Characteristics of the cooling system

The Gazelle was equipped with engines from the Zavolzhsky Motor Plant marked ZMZ 402, ZMZ 405 and ZMZ 406. The design, circuit and operating principle of all three cooling systems are similar. Of course, there are some differences, but they are not that big.

Like any other cooling system, the ZMZ 405 engine has both positive and negative sides. So, if the thermostat breaks down, the power unit begins to overheat very much, especially in the summer season, when the temperature outside is 30 degrees Celsius or higher.

The most dangerous thing in this case is the failure of the cooling fan.

Characteristics of the ZMZ-405 engine

| Production | ZMZ |

| Engine make | ZMZ-405 |

| Years of manufacture | 2000-present day |

| Cylinder block material | cast iron |

| Supply system | injector |

| Type | in-line |

| Number of cylinders | 4 |

| Valves per cylinder | 4 |

| Piston stroke, mm | 86 |

| Cylinder diameter, mm | 95.5 |

| Compression ratio | 9.3 |

| Engine capacity, cc | 2464 |

| Engine power, hp/rpm | 152/5200 |

| Torque, Nm/rpm | 211/4200 |

| Fuel | 92 |

| Environmental standards | Euro 3 |

| Engine weight, kg | 193 |

| Fuel consumption, l/100 km - city - highway - mixed. | 13.5 8.8 11.0 |

| Oil consumption, g/1000 km | up to 100 |

| Engine oil | 5W-30 5W-40 10W-30 10W-40 15W-40 20W-40 |

| How much oil is in the engine | 6 |

| When replacing, pour, l | 5.4 |

| Oil change carried out, km | 7000 |

| Engine operating temperature, degrees. | ~90 |

| Engine life, thousand km - according to the plant - in practice | 150 300+ |

| Tuning - potential - without loss of resource | n.d. up to 200 |

| The engine was installed | GAZ 3102 GAZ 31105 GAZ GazelleGAZ Sobol |

Composition of the Gazelle cooling system

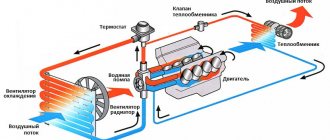

Any engine cooling system consists of certain components, each of which performs its own function. So, to understand what the entire structure of the system consists of and the purpose of the nodes, it is not enough to look at the diagram. Let's look at all the details, as well as their characteristics.

Radiator

The radiator is one of the indispensable parts of the cooling system. It is in this element that the coolant is cooled and circulates through the system. The Gazelle is often equipped with an aluminum radiator, in which tubes run in three rows.

It has an inlet and an outlet, where the hot “coolant” enters the first, and the cooled liquid comes out of the second. Cooling occurs due to the oncoming wind flow that passes through the part.

Electric fan

If the radiator cannot cope, a cooling fan comes to the aid of the radiator, which operates automatically when the temperature of the liquid in the system reaches 105 degrees. At the same time, the fan quickly and efficiently cools the radiator cells, and when the temperature drops, it turns off.

This unit is turned on and off using a coolant temperature sensor and an electronic engine control unit, which regulates all engine operation processes.

Thermostat

The thermostat is one of the elements that is familiar to almost all motorists. The element helps warm up the engine and also cool it. As you know, car engines have two cooling circles, each of which performs its own function. So, if the thermostat is closed, then the liquid circulates in a small circle without the participation of the radiator.

Typically, this system is necessary for quick and efficient warming up of the power unit. When the thermostat opens (at 65-70 degrees), the coolant begins to circulate through the radiator, which allows it not to overheat.

temperature sensor

The temperature sensor is the only electrical part of the engine cooling system that reads system temperature data and sends it to the electronic engine control unit. Subsequently, the “brains”, based on the data received, make a decision whether to turn on the cooling fan or not.

It is worth noting that the malfunction of this sensor usually brings many problems to the owners of the power unit, since based on temperature data, not only the activation of the electric fan is regulated, but also fuel consumption, as well as the operation of auxiliary systems.

Expansion tank

The expansion tank is a plastic container that is located above the other elements of the cooling system and shows the level of “cooling” in the engine. In addition, excess fluid from the system is squeezed into it.

Heater Gazelle business troubleshooting.

What to do if something in the heater does not work? Due to the design of the heater, diagnostics in case of failure of its parts is difficult. Initially, as always, you need to check the fuse.

Checking the heater tap.

When operating the Gazelle Business heater, a problem may arise in the supply of hot air when the ventilation is turned on, or, conversely, cold air when the heater is turned on. The reason is that the heater tap does not work. It does not open or shut off the coolant flow to the heater core. The design of the crane is quite simple and at the same time somewhat more complex than the similar crane installed on the Gazelle restyling. It's all about the built-in crane control unit,

To find the cause of a heater tap failure, you will need a piece of copper wire and a test lamp. No special knowledge or skills are needed to determine the malfunction.

First you need to check the presence of plus and minus on the connector connected to the tap. This is done with a test lamp by connecting its probes (wires) to the black and white wires of the connector. If the warning light does not light, then move the wire connected to the black wire to a metal part of the engine where there is a good minus. If the lamp lights up, repair the break in the black wire or clean its attachment to the body. If the lamp does not light up in this case, then you need to check fuse F13 and the serviceability of the wire from it to the connector.

If there is a plus and minus on the connector, use a small piece of copper wire to alternately connect the black wire with the brown and green wires. If the heater valve gearbox is in good working order, the characteristic sound of its operation will be heard. If nothing happens, the tap needs to be replaced.

Checking gearmotors.

Checking the gear motors of the windshield blower dampers and deflectors can be checked without completely removing the panels. It is enough to remove its lower part. The main damper motor is accessible from the driver's side. To check gearmotors, you need to disconnect the connector of its electric motor, the connector with a lock, and connect a tester to it in voltmeter mode or a test lamp. With the ignition and heater on, you must press the button that controls this damper. The control lamp should light up. If the lamp is on and the gearmotor does not work, it must be replaced.

If you are on the road and do not have the opportunity to replace the damper drive with window defroster, you can remove the rod from the damper lever on the driver’s side and turn it manually, locking it in the open position. To open the damper on the passenger side, you will need to unscrew the screws securing the gearmotor and, by turning its housing, secure it in the same way.

Checking the electric motor and speed controller.

To check the heater fan motor and the cause of its failure if the fan does not work, you will need to remove the air intake in the engine compartment. Inside the opened approx.

You will see two wires with a connector. To check the power supply, connect a test lamp to the connector terminals and, with the ignition on, turn the heater speed control toward maximum speed. The control lamp should light brightly. When turning the handle towards the minimum speed, the brightness of the lamp should decrease. This indicates that the speed controller is working properly.

If the control lamp is on and the fan does not rotate, then its electric motor is faulty. To check, measure the resistance between the motor terminals in the connector. Motor malfunction may be caused by stuck brushes. In this case, you can try knocking on the heater body. In this case, the operation of the fan can be restored before the next time it is turned off, possibly longer, but you can still get to the service center in a warm place.

If the control lamp does not light up when checking the power supply, the speed controller is faulty. If the speed controller malfunctions, you can temporarily connect the positive wire on the connector to the fuse near the battery with a wire. This will allow you to get to the garage or service station in winter.

Repair of main components

Repair of parts and the entire engine cooling system can be found in the ZMZ 405 repair manuals. The most common system breakdowns are the water pump and thermostat. Replacing the pump is quite simple:

- Drain the coolant.

- The drive belt is dismantled.

- The water pump mounting bolts are unscrewed.

- The old pump is removed and a new pump is installed. It is important not to forget to install the gasket.

- Install the belt into place.

- Fill the system with coolant.

Replacing the thermostat is carried out in the same way as a pump, only the element itself is located in a housing that consists of two elements. To change it, you just need to drain the liquid and disconnect the pipe. Then remove the cover and change the thermostat directly.

Recently, radiators have become a common malfunction; they become punctured by pebbles on the highways when the speed is high enough. Typically, motorists try to solder this element, but it does not always work.

Diagram of the control system for the ZMZ-40522, UMZ-4216 GAZelle engines.

Diagram of the control system for the ZMZ-40522, UMZ-4216 GAZelle engines.

Engine control system diagram.

1 – electronic unit of the engine control system; 2 – phase sensor (camshaft position sensor); 3 – synchronization sensor (rotation speed and crankshaft position sensor); 4 – throttle position sensor; 5 – knock sensor; 6 – mass air flow sensor; 7 – coolant temperature sensor; 8 – air temperature sensor in the intake pipe; 9 – oxygen concentration sensor (for engines with a catalytic converter); 10 , 11 , 12 and 13 – nozzles; 14 – idle speed regulator; 15 – canister purge valve (for a car with a fuel vapor recovery system); 16 – fuel pump relay; 17 – fuel pump electric motor; 18 – engine control system relay; 19 – diagnostic connector; 20 – block for connecting an oxygen concentration sensor; 21 – block for connecting the engine control system to the vehicle’s electrical network; 22 – relay for turning on the electromagnetic fan clutch; 23 , 26 – ignition coils; 24 , 25 , 27 and 28 – spark plugs; a – diagram of the connection of injectors on a car with a UMZ-4216 engine ( 1 , 2 , 3 and 4 – injectors).

( 2 ratings, average 4.5 out of 5 )

Conclusion

The cooling system of the 405 Gazelle engine is quite characteristic and typical for power units. It includes a radiator, electric fan, water pump, thermostat, temperature sensor and other elements. The cooling system is easy to repair because it has a simple design. Restoring the functionality of the nodes can be done at home.

Source

Performance characteristics

To carry out repairs on the power plant yourself, a thorough knowledge of the design is not enough. Almost every parameter of the technical features of the unit is also important. The engine in question is characterized by the following indicators:

- The four-stroke power plant is equipped with two camshafts. For them, manufacturers provide an upper location in the engine compartment;

- The 192 kg engine has four cylinders with a diameter of 95.5 mm, each of which is equipped with four valves;

- the workspace is designed for a volume of 2.46 liters;

- the cylinders in the engine compartment are placed longitudinally, in one row;

- the established compression ratio is 9.3;

- the piston movement is characterized by a working stroke of 86 mm;

- making 5200 rpm, the power unit reaches a power of 152 hp, which corresponds to 111.8 kW;

- the engine is fueled with gasoline, and manufacturers recommend using fuel with an octane rating of at least 92;

- The engine is equipped with a liquid cooling system, and the nominal coolant temperature is considered to be 110 degrees.

In addition to the listed characteristics, it is necessary to note the presence in the design of the unit of a specific three-component catalyst, which allows the engine to meet the requirements of Euro-3 environmental standards.