists of three main components:

- The outer housing, which is made in the shape of a bowl and is connected to the axle shaft.

- Inner ring. It has a spherical shape. There are six grooves on it, thanks to which the clip is attached to the outer casing.

- Six small balls in the separator. They are located between the bowl holder and the machines.

The problem is that during operation, with the constant “walking” of the balls in the structure, wear and small scuffs form. The movement of the balls becomes more free, which leads to a characteristic sound. Even inexperienced drivers will be able to determine the presence of this problem. You may hear clicking sounds accompanied by vibration or whistling. In most cases, the sound will resemble the crunching of metal.

What is a CV joint and how does it work?

Experienced car owners often call these parts “grenades.” And such an alternative name is telling - the presence of such a “grenade” in a car can sooner or later cause serious trouble, in other words, an explosion.

Of course, this is a joke in which there is a certain amount of truth. The abbreviation CV joint stands for the following: constant velocity joint. The function of these units on almost all front-wheel drive and some all-wheel drive vehicles with independent suspension is to transmit torque from the power unit to the drive wheels. Front CV joints, which are very modest in size and weight, make the car's wheels rotate and also provide control of them.

Torque is transmitted from one axle shaft to another at a constantly changing angle. Car enthusiasts call front CV joints “grenades” not only because they have some external similarity, but also because if this unit breaks down (which usually happens suddenly), the car will not be able to continue moving (in the absence of a cross-axle differential lock).

The principle of operation of the hinges is similar to the principle of operation of the cardan. But the node itself is more advanced and complex. During the rotation of the cardan shaft, torque is not transmitted synchronously (one shaft rotates evenly, the other does not), and the shafts can hardly intersect at a large angle. At the same time, for hinges with significant resources, rotations relative to the axis at an angle reaching 70° are not difficult.

The active position of front CV joints in the market is due to the widespread demand for front-wheel drive cars and the spread of independent suspension. Moreover, the first developments of hinge elements were carried out by engineers 100 years ago.

Front CV joints have different features; different car factories produce constant velocity joints of different designs. Despite this, they all work the same. The drive shaft is connected on one side to the wheel bearing and on the other to the differential. Thus, torque is transmitted from the internal combustion engine to the drive wheels.

The design of the front outer unit includes a housing and a cage with grooves for moving balls, with the help of which the component elements are rigidly connected to each other. The task of external components is to transmit torque regardless of rotation angles.

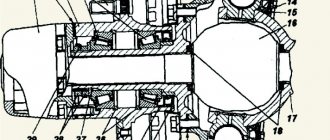

The mobility of the inner front CV joint is much less, its rotation angle does not exceed 20°. Structurally, it consists of rollers on bearings moving inside grooves in the glass. The purpose of this joint is to compensate for the suspension travel and ensure the continuity of the shaft.

During vehicle operation, the front CV joints are subject to serious loads, therefore, in order to increase their service life, the part must be lubricated and protected from the external environment. The hinges are placed inside sealed boots (plastic or rubber), filled with lubricant and attached to the shafts using clamps. The quality and integrity of this protective shell ensures the functioning of components whose location is such that they are constantly exposed to precipitation and road dirt.

Is the CV joint really to blame?

As soon as you hear a crunching sound in your car, you should not draw any clear conclusions, because the source may be some other component. The involvement of constant velocity joints can be determined in two ways.

Turn the wheels of your car all the way to the side, and then try to drive off in this position. If in this particular situation a crunching sound is heard, then the problem is really in the hinges. This problem can also occur when overcoming small obstacles, for example, potholes on a country road. There will be increased stress on the CV joints and you should hear crunching sounds.

Types of CV joints

During its existence, the design of the internal CV joint and its external version has been modified several times. Previous hinge models remained in use along with new developments. Today there are 4 main hinge designs known.

- Cam (cracker). Consist of 2 shaped discs and a similar number of forks. Due to the large adhesion area, they are able to withstand intense loads, but are not without significant design flaws.

Vehicles equipped with cam joints can only be driven at low speeds. Otherwise, the unit heats up and fails. The cracker type device is common in freight transport. - Tripod. This type of hinge consists of 3 rollers, which are placed in a special bowl. The transfer of angular momentum occurs due to the displacement of the rollers.

These types of CV joints are used for small cars. Some passenger cars and vehicles not designed for transporting heavy loads ride on a tripod. - Cardan shafts are paired. In fact, they are a pair of cardan joints, due to mutual rotation, equalizing each other’s operating speed. Such designs were actively used in the American automotive industry in the 20s of the last century. Today, some models of construction equipment and tractors are equipped with twin hinges.

- Ball. This node model is the most common. The hinge consists of a body, a separator, a cage and 6 balls. The latter move along oblique grooves on the inner surface of the outer race, thereby ensuring torque transmission.

There are also intermediate models of the unit: four-ball, rigid tripods. However, they are not widely used because they are not very reliable and perfect.

Reasons for appearance

Before we talk about how to determine which CV joint is crunching, it is necessary to find out the most common causes of this problem. Correct diagnosis greatly simplifies repairs. The key reasons for this phenomenon include:

- Defective part. At a car service center, you could have had a CV joint installed that was not made to the standards, which is why there were gaps from the factory. In this situation, the best solution would be to completely replace the CV joint.

- Lack or insufficient amount of granite lubricant. It is recommended to replenish it to the required volume.

- Severe wear on the anthers. During operation, these components lose their elasticity, which is why sand, dirt, water and dust get into the hinge structure. All of them lead to the appearance of a specific crunch.

- Aggressive driving style. In such situations, a very large load is placed on the hinges, which significantly reduces their service life. With constantly aggressive driving, the crunch will not take long to occur.

Diagnostics of the condition of CV joints

If there is a suspicion that there is play in the CV joint on a VAZ 2109, the unit must be disassembled and all parts diagnosed. To do this, the structure is disconnected from the car, and then the procedure is as follows:

- The clamps holding the protective cover are removed.

- The part moves along the wheel drive shaft. The cover on the right wheel drive is tightened or turned out.

- The hinge must be knocked off the shaft with a hammer or a special drift.

- The hinge is secured in a vice.

- The separator and cage are tilted so that the ball can come out of the CV joint housing.

- Using a screwdriver made of soft metal, the ball is squeezed out of the separator.

- The remaining balls are pulled out in the same way. They can be pulled out one after the other or through one.

- It is necessary to install the separator with the holder in such a position that the elongated windows of the separator are opposite the protrusions of the assembly body.

- The separator and clip are pulled out.

- The cage is removed from the separator after placing its protrusion in the separator window.

CV joint parts for VAZ 2109

- Building 1.

- Separator – 2.

- Clip 3.

- Balls – 4.

The CV joint parts are washed well.Next:

- Their condition is being examined. There should be no cracks on the separator jumpers, there should be no burrs or deep holes on the cages, and no traces of corrosion on the working surfaces of the hinges.

- Backlash in VAZ 2109 CV joints occurs when the working surfaces of the elements are worn by more than 0.1 millimeters.

- If deviations are found that cannot be eliminated, a complete replacement of the CV joint is necessary.

https://youtube.com/watch?v=G7mVjOYDbjY

Assembling the hinge of a VAZ 2109 car

So:

- Before starting the operation, you need to lubricate all parts with special CV joint-4 lubricant.

- When assembling the cage with the hinge body, it is necessary to ensure that the marks made before disassembling the assembly match.

- In the separator, the balls are installed in an inclined cage. The angle of inclination should be twice that of the separator.

- The CV joint is filled with lubricant, the filling volume is 40 cm3.

- A new retaining ring is mounted into the shaft groove strictly in the center. The groove must first be filled with grease.

- While maintaining the alignment of the shaft and the cage relative to the ring, the shaft must be rested against the cage.

- After a sharp blow with a hammer on the end of the shaft, the ring should shrink and slide through the hole in the cage.

- “Excess” air is released from the cover by pulling the seating belt of the cover away from the drive shaft.

- The fastening clamps are put in place.

- The area of fixation and tightening of the boot with clamps is checked. There should be no deformations or traces of parts contacting the road surface. Otherwise, the parts are replaced with new ones.

- If the VAZ 2109 CV joint rotates smoothly, without jamming from force applied by hand, it means that the unit is assembled correctly.

You can watch the video on how to remove the CV joint play in a VAZ 2109.

How to find out which CV joint is crunching

Each wheel has two hinges: internal and external. This significantly complicates the diagnostic process, since they are located next to each other, so it is almost impossible to determine by ear which of the components makes sounds. A few tips will help you find out which CV joint is crunching (internal or external):

- Turn off the vehicle, and then use a flashlight to locate the hinge pins. Pull them one at a time without applying much force. If no play is detected, then the part is fully operational. If a large amount of wear occurs, your actions will lead to a crunching sound, which will help diagnose the failure of a particular hinge.

- The second method allows you to diagnose a breakdown of the external hinge. You need to drive onto a flat road, and then turn the wheels to the side until they stop. If at this moment you hear a characteristic sound, then the problem is in the internal CV joint. The left part is worn out when there is a sound when turning right. With the right part there will be a sound when turning left. This is due to the fact that when turning, the entire weight of the car falls on the opposite side of the turn.

The CV joint is crunching - how to determine which one, and what to do?

We determine which CV joint crunches (internal or external).

find out why and how to eliminate the crunch of a grenade Hello, dear motorists! A car enthusiast can only consider himself a real car owner when he is truly concerned about the condition of the car’s components and assemblies, and every new knock, creaking and other signs of car breakdowns haunt him.

Driving a car can be called comfortable only if all elements are in good working order.

However, each part, especially those that operate under load and friction like a CV joint, has its own working life.

Sooner or later, the material wears out and loses its properties, which leads to failure of the part. This is objective. And a “hint” about an impending breakdown from the part itself must be taken seriously. It’s better not to wait for the car to stop on a long journey, but to immediately begin troubleshooting and fixing it.

Owners of front-wheel drive cars are familiar with such an unpleasant phenomenon as a CV joint crunching. Considering that the front suspension of the car, in addition to its main functions, must also ensure the transmission of rotation from the differential gears to the drive wheels, it is equipped with unique devices: constant velocity joints, which in its abbreviated version sounds like “CV joint”.

This part is very important and quite complex in design; therefore, it is expensive and requires increased attention. If the CV joint crunches, then without any hesitation you need to take the car in for repairs and change it.

Why does the CV joint crunch?

Video of replacing the outer left CV joint

Experienced drivers are able to determine the location of a car breakdown by ear. Such skills are acquired over time, but the crunch of a CV joint cannot be confused with anything.

In order to understand the nature of this characteristic noise, you should remember how the CV joint is designed. The task of the CV joint is the transmission of rotation from one axle shaft to another, provided that the angle between them continuously changes.

This property is due to the need not only to rotate the drive wheel, but also to give it the ability to turn and move up and down on a spring.

The CV joint consists of the following main elements:

- outer body in the form of a bowl with six semicircular grooves inside and a semi-axis outside;

- the inner race is in the form of a spherical fist and also has six grooves and a splined connection for the axle shaft;

- Between the inner walls of the bowl and the holder there are 6 balls in the separator.

All elements are made so precisely that they have no play when assembled. The cage transmits force through the balls to the body and rotates it, and moving the balls along the grooves makes it possible to change the angle between the axle shafts.

Over time, a hole forms at the point where the balls come into contact with other elements and a backlash appears. The free movement of the balls (rolling) generates a sound that is very similar to crunching.

Considering that CV joints are installed two on each wheel, when alarming symptoms appear, it becomes difficult to find out which CV joint is crunching: inner or outer, right or left.

How to determine which CV joint is crunching: external or internal, right or left?

As you know, each drive wheel of a front-wheel drive car has two equal angular velocity joints: the inner one transmits rotation from the differential gears to the axle, and the outer one directly from the axle to the wheel hub. The outer and inner CV joints have the same design, but different sizes. The outer one wears out more intensively and fails faster.

You can determine for yourself which CV joint is crunching in two ways:

- on a stationary car, trying to pull the axle one by one at the hinges. In a working CV joint there should be no play. If it knocks, it means the output is already large enough;

- in motion, performing various maneuvers and listening to the sounds made.

First you should try to diagnose the outer CV joints. To do this, turn the steering wheel as much as possible while moving on a flat surface in one direction, and then in the other.

If the CV joint knocks when turning to the right, then, accordingly, the right one is faulty, and when turning to the left, the left one is faulty.

The wear of the inner CV joint is determined during straight-line movement, but it is necessary to deliberately select an uneven section of the road, where there will be a ditch or hole, so that the wheel drops as low as possible while moving.

By driving the right and left wheels alternately into the recess, you can determine which side of the CV joint requires replacement. And of course, after you diagnose which one is crunching, immediately begin replacing the CV joint.

Diagnostics of the internal CV joint

It can be quite difficult to determine the malfunction of this component, and sometimes it is impossible to do without the help of specialists.

Drivers can try a number of tests to try to determine if this part is faulty on their own. To do this, you need to find a straight road with small potholes. Drive along it without turning. If you hear a familiar sound, this indicates a clear failure of the internal joint.

You can also load the rear of the car (with passengers or luggage) so that the front of the car rises. In such a situation, the axis of the inner CV joint will bend, so when driving even on a flat road, characteristic sounds should be heard.

Is it possible to drive if the CV joint crunches?

There is no clear answer to this question, since the component can only be partially worn out, so it will still last a certain number of kilometers without any consequences. If a crunching sound occurs, all experts strongly recommend contacting service, as delay can lead to more serious consequences, which include:

- Structure jamming. The hinge stops rotating completely. This is extremely dangerous when driving at high speed. Losing control of a car can lead to death and a traffic accident.

- Broken axle shaft or shaft. No torque will be supplied to the wheels, making it impossible to continue driving your vehicle. There is also always the danger that a rupture will damage other components in the immediate vicinity.

In most cases, a complete replacement of the constant velocity joints is necessary, however, with minor wear, drivers can carry out a number of works that will help eliminate the crunching noise. These include:

- checking the integrity of the anthers and replacing them in case of wear;

- cleaning the structure, replacing lubricant;

- in some cases, you can try sanding the surface to eliminate play.

How to determine a CV joint failure

There are two CV joints installed on each of the driving wheels of the car. One of them is called internal (the one closer to the gearbox), and the second external (the one closer to the wheel). Usually the fault can simply be “ heard ” . But how to determine which CV joint crunches , squeals or rattles out of all the available ones?

It is not difficult to identify problems with the operation of the external CV joint. To do this you will need:

- start the car;

- engage forward gear;

- turn the steering wheel all the way to the right or left;

- start moving.

If an extraneous sound is heard and vibration is felt in the wheel area, then with almost 100% probability the culprit will be a faulty CV joint. However, the wheel bearing, for example, has similar symptoms of a malfunction. Therefore, in any case, further diagnosis is necessary.

You can determine the malfunction of the internal CV joint when driving in a straight line and one of the wheels gets into a hole (in fact, you can disable it in the same way). If a loud grinding noise is heard in such a situation, then the CV joint is faulty.

There are also visual signs of CV joint failure. If you look at the wheel from the inside, you can see the boot that protects the CV joint from foreign objects, dust and dirt. If it is torn, and traces of leaked lubricant are visible on the wheel disk, then not only the boot is damaged, but also the CV joint itself. If no traces of grease are visible, and you are sure that the rubber has broken recently, then it makes sense to remove the boot and inspect the hinge. If there are no signs of damage, then the CV joint can simply be cleaned and the boot replaced.

Crunching with osteoarthritis

A constant, pronounced crunch, which is accompanied by pain, is a characteristic symptom of shoulder arthrosis. Unlike a similar disease that affects the knee or hip joint, arthrosis of the shoulder joint is most often secondary. That is, it develops not as an independent disease, but as a complication of other pathological processes.

Features of the pathology:

- develops mainly after 40 years;

- there is a restriction of not only active (initiated by the patient), but also passive movements in the joint (performed by the doctor);

- the history often includes a shoulder injury, repeated microtraumas, and a high level of physical activity (sports, heavy physical labor).

Arthrosis is diagnosed by X-ray examination. The doctor detects osteophytes along the lower edge of the articular surface of the humeral head. The joint space is narrowed. Possible cysts in bone tissue. There are signs of subchondral osteosclerosis.

Do-it-yourself replacement or professional help

So, knowing how to check the CV joint and being sure that it is the one that is faulty, the car enthusiast has a question about how to fix the breakdown. It is irrational to repair CV joints; such parts must be replaced. If you have a convenient garage and all the necessary tools, you can carry out the repairs yourself.

If you have doubts about your own abilities, or do not have an experienced mentor or the necessary tools, then it is better to seek help from a car service center. Otherwise, there is a risk of incorrect installation and damaging the new part.

Consequences of untimely replacement of the CV joint

If you do not pay attention to the obvious signs of a CV joint malfunction , this will sooner or later lead to the following consequences:

- The CV joint will simply fall apart while driving and the car will lose the ability to move. This is the most favorable scenario.

- The CV joint will jam. One of the drive wheels will stop rotating, but the other will not. At high speeds, this can cause loss of control and a serious accident.

You definitely shouldn’t turn a blind eye to the emerging symptoms of a malfunction; in the future, because of this, you can lose not only money and time, but also your own health.

Where to buy quality CV joints

In order to change worn-out CV joints as rarely as possible, you need to competently approach the issue of their choice. There are several brands that have been tested by motorists and service center workers and have proven themselves to be excellent. Among them is the company IBERIS. CV joints from this manufacturer are distinguished by:

- excellent quality of materials used;

- high-precision assembly;

- adequate price;

- big choice.

You can purchase IBERIS products (and not only) in the IXORA store. Managers-consultants will certainly help you make the right choice, and the quality of the product will certainly leave the most demanding buyer satisfied.

1200 rub. for the photo report

We pay for photo reports on car repairs. Earnings from 10,000 rubles/month.

Write:

When joint (constant velocity joint) crunches when turning The most important thing in this case is to find out which CV joint is crunching , because front-wheel drive cars have as many as four “grenades,” as this unit is popularly called. It is also important to understand whether it is the CV joint that is the source of the unpleasant sounds or another part of the car’s suspension. Next, we will try to systematize the information and shed light on the issue of diagnosing and repairing the constant velocity joint of a machine.

Types and design of CV joints

Before we move on directly to describing the signs and causes that indicate problems with CV joints, we need to find out what they are for and what they are. This will make it easier for you to understand how to diagnose and repair them in the future.

Types and location of CV joints

The job of any constant velocity joint is to transmit torque between the axle shafts when they are at different angles at different times. CV joints are used in front-wheel drive and all-wheel drive vehicles to allow the front wheel to turn and rotate under load. There are several types of hinges, but we will not dwell on this in detail. It is important to know that, basically, they are divided into internal and external . Any front-wheel drive car has only four CV joints - two internal and two external, in pairs on each front wheel. The task of the internal one is to transmit torque from the gearbox to the shaft. The task of the external one is to transmit torque from the internal joint directly to the wheel.

a tripod inserted into it - a set of needle bearings operating in three planes.

The main shaft (from the “glass” side) is inserted into the gearbox, and another axle shaft is inserted into the tripod, to which torque is transmitted. That is, the design of the internal CV joint is simple, and, as a rule, problems with it arise infrequently. The only mandatory condition for the normal operation of the hinge (this also applies to the external “grenade”) is the presence of lubricant inside it and the integrity of the boot. You can read about choosing a lubricant in a separate article.

How to recover?

With an average degree of wear, the problem with crunching can be solved by washing the unit and adding new lubricant to which soft plastic shavings have been added (a Champagne cork or a nylon lid for cans will do).

During operation, the CV joint assemblies will easily crush such chips and fill with them the formed traces of wear on the working surfaces, thereby eliminating the backlash. But the effect of such a restoration will be short-lived, and ultimately the hinge will have to be replaced.

In the end, we note that for long-term and trouble-free operation of constant velocity joints, it is enough to only periodically check the condition of the anthers, if a tear is detected, immediately replace them and wash the assembly.

With such measures, the CV joint can fail only with severe natural wear, but this will not happen soon.

How to identify a crisp CV joint

Finding out which “grenade” crunches is quite simple. First of all, you need to understand that the characteristic crunching or creaking noise when turning is produced by the outer CV joint. The inner joint may make a clicking noise on a straight road. We will touch on diagnostic algorithms below.

The crunching sound of the outer CV joint usually occurs when the driver turns with the wheels fully or strongly turned (in their direction). This is especially audible if you also “give on the gas” at this time. At this moment, the hinge experiences maximum or close to this load, and if it is faulty, then the mentioned sounds occur. Externally, this may manifest itself in the fact that you will feel “kickback” in the steering wheel when turning.

As for internal CV joints , their failure is more difficult to diagnose. Usually a similar sound comes from them when driving on an uneven road, and the deeper the holes the wheel gets into, the greater the load the joint experiences, and accordingly, the more it crunches. In some cases, a malfunction of the internal CV joint is diagnosed by vibration and “twitching” of the car during acceleration and at high speeds (about 100 km/h or more). Even when driving on a straight and level road (symptoms resemble a situation when the wheels are not balanced).

Next, let's move on to answering the question of how to determine which CV joint is crunching, internal or external. There are several verification algorithms. Let's start with the outer hinges.

Signs of malfunction when turning and accelerating

Symptoms of malfunctioning external and internal hinges manifest themselves in different ways.

It is quite simple to determine the wear of the outer CV joint by the characteristic crunch when turning, which appears when you start driving with the wheels fully turned, especially when starting at high engine speeds.

Additionally, vibration may occur on the steering wheel. When the wheels are aligned, the sound disappears. This is all due to the peculiarities of the operation of the hinges - as the angle between the shaft and the limit switch increases, the load on the CV joint increases, and if there are backlashes in it due to wear, then they lead to a crunch in the unit.

Internal hinges do not work at such significant angles as external ones, so they do not always make a crunching sound, which complicates their diagnosis.

Malfunction of CV joints installed near the gearbox often manifests itself in the form of vibrations and knocking in the front suspension when the car moves over uneven surfaces. Moreover, the more unevenness (deep holes, strong bumps), the stronger the knocks.

In some cases, symptoms of a faulty inner joint appear even when driving on a flat and straight stretch of road when accelerating to 100 km/h or above.

Definition of a crunching sound from an outer CV joint

Outer CV joint design

It is necessary to choose a flat area on which you can drive a car. Turn the wheels to one side as far as they will go and drive off quickly. This will put more stress on the hinge, and if it is faulty, you will hear a familiar sound. By the way, you can listen to it yourself (with the windows open) or with an assistant so that he is near the wheel while the car is moving. The second case is especially good for diagnosing right CV joints, since the sound from there reaches the driver worse. However, similar procedures can be carried out on the road or in the field, so as not to bother and look for an additional place for tests.

When turning the car to the left , the right outer CV joint will crunch , and when turning to the right , the left one . This is due to the fact that at this moment the corresponding hinges are the most loaded, since most of the mass of the machine is transferred to them, subject to the creation of significant torque. And the greater the load, the louder the sound. However, in rare cases the opposite happens. Therefore, it is advisable to listen to which side the noise is coming from, outside the car,

External and internal grenade (CV joint): differences and features

So, before checking the CV joints, it is necessary to separately take into account a number of features. First, the hinges can be internal or external. So, they rarely fail at the same time. In fact, the outer CV joint breaks more often. However, it cannot be ruled out that the problem is not, for example, the left internal grenade or the right internal hinge.

The design of the outer and inner CV joints is slightly different due to the different operating modes of these hinges

The outer CV joint is connected to the hub, and its main task is the need to transmit torque at any angle of rotation or inclination of the wheel. In turn, it is important for the inner joint to compensate for the misalignment of the transmission and the drive shaft, thereby partially relieving the outer CV joint. At the same time, the internal joint ensures complete “integrity” of the shaft, provided there is a large suspension travel

In other words, it is the inner CV joint that allows the drive shaft to become slightly longer or shorter under certain conditions. If you compare the hinges visually, the body of the inner CV joint is larger than the outer one. Due to this, the inner race of the CV joint can move along with the shaft and balls inside the housing along the tracks. Also, the inner hinge can be rotated at an angle, although less than the outer hinge. If we consider the outer CV joint, it is rigidly fixed to the shaft and is more responsible for the ability to turn. On some cars, the outer grenade is so firmly attached to the shaft that it must be cut off to remove it.

Also note that front-wheel drive cars have a transverse engine, that is, the gearbox is shifted to the left. The result is that the left drive shaft will be shorter than the right one. So, the longer right shaft is not always solid. There are options when it is made of two parts, which are connected using a suspension support (suspended bearing).

The fact that on some cars a tripod is used as an internal joint, rather than the usual type of CV joint discussed in the article, deserves special attention. In any case, the operating principle of the tripod is still similar and there are no fundamental differences.

How the inner CV joint crunches

Inner CV joint design

Internal hinges are diagnosed differently. To determine which CV joint is faulty, left or right, you need to find a straight road with significant potholes and drive along it. If the hinge is broken, it will “knock.”

Let us describe another interesting method for determining how the inner CV joint crunches, which consists in not hanging the wheels, but significantly making the rear part of the car heavier (put a lot of people in, load the trunk), that is, make the front of the car rise and the axle of the inner CV joint curved as much as possible. If in this position you hear a crunching sound while moving, then this is one of the signs of a malfunction of the mentioned unit.

Universal diagnostic method

Diagnosis of a malfunction of the internal CV joint

We present to you an algorithm for another, universal option, how to find out which “grenade” is crunchy. You need to act in the following sequence:

- Place the car wheels level.

- Raise one of the front wheels using a jack.

- Put the car on the handbrake and neutral gear.

- Start the engine, depress the clutch, engage first gear and slowly release the clutch, that is, “move off” (as a result, the suspended wheel will begin to rotate).

- Slowly press the brake pedal, creating a natural load on the joint. If one of the internal “grenades” is faulty, then at this time you will hear familiar knocking sounds on the left or right side. If the internal CV joints are in order, then the car will simply start to stall.

- Turn the steering wheel all the way to the left. Slowly press the brake pedal. If the internal “grenade” is faulty, it will continue to knock. If the outer left CV joint is also faulty, then sound will also be added from it.

- Turn the steering wheel all the way to the right. Carry out similar procedures. If a knocking noise occurs when the steering wheel is turned to the right, it means that the right outer joint is faulty.

- Be sure to put the gear in neutral, turn off the engine, and wait until the wheel comes to a complete stop before lowering it to the ground.

Why does the CV joint start to crunch?

Constant velocity joints, both internal and external, are quite reliable mechanisms, and with proper care their service life can be calculated in years. In some cases, it is even comparable to the service life of the entire car. However, this circumstance directly depends on the care and operating conditions of CV joints.

One of the reasons why joints fail prematurely is an aggressive driving style and/or poor road surface on which the car is driven. As mentioned above, CV joints experience maximum load during sharp turns and high torque from the engine (in other words, when the driver enters a turn “with gas”). As for bad roads, they can damage not only the car’s suspension, but also the CV joint, since a similar situation is created here. For example, the driver accelerates the car through the CV joint, and at this time the wheel oscillates significantly in the vertical plane. Accordingly, under such conditions the hinge also experiences increased load.

The CV joint crunched. Do-it-yourself CV joint repair

CV joint (Constant velocity joint, or simply “grenade” in common parlance) is a device that provides torque transmission with a rotation angle of about 70 degrees relative to the axis. CV joints are used in passenger cars, more precisely in drive systems with steered wheels, usually paired with independent suspension, sometimes found on the rear wheels.

What to do if the CV joint crunches, and what does this mean?

As a rule, the CV joint has a fairly large margin of safety, sometimes its life exceeds the life of the vehicle itself. Often, premature failure of this mechanism is associated with rupture of the protective cover, as a result of which dust mixed with sand and moisture gets onto the rotating parts of the hinge. Because of this, increased wear of all parts begins in the CV joint. It also happens that the boot is intact, but the cracking sound is very strong. This may indicate obvious problems that are caused by aging of the lubricant inside the mechanism. Sometimes when buying a foreign car with “decent” mileage (from 250 thousand km), owners interested in selling stuff the CV joints with pieces of rags or paper mixed with lubricant. All this “vinaigrette” will make itself known after 2-3 thousand km. If you ignore the crunching of the CV joint, then over time it will intensify, as a result of which wear will increase and the CV joint will simply need to be replaced with a new one, since parts with a large “wear” cannot be restored.

In order, as they say, to get to this ingenious mechanism, you should dismantle the axle shaft, loosen the boot clamps a little, and then pull it towards the axle shaft. In order to remove the CV joint from the axle shaft, you will need a hammer, but without fanaticism, please. And also a drift made of soft material (aluminum, copper, or wood). A CV joint is a rather complex product, despite the fact that it consists of only four elements: a knuckle, balls, a separator and a housing.

CV joint repair. Dismantling and replacement

First of all, you need to make marks for the general location of the outer, as well as the inner, frame; for this you will need to get a core or scriber, or something more modern - a marker or paint.

So, let's get started...

1. Clamp the hinge in a vice, then turn the inner part of the cage until it stops, then remove the balls in pairs. Help yourself with a screwdriver, tap with a hammer.

2. Once all the balls have been removed, install the separator in a vertical position so that its elongated windows can intersect with the end of the body.

3. After this, remove the fist with the separator. Rotate your fist, while recessing one of the protrusions located in the separator window, then separate these parts.

4. Inspect the parts after washing and drying them. If there are no chips or wear at the joints, as well as obvious scuffs and tarnish, the device will still serve. If any of the above defects are found on the parts, they must be replaced with new ones.

CV joint assembly

Assembling the mechanism, of course, follows in the reverse order, but before proceeding to this stage, everything must be properly lubricated. The inner race with the separator should be inserted into the outer one, also remember the marks that you put at the beginning. Place the balls in pairs, as when disassembling. Fill the hinge with CV joint-4 grease in a ratio of 80-100 g per hinge. As an alternative, litol is suitable, as well as other lubricating grease analogues. Don’t try to save money, you’re trying for yourself. The performance of the CV joint depends to a large extent on how much lubricant it contains. It wouldn’t hurt to put 40-50 grams directly into the case. When assembling the CV joint, knock out the hinge along the splines and put on the boot, then tighten the clamp. The purpose of the boot is to ensure good sealing of the hinge. When lubricating parts, rotate the CV joint to evenly distribute the lubricant inside. Make sure once again that it is assembled correctly - there should be no snagging or strong resistance when rotating.

The CV joint crunched. Do-it-yourself CV joint repair 2.3 (46.67%) 3 votes

Consequences of a CV joint crunch

Is it possible to drive with a CV joint crunching? It all depends on the degree of wear and tear. At the initial stage of the breakdown, you can drive, but it is not advisable , since the operation of the unit leads to even greater damage. Therefore, the sooner you try to repair the hinge, the, firstly, it will cost you less (perhaps everything will cost you by replacing the lubricant), and secondly, you will not put the life and health of you and your passengers in the car at risk.

So, the consequences of a CV joint crunching can be:

- Jamming . That is, the CV joint will stop rotating. This is especially dangerous at speed, as you risk losing control of the car, which can be fatal. You can try to wedge the hinge, but the best solution is to replace it.

- Clip break . If we talk specifically about an external grenade, then when it comes to the wedge, the clip simply breaks, the balls scatter, and then the consequences are unpredictable.

- Shaft or axle shaft rupture . In this case, the gearbox will turn only the designated parts, but for obvious reasons the torque will not be transmitted to the drive wheel. This is the most extreme case, and further movement of the car is possible only with a tow truck or tow truck. Naturally, the only correct solution in this case will be to replace the CV joint. And you will be lucky if you only have to change the hinge itself. After all, there is a risk that other parts nearby will be damaged during this accident.

In the worst case scenario, the CV joint can jam or break, which will lead to an emergency on the road. When this happens at speed, it is fraught with serious consequences! Therefore, if you hear that a “grenade” is crunching on any side of your car, carry out diagnostics as quickly as possible (on your own or at a service station) and repair or replace the hinge.

Additionally

Subluxation of the elbow joint

A very common injury in children is subluxation of the head of the radial bone in the elbow joint. Three bones connect at the elbow joint: the humerus, ulna and radius. To hold these bones together, there are ligaments. In young children, the ligaments are very elastic, loose and can easily slide down the bone. With age, the ligaments become stronger, and subluxation no longer occurs so easily.

This injury occurs when the child is pulled sharply by the arm: the father twists it, the child is simply abruptly lifted by the wrists (the child must be lifted, supported by the armpits), or it even happens that the parent leads the child by the hand, the baby slips, hangs on the arm - and subluxation occurs .

At the moment of injury, you can hear the joint click. Typically, when an injury occurs, a child experiences short-term sharp pain that goes away almost immediately. The main sign of injury is that the child stops bending his arm at the elbow - children keep the injured arm fully extended.

When should you contact a traumatologist?

Children often fall, hit, or get injured in one way or another. How to determine when you can get by with a patch and iodine, and when you need to go to the emergency room?

- Any cut or puncture wound should be shown to a doctor. Do not fill the wound with brilliant green or iodine! This will add a chemical burn to the cut. There is no need to apply cotton wool to an open wound - its fibers are then extremely difficult to remove from the wound. If the injury site is heavily contaminated, rinse with clean water. Then cover the wound with a clean cloth (sterile bandage, handkerchief, etc.), apply a pressure bandage and go to the emergency room as soon as possible. The doctor will perform initial surgical treatment of the wound, thoroughly clean it (you are unlikely to be able to do this on your own so efficiently), restore the integrity of all structures and apply a bandage.

- If noticeable swelling appears at the site of injury. This may indicate that it is not just a bruise, but also a fracture, dislocation or rupture of ligaments.

- If the child has lost consciousness, even briefly. This may indicate a traumatic brain injury, which can have serious consequences.

- If the child has vomited after the injury. Vomiting, nausea, and pallor also indicate the possibility of traumatic brain injury.

- If the child hits his head. The effects of a head impact may not be immediately noticeable, but can still have very serious consequences.

- If the child hits his stomach. A blow to the stomach may cause damage to internal organs and internal bleeding.

- If a child falls from a height (from a chair, table, etc.), falls from a bicycle, etc. It happens that it does not manifest itself externally, but the internal organs are damaged.

- If the child is worried, he behaves unusually.

In general, if you have any doubt, it is better to play it safe and see a doctor. Injuries in children are a matter of when it is better, as they say, to be safe than sorry. There is no need to be embarrassed or afraid that you are distracting emergency doctors or emergency room doctors over trifles.

Your child's health is the most important thing!

Caution: trampoline!

Trampoline is a very popular entertainment among modern children. Unfortunately, this fun can lead to serious problems. The most common injuries that children and adolescents receive on trampolines are compression fractures of the spine. Recently, there have been a lot of cases of compression fractures of the spine, including among those who professionally engage in trampoline sports.

There is no safe way to be on trampolines. A child, even without falling, can break his spine, since during jumping the spine receives very large axial loads. This is especially dangerous, of course, for children with weak muscles.

How to repair a CV joint

Damage to the internal parts of the hinge most often leads to a complete replacement of the mechanism. However, this only happens with significant wear. In most cases, it is recommended to simply replace the CV joint grease and boot. This is often enough to get rid of the annoying sound and make it easier for the parts to interact.

Therefore, if knocking or clicking sounds appear on one of the four CV joints (we will assume that you have already found out which one), you must perform the following steps:

New inner CV joint

- Drive the car into the inspection pit in order to check the integrity of the boots and the presence of lubricant splashes from under them on nearby surfaces.

- If traces of grease are visible on the boot or other parts, it is necessary to remove the CV joint. Next, disassemble it, remove the boot, wash the internal parts and surfaces, change the lubricant and boot.

- If during the inspection process you find significant play and/or damage to the working surfaces of the parts, you can try to polish them. However, as practice shows, this procedure is ineffective, since you cannot eliminate significant waste with anything. Therefore, the best recommendation would be to completely replace the CV joint .

You can replace the lubricant and boot yourself, as the procedure is simple. The main thing is, when disassembling, do not forget to wash all internal parts and surfaces with gasoline, thinner or other cleaning liquid. And only then apply new lubricant. However, if you are dismantling and replacing the lubricant for the first time, then it is better to have a more experienced car owner or technician with you. Or have him perform the procedure and show you its algorithm. In the future, you can easily cope with such work.

Conclusion

Constant velocity joints are reliable and durable mechanisms. However, during operation, it is necessary to constantly monitor their condition in order to determine in time which CV joint is crunching or making other unpleasant sounds. After all, this indicates a malfunction in its operation. Hinge failure at the initial stage is not critical . You can drive hundreds or even a thousand kilometers with a crunch. However, you should remember that the sooner you repair or replace the CV joint, the cheaper it will cost you. In addition, do not forget about safety. Do not bring the condition of the hinge to a critical state , as this threatens you with a serious emergency situation, especially at high speed. We hope that the above information helped you figure out what to do when the CV joint crunches and accurately determine which one is faulty.

Elimination of crunches and knocks, restoring the operation of CV joints

How to find out which CV joint is crunching - we figured it out, now about the measures that should be taken to fix the problem, since it is undesirable to operate a car with problematic joints.

One of the disadvantages of CV joints is their non-repairability, that is, if the joint crunches, then it is worn out and requires replacement. The only thing that can be done is to “extend the life” of the node and delay its replacement.

Since the main reason for the appearance of crunches is dust and dirt, when they appear, you should immediately inspect all the anthers for damage. If none are found, we determine which CV joint is crunching using one of the above methods.

After identifying the problematic hinge, we try to extend its service life. To do this you need:

- Remove the drive from the car;

- Disassemble the CV joint;

- Thoroughly wash all components with gasoline, solvent or other means (white spirit, etc.);

- Apply new CV joint grease or equivalents (see above) and assemble the hinge;

- Install a new boot;

- Install the rebuilt drive on the car.

At the initial stage of wear, these measures are enough to get rid of the crunches, but they will eventually return (when the wear intensifies) and then the hinge will have to be replaced.