Removing air from the power steering system on a KamAZ (correct “bleeding the steering”)

When filling the KamAZ power steering system with oil or after troubleshooting, it is necessary to remove air from it (“bleed” the steering).

To do this you need:

- Raise the front axle so that the wheels do not touch the ground. Using a jack, place trestles under the beam on both sides. But under no circumstances start pumping with the wheels standing on the ground. Or disconnect the longitudinal link from the steering bipod.

- Remove the pump reservoir filler cap.

- Remove the rubber cap from the steering gear bypass valve and place a transparent elastic hose on the spherical head of the valve, the open end of which is lowered into a glass container with a capacity of at least 0.5 liters. The vessel should be filled with oil to half its volume.

- Unscrew the steering gear bypass valve ½……3/4 turn.

- Turn the steering wheel LEFT until it stops.

- Pour oil into the pump reservoir until the level stops decreasing.

- Start the engine and, while operating at minimum crankshaft speed, add oil to the pump reservoir, not allowing the level to drop until air bubbles stop emitting from the hose placed on the bypass valve.

- Close the bypass valve.

- Turn the steering wheel to the RIGHT until it stops and back to the LEFT position. Keeping the steering wheel in the left position, unscrew the bypass valve ½……3/4 turn and again watch for the release of air bubbles. After the bubbles stop, close the bypass valve.

- Repeat the previous operation at least two times. As a result, clean (without air) oil should come out of the bypass valve. If the release of air bubbles continues, repeat the operation 1-2 more times, while monitoring the oil level in the pump reservoir, maintaining it between the marks on the level indicator.

- Stop the engine.

- Remove the hose from the spherical head of the bypass valve and place the protective cap on it. Check the oil level in the pump reservoir again and, if necessary, add oil. Install the pump reservoir filler cap. If you disconnected the longitudinal steering rod, install it in place.

The process of removing air from the system is complete.

Pumping power steering on a KAMAZ

In this part of the article we will talk about how to bleed the power steering on a KAMAZ. The air that remains in the hydraulic system elements after the procedure can cause incomplete operation of the power steering. To properly bleed the system, you must perform the following steps:

- using a jack, fix the front wheels of the car in the air;

- unscrew the allowance valve, which is located on ;

- turn the steering wheel all the way to the left;

- fill the pump with new oil;

- start the engine and fill the power steering tank with oil at the lowest speed until the air bubbles disappear from the hoses;

- secure the relief valve to the steering device;

- turn the steering wheel all the way to the right, then return it to the left and loosen the relief valve again to allow air to escape, and screw it back in;

- perform the last described procedure until clean oil begins to come out of the valve.

We will describe below how to bleed the power steering on a Gazelle, but for now let’s look at the process

Bleeding and adjustment of PGU and GUR on KamAZ trucks

KamAZ PGU is a device designed to reduce the level of pressure exerted by the driver on the clutch pedal.

PGU - hydraulic power steering of a KamAZ pneumatic clutch type.

Design and principle of operation

The PGU device includes:

- spherical type nut;

- lock nut;

- a piston pusher that deactivates the clutch system;

- a cover that protects against damage;

- piston;

- complex type seal;

- bypass and inlet valve;

- cork;

- fuel fluid supply;

- system for compressing air flow.

The diagram also includes the following elements:

- spring mechanism;

- gearbox;

- diaphragm seats.

The operating principle of the PSU is as follows:

- The driver presses the clutch pedal.

- Under the pressure of the fuel fluid, the rod and piston part of the mechanism are activated.

- Movement occurs until the intake valve opens.

- The air flow moves in the direction of the pneumatic piston.

- The fork is retracted and the clutch system is disengaged.

Bleeding and adjustment

In order to adjust the CCGT, it is necessary:

- Adjust the pedal free play. Lower the pedal until the master cylinder starts to operate. After this, debugging is done using an eccentric finger. The gap between the piston part and the pusher should not exceed 1.2 cm. At the end of the procedure, you need to tighten the castle-type nut tightly.

- Adjust the clutch free play. Move the fork handle, remove the spring mechanism and perform debugging.

Procedure for pumping:

- Clean the rubber protective cap of the bypass valve.

- Place a rubber hose onto the valve.

- Place one end into a glass container with working fluid.

- Press the pedal jerkily 3 times, and the fourth time, while holding the pedal, loosen the bypass valve.

- As soon as the release of air bubbles from the liquid stops, you need to close the bypass valve and remove the hose.

Disassembly and repair

Repair of a CCGT unit involves its disassembly. To disassemble the mechanism with your own hands, you need to:

- Place the pneumatic power steering in a vice and clamp the rear housing.

- Unscrew the bolts and remove the air supply cover.

- Remove the amplifier valve from the front housing.

- Remove the spring and diaphragm.

- Pull out the thrust ring and piston part.

- Unscrew the mounting breather and remove the cover from the seal.

- Pull out the retaining ring.

- Remove the seats and washer.

- Remove the cuff.

- Installation and assembly of the KamAZ PGU is performed in the reverse order.

Possible malfunctions of the PSU:

- The drive is jammed. In this case, it is recommended to flush all hydraulic system elements and change the oil.

- The clutch is lagging. Use higher quality fuel fluid (for example, meeting Euro-5 standards). If this does not help, replace the piston seal.

- The clutch hisses and there is no boost. Inspect the intake valve and replace if necessary. It is also recommended to inspect the cuffs and the follower piston ring.

Adjusting pressure in KAMAZ power steering

Installing EUR on UAZ 469

It is necessary to begin this operation by determining the force in the 3rd of the above positions. Using the adjusting screw, you need to bring the force back to normal. When this screw rotates in a clockwise direction, the force increases and vice versa.

To adjust the force in the 1st position, it is necessary to partially disassemble the steering mechanism to tighten or loosen the nut used to secure the bearings. To eliminate the factors causing the force to not correspond to the norm in the 2nd position, it is necessary to completely disassemble the power steering.

When checking the pressure in the power steering in the section of the pressure line located between the steering mechanism and the pump, you should use a device that includes a pressure gauge whose scale reaches 9810 kPa, as well as a valve that stops the flow of oil to the power steering.

When checking the pressure, you need to open the valve, then turn the steering wheel to the stop position and apply at least 98.1 Newtons to it. The oil pressure when the crankshaft rotates at 600 rpm must be a minimum of 7355 kPa.

When the oil pressure is less than 7355 kPa, slowly close the valve while monitoring the level of pressure increase using a pressure gauge. When the pump is in good condition, it should increase to a minimum of 8336 kPa.

Signs of malfunctions in the power steering system

There are several signs that the power steering system is airy, in which case it is necessary to bleed it. Among them:

- the appearance of strong noise in the area where the power steering or its pump is installed;

- increased pressure on the steering wheel , difficulty turning it;

- leakage of working fluid from the power steering system.

In addition, there are several other signs that indicate the system is becoming airy - the appearance of foam on the surface of the working fluid in the expansion tank, spontaneous turns of the steering wheel to one side. If you encounter at least one of the described symptoms, it means you need to bleed your power steering.

Why might the power steering act up?

Bleeding the power steering system is necessary to remove air from the system when there is increased noise under the hood. You should pay attention to this feature: if the car hits an obstacle, then the wheels experience resistance, which tends to turn them around. The wheels close the drain line, and the working fluid moves into the cylinder. The piston enhances the action of the wheels working in reverse. In this case, the system prevents the wheels from turning. If the pump is turned off, the driver will feel the steering wheel become heavier, but the car can be driven even in this case.

The power steering system may show the following signs of malfunction: loud noise under the hood, increased pressure on the steering wheel, fluid leakage

. Increased noise may occur due to the presence of air in the system; the situation requires bleeding. It is necessary to bleed the power steering system when air gets into it during repairs or depressurization. This happens when the steering wheel jams (sharp turns, the pump makes noise when turning, the liquid is foamy). We suggest performing this operation yourself, let's think about how!

How to pump power steering

How to fill oil and bleed power steering

The procedure for replacing fluid and pumping power steering is carried out in strict accordance with the existing algorithm. Some automakers may add their own features to it. If you have a manual for your car, we recommend that you read the relevant section. In general terms, the steps must be performed in the following sequence:

- Raise the vehicle completely on a lift or with the front wheels off the ground.

- If necessary, drain the old fluid from the expansion tank. To do this, remove the return hose (going to the power steering system) from the expansion tank and put a plug on it so that liquid does not spill out of the hose. A hose leading to an empty bottle is connected to the released tap on the tank, where the old hydraulic fluid is supposed to be drained.

- It is most convenient to pump out the main volume of liquid with a syringe and pour it into a separate bottle. When there is very little liquid left, move on to the next point.

- Fill the expansion tank with working fluid to the top.

- Next, you should turn the steering wheel from side to side (from lock to lock) several times so that the old fluid remaining in the system flows out through the hose. Since the new fluid displaces the old, do not forget to monitor the oil level in the tank so that air does not get into the hose.

- If the fluid level drops, add it again.

- Start the engine for 2-3 seconds and turn it off. This is done so that the liquid begins to spread throughout the system.

Changing the power steering fluid

The fluid in the power steering system needs to be changed when it becomes dirty, as well as after using the car for six years. How to perform this simple procedure?

- First of all, you need to unscrew the pressure hose that leads to the steering device, while keeping the nut from turning.

- It is necessary to bleed the fluid from the power steering system without starting the engine, turn the steering wheel right and left until it stops until fluid stops flowing out of the pressure hose. Then reattach the hose to the pump.

- Fill the system with fresh fluid.

- Start the engine. At this time, the liquid will leave and be distributed throughout the system. Fill the system with liquid until its level remains the same.

- Bleed the power steering system.

The fluid in the power steering is PSF type oil intended for power steering.

Power steering fluid must have the following properties:

- oil operating temperature 110 degrees C;

- the presence of additives to improve the quality of work under pressure;

- constant viscosity under different loads;

- no foam;

- preventing rust.

Typical power steering malfunctions

Malfunctions in the operation of the hydraulic booster can be easily identified by characteristic signs. Among them:

- The steering wheel turns hard . Probable causes are failure of the power steering pump, use of unsuitable working fluid, sticking of the spool mechanism channels.

- , a high-frequency sound (similar to a whistle) is heard while driving The probable cause is a loose drive belt.

- The steering wheel turns jerkily . Probable causes of the malfunction are the working fluid not meeting the specifications declared by the manufacturer, a malfunction of the fluid distributing mechanism, or a pump malfunction.

- The presence of intense foaming in the expansion tank. Probable causes are mixing of different types of fluids, failure of the power steering pump.

- When the engine is running, the steering wheel spontaneously turns in any direction . The probable cause is malfunction of the spool mechanism, most often, clogging of its working channels, incorrect assembly (for example, after installing a repair kit).

Recommendations for operation and maintenance of power steering

In order for the power steering and its system to operate normally, as well as to extend their service life, you must adhere to several simple rules:

- use working fluids recommended by the automaker , and also replace them in a timely manner (most automakers recommend replacing power steering fluid every 60.120 thousand kilometers, or once every 2 years, it depends on the driving style and intensity of use of the car);

- carry out bleeding of the power steering system in strict accordance with the algorithm described above (or observing individual requirements, if any are set by the car manufacturer);

- monitor the condition of the steering rack boot , because if it is torn, dust and dirt will enter the system, which leads to the power steering pump exiting. A sign of a problem that has already occurred is the hum of the power steering, which is not eliminated even by replacing the fluid.

Cost of replacing fluid and pumping power steering

If you plan to carry out work on replacing the fluid and pumping the power steering yourself, then you will only need to buy oil in a volume of 1 to 3 liters (including flushing, while the volume of the power steering system of a passenger car is up to 1 liter). The price of the liquid depends on the brand and store. It is within $4.15 per liter. If you do not want or cannot carry out such work yourself, contact a service station for help. Approximate prices for January 2021 are:

- fluid replacement work - 1200 rubles;

- power steering pumping - 600 rubles.

Common power steering failures

We'll tell you how to bleed the power steering below, but for now let's look at some typical malfunctions and solutions for the power steering system:

1. Unstable movement of the car on the highway; it is necessary to periodically correct the direction of the car with additional movements of the steering wheel.

Possible causes and solutions:

- presence of free play of the steering wheel - if it exceeds the permissible threshold, then adjustment is required;

- wear of the steering gear screw pair elements; if wear is present, the screw pair must be replaced.

2. Damage to the pump filter, or contamination: air has entered the hydraulic system, signs of this fact: cloudy oil and the presence of foam in the tank. To solve the problem, it is necessary to flush and bleed the system, then change the filter.

How to bleed the power steering on a KamAZ - The design and principle of operation of the hydraulic booster on a KamAZ

It’s hard to imagine how the truck would handle if it weren’t for the KamAZ power steering system. The operation of the parts and mechanisms of this device has become familiar to a heavy unit. The unit helps the user apply minimal force to turn the steering wheel. In addition, a number of complex functions are performed that affect the safety of the machine.

Each mechanism is subject to wear and tear, which will lead to loss of performance. Hydraulic power steering is no exception; the condition of the unit affects other components of the engine. That is why timely maintenance is important to maintain the performance of the amplifier.

The weak link in the steering is the hydraulics. The entry of air bubbles into the channels of the mechanism can stall the work and create an emergency situation. In order to respond to an emergency situation in a timely manner, an experienced user knows how to upgrade the power steering on a KamAZ and restore functionality.

Power steering KAMAZ

How to properly bleed ABS brakes

Power steering is an important and practical mechanism of any truck, greatly facilitating the already difficult work of the driver. Read about the design features of the power steering on KAMAZ, its typical breakdowns, rules and operating recommendations.

Not every driver of a passenger car really appreciates power steering (hydraulic power steering), taking it for granted: “well, the steering wheel turns easily and without strain, but what happens otherwise?” How it happens! A faulty power steering on a KAMAZ means heavy efforts with every turn of the steering wheel; After a few kilometers of riding like this, your arms simply fall off from fatigue. It would seem that such a small and inconspicuous mechanism, but plays such an important role. It is about this device that we will tell you in more detail.

Power steering: definition, design and functions

Power steering is a hydraulic system that is an integral part of the steering mechanism and serves to make driving easier.

The main functions of the power steering are:

— ensuring the stability of the given trajectory of movement; - reducing the effort the driver makes to turn the steering wheel;

— maintaining feedback between the steering wheel and wheels.

The power steering consists of the following systems and mechanisms:

— a distributor that directs fluid flows in the cavities of the system; — a hydraulic cylinder, which converts fluid pressure into the work of the rod and piston; — working fluid, which is necessary to lubricate friction pairs and transmit pressure from the pump to the hydraulic cylinder; — a pump that maintains a given pressure and fluid circulation; — connecting hoses that connect all elements of the system;

— an electronic unit that regulates the operation of the hydraulic booster.

Operation of power steering on KAMAZ

In order for the power steering to last for a long time, you must follow several recommendations:

— regularly (once a week) check the oil level in the system; — change oil and oil filters at least twice a year. If the color of the oil changes before the appointed time, change it immediately; — do not allow the vehicle to be used if there are leaks in the power steering system and eliminate them as early as possible;

— adjust and check the tension of the drive belt.

Typical power steering faults

The KAMAZ power steering is characterized by several main types of breakdowns. We will focus on the most common malfunctions and the reasons for their occurrence.

Unstable movement of the car on the road (it is necessary to constantly level the car with additional manipulations of the steering wheel):

- check the free play of the steering wheel - if it is too high, adjust it; - make sure that the parts of the steering gear screw pair are not worn out - replace them if necessary;

- sometimes the cause of unstable vehicle movement is jamming of the reaction plungers in the body of the power steering control valve or spool. In this case, it is necessary to wash the parts and eliminate the cause of the jamming.

Damaged or clogged pump filter:

— air trapped in the hydraulic system (signs: cloudy oil and foam in the tank) — rinse and bleed the system, replace the filter; — the manifold gasket is damaged or the manifold itself is bent.

Uneven or insufficient operation of the power steering. The reasons may be the following:

— excessive tension in the gearing — adjust the steering mechanism, bring the force to normal; — clogging of the pump filter or wear of parts of the pumping unit. It is necessary to disassemble the mechanism and replace worn parts; — violation of the tightness of the check valve of the steering mechanism;

— presence of air in the system — remove the air by bleeding the system.

Purpose of the hydraulic power steering

The purpose of power steering is to reduce as much as possible the user's force applied to the steering wheel. In addition, the operation of KamAZ power steering affects stability when driving at low speeds. When moving quickly, in order to avoid an emergency, the amplifier creates additional resistance on the steering wheel. This stabilizes the ride along the road and keeps it on course.

The peculiarity of the power steering on the KamAZ-4310 and other models is that if the mechanism breaks down or fails, control of the vehicle is not lost, but remains in working order. The only drawback is that the user is forced to turn the steering wheel with greater force when turning the vehicle.

KamAZ power steering device

An amplifier is a set of parts and mechanisms combined into a closed system. The element bases are:

Directs streams of liquid (lubricant) into the nozzles, channels and cavities of the power steering.

- Volumetric hydraulic motor of reciprocating motion of a cylindrical shape.

The product converts the pressure generated by oil into the mechanical action of pistons and rods.

The working fluid, which is oil, is poured into the KamAZ power steering. The lubricant transmits force to the hydraulic cylinder from the pump. The material also prevents wear of surfaces, acting as a lubricant and sealant.

- Hydraulic power steering pump KamAZ-65115, etc.

The mechanism serves as a guarantor that maintains the level of constant pressure necessary for the normal functioning of the system. In addition, the pump constantly moves lubricant through the cavities and lines of the device.

Parts help connect and close parts, mechanisms, assemblies into one device.

The mechanism controls the operation of the system, analyzes and distributes efforts across work areas.

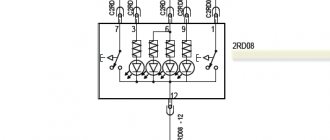

KamAZ power steering diagram:

Power steering pump

The pump is considered the main device of the amplifier, since it creates pressure for the KamAZ power steering, without which operation is not possible. The mechanism is mounted in the area of the power plant frame. The pump is powered by a motor and is driven by a gear transmission. The creation of lubricant pressure in the system occurs due to the blades with which the pump is equipped. The unit performs 2 cycles of fluid intake and release per revolution of the steering wheel. You can also read about the KAMAZ cab tilting (lifting) pump.

Principle of operation

By turning the wheels of KamAZ-5410 and others, the rotor blades perform rotational movements and are adjacent to the stator. The parts that coincide with each other form passages into which lubricant is supplied and passes further due to the resulting pressure. The formed pressure pushes the liquid through the lower valve due to the fact that the oil, at the moment the passages of the distribution disk and the surface coincide, goes beyond the products.

Power steering pump KamAZ-65116, etc.:

The oil enters the rotor blades, having previously passed through the distribution disk. Due to the pressure, the blades adhere more strongly to the stator. The inlet and injection of liquid occurs simultaneously in two directions. An increase in rotor speed prevents the passage of lubricant through a calibrated hole from the area located behind the disk. The resulting pressure acts on the bypass valve, forcing it to open. As a result of valve activation, part of the working fluid passes through the manifold and again enters the suction surface.

KamAZ power steering malfunctions

The advantage of the product is that KamAZ power steering malfunctions appear due to violations of operation and maintenance. Mechanism repair is a rare occurrence, but if breakdowns do occur, they occur at sub-zero temperatures.

Since the amplifier involves mechanics that interact between devices via hydraulics, faults are divided into:

- Mechanical type;

- Hydraulic type.

Replacing the KamAZ power steering oil seal:

Temperature changes negatively affect the hydraulics of the mechanism. Minus values make the working fluid thick, which increases the load on the oil seals and joint seals of the KamAZ-65222 vehicle, etc. The impact of increased pressure leads to oil leaks.

Violation of operating rules negatively affects the components and mechanisms of the amplifier. To extend the service life of the hydraulic booster, you need to take a competent approach to operation. So, leaving the car in the parking lot, the wheels of the vehicle are set to a level position. Otherwise, uneven load on the oil seal will lead to damage.

During the warm season, dirt and dust pose a danger. The penetration of abrasive particles into the mechanism of KamAZ-65117 and other models leads to increased friction and wear of the surfaces of parts. The impact entails depressurization of the system, wear of bushings, rods and other components.

Moisture seeps into the resulting gaps, causing rust on unprotected parts and causing increased wear. Operating the amplifier with similar problems leads to knocking in the steering rack, after which only replacing the KamAZ power steering will help. In order not to go to extremes, you need to tune the amplifier on time. The procedures performed are adjustment and pumping of the device.

How to bleed power steering on a Gazelle

Bleeding the power steering system on a Gazelle car is required in the following cases:

- when air enters the system;

- after performing repairs, which were accompanied by depressurization of the system.

Procedure for removing air from the system:

- Fill the power steering system with hydraulic fluid.

- Lock the handbrake in the upper position and place brake pads under the rear wheels of the car. Raise the front of the machine.

- Set the steering wheel to a straight position. Start the engine.

- Turn the steering wheel to the right until it stops. At this time, air bubbles will appear in the fluid reservoir.

- Turn the steering wheel all the way to the left to release any remaining air from the hydraulic system.

- Repeat the procedure until air bubbles stop appearing in the tank. If necessary, add fluid to the maximum mark.

With these simple procedures you will extend the life of the power steering system on your car and will enjoy comfortable driving for a long time.

Pumping the KamAZ hydraulic booster

If the mechanism has been repaired or filled with fluid, the next mandatory action is to pump the KamAZ power steering. The procedure is performed to eliminate air bubbles trapped inside the amplifier. If the air is not eliminated, the useful effect of the hydraulic control will drop sharply.

Power steering diagram of a KamAZ car:

- Raise a car with a KamAZ-740 engine, or another model, so that the wheels of the car hang in the air. For this purpose, support the beams on supports.

Important. If at least one wheel is on the surface, the procedure for bleeding the hydraulic power steering is not carried out.

- Dismantle the filler plug of the expansion tank neck; Remove the rubber pad from the exhaust valve. Install the rubber tube in the vacant space, dip the free edge of the product into a container with lubricant in an amount of about 1/2 liter;

- Unscrew the transfer valve one-half turn;

- Turn the steering wheel all the way to the left, pour lubricant into the expansion tank;

- Start the power plant and let it idle. At this time, with the engine running, pour lubricant into the conservator reservoir, without allowing the level to drop. Make sure that no air bubbles come out of the valve tube - close the valve;

- Alternately turn the steering wheel to the right and left. Make sure that the steering wheel remains stationary, unscrew the bypass valve 1/2 turn. Check to see if any air bubbles come out. When air does not flow, tighten the valve;

- Repeat the procedure, bleeding the power steering in a similar way as many times as required. A sign of the end of the process is the release of clean liquid from the free end of the hose without air impurities. If bubbles continue to come out, regulation is continued until the bubbles disappear completely;

- Turn off the power plant, remove the pipe, install the cap, diagnose the level of working fluid in the expansion tank, and add oil.

We repair and adjust the power steering on a KAMAZ with our own hands

The hydraulic steering control system is an integral part of any KAMAZ, since without it, steering the vehicle will be, if not impossible, then very difficult. Thanks to this unit, the driver can turn the steering wheel with greater ease. You can learn more about what the KAMAZ power steering system is and how to de-air it from this material.

Content

[ To uncover]

[Hide]

Characteristics of power steering

First, let's look at the main characteristics of the power steering on a KAMAZ 6520 or any other model. Let's start with the purpose and device.

Purpose

The main purpose of the power steering system is to minimize the effort used to turn the steering wheel when steering, as well as performing many maneuvers when driving at low speeds. In addition, thanks to the power steering system, the impact on the steering wheel will be more noticeable if the car is moving at high speed. If the power steering fails for some reason, this will result in the driver having to exert significantly more effort to turn the steering wheel.

General diagram of the KAMAZ steering control operation

Device

Now let's briefly look at the power steering device.

This system consists of the following elements:

- Switchgear. This component is used to direct the flow of working fluids, in particular hydraulic oil, into the lines and cavities of the system.

- Hydraulic cylinder. This device performs the function of converting hydraulic pressure into mechanical work of pistons and rods.

- The working material in this case is hydraulic fluid. With its help, force is transferred from the pump to the hydraulic cylinder. In addition, thanks to the liquid, all rubbing components and components of the system are lubricated.

- KAMAZ power steering pump. Thanks to this device, the pressure required for normal operation is constantly maintained in the system. This element is also used to circulate the working fluid.

- Connecting elements or lines. They are used to bring together all the working components of the system.

- Control device or electronic unit. With its help, direction and adjustment of the operation of the amplifier are carried out.

Photo gallery “Main elements of the power steering system”

Features of the pump

The pumping device is installed in the collapse of the BC. Domestic trucks use a gear top drive, but the device itself is of the blade type. In accordance with the technical documentation, this unit is characterized by double action, that is, with one turn of the steering wheel it carries out two cycles of suction and discharge.

Let's take a brief look at the operating principle. When the wheel turns, the rotor blades begin to rotate, which, in turn, are pressed against the stator device. Working fluid begins to flow into those blades that, when pressed, coincide with the holes on the body. Further, thanks to the same blades, the consumable material enters the narrower holes that exist between the stator and the rotor.

At the moment when the working surfaces can coincide with the holes on the distribution disk, the consumable material will come out beyond it. Next, the oil will pass through the lower valve; for this, high pressure is formed in the system.

The working fluid, leaving the cavity behind the distribution disk, will flow onto the rotor blades, as a result of which they will be pressed even more tightly against the stator plane. The process of pumping the substance, as well as its absorption, is carried out simultaneously in two places. As the number of revolutions of the rotor device increases, liquid from the surface behind the disk will not pass through the calibration hole. By creating pressure in the system, the bypass valve is opened, and part of the consumable material, through the manifold, is again supplied to the suction surface (the author of the video about replacing the hydraulic booster on a KAMAZ is Mathur Malay).

Common power steering faults

It must be said right away that repairing KAMAZ power steering is a procedure that our compatriots do not encounter so often. If the driver follows the basic rules for operating the unit, and also carries out its maintenance in a timely manner, then the likelihood that it will fail will be minimized. As practice shows, problems with the performance of the hydraulic booster mainly arise in the cold season. In general, all malfunctions can be divided into mechanical and hydraulic failures, both of which can occur in any part of the device.

As you know, any hydraulic system most often exhibits malfunctions in frosty conditions, in particular, temperature changes. After all, you need to remember that the pumping device pumps high pressure, so if the viscosity of the liquid in the system increases, this will lead to the squeezing out of the seals and, accordingly, its leakage. The problem of oil seals is especially evident in cars whose drivers do not follow operating rules, for example, leaving the car in a parking lot with the wheels twisted. This will lead to the fact that after starting the engine, the pressure will increase only on one side, accordingly, the oil seal will squeeze out in any case.

As for the warm season, in summer malfunctions usually appear as a result of dirt and dust getting into the system. If any part is depressurized, the wear of the bushings, as well as the rods, will be faster. Rods usually rust quite quickly, resulting in accelerated wear of the bushings. When operating a car with such a problem, after several hundred kilometers, there will be a large gap between these elements, and this, in turn, will lead to the steering rack starting to make a knock (author of a video about repairing the system in a garage - channel EIGHT ATMOSPHERE).

How to remove an air lock from the system?

The need to bleed the system usually arises after refueling it or eliminating breakdowns in the operation of the unit. Air entering the lines leads to less efficient operation of the hydraulic booster, so the only solution in this case is to remove the air.

So, how to bleed the power steering:

- First you need to move the front axle so that the car's wheels do not touch the ground. Using a jack, you should place supports under the beam on both sides. If the wheels are on the ground, bleeding of the system cannot be started.

- Then you need to remove the filler cap of the expansion tank located under the hood.

- Next, the rubberized cap should be removed from the bypass valve, and an elastic pipe should be installed on its head. In this case, its open part should be lowered into a glass container, the volume of which will be at least half a liter. The vessel itself should be filled halfway with the working fluid.

- Then the bypass valve should be opened slightly, half a turn.

- After completing these steps, turn the steering wheel to the left all the way. After this, the working fluid is poured into the expansion tank until its level decreases.

- Then you need to start the power unit, and while it is operating at minimum speed, pour a little liquid into the expansion tank, but without allowing the level to drop. Do this until bubbles stop coming out of the pipe that is installed on the bypass valve. After this, the valve itself can be closed.

- Next, the steering wheel should be turned all the way to the right, and then to the left. And holding the steering wheel in this position, again unscrew the bypass valve halfway and observe whether bubbles come out of the pipe. When they stop coming out, the valve can be tightened.

- This operation must be carried out several times, ultimately a clear liquid will come out of the valve, in which any impurities or air bubbles should be absent. If bubbles continue to come out, the procedure should be repeated several more times, but do not forget to monitor the volume of working material in the expansion tank.

- Then all you have to do is turn off the motor and remove the pipe from the valve head. Put the cap on the head itself, and then again diagnose the volume of liquid in the tank. If there is a need, it will need to be added. Further assembly of all components is carried out in reverse order.

Video “Assembling and adjusting the hydraulic system on a stand”

The process of assembling and adjusting the power steering using a special stand is presented in the video below (the author of the video is the Zavod Avtoagregatov channel).

avtozam.com