The design and principle of operation of the clutch pedal

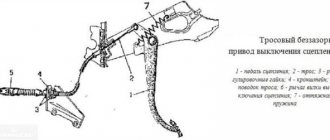

1 — release bearing guide sleeve; 2 — gearbox input shaft; 3 — cable lead; 4 — clutch release fork; 5 — fork axle bushing; 6 — pressure disk assembly (basket); 7 — driven disk; 8 - flywheel; 9 — clutch pedal ; 10, 11, 12 — mechanism for automatic adjustment of cable length; 13 — release bearing; 14 — clutch cable; 15 — cable stop

What happens when we press the clutch pedal.

We press the clutch pedal (9), at this moment the clutch cable (14) is tensioned, which moves the clutch release fork (4), the fork rotates on the axle bushing (5). The fork presses on the release bearing (13), which in turn presses the paddles in the clutch basket (6), and the paddles are connected directly to the pressure plate, which is located inside the basket. The basket is bolted to the flywheel (8), and the flywheel is rigidly connected to the engine crankshaft and always rotates when the engine is running. The pressure plate presses the driven disk (7) against the flywheel. The driven disk is located between the basket and the flywheel on the splines of the input shaft of the gearbox (2) and when the clutch pedal is released, the driven disk is clamped, thereby ensuring the clutch of the engine with the gearbox, and then with the entire chassis. When the clutch pedal is pressed, the drive disc releases the driven disc (7) and the engine's traction with the wheels is released.

Clutch actuation moment

Perhaps it will immediately become clear to you at what exact moment, when releasing the clutch pedal, the load on the engine occurs, and in order to get the car moving, we must try to hold the clutch pedal and prevent the engine from stalling. And to increase the traction force of the engine, we press the gas pedal.

It will be necessary to achieve slipping of the clutch discs by operating the pedal - which leads to a smooth transition of engine speed to the wheels.

But this is not enough - you need to firmly grasp the moment of coupling. You can't do this without training.

When we begin to release the clutch pedal, during the slightest actuation of the clutch we will immediately press the pedal again.

When you release the clutch pedal, approximately until the middle of its stroke, the pedal goes to idle, therefore, before the clutch is activated, the pedal can be released faster. In the future, you will, unnoticed by yourself, skip the idling pedal. The idle speed is designed to give you time to set up for work.

The clutch process itself occurs within an interval of no more than one to two centimeters of pedal travel. But you will need to directly capture the moment the clutch operates.

Repeat this procedure several times to figure out in what position the clutch starts to engage, preventing the engine from stalling.

Try not to strain your leg too much, but rather try to feel the process at the level of anticipation. When starting off, try to press the clutch pedal again and again in order to quickly grasp this moment and let your foot get used to it.

If you do not allow the clutch to fully engage with the pedal, the car will begin to move smoothly.

At the same time, without releasing the clutch pedal, but rather even pressing it a little, slipping of the discs should prevent rapid acceleration, but should not lead to a stop.

This is interesting: How to tighten the Daewoo Matiz alternator belt

Driving capabilities with correct clutch pedal operation

Once you figure out at what point the clutch engages, you will need to achieve a smooth ride when starting off.

With proper operation of the clutch pedal, you can achieve:

- the most minimal speed,

- when parking or reversing, in order to have time to turn the steering wheel in the right direction,

- during other maneuvers requiring minimum speed, both forward and reverse

To achieve a minimum driving speed, practice taking off on a straight section and immediately pressing the clutch. After pressing the clutch pedal, your car will coast and, without touching the gas pedal, try to slowly release the clutch, the car will begin to slow down, the so-called engine braking, and press the clutch pedal again. And you can do this as much as you like until you stop completely.

Just try not to make the engine jerk, so to speak, “coughing.” The engine must run smoothly. This is how you can use the clutch to reduce the speed to a minimum. You can drive without even pressing the gas pedal or with minimal gas supply.

As soon as you begin to catch this moment when the car starts moving, or feel the load on the engine by sound - this is the moment the engine’s work is transferred to the rotation of the wheels, then everything else is a matter of technology.

The clutch mechanism experiences stress almost all the time during vehicle operation. It depends on the road conditions, how loaded the car is, how you learn to control the clutch when changing gears and starting, and driving in general.

Learn to change gears in a timely manner, according to road conditions.

First of all, you don’t need to “gas” too much when starting from a stop, but “gas” only to support the engine’s operation.

THESE ACTIONS SHOULD BE POSTED IN YOUR HEAD AND FURTHER IN YOUR HANDS AND LEGS.

Practice thoroughly to catch this clutch moment.

What not to do with a manual transmission

A manual transmission is a reliable type of transmission, but improper operation can significantly reduce its service life and lead to significant damage.

What not to do with a manual transmission:

- engage reverse gear until the car comes to a complete stop (manual transmission failure);

- depress the clutch except for the moments necessary to change gears (increased wear of the release bearing and clutch occurs);

- keep your foot on the clutch pedal while driving (leads to increased wear on the clutch);

- select a high gear (3,4,5) when the speed and low revs are insufficient for this (increased load on the engine and gearbox);

- When stopping for more than 40 seconds, depress the clutch; select neutral gear (increased clutch wear);

- change gears without squeezing the clutch (manual transmission failure);

- constantly keep your hand on the gearshift lever (increased wear of various gearbox mechanisms);

- incomplete clutch release when changing gears;

- dropping the clutch.

If you follow some rules and drive thoughtfully, the experience of driving a car with a manual transmission will come quickly, despite the apparent complexity of such a transmission.

The main advantage of a car with a manual transmission is complete control over it, which is realized only after driving kilometers.

Tip 5: How to learn to drive a manual car

The majority of Russian car enthusiasts are owners of cars with a manual gearbox (MT).

Most driving schools teach driving on just such vehicles. Therefore, the problem arises of how to learn to drive a car with a manual transmission. Helpful advice

All manual transmissions have a neutral position. Unlike other gears, driving on it is impossible. But if you put it in neutral and release the clutch pedal, the engine will not stall. This is very useful when driving in urban conditions, when you have to stand at traffic lights and in traffic jams, relieving stress from your legs.

Source

Starting a car on a hill

Many novice drivers experience serious difficulties when starting a car on an incline. But, knowing the principle of operation of the manual transmission clutch and the sequence of actions, they will do it much more confidently. This sequence of actions can be used when the handbrake in the car does not work well:

- the clutch and brake pedals are initially depressed with the engine idling;

- the clutch pedal is slowly and smoothly released until the engagement of the clutch disc and transmission is felt, at which point the car begins to tremble;

- the foot is removed from the brake pedal, but the car will not roll backwards, since the clutch acts as a brake;

- the gas pedal is pressed and the car begins to roll forward.

Why does a partially released clutch replace the brake pedal? This effect is the result of the captured force balance between the force of gravitational attraction and the static friction force of the wheels. Their immobility is ensured by the balance of the engine force that pushes the cars forward and the same static friction force. But such work with the clutch when stopping increases wear on the friction material of the clutch disc.

How the clutch works and how to depress the clutch

Press your palm against the sofa and pull it towards you, slowly reducing the pressure on your palm. The less you push, the less you drag the sofa with you.

The clutch pedal of a new car works throughout almost the entire pedal stroke. As this unit wears out, the useful pedal travel will decrease. In training cars, as a rule, the clutch operates far from the floor. By the way, I must say that the clutch pedal is quite tight, and as you get older it doesn’t get any easier.

All starting exercises should be performed strictly on a straight line, where the distance in front and behind to the nearest obstacle is at least 30 meters. Otherwise, learning to touch may end badly. The front wheels must be strictly straight.

Let's start mastering the pedal. Get into the car. Make sure that the car is on the handbrake and that the handbrake itself is holding the car properly. After this, depress the clutch pedal with your left foot and engage third or fourth gear. In first gear the car can go, but in third or fourth it will stall rather than go anywhere. This is what we need. The pedal is depressed, the gear is engaged. We begin to smoothly release the clutch pedal. There is no need to press the gas yet. As smoothly as possible. The release limit should be the sag of the car. The revs will also start to drop. Of course, such an exercise will not improve the health of the car, but it will also do little harm. You need to study. I taught my wife this way in my personal car. The most important thing is to act gently. So we have found the limit. The revs began to drop and the rear of the car began to squat. Now press the clutch pedal to the floor and repeat the exercise. The more we train, the more often and more accurately we should hit that very moment of drawdown. It happens that the clutch is lowered more than necessary, and the car is about to stall, but instead of panicking, quickly correct the situation by lightly pressing the pedal. Once you get the hang of it, get out of the car and walk around a bit. Then sit down and immediately engage the gear and release the clutch pedal. Don't forget to check the handbrake. Just make sure it's up and don't touch it for the entire exercise. If you do everything with concentration, then after 30-40 minutes you should be able to squeeze the clutch right away and right on target. A big plus will be the pure execution of the technique “start the car, squeeze the clutch, engage the gear, release the clutch to the operating threshold, squeeze the clutch, disengage the gear.” The next day, review what you learned today.

By the way. The clutch can be ruined if it overheats. Therefore, after several attempts, give the machine a rest. You can even turn off the engine.

If you succeed in this exercise, you need to master the skill of sudden braking. First you need to learn to slow down at least somehow, the main thing is on time. How to develop the skill of sharp braking is described in detail in this article: mastering the skill of braking. Until you read this article, don’t read any further.

This is interesting: How to understand that a CV joint has died

What is a car clutch

Structurally, the clutch (friction clutch) in a car is designed to connect and disconnect the engine shaft with an automatic or manual transmission.

This allows you to move away without sudden jerks and ensures smooth gear shifting on the move, preventing overload of the transmission components due to changes in the crankshaft speed.

There are different drive designs for transmitting force from the pedal to the pressing mechanisms, such as mechanical, hydraulic and electric.

Tip 3: How to learn to drive a car

Studying at a driving school is the basics, and perfection comes with kilometers behind the wheel. At a driving school you will only be given a theoretical and practical knowledge base, which will be very difficult for you during your first days on the road. Improving your skills should be done with an experienced person who can point out mistakes and teach you how to perform elements and technical nuances.

Instructions

Where is the clutch located in a car?

The purpose of the clutch is to transmit torque from the engine crankshaft to the gearbox, so structurally it is located between these two units.

The specific location may depend on the layout of the base units, front-wheel drive or rear-wheel drive transmission, but in any case it will be at the front of the car under the hood.

Car clutch device

Being a connecting unit for transmitting rotation, the design of a friction clutch in a car is not particularly complicated.

The main components are: Pressure disk - has release springs at the base and is designed to connect to the flywheel. Due to its petal design, it received the title “basket” for its similarity in appearance. The driven disk has a coupling, a radial base and linings.

Special damper springs help reduce shaking when switching. Release bearing - located on the input shaft and drives the drive fork. Some designs may use locking springs for a more secure fit.

Clutch pedal - with the help of it, the driver from the cabin controls the work process, transmitting instructions to connect or disconnect the engine drive shaft and gearbox. In cars with an automatic transmission (automatic transmission) there is no pedal; the system operates using a special servo drive.

Modern car manufacturers offer customers different design options for friction clutches. Differences may relate to: number of disks - single or multi-disk systems; work environments – dry or wet options; drive - mechanical, hydraulic, electrical methods; method of pressing the pressure disk - clutch with a central diaphragm or springs in a circle.

Why is a clutch needed in a car?

It’s very simple to understand how a car’s clutch works - while the pedal is not pressed, the drive and driven disks are in contact, transmitting torque from the engine flywheel to the gearbox, and then through the driveshaft to the wheels. Pressing the pedal disconnects the discs, rotation is no longer transmitted, and the driver can change gear. Then you need to slowly lower the pressure so as not to burn the friction clutch if the discs contact too sharply, and it is important not to hold the pedal down for too long.

Clutch operating principle

In words, this is explained simply - the friction clutch ensures the interaction of the engine flywheel and gearbox, ensuring their separation for changing gears.

But how much time does it take for novice drivers to master in practice how to properly depress the pedal so that there is a smooth and soft start from a standstill without jerking or jerking.

It will take more than one hour until the car enthusiast starts driving well, but we should not forget that maneuvers on the road can ruin the clutch of your car.

Causes of malfunctions

Knowing the principle of operation of the car’s clutch, the car owner will be able to determine its malfunctions.

When the clutch does not disengage completely due to large free play, you need to adjust this very move by removing air from the hydraulic drive. If you feel the clutch slipping due to small free play, then you need to adjust the pedal travel or replace the discs and springs. Due to jamming of the drive in the mechanism, the clutch may suddenly engage. To eliminate the problem, it is worth replacing faulty components or eliminating scuffs on the disks.

And another common problem is brake fluid leaking from the main or working cylinder. The problem can be fixed after the leak has been found. Faulty components are replaced with new ones, not forgetting to pump the hydraulic drive.

Car with manual transmission

Photo: clutch pedal - left side

In a car, the clutch pedal is located in the leftmost position of the three pedals - the pedal in the center is the brake, the pedal on the right side is the gas, the left pedal is the clutch - and with its help the driver controls the connection of the engine to the gearbox.

Manual operation requires more attention compared to automatic, but for many users this is a matter of habit and a matter of price.

A car with an automatic transmission will be much more expensive to purchase and maintain, which is why many drivers choose cars with manual controls that have a clutch pedal.

Correct use of the clutch pedal

It will be useful for a beginner to learn how experienced motorists use a car clutch correctly and how the clutch works.

By applying simple recommendations in everyday driving, a beginner will achieve mastery much faster if he learns to change gears correctly and engage the desired speed, reducing the load on the tires and brake discs.

This applies to such driving moments as short stops, for example, at traffic lights and on turns.

How to properly depress the clutch

In essence, the correct use of a friction clutch involves the precise execution of two interrelated operations - the pedal must be pressed and then released.

Simple tips will tell you how to properly squeeze the clutch:

The pedal is pressed all the way and without delay. Since the main thing is experience, it is better not to waste time on training, finding a suitable platform for this and hiring an experienced driver for the company.

At the very beginning of training, shoes are important - to make the sensations more pronounced, they should have thin soles and no heels.

How to release the clutch correctly

By releasing pressure on the pedal, the driver begins to connect the engine flywheel and the driven disk to transmit rotation to the gearbox.

This must be done very carefully and smoothly - there are several recommendations for novice car enthusiasts on how to release the clutch so that the ride is as comfortable as possible:

The pedal should not be depressed for a long time; the pedal should be gradually released without sudden thrusts, pausing slightly when it is pressed halfway.

The car must start moving from first gear. You can start from second gear only in winter, when the road or some sections of the road are very slippery (if you start on slippery ground in first gear, the wheels will slip and it will be difficult to move at all).

Video: How to properly use the clutch in a car

Anti-lock braking system

Another discovery of the modern automotive industry is the anti-lock braking system ABS. When you press the brake pedal sharply, the car's wheels will not skid, but will remain under the control of the car computer.

Under normal road conditions, a vehicle equipped with ABS has a significantly reduced braking distance. Extreme situations, when the wheels of the car skid or slip, are minimized. A car equipped with an ABS system does not skid.

If your car has such a system, questions about proper braking with ABS are unnecessary, just start braking. At some points on a slippery road surface or in other difficult road conditions, the brake pedal begins to tremble and put pressure back on the driver's foot. There is no need to worry, the ABS system is working, continue to brake confidently.

A number of car models are now equipped with a button to turn off the ABS system. Sometimes seasoned car owners use this function. But even for them, we do not recommend turning off the system! If your car does not have such a button, but you still need to disable the ABS, then this can be easily done by removing the fuse responsible for its operation.

There is an opinion that the use of the ABS system leads to an increase in braking distance. This opinion will be correct only under the following conditions:

- The road surface is uneven and loose . For example, gravel or sandy surface, deep snow. Under such conditions, a car not equipped with ABS will most likely “burrow” and stop moving if the wheels are blocked. It is in such conditions that experienced motorists use the function of disabling the anti-lock braking system.

- “Bald” tires . Driving on such tires becomes much more dangerous in a car equipped with ABS.

ABS has a number of irrefutable advantages that make braking easier in difficult conditions:

- There is no need to make a series of quick and intermittent presses on the brake pedal - the ABS is activated with 1 long press

- The car remains under full control of the driver.

- Even sharp maneuvering at higher speeds is now possible, since the ABS braking system is more sensitive and confident.