Knocks and extraneous noises

Rattling, tapping and other noises during switching on may be due to:

- Sufficiently large settlement, defects or damage to the damper springs (vibration damping mechanism);

- wear (depletion) of openings for damper springs;

- deterioration or damage, deformation of the linings;

- loosening the fastening rivets securing the linings;

- deformation or damage to the HP surface.

All of the above problems are eliminated when replacing the VD with a new analogue. In some cases, extraneous noise may be caused by a lack of lubrication, or damage due to wear, or significant deformation of the release bearing housing. Accordingly, to eliminate the malfunction, you will have to replace the bearing.

Pedal squeaking can occur in two cases:

- lack of lubrication on plastic bushings;

- high wear (wear) of bushings.

For lubrication, CV joints-4 or Litol-24 are usually used. When replacing damaged elements with new analogues, they must also be treated with lubricant. It very rarely happens that the fork can bend strongly as a result of deformation and then the clutch pedal simply cannot be pressed. In such cases, it is recommended to simply replace the damaged part.

Node improvement

In order to bleed the clutch system, you will have to completely remove all the old parts of the assembly. The factory design itself is unreliable, so you shouldn’t hope that replacing 1-2 elements will change anything. If you don’t want to spend a long time with repairing the Gazelle, then replace everything at once.

It is not recommended to use structural elements from one GAZelle model to another. For example, the clutch basket from 406 is also suitable for 402 gazelle, but during operation there are difficulties with switching to 5th gear and reverse gear.

Experimentation is not recommended. It is best to carry out replacement at a trusted car service center. It is worth finding out about the quality of the service in advance, because if something is installed incorrectly, you will have to redo it. You can install the components and the entire assembly yourself, but this will require a platform or several jacks, which not every driver has.

Clutch not fully engaged or not engaged

Slipping usually appears when you sharply press the gas, when the speed increases, but no noticeable acceleration is observed. In this case, a characteristic burning smell may appear. If slippage is detected, which indicates that the clutch is not fully engaged, the reason should be sought in the following:

- the surface of the flywheel, pressure plate (pressure plate) or linings is oily;

- increased production (wear) or burnout of linings;

- insufficient rigidity of the diaphragm spring;

- swelling of the cuffs of the main cylinder (main cylinder), which leads to a slow return of the piston.

First wipe oily surfaces with gasoline or white alcohol, and then dry them thoroughly until completely dry. You should also find out the cause of the oil leak. This may be a violation of the engine or gearbox seals.

If the friction linings have become unusable, replace the HP with a new analog assembly.

Insufficient rigidity of the diaphragm spring does not provide sufficient force for hard contact, which is why slippage occurs. Simply replace the “basket” (pressure plate) with a new set along with the housing.

To restore the performance of the master cylinder, you can replace the cuffs or purchase a new spare part assembly.

The clutch does not disengage when the flywheel sticks to the disc. This sometimes happens when the car is parked for a long time. You need to break the disc by starting to move without pressing the pedal. After accelerating, depress the pedal and brake sharply.

I have a GAZ-3110, I recently noticed that the clutch pedal has become higher, what should I do?

March 9, 2015, 14:20 #1

The pedal became higher and the clutch began to slip.

Eastern region of Voronezh region

9 March 2015, 17:51 #2 + 1

Who turned on the pedal for you? Try releasing the rod on the pedal until it moves freely. If it doesn't help, change the clutch.

March 9, 2015, 21:34 #3

ajirkov36, March 9, 2015, 17:51, #2

Who turned on the pedal for you? Try releasing the rod on the pedal until it moves freely. If it doesn't help, change the clutch.

First you need to check the adjustment on the working cylinder and then get to the rod on the pedal

Toyota Fortuner SR5 Nissan X-Trail T-30

March 10, 2015, 00:06 #4

Denis174, March 9, 2015, 14:20, #1

The pedal became higher and the clutch began to slip.

The check valve in the clutch master cylinder, which allows fluid to drain into the reservoir, became clogged, so the pedal became higher and the clutch began to slip. You just need to remove and wash the clutch master cylinder and change the dirty fluid too. Good luck!

March 10, 2015, 10:21 #5

Denis174, March 9, 2015, 14:20, #1

The pedal became higher and the clutch began to slip.

The bushings and the attachment of the master cylinder to the pedal may be worn out.

Opel Mokka X Suzuki S-Cross GL

March 10, 2015, 11:14 #6

How can it become taller on its own if no one tightened the stop screw?

March 10, 2015, 11:34 #7

Topicstarter apparently no longer needs our advice - it appeared and disappeared forever. And I will also say that this is another “miracle behind the wheel”, for which it is easier to go online than to stick your hand to the clutch pedal and feel how this very rod spins there from the pedal to the clutch master cylinder - after all, it just had the lock nut unscrewed on it.

March 10, 2015, 11:35 #8

Toyota Fortuner SR5 Nissan X-Trail T-30

March 10, 2015, 11:48 #9

Guys, what are you talking about, what does the locknut have to do with it! If it were unscrewed, then the rod, under the action of longitudinal forces, would, on the contrary, rotate clockwise, since the thread is right-handed and would be wrapped even more into the tip. The pressure on the rod is always greater than the return force and therefore the pedal would sink even more, and not rise as in his case. And the clutch began to slip, but otherwise it would, on the contrary, not be depressed and the gears would not be engaged. The same garbage sometimes happens with brakes when the pads jam due to non-return of the rod in the main brake. The poppet return valve just sometimes gets clogged here and there, it takes about three kopecks to clean.

March 10, 2015, 12:04 #10

Do you know how to read the conditions of the problem? The pedal has become higher. That is, the rod has become longer. It could only get longer by twisting it out!

If you claim that the pedal could have gone up for another reason, take it to the studio!

Eastern region of Voronezh region

March 10, 2015, 2:43 pm #11

64region, March 9, 2015, 21:34, #3

First you need to check the adjustment on the working cylinder and then get to the rod on the pedal

On the worker, the rods are usually without adjustment. Until the 2000s they came with adjustments.

Opel Mokka X Suzuki S-Cross GL

March 10, 2015, 15:14 #12

actros, March 10, 2015, 12:04, #10

Do you know how to read the conditions of the problem? The pedal has become higher. That is, the rod has become longer. It could only get longer by twisting it out!

If you claim that the pedal could have gone up for another reason, take it to the studio!

the pedal rests in the upper position against the bolt stop; if you do not touch it, the pedal will remain in its place

or am I confusing something?

Toyota Fortuner SR5 Nissan X-Trail T-30

March 10, 2015, 15:57 #13

actros, March 10, 2015, 12:04, #10

Do you know how to read the conditions of the problem? The pedal has become higher. That is, the rod has become longer. It could only get longer by twisting it out!

If you claim that the pedal could have gone up for another reason, take it to the studio!

Not the rod has become longer, but the pedal has become higher because the rod has moved back along with the “piston” pushing it. Read more carefully for yourself - the clutch began to SLIPP, have you ever wondered why all of a sudden? Spontaneous twisting of the rod does not roll at all, otherwise the clutch would move and not slip. I hope there is no need to explain the difference between “driving” and “slipping”?

March 10, 2015, 16:49 #14

“because the rod moved back along with the “piston” pushing it.”

The piston has its own place in the cylinder; when the pedal is released, it cannot be at rest in another place of the cylinder - further or closer. The spring inside always pushes it back - as long as there is free play of the pedal.

10 March 2015, 16:54 #15

In the case of this topic, it turns out that the car always drives with the clutch pedal slightly pressed (the piston has not reached the rear wall) - so it slips.

10 March 2015, 17:31 #16 + 1

Let me finish by reminding you that the rod cannot leave the body of the master cylinder - there is an expansion inside it larger than the hole. The pedal is pulled back by its spring and can eventually reach the bolt that limits its stroke. With proper adjustment, it does not reach the bolt - the rod is holding. But when the lock nut of the rod is unscrewed, the pedal, with the help of a spring, begins to pull the rod out of the cylinder. Of course, it cannot get out, but now it is already capable of spinning. So it lengthens, unscrewing. Now the pedal has rested on its bolt and the rod continues vibrations spin, pushing the piston further into the cylinder. The piston has already blocked the hole in the reservoir and the liquid is not completely released after the next press - here you have axle box when moving.

Jerking when engaging the clutch

Characteristic jerks at the beginning of movement after engaging the clutch can mainly be caused by the following circumstances:

- sticking of the hub on the shaft splines;

- disc deformation;

- wear, wear, damage and weak fastening of the linings;

- weak elasticity of the plates;

- failure of the damper spring;

- the appearance of scoring on the contacting surfaces of the basket and/or flywheel.

The hub may stick if there is heavy dirt, wear or damage to the shaft splines. First, you should clean the parts and inspect them carefully. If necessary, replace damaged elements with new spare parts.

If wear and insufficient fastening of the linings, changes in the shape of the disk, weak elasticity of the plates and/or springs are detected, a new disk must be installed.

When scoring appears on the working surfaces, as a rule, the flywheel or basket with casing is replaced.

Clutch not disengaging

When disengaging is difficult or the clutch is slipping, the causes of the malfunction can most often be due to the following points:

- insufficient (too short) pedal travel;

- presence of air;

- weak fastening of the linings;

- wear or scoring on the surfaces of the HP and flywheel;

- erasing overlays;

- distortion or damage to the ND;

- hub sticking;

- VP jamming;

- Damage or wear out of the diaphragm spring.

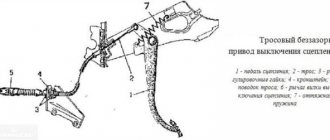

First of all, if the clutch does not disengage, you should adjust the drive or install a new fork instead of the damaged part.

If air gets into the system, bleed it and check the connections. Inspect the system; if any deformation or damage is detected, replace them with new analogues.

Before you start adjusting

Clutch adjustment is carried out only if the unit is fully operational. The GAZelle's clutch is very fragile and often breaks even due to slight overload, so problems can arise even before any adjustment work begins. Not the highest quality production technology has become the main reason why parts of the assembly fail almost one after another. It is worth checking whether all elements of the clutch structure are intact before starting other work. What you need to check most carefully:

- The working cylinder often breaks. It is worth checking first of all for leaks, breakdowns, and damage to the hoses. If it does not work properly, the gear shift system will slow down, and this may cause other driving problems (jerking, loss of speed).

This is what the Gazelle clutch slave cylinder looks like