Any internal combustion engine requires proper cooling. Without it, the motor will simply overheat, as a result of which the moving elements will instantly fail. The engines of modern cars are equipped with a liquid cooling system, which provides for constant circulation of coolant (coolant), achieved through the operation of a water pump (pump). Whatever coolant is used in the engine, prolonged heating will invariably lead to boiling. To prevent this process, a radiator is used in the cooling system. It is a system of thin tubes equipped with special lamellas that increase the area of the cooler.

When the car is in motion, the air flow hits the working surface of the radiator and passes between the lamellas, cooling the metal. Thus, the coolant temperature gradually decreases.

However, the radiator is not able to cope with overheating on its own, especially if the car is stationary or moving at low speeds. He is helped in this by an electric fan, which turns on automatically when the coolant reaches a certain temperature.

If it fails, the engine inevitably faces overheating with all the ensuing consequences. In this article, we will talk about possible reasons why the cooling fan does not turn on, as well as how to identify and resolve the related problems.

What is a radiator fan

To begin with, let us note that all the information provided is more intended for VAZ owners, although it can also be useful for drivers of foreign cars.

The VAZ cooling fan is an ordinary electric motor powered by 12 V from the vehicle’s on-board network. Its shaft is equipped with an impeller that generates a powerful air flow and directs it to the working surface of the radiator. The fan is mounted on a special frame (frame) to the front part. At the rear it is protected by a radiator grille.

Most VAZ cars are equipped with one fan. But there are also exceptions. For example, the NIVA cooling fan has two independent electric motors with an impeller that turn on simultaneously. This is necessary so that the engine of a domestic SUV cools faster.

Radiator fan device

A car fan for an internal combustion engine cooling system has at least four blades, which are mounted on a single common pulley. The blades are located at a certain angle relative to the plane of rotation. This is done for the most efficient intake and subsequent supply of air. There are no strictly established patterns in the design of the fan, although the most common design has become one that includes an impeller with 8 blades.

Drive types

The radiator fan may differ in drive design. Existing types are divided into:

- mechanical;

- hydromechanical;

- electric;

Mechanical drive

Such a drive is a design that is essentially a permanent drive from the crankshaft of the power plant. This drive is the simplest and is implemented using a belt drive. The main disadvantage of a mechanical drive is the power taken from the unit, which is spent to ensure constant rotation of the fan. Today, mechanical drives are practically not used in cooling systems on civilian cars.

Hydromechanical drive

This type of drive is a solution that is implemented by installing a viscous coupling (viscous coupling) or a hydraulic coupling. These couplings are constantly driven by the engine crankshaft. In order to keep the fan blades intact when the internal combustion engine is operating at maximum speed and high crankshaft rotation speed, the fan impeller is connected to the pulley via a hydraulic or viscous coupling. There is also a definition of a thermal coupling, which depends on the design features.

The clutch may become partially or completely blocked due to the increasing temperature of the fluid with which it is filled. Silicone is such a filling fluid. The increase in temperature occurs as a result of increased crankshaft speed and increased load on the engine. The clutch is blocked and the cooling fan begins to rotate. A hydraulic coupling differs in design from a viscous coupling and is blocked depending on the amount of oil in the coupling.

It turns out that the viscous coupling is often filled with silicone gel, which has the ability to change its properties under the influence of temperature. Silicone oil is poured into the coupling in an amount of about 30 or 50 ml. Clutch blocking affects the fan rotation speed regardless of the engine crankshaft speed. If the power unit reaches high speed mode, then the clutch slows down the rotation of the impeller, thereby protecting the fan from destruction at high rotation speeds. The main task of all types of couplings, which differ in operating principles and design features, is to maintain the fan rotation speed within strictly limited limits. The viscous coupling provides the speed range that the impeller needs for the most efficient cooling.

As already mentioned, mechanically driven fans have become rare, but have not completely disappeared. Such a device can still be found on some car models that have a longitudinally located power unit. Another segment of cars in which the installation of a fan with a similar type of drive is widespread and justified is powerful SUVs. Such machines are able to overcome water obstacles and are prepared for operation in conditions of extremely high humidity. The fact is that any electronics fails after contact with water, and viscous couplings are completely sealed devices and are not afraid of moisture.

Electric drive

The active development and implementation of electronic control and monitoring devices for various systems during engine operation has led to the emergence of an electrically driven radiator fan. This drive has a separate electric motor and its own control system. The controller allows you to set the intensity of the impeller operation and flexibly change the speed and duration of fan rotation based on the readings of the temperature sensor. The sensor measures the temperature of the coolant in the internal combustion engine. This solution not only increased efficiency, but also made it possible to achieve improved uniformity of engine cooling compared to systems that are based on the use of a viscous coupling.

How does the fan turn on?

The device turns on differently in different models. In cars with carburetor engines, it starts after the coolant reaches a certain temperature (105-107 0C) and the fan switch (not to be confused with the coolant temperature sensor), which sends a signal to the relay, is triggered. It closes the electrical circuit, supplying power to the electric motor.

The cooling fan circuit for cars with an injector is slightly different. Everything here is controlled by an electronic unit. Information from the switch-on sensor is first analyzed by the controller, and only then transmitted to the relay.

Video card coolers

The reasons why the GPU cooling system stopped working are generally similar to those for the previously discussed case, but in the overwhelming majority this indicates a breakdown of the device. You can learn more about the sources and solutions to the problem in the following article.

Read more: Video card fan malfunction

We are glad that we were able to help you solve the problem. In addition to this article, there are 11,991 more instructions on the site. Add the Lumpics.ru website to your bookmarks (CTRL+D) and we will definitely be useful to you. Thank the author and share the article on social networks.

Describe what didn't work for you. Our specialists will try to answer as quickly as possible.

Possible fan malfunctions

If the fluid temperature has reached a critical value, but the radiator cooling fan does not work, it means that there is a problem somewhere. Our task is to find it and eliminate it. Let us indicate the most common malfunctions due to which the cooling fan does not work. There aren't that many of them.

- The fan motor has failed.

- The integrity of the wiring supplying the electric motor or connecting the fan switch sensor is damaged.

- Poor contact in the motor or sensor connectors.

- The cooling fan fuse has blown.

- The fan relay is faulty.

- The sensor is faulty.

- Malfunctions in the operation of the safety valve of the expansion tank.

What to do if the radiator cooling fan does not work

Making sure that the radiator cooling fan has failed and is not working is quite simple. To do this, you need to start the car engine and let it idle for some time. When the dashboard shows that the coolant temperature is approaching the critical zone, the sensor will notify the radiator fan so that it starts working. At this moment, the driver will hear additional noise from under the hood, and when he opens it, he will see that the fan impeller is spinning near the radiator.

If the coolant temperature has reached a critical value, and the radiator cooling fan does not turn on, you need to find out why this is happening. The following are the main reasons why the radiator cooling fan does not work:

Problems with the electric motor. If the electric motor fails, its rotor will not spin, and accordingly, the impeller will not rotate. You can check the performance of the electric motor by connecting it directly to the battery. To do this, you will need to take two wires, connect them to two battery terminals and two electric motor terminals. If the fan does not spin when connected directly to the battery, we can conclude that the electric motor needs to be replaced;- Problems with the sensor. If the sensor is unable to detect the coolant temperature and transmit a signal to turn on the electric motor, it will need to be replaced. To make sure that it is not working, you need to disconnect two wires from it and short them together. If the electric motor starts to spin the impeller, this will indicate that the sensor is faulty and needs to be replaced;

- There is no tension. The third and most common reason for a non-working radiator cooling fan is the lack of voltage in its power supply circuit. If there is a break in the wires or a fuse fails, the circuit will be de-energized. To make sure that this problem exists, you need to “ring” the wires and check the fuses.

If the radiator cooling fan does not turn on, it is quite easy to find the cause of the problem; just perform the checks described above.

Checking the electric motor

If the cooling fan does not work, the first thing you need to do is check its drive (electric motor). It's easy to do. It is enough to take two wires, connect them to the fan and power it directly from the battery. If it starts, then the problem is not with it. We need to look for it further. At the same time, you can check the contacts in the motor connector. Sometimes it happens that the problem is in them. The ingress of dirt and dust, as well as oxidation of metal surfaces can cause contact failure.

If the electric motor does not turn on after connecting to the battery, most likely it is the battery that has broken down. The reason for this may be:

- worn brushes;

- reservoir destruction;

- short circuit of the rotor or armature windings.

In the first case, it is enough to replace the brushes with new ones, and the fan motor will work like new again. In the case of destruction of the commutator or short circuit of the windings, repair may not help.

Radiator cooling fan does not work: how to use the car

If the radiator cooling fan fails, it is better to immediately figure out the cause and fix the problem. But the problem can arise suddenly, and the driver must know the basic rules of how to drive a car with the fan turned off so that the engine does not overheat:

- Try turning on forced operation of the fan from the battery;

- If the fan is not forced, you should drive at a constant speed of about 60 kilometers per hour or higher so that the oncoming air flow cools the fluid on the radiator without the help of a fan. It is also recommended to turn on the heating system in the car interior so that some of the heat from the coolant escapes into the cabin.

Remember that if the coolant is overheating, it is better to stop and wait a while for it to cool, rather than continue driving the vehicle and risk overheating the engine.

( 433 votes, average: 4.58 out of 5)

Plastic, metal, aluminum gas tank - which is better?

Why do hydraulic compensators knock on a cold or hot engine?

Related Posts

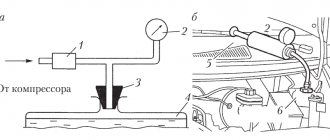

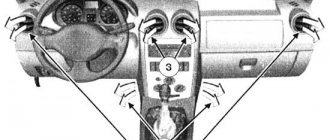

Checking the fuse and fan relay

If everything is in order with the electrical wiring, we move on to other equipment. First, let's check the cooling fan fuse. It is usually located in the mounting block under the hood of the car and is marked F7. We check it with the same car tester. If the fuse is good, move on. We are looking for the fan switch relay. It is located under the cover of the right panel of the center console. There are three relays located there. The car owner's manual will help you determine what you need, since different models have different locations.

But how to check the relay? In field conditions, it is almost impossible to determine its performance. It’s easier to take an adjacent relay (if its parameters match) and install it in the desired slot.

Design

Cooling system diagram

The cooling system includes many components. Among those that interest us today, which can cause problems with the radiator fan, we note:

- Electric fan. This unit starts working when the coolant temperature reaches 100-105 degrees Celsius;

- Fan switch sensor. It is configured to operate precisely within the specified temperature range. The sensor is located on the inlet pipe of the cylinder block (labeling from the sensor factory is LS0112);

- Fuse marked F7. It is located in the mounting block;

- Fan relay. You will find this unit already in the cabin, under the right panel of the front console.

If the radiator fan does not work on your VAZ 2110, the cause of the malfunction should be looked for in the above-mentioned system elements. Although there may be one situation in which the electrical circuit has nothing to do with the fault.

Testing the fan switch sensor

The next reason why the cooling fan does not work may be a faulty sensor. Cases of failure of this element are not so rare. It is possible to accurately determine that it is the sensor that has broken down only in a car with an injection engine. If you disconnect it from the power supply, the electronic control unit will perceive this as a system malfunction and start the fan in emergency mode.

The check is carried out as follows. We warm up the car until the coolant temperature reaches 100 0C, then turn off the engine, lift the hood and disconnect the sensor by disconnecting the connector on it. After this, we start the engine. If the fan turns on, then the problem is with the sensor.

Unfortunately, such a check is not possible in cars with carburetor engines. Here, you can determine the functionality of the fan switch sensor only by replacing it with a new one and warming up the engine to operating temperature.

Why do you need a radiator cooling fan?

The liquid cooling system means that coolant circulates in special circles in the engine. The first circle is “small” - it is necessary to quickly warm up the coolant and bring it to operating temperature. The second circle is “large”, and it differs from the “small” one in that it includes a radiator where the superheated liquid cools.

The cooling efficiency of the liquid as it passes through the radiator makes it possible to increase the oncoming air flow that occurs when the car is moving. It passes through the radiator honeycombs, removing heat from them, thereby lowering the coolant temperature more effectively. However, when driving at low speeds or when the engine is idling, there is not enough air flow to effectively cool the radiator. Accordingly, the coolant will become very hot during operation, which may cause the engine to overheat. To avoid this, the radiator cooling fan is turned on, which directs air flow to the radiator and cools it.

Changing the safety valve

There is another malfunction that can lead to system failure. If the cooling fan does not work even after confirming the operability of all the listed elements of the chain, it is worth checking the safety valve on the expansion tank.

The role of this valve is to maintain the operating pressure in the system above atmospheric pressure. This is necessary so that the water included in the coolant does not boil when heated to 100 0C. If the safety valve fails, the pressure in the system will equalize with atmospheric pressure and the liquid will boil, reaching the boiling point of water.

The switch-on sensor, as already mentioned, can only turn on at 105-107 0C. Thus, our coolant will boil, but the fan will not work.

How to check the safety valve? This is impossible at home. It’s easier to buy a new valve, especially since it costs pennies.

What to do if the radiator cooling fan runs constantly

Another problem that can arise with the radiator cooling fan is its constant operation. If the electric motor does not turn off or turns on too early, when the coolant temperature is still far from the critical zone, it is necessary to determine the cause of such a malfunction and eliminate it.

Running the radiator cooling fan without stopping may be associated with the following problems:

Relay contacts are stuck. If the relay contacts are fixed in the “On” position, the electric motor will start immediately after starting the car engine;- Problem with the sensor. In a situation where the radiator cooling fan motor starts to turn on prematurely, the temperature sensor is most often to blame. In such a situation, it should be replaced;

- The thermostat is stuck. If the radiator cooling fan is not equipped with a separate sensor for temperature control, it will be guided by the general indicator. When the thermostat jams and does not allow the coolant to move to the “large” circle, it quickly overheats and the electric fan drive turns on. Since the liquid does not reach the radiator, the fan runs “idling” and the coolant temperature will not decrease, which will lead to rapid overheating of the engine. It is also possible that the thermostat is stuck in an intermediate position, which will not provide sufficient cooling of the liquid, which will lead to constant operation of the fan.

It is worth noting that constant operation of the cooling fan is not as dangerous as its complete failure, but not in a situation where the problem is associated with a stuck thermostat and overheating of the engine.

Useful tips

Finally, check out these useful tips that will allow you, if not to avoid problems with turning on the cooling fan in a timely manner, then at least to correct the situation a little.

- Systematically check the operation of all elements of the cooling system. Pay attention to the coolant temperature indicators on the instrument panel, and also listen to whether the fan turns on.

- Monitor the coolant level in the system. Replace it in a timely manner.

- At least once a year, wash the expansion tank cap under running water. This solution will extend the life of the safety valve.

- If there is the slightest malfunction in the cooling system, stop driving and take corrective action.

- If the cooling fan does not work due to a sensor, fuse or relay failure, and this malfunction caught you on the road, disconnect the sensor (for an injector) or connect the electric drive directly to the on-board network (for a carburetor). This way you can drive to the nearest service station without the risk of engine overheating.

Why doesn't the fan work? Let's find out!

- Wiring and contact. Any of these reasons, despite their harmlessness, can be the reason why the fan simply does not turn on at the right time. It also often happens when the reason lies in the malfunction of the electric fan motor itself, which for one reason or another cannot start working. In cases with the electrical network, I would recommend finding an experienced electrician who will empirically determine the fault and answer the question of why the cooling fan does not turn on.

- Fuse. A blown fuse can also be attributed to common causes that occur quite often. An open circuit due to a blown fuse will prevent the electric fan from turning on, resulting in an increase in engine temperature. You can check the fuse very simply, just remove the fuse that is responsible for the operation of the fan, and replace it with a new fuse or simply insert a piece of wire in such a way as to close the circuit. If during the test the electric fan starts to work, then the reason is in the fuse.

- Air lock or low coolant level. Check the coolant level and the cooling system hoses. At operating temperature, the hoses leading to the radiator should be hot and the coolant level should be correct in both the expansion tank and the radiator. Be careful, checking the antifreeze level is only done on a cold engine. Also, if the fan does not work, you should pay attention to the circulation of antifreeze; after warming up, it should circulate in a large circle. If this is not the case, there may be an air lock in the system; read how to remove it here. A decrease in coolant level may indicate a leak in the cooling system. In the best case, it will be a question of replacing the cylinder head gasket, in the worst case, a crack in the block or a burnout...

- Temperature sensor. Thanks to this sensor, the electronic unit (ECU) decides whether to turn on the fan or not. Unstable operation or malfunction of this sensor will lead to the ECU receiving incorrect information about the coolant temperature, as a result of which the fan will not turn on.

- The last suspect is the thermostat. If it is faulty, the circulation of antifreeze will be difficult, as a result, the operation of the fan will be compromised. For example, when the thermostat is stuck on the “small circle”, the fan does not turn off and runs constantly, because the engine is warmed up, the temperature rises and the fan tries to fix it all. The only problem is that due to the stuck thermostat, the liquid in the radiator does not circulate and cooling does not occur. In some cases, the opposite happens: the temperature sensor does not work, because a jammed thermostat does not allow liquid to pass through a large circle, and as a result, the electric fan does not turn on.

That’s all I have, write in the comments about what reasons you know for a non-working fan, share your experience and perhaps your story will help someone solve their issue. Thank you for your attention and see you again at Ford Master. Bye!