Adjusting the KamAZ clutch basket

By adjusting the clutch basket we mean adjusting the tabs placed on the basket. This debugging can be done with the box removed or adjusted directly on the car.

When performing the task without removing the box, you will need a homemade tool, which is a 3.5 mm thick wire with a 20 mm long end bent at a right angle. Using such an improvised feeler gauge, check the gap between the release bearing and the support ring of the clutch feet. The gap is adjusted using a nut on the PSU rod. You can bring the paws to the ring through the hatch in the upper part of the clutch housing. At the same time, it is important to ensure that the paws fit as uniformly as possible to the surface. But it is more correct and reliable to adjust the clutch removed from the engine.

To do this you need:

- Place the assembled pressure plate on the template, which will provide a gap of 29 mm.

- Loosen the mounting bolts.

- Set the position of the stop ring for the feet. All four paws should touch the ring at the same time.

- Check the runout of the working surface of the disk.

- Lubricate the front bearing located in the crankshaft.

- Install the clutch using a mandrel, which will ensure alignment of the mechanism discs and the engine shaft.

This adjustment is carried out only with a double-disc clutch. A unit with one disk does not need such adjustment.

The video from the Auto and Moto channel shows the removal of the clutch and clearly shows the design features, as well as the drive for the operation of the mechanism.

Stages of work

It is advisable to adjust the clutch basket in compliance with existing recommendations, strictly adhering to the order of work.

The first stage is adjusting the pedal

According to technical standards, the clutch pedal should move freely, without encountering resistance, by 6-12 millimeters. If this indicator has changed, then it needs to be restored. This work is performed by adjusting the gap between the pusher of the pneumatic hydraulic booster. To do this, you need to rotate the eccentric pin.

The second stage is debugging the coupling

Its stroke should be within 3.2-4 mm. The check is carried out as follows: the fork is moved to the side manually and the spring is removed. Next, using a spherical nut, the required range of motion of the coupling is set. You can also read about Ruchnik on KamAZ.

The third stage is adjusting the pusher stroke

If it is not enough, it means that the mechanism will not completely shut down, that is, the disk will not be disconnected from the motor. The normal stroke is approximately 25 mm. You can check it by first depressing the clutch pedal until it hits the bottom.

There are two ways to fix the existing problem:

- adding fluid - the corresponding marks on the cylinder tank indicate that it is not enough;

- bleeding - the method is to remove excess air from the system. You can pump it using a regular pump, hose, glass or plastic bottle.

If, after carrying out all the work described above, the problem with the clutch basket has not gone away, you will have to resort to a more complex measure - replacing this mechanism.

Photo gallery

The photographs below show some elements of the clutch drive system of a KamAZ truck.

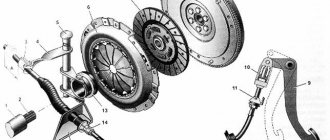

Conventional double disc clutch

Euro single disc clutch

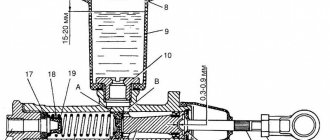

Classical PSU

Clutch cylinder, the rod for the pedal and the fitting for supplying fluid to the PSU are clearly visible

Debugging the full stroke of the amplifier pusher

Before starting to debug the mechanism, it is necessary to find out the stroke length of the pusher. To do this, you need to completely disengage the clutch and measure the stroke. If its value is 25 mm or less, then the clutch will not disengage completely. The driver will notice this problem immediately by the difficulty of shifting gears. To find the cause of the problem, you need to check the level of working fluid in the pusher cylinder. The standard volume is 380 cubic meters. see. If the level of the substance is insufficient, it should be topped up.

Hydraulic system diagram

Using the KamAZ 5511 model as an example, adding fluid is done as follows:

- You need to open the reservoir cap located on the drive housing.

- Add liquid to a level 15-20 mm below the edge of the neck.

The second reason for unsatisfactory operation of the amplifier may be air in the system. In this case, the drive system must be bled. This procedure is somewhat more complicated.

On KamAZ 55102 for this you need:

- Add fluid to normal level.

- Remove the protective cap from the bypass valve (installed on the CCGT housing), put on a rubber hose and lower it into a container with liquid.

- Sharply press the clutch pedal all the way.

- Open the valve one turn and press the pedal until the substance stops bubbling at the outlet of the hose. In this case, it is necessary to constantly add new fluid to the supply tank, not allowing it to fall below the 40 mm mark from the top of the tank.

- Close the valve, remove the hose and replace the cap.

- Add fluid to the operating level.

- To control the quality of work, you must press the pedal all the way - the pusher stroke should not be less than 25 mm.

Work related to clutch replacement

It is recommended to replace the basket if the following shortcomings are found:

- even after adjustment, the car jerks and starts abruptly;

- extraneous sounds in the basket were and are still present;

- the car “thinks” for a long time and does not immediately start moving, despite the fact that the clutch was depressed according to all the rules;

- There is a characteristic burning smell in the cabin - this indicates that the clutch mechanism has simply burned out.

This activity begins with removing the gearbox. This is a very heavy unit that requires several people to work with. After this, you can begin to dismantle the clutch basket.

We see how the clutch discs on KamAZ are arranged - first the driven one, then the middle one, then the driving one. They are all removed. New parts are installed in place of dismantled parts. How to correctly install clutch discs on a KamAZ:

they must be installed in a strict order - initially the first slave comes, then the middle one, and at the final stage the leader;

- since this is a dry type of clutch, there is no need to use any lubricant, this will only worsen the quality of the mechanism;

- instead of traditional discs with friction linings, you can install more modern ones equipped with ceramic elements - they are much more reliable and durable;

- carefully tighten all bolts and nuts. Due to heavy loads, poorly tightened fasteners can become loose over time.

You only need to install clutch discs on a KamAZ yourself if you clearly understand what exactly you are doing. This is a difficult task; if you lack experience or lack the necessary tools, it is strongly recommended to seek help from specialized specialists.

Video “Adjusting the clutch on KamAZ”

The video, shot for the Auto and Moto channel, demonstrates the adjustment of the clutch installed on a KamAZ 740 diesel engine.

Do you have any questions? Specialists and readers of the AUTODVIG website will help you ask a question

Was this article helpful?

Thank you for your opinion!

The article was useful. Please share the information with your friends.

Yes (88.89%)

No (11.11%)

X

Please write what is wrong and leave recommendations on the article

Cancel reply

Rate this article: ( 9 votes, average: 4.89 out of 5)

Discuss the article:

How to extend clutch life

Timely maintenance extends the life of the basket, an expensive and complex mechanism. First of all, you need to know how to properly adjust the clutch on a KamAZ. Check the pedal travel from time to time, because you don’t need to disassemble anything to do this. All accessible mechanisms and components must be lubricated.

Holding the pedal down for a long time to stop, for example, to slip, is categorically not recommended - this increases the load on the mechanisms and, accordingly, accelerates their wear.

Ignoring detected clutch problems is guaranteed to lead to deterioration in the functionality of the entire machine. The logical conclusion of such neglect will be the failure of the gearbox, the repair or replacement of which will cost a tidy sum. Failures of other KamAZ transmission mechanisms and components are also possible.

The proven quality of the cars will not let the driver down if the mechanisms are regularly serviced. Attention is paid to adjusting the KamAZ clutch, since the device performs many functions. The mechanism separates the gearbox from the motor when changing gears, then connects them to minimize gear tooth impact. Using the module, the load on the transmission is reduced when the speed changes.

What is the price

The purchase price of individual mechanisms is high, so it is better to adjust the clutch system by correcting the shortcomings of existing parts.

- A Euro 2 clutch disc, depending on the type, costs 1500-6000 rubles;

- shutdown fork included - RUB 3,860;

- piston group, depending on the manufacturer and brand of KamAZ - 6,000-25,000 rubles.

In order to perform clutch repairs infrequently, you need to regularly perform technical inspections and maintenance of the machine.

«>

Basic information. Clutch functions

The operation of the clutch is based on the influence of sliding friction (friction clutch). Together with the transmission of torque, it ensures smooth gear shifting, damping of torsional vibrations, and short-term disconnection of the transmission from the engine flywheel. The clutch compensates for vibrations and loads from uneven engine operation, reducing their negative impact on various elements of the engine and transmission.

The clutch briefly disconnects the crankshaft of the internal combustion engine from the power transmission of the machine. This is necessary for smooth shifting of gears in the gearbox and for braking the car, until it comes to a complete stop. The clutch also makes it possible to move off smoothly, without jerking.

The equivalent of a clutch on tractors and armored vehicles are friction clutches.

Many different types of clutch were invented, but the most popular were mechanisms based on one or more friction discs, which are tightly compressed by springs with each other or with the flywheel.

The friction material that makes up clutch linings is similar to that used in brake pads. Previously, asbestos was used for its production, and in recent years, asbestos-free material has been used.

The clutch is installed between the internal combustion engine and the gearbox, and is one of the busiest elements of the transmission.

Maintenance

In addition to settings, the clutch of KamAZ vehicles requires regular maintenance, since this significantly increases the service life and reliability of the mechanism on all KamAZ brands.

Using model 53215 as an example, maintenance consists of the following main points:

- Checking the tightness of the amplifier mounting bolts in the clutch drive circuit.

- Monitoring the tightness of hydraulic lines. There should be no oil stains on them.

- General check of serviceability of pedal assembly parts. All elements must be in good condition and not have large gaps in the connections.

- Checking the presence of lubricant in the clutch bearing and fork connection bushing. To supply oil in the clutch housing there are three points equipped with grease nipples. Oil is injected into them using a syringe.

- Draining condensate from the CCGT housing.

- Checking the fluid level in the amplifier reservoir.

When is clutch replacement required?

If all the work performed does not lead to the restoration of the clutch mechanism, then this becomes one of the signals to replace it.

Other signs of critical wear of structural elements are:

- sudden turning on of the disks, resulting in a hard jerk of the car;

- difficulty engaging all gears, accompanied by a characteristic crash;

- sluggish acceleration of the car, while the engine speed clearly does not correspond to the selected gear and speed;

- smell of burning pads when driving.

If such problems occur, it is necessary to stop moving as soon as possible and repair the mechanism. Continued operation of the vehicle with faulty or burnt-out clutch discs will lead to failure of the gearbox.