Replacing the unit

Despite the fact that the system is quite reliable, sometimes you still have to replace the coolant pump. It is much more profitable to carry out replacement rather than repair. It is often not possible to repair this system, and if it is possible, it usually costs either the same or more than replacing it and installing a completely new device. The most common problem with the coolant pump is fluid leakage. In this case, the only option is to replace the device. Typically the cause of this problem is the following:

- low quality device;

- wear.

If a fairly loud noise occurs during operation, this is also a sign of technical problems. In the worst case, this means a breakdown or failure of the impeller, that is, the impeller.

Why do you need a pump in a car?

Any power unit operates at high temperatures. In particular, for Gazelle cars, the operating temperature of a well-heated engine is considered to be 92–99 degrees. Starting to overheat due to increased loads, the engine is immediately cooled by the timely supply of the required amount of coolant (depending on the model, Gazelles are filled with either antifreeze or antifreeze).

The pump ensures stable circulation of antifreeze, thereby always supplying fresh liquid to the engine. It is thanks to its operation that the engine does not have time to warm up to a critical temperature.

The device has a metal case and special hinges for secure fastening in the car body

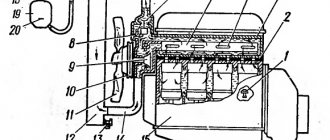

description of the cooling system on the Volga GAZ 31105 car

download photo to mobile phone

description of the car Volga GAZ 31105 maintenance and repair manual

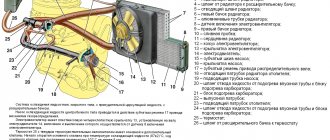

cooling system of the ZMZ 406 engine of the Volga GAZ 31105 car. Diagram of the cooling system of the Volga GAZ 31105 car 1 - drain valve of the engine cylinder block; 2 — heater radiator; 3 — heater valve; 4 - engine; 5 — throttle assembly; 6 — thermostat; 7 — temperature indicator sensor; 8 — coolant overheat warning lamp sensor; 9 — electric fan; 10 — sensor for turning on the electric fan; 11 — engine radiator; 12 — expansion tank plug; 13 — expansion tank; 14 — radiator drain plug; 15 — coolant pump; 16 — main thermostat valve; 17 — thermostat bypass valve;

A - thermostat is closed; B - thermostat open

| The cooling system is liquid, closed type, with forced circulation. The cooling system of the Volga GAZ 31105 car consists of a pump, engine radiator, fan, thermostat, expansion tank, cooling jacket (ducts in the block and channels in the cylinder head of the ZMZ 406 engine), connecting hoses and tubes, as well as a radiator and heater tap. The coolant pump is a centrifugal type, installed in the front part of the cylinder block and driven from the crankshaft pulley by a poly-V-belt. The pump provides a constant flow of coolant to the engine. The thermal regime of the ZMZ 406 engine is set by the parameters of the thermostat and the radiator fan switching sensor. The distribution of liquid flows is controlled by a thermostat with two valves; main and bypass. On a cold engine, the main valve is closed, and all the coolant circulates in a small circle - through the cooling jacket of the block and cylinder head, bypassing the engine radiator and immediately returning to the pump. This speeds up warming up of a cold engine. At a temperature of 80-84°C, the main thermostat valve begins to open, allowing part of the liquid to pass through a large circle, and the thermostat bypass valve closes. | At a temperature of 94°C, the main thermostat valve is fully open, and the bypass valve is closed and all liquid circulates through the cooling jacket, then through the main thermostat valve and the engine radiator, forming a large circulation circle. The coolant, passing through the radiator, is cooled, giving off some of the heat to the surrounding air. The radiator is a tubular-tape radiator with side plastic tanks. The tanks are connected to the radiator frame through rubber sealing gaskets by pressing the support plates along the flanges of the tanks. On the plates of the radiator frame there are brackets for attaching the radiator to the body of the GAZ 31105 car, as well as for attaching the fan casing to the radiator. The fan has a six-bladed plastic impeller. Driven by an electric motor. The electric motor is turned on at the command of a sensor installed in the left radiator tank at a coolant temperature of 92 °C. The heater radiator is included in the small circle of the cooling system. The amount of coolant passing through the heater core is independent of the thermostat and is controlled only by the heater valve. Since 2005, a heater valve with a pneumatic drive has been installed on Volga GAZ 31105 cars (see “Heating and ventilation system”). | The expansion tank is plastic, mounted on brackets above the vacuum brake booster. The expansion tank is connected by steam removal hoses to the branch pipe of the left radiator tank (at the top) and to the fitting in the thermostat housing cover, as well as the filling hose to the pump through a tee installed in the lower radiator hose. There is a MAX mark on the expansion tank, indicating the upper level of coolant in the expansion tank. The expansion tank is closed with a screw plug. The tightness of the system is ensured by valves in the expansion tank plug. The exhaust valve maintains excess pressure in the system when the engine is hot (due to this, the boiling point of the liquid increases to 115°C and its evaporation losses are reduced). The intake valve opens when the pressure in the cooling system decreases (on a cooling engine). The cooling system is filled with 10.5 liters of antifreeze liquid “Tosol”. To drain the coolant, there is a drain hole in the lower part of the right radiator tank, closed with a screw plug, and a drain valve is provided on the left side of the cylinder block. |

Why do you need a pump in a car?

Any power unit operates at high temperatures. In particular, for Gazelle cars, the operating temperature of a well-heated engine is considered to be 92–99 degrees. Starting to overheat due to increased loads, the engine is immediately cooled by the timely supply of the required amount of coolant (depending on the model, Gazelles are filled with either antifreeze or antifreeze).

The pump ensures stable circulation of antifreeze, thereby always supplying fresh liquid to the engine. It is thanks to its operation that the engine does not have time to warm up to a critical temperature.

The device has a metal case and special hinges for secure fastening in the car body

Fan and radiator

These elements in the ZMZ-406 engine cooling system are needed to ensure reliable cooling of the engine itself. When the car is moving, the radiator can be cooled by the oncoming air flow. But in the summer it is hot and the radiator is helped by a fan.

The radiator on these engines is aluminum, 3-row, to ensure maximum cooling of antifreeze or antifreeze. The fan on it is turned on by a temperature sensor, which is installed in the cylinder block on the carburetor version, and on the injection version there is a sensor in the block and an electronic unit that also controls the fan.

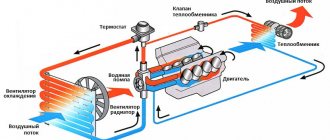

Diagram, elements of the cooling system and their operation

The main elements that make up the engine cooling system circuit are found and are similar in different types of engines: injection, diesel and carburetor.

General diagram of a liquid engine cooling system

Liquid cooling of the motor makes it possible to equally absorb heat from all components and parts of the engine, regardless of the degree of thermal load. A water-cooled engine creates less noise than an air-cooled engine and has a faster warm-up rate when starting.

The engine cooling system contains the following parts and elements:

- cooling jacket (water jacket);

- radiator;

- fan;

- thermostat;

- liquid pump (pump);

- expansion tank;

- connecting pipes and drain taps;

- interior heater.

- A cooling jacket (“water jacket”) is considered to be cavities communicating between double walls in those places where excess heat is most needed to be removed.

- Radiator. Designed to dissipate heat into the surrounding atmosphere. It structurally consists of many curved tubes with additional ribs to increase heat transfer.

- The fan, activated by an electromagnetic or, less commonly, hydraulic clutch, when the coolant temperature sensor is triggered, increases the air flow flowing into the car. Fans with a “classic” (always on) belt drive are rarely found these days, mainly on older cars.

- The centrifugal liquid pump (pump) in the cooling system ensures constant circulation of coolant. The pump drive is most often implemented using a belt or gears. Turbocharged and direct injection engines are usually equipped with an additional pump.

- The thermostat is the main unit that regulates the flow of coolant, usually installed between the radiator inlet pipe and the “water jacket” of the engine, and is designed in the form of a bimetallic or electronic valve. The purpose of the thermostat is to maintain the specified operating temperature range of the coolant in all engine operating modes.

- The heater radiator is very similar to the smaller radiator of the cooling system and is located in the car interior. The fundamental difference is that the heater radiator transfers heat to the passenger compartment, and the cooling system radiator transfers heat to the environment.

Principle of operation

The principle of operation of liquid engine cooling is as follows: the cylinders are surrounded by a “water jacket” of coolant, which removes excess heat and transfers it to the radiator, from where it is transferred to the atmosphere. The liquid continuously circulates to ensure optimal engine temperature.

Operating principle of the engine cooling system

Coolants - antifreeze, antifreeze and water - during operation form sediment and scale, disrupting the normal operation of the entire system.

Water is not chemically pure in principle (with the exception of distilled water) - it contains impurities, salts and all kinds of aggressive compounds. At elevated temperatures they precipitate and form scale.

Unlike water, antifreezes do not create scale, but during operation they decompose, and the decomposition products negatively affect the operation of mechanisms: corrosion deposits and layers of organic substances appear on the internal surfaces of metal elements.

In addition, various foreign contaminants may enter the cooling system: oil, detergents or dust. Special sealants used for emergency repair of damage in radiators can also get in.

All these contaminants settle on the internal surfaces of components and assemblies. They are characterized by poor thermal conductivity and clog thin tubes and honeycombs of the radiator, interfering with the efficient operation of the cooling system, which leads to engine overheating.

Video about how engine cooling works, operating principles and malfunctions

Something else useful for you:

- The stove in the cabin does not heat well, reasons, what to do and prevention

- Why the car engine does not start: how to find the reason

- Engine cooling radiator: design and principle of operation

Cooling system GAZ 3110 Volga

- Repair manuals

- Repair manual for GAZ 3110 (Volga) 1996-2004.

- Cooling system

2.4.1 Cooling system The cooling system is closed liquid with forced circulation of liquid.

The cooling system consists of an engine cooling jacket, radiator, water pump, thermostat, expansion tank and connecting hoses and tubes. The heater radiator is also connected to the cooling system. D... 2.4.2. Radiator (Category). See the list of materials inside...

2.4.3. Replacing the thermostat (Category). See the list of materials inside...

2.4.4. Water pump (Category). See the list of materials inside...

2.4.5 Replacing the coolant PROCEDURE 1. When replacing the coolant, the heater valve must be open. 2. Place containers under the engine and radiator to collect waste fluid. 3. Place a hose to drain the fluid onto the radiator drain valve. 4. Open the radiator drain valve...

↓ Comments ↓

1.Operation and Maintenance

1.0 Operation and maintenance 1.1 Interior heating and ventilation 1.2. Running in the car 1.3 Checking the car before leaving 1.4 Frequency of replacing operating fluids and lubricants 1.5 Caring for the paintwork of the body 1.6 Frequency of lubrication of vehicle components

2. Engine

2.0 Engine 2.1. Removal and installation 2.2. Engine of models 402 and 4021 2.3. Lubrication system 2.4. Cooling system 2.5. Exhaust gas system 2.6. Engine power supply system ZMZ-4062 2.7. Power supply system for ZMZ-402 and ZMZ-4021 engines

3. Transmission

3.0 Transmission 3.1. Clutch with diaphragm spring 3.2. Clutch with peripheral springs 3.3. Five-speed gearbox 3.4. Four-speed gearbox 3.5. Cardan transmission 3.6. Rear axle 3.7. Axle shafts 3.8. main gear

4. Chassis

4.0 Chassis 4.2. Rear suspension

5. Steering

5.0 Steering 5.1. Steering wheel 5.2. Steering column 5.3. Steering mechanism 5.4. Steering linkage 5.5. Ball joints of the steering linkage 5.6. Pendulum arm 5.7. Ball joint of the pendulum arm 5.8. Power steering mechanism 5.9 Possible steering malfunctions.

6. Brake system

6.0 Brake system 6.1. Brake pedal 6.2. Vacuum booster 6.3. Main brake cylinder 6.4. Front brake mechanism 6.5. Rear brake mechanism 6.6. Pressure regulator 6.7. Parking brake 6.8 Bleeding the brake system 6.9 Possible malfunctions of the brake system.

7. Electrical equipment

7.0 Electrical equipment 7.1. Battery 7.2 Fuse block 7.3. Generator 7.4. Generator 9422.3701 or 2502.3771 7.5. Generator 1631.3701 or 192.3771 7.6. Voltage regulator 7.7. Starter 7.9. Sound signal 7.10. Ignition system 7.11 Electrical diagram of a GAZ-3110 car with a ZMZ-4062 engine 7.12 Electrical diagram of a GAZ-3110 car with a ZMZ-402 engine

8. Body

8.0 Body 8.1. Front buffer 8.2. Rear buffer 8.3. Radiator lining splash guard 8.4. Hood 8.5. Front fender 8.6. Trunk lid 8.7. Front door 8.8. Rear door 8.9 Replacing windshield and rear windows 8.10. External rear view mirror 8.11. Instrument panel 8.12. Windshield wiper 8.13. Front seat 8.14 Rear seat 8.15 Seat belts 8.16 Rear parcel shelf 8.17 Interior attachments 8.18. Heater 8.19 Possible malfunctions of components and body parts.

9. Applications

9.0 Applications 9.1 Weight of units 9.2 Lamps used on the vehicle 9.3 Rolling bearings used on the vehicle 9.4 Cuffs used on the vehicle 9.5 Fuels and lubricants and operating fluids 9.6 Tightening torques of critical threaded connections *

10. Vehicle specifications

10.0 Technical characteristics of vehicles 10.1. Engine

System parts and components

The design of the engine cooling device is quite simple and common to all versions. The coolant circulates in circles - large and small. Let's look at the details of the “cooler” assembly in more detail.

Radiator and fan

The radiator and electric fan ensure a constant engine temperature within the range of 87-103 (in some cases up to 110) degrees Celsius so that the engine does not overheat. On the first engine models, a three-row cooler of copper construction was installed.

Cooling system radiator.

Copper radiators are widespread on domestic Volgas, UAZs and trucks produced during the USSR era. But, after unsuccessful tests, the designers decided to change the radiator to a three-row aluminum one.

There are two types of fans - electric (installed on all modern cars) and forced action (on old Volgas, VAZs and other cars). A mechanical fan is driven by a crankshaft on which blades are mounted. They ensure constant cooling of the radiator.

Forced action fan.

The electric fan is turned on by a control unit, which regulates the engine temperature using a coolant temperature sensor. Temperature data is read from the cooling jacket and sent to the ECU, which turns the main fan on and off.

Electric cooling fan.

A malfunction of the fan and cooling radiator leads to poor circulation and insufficient cooling of the system. In this case, the motor may overheat. If this is coupled with a faulty thermostat, this will lead to overheating of the motor, which will lead to more serious problems.

Thermostat

Provides transfer of coolant flows from a small to a large circle, and vice versa. So, the thermostat opens at a temperature range of 60-70 degrees. This is one of the most important parts of the engine, since it is what regulates the efficient and rapid warming up of the engine, as well as the normal operation of the coolant system.

Thermostat device.

A malfunction of the thermostat leads to the fact that the engine begins to heat up, since it is in a closed state and often this malfunction is accompanied by frequent activation of the electric fan. Changing the thermostat is easy; to do this, you just need to drain the coolant to a level below the part and unscrew the housing. The product is located under the body. When replacing, it is worth changing the sealing rubber.

Water pump or water pump

The water pump or pump serves to circulate coolant throughout the system. Failure of this element leads to loss of fluid and overheating of the power unit. Typically, wear on the bearings inside the product will cause it to seize, causing the water pump to start leaking.

Water pump.

Heater

One of the integral elements of the cooling system is the heater system. It includes an inlet and outlet pipe, a radiator and an electric fan. In winter, it is actively used, which further cools the engine.

Expansion tank and plug

Gases and vapors that are formed as a result of the operation of the system are displaced into the expansion tank. There, this element also serves as the coolant level in the system. Air is forced out through the plug, as well as hot “coolant” when the power unit overheats.

Pipes

Pipes are intermediate elements through which coolant circulates and also connect different elements of the system. Failure of these parts can lead to loss of fluid, which can significantly reduce the level in the engine. Typically, depending on the mileage and terrain of operation, it is recommended to change these parts once every 100,000 km.

temperature sensor

The cooling temperature sensor reads temperature data and transmits it to the electronic control unit, which adjusts the temperature. It is installed on the thermostat.

Coolant temperature sensor.

A faulty element may cause the motor to overheat because the electric fan will not turn on. This is especially dangerous in the summer. Also, problems with the sensor can lead to a number of other problems associated with the motor.

Water jacket

The cooling water jacket is located inside the cylinder block and cylinder head. It ensures the removal of heat from these elements, which heat up during operation. So, with the help of a water pump and pipes, the liquid moves into the radiator, where cooling actually occurs, and then returns to absorb new heat.

Parts and spare parts: description

Many car enthusiasts are familiar with the elements of the engine cooling system. But, novice motorists do not know what this unit consists of and what the purpose of the elements is, for which they are often punished by fate. So, let’s look at the purpose of individual elements of the cooling system of the ZMZ 406 engine.

Thermostat

The thermostat is an element of the car’s cooling system, which plays the role of a valve that redirects the coolant flow from small to large. The operating temperature of the ZMZ 406 power unit is 87 – 103 degrees Celsius.

When the car warms up, the thermostat is closed, which allows the engine to heat up more quickly and efficiently. After the liquid temperature reaches 60-70 degrees, the thermostat opens and the coolant begins to circulate in a large circle, passing through the radiator.

The thermostat can rightfully be considered the most broken part of a car's cooling system. This is often due to the fact that the unit is jammed and the motor either overheats or does not heat up. The simplest solution to the problem is to replace the damaged part.

A - thermostat is closed; B - thermostat open

Water pump

A water pump or water pump circulates coolant throughout the system. The part is located in the cylinder block and is driven by a drive belt from the crankshaft. The part has a service life of 100,000 km, but due to low-quality spare parts it can fail much earlier.

Radiator and fan

The radiator and coolant fan are designed to ensure optimal engine cooling. The radiator itself is cooled with the help of a counter flow of air, but in the summer this is not enough, and the fan turns on.

The cooling system radiator on the ZMZ 406 is installed in aluminum with a 3-row system to ensure maximum cooling of the liquid. The fan is activated by automatically closing a circuit with a temperature sensor located on the cylinder block.

If the engine has an injector, then the electronic engine control unit is also included in the sensor-fan operating circuit. The coolant temperature sensor causes many problems related to engine performance.

Pipes and water jacket

The pipes play the role of a conductive and connecting link between different elements of the coolant system. Due to their malfunction, a coolant leak may occur, and the engine will simply begin to overheat.

Coolant circulates through the water jacket in the power unit, where it absorbs heat and transfers it to the radiator. Due to the breakdown of this element, a water hammer may occur.

This is due to the operation of the power unit on water, which causes corrosion.

Replacing the pump: instructions for various modifications of Gazelle engines

After the coolant has been drained, you can begin to dismantle the device:

- The first step is to remove the cooling radiator.

- Next, after access to the timing belt is opened, you will need to unscrew the three bolts of the water pump pulley.

- It is recommended to keep the pump from turning with a long bolt or a special blade.

- Remove the pump drive belt.

- Then remove the unscrewed pulley and reflector.

- From the pump body, unscrew the fitting of the pipe through which antifreeze is supplied.

- Loosen the fastening clamps and disconnect all hoses and pipes from the mechanism.

- After this, use a hex key to unscrew the four screws that secure the device to the motor housing.

- There is also another fastening bolt under the pump - it needs to be unscrewed last.

- Remove the water pump.

- Remove the seal from the landing site.

Installation of a new pump is carried out in the reverse order. Moreover, it is necessary to correctly set the marks on the pulley and roller so that the timing belt does not break when the engine is first started.

Video: DIY water pump replacement

For all modifications of UMZ and ZMZ engines on Gazelles, the principle of replacing the pump will be the same. There may be differences in the location of the pump, but it will always be part of the timing belt.

On Gazelle-Business UMZ-4216 engines, it is not necessary to remove the radiator, since access to the pump is through the lower right part of the car. However, this will require removing the front wheel.

A new generation car with a revised pump installation location

Thus, for all modifications of Gazelle cars, the process of replacing the pump will look approximately the same. You will need to remove the drive belts and drain the coolant from the system. Moreover, the procedure itself is not considered difficult; replacing the water pump can be performed by a driver who has basic skills in servicing his car.

Replacing the pump on other engine models

For almost all engines of modifications UMZ, ZMZ, which are installed on Gazelle vehicles, the main steps for replacing the water pump will be similar. Only minor differences regarding the structural arrangement of the unit are possible.

When performing work on the power units of the Gazelle Business vehicle, model UMZ-4216, there are some differences in the actions and their sequence:

- The water pump is accessible from the lower right side of the car.

- It is not necessary to dismantle the cooling radiator.

- It is necessary to remove the front right wheel of the car, after first raising the body with a jack.

- The further process is similar to the work described above with ZMZ 405 engines.

On Gazelle-Business UMZ-4216 engines, it is not necessary to remove the radiator, since access to the pump is through the lower right part of the car

In all modifications of Gazelle cars, replacing the water pump involves almost the same steps. In any case, the coolant is removed from the motor fluid supply system, and the drive belt is also dismantled. The procedure is not complicated: it is quite feasible for drivers with basic car maintenance skills.

As a result of vehicle operation, it may be necessary to replace the water pump. The urgency of replacement is due to natural wear and tear. The main sign of a malfunction is a strong noise coming from under the hood. Let's consider the step-by-step execution of work on the ZMZ 405 power unit.

Specifics

Reduced pump pulleys for ZMZ The photo shows a reduced ZMZ pump pulley for two belt schemes. Pulley diameter is about 90 mm. Material of manufacture: aluminum. As you might guess, one is for a single-belt circuit, the other is for a two-belt circuit. One more funny thing needs to be said here. “Volgovodov and uasophiles” get confused in pulleys and circuits. People believe that if there is room on a pulley for one belt, it is a spare part for a single belt circuit. Horseradish!! . This is a pulley for a two belt scheme. (ZMZ 409, UAZ Patriot or Hunter without air conditioning). A pulley with space for two belts, this is a spare part for a single belt scheme (ZMZ 409, UAZ Patriot with air conditioning). In the price list both spare parts are called – reduced pump pulley.

Pump operating diagram

How the coolant pump works was described above. To make it easier to understand this system, you can give a diagram of the flow of coolant after the pump is turned on.

- Initially, the engine cooling fluid is located in the lower radiator tank. After the pump turns on, the liquid enters the pump through a certain channel.

- When the device is turned on, the impeller begins to rotate, which creates centrifugal pressure, throwing the coolant towards the walls of the pump. Because of this, pressure arises, and the liquid will be pumped into the tube in which distribution will occur.

- The distribution-type tube has several holes, the number of which is equal to the number of cylinders. Each tube leads to its own cylinder.

The use of such a liquid circulation system in the system allows for uniform cooling of all necessary areas.

Conclusion

Judging by the reviews of car enthusiasts, the ZMZ 406 cooling system is considered one of the most reliable that the Zavolzhsky plant produced. The Gazelle cooling system is slightly adapted to withstand heavy loads. But on Sobol, everything was unchanged, as on the Volga.

I’ll duplicate it from the Gazelle community, note to Volgovo drivers! I’ll be brief, if you don’t understand anything, ask in the comments.

Here is the cooling system of ZMZ-406, 405, etc. (402 and analogues are almost identical)

The main task of the system is to maintain its temperature in a certain range, called operating temperature. At operating temperature, the motor operates as efficiently and safely as possible.

The cooling system should help the engine reach operating temperature as quickly as possible and maintain it in the required range as stably as possible.

If we simplify the previous picture a little to make the principle of operation more clear, we get:

Pump 12 pumps coolant (coolant) into the cylinder block. From there it exits in two ways: 1) through the interior heater 3 (selection occurs in the far part of the block near the 4th cylinder) and then enters the pump again through its lower intake. 2) Through the cylinder head in the front of the engine and through the thermostat it enters the upper intake of the pump.

A thermostat 4 is also installed there, which sends the coolant flow either directly to the pump (if the liquid is cold) or through the radiator (if it is hot). After the radiator, the flow again enters the lower intake of the pump.

Sometimes, as in our case), the selection for the heater is not made from the 4th cylinder in the block. and from the end of the block head (this improves fluid circulation in the block). After all, the operating temperature in the engine is like the average temperature in a hospital, where it is significantly lower, and sometimes it goes off scale. (the concept of local overheating).

When operating in the cold season with the heater running, this circuit works as it should, the liquid circulates throughout the block, the most remote place in the block is cooled both due to the different diameter of the holes in the head gasket for the passage of coolant, and due to the intake of coolant into the heater (intake from the Head is preferable) and good circulation.

What happens in the summer? You either manually close the heater tap or, as in Sobol, the electric heater tap does it

And as a result, we get the following cooling picture. In summer. In the hottest...

the first cylinder cools perfectly, the second worse, the third even worse, and in the fourth we have a picture of local overheating. Little of the already heated coolant enters there, and the circulation there is also minimal... Because of this, problems most often occur with the fourth cylinder.

Modern engines use various ways to combat such overheating. With similar cooling systems. 1) circulation through the radiator continues at any time of the year; the heater simply directs air past its radiator using dampers. The option is not bad, on the one hand, the liquid cools at least a little. on the other hand, we have extra resistance for the pump when pumping liquid, again there is circulation. but far from ideal 2) the heater valve closes the heater radiator and opens a liquid bypass branch that bypasses the heater radiator

Auto repair

The process of combustion of the fuel mixture in the engine cylinders is accompanied by the release of a large amount of heat, which heats the engine. If you do not cool the engine during operation, then after a few minutes its temperature will exceed the critical temperature and it will collapse. To prevent this from happening, the car uses an engine cooling system.

Composition of the engine cooling system:

- coolant (antifreeze or antifreeze);

- radiator;

- fan;

- thermostat;

- water pump (pump);

- connecting pipes;

- expansion tank;

- interior heater.

The water pump (pump) begins to work together with the engine. Once the engine is running, the rotating blades of the pump force coolant to circulate through a small circle of the cooling system (bypassing the radiator). This is necessary so that the engine warms up as quickly as possible and reaches its operating temperature.

When the coolant temperature of a running engine has reached the operating value, the thermostat opens and the coolant begins to circulate in a large circle - through the radiator.

Coolant (antifreeze, antifreeze) is supplied to the radiator through the upper pipe, passes from top to bottom through its honeycombs, and through the lower pipe (already cooled liquid) is fed back into the engine jacket.

When the coolant temperature rises to the upper values (100 °C or more), the fan turns on, which increases the air flow through the radiator grille and increases cooling efficiency. On older machines, the fan is rigidly connected by a belt to the pump shaft and rotates constantly.

To prevent the liquid in the cooling system from freezing at low temperatures and boiling at 100 °C, special coolants are used: antifreeze or antifreeze. These liquids contain ethylene glycol or propylene glycol, chemical compounds that prevent water from freezing. In addition, coolants contain rust, corrosion and foam inhibitors, which prevent rust from forming on the metal surfaces of the engine and radiator, lubricate the water pump and prevent the fluid from foaming as it circulates through the system.

ATTENTION! Do not use water as a coolant!!!!. Water is a rather aggressive environment that quickly destroys all metal parts of the cooling system. When heated, the coolant expands and increases in volume

Since the cooling system is sealed, excess coolant is pushed into the expansion tank, which is connected by a flexible hose to the radiator neck. When the coolant cools down, it is again supplied to the cooling system through the lower pipe of the expansion tank. The expansion tank also serves to fill and top up coolant into the cooling system. When opening the expansion tank cap, you must be very careful, because... hot fumes can scald your hand

When heated, the coolant expands and increases in volume. Since the cooling system is sealed, excess coolant is pushed into the expansion tank, which is connected by a flexible hose to the radiator neck. When the coolant cools down, it is again supplied to the cooling system through the lower pipe of the expansion tank. The expansion tank also serves to fill and top up coolant into the cooling system. When opening the expansion tank cap, you must be very careful, because... hot fumes can scald your hand.

In the car interior there is another small radiator, hidden under the dashboard, which is usually called the car interior heater, or simply a stove. In the cold season, the driver opens the heater damper, and the heated coolant begins to circulate through the heat exchanger, heating the air inside the car.

The cooling system is quite simple and does not require any maintenance during normal operation. If there are no coolant leaks, then you can safely drive for a couple of years. Once every two years, it is recommended to completely change the coolant in the car's cooling system. Also, you need to monitor the condition of the rubber pipes, since rubber dries out and cracks over time. It will be very unpleasant if a pipe suddenly ruptures on the road - further movement will be almost impossible. Therefore, it makes sense after 5-6 years to completely replace all rubber pipes with new ones.

Top of page

Thermostat

In the ZMZ-406 cooling system, it plays the role of a valve that redirects coolant from a small circle to a large one. The engine is designed to operate at temperatures from 87 to 103 degrees.

While the engine is warming up, the thermostat is closed, which makes it possible to quickly warm up the internal combustion engine to its operating temperature. When the coolant heats up to 60 degrees, the thermostat will open and the liquid will flow through a large circle of the cooling system through the radiator.

Many drivers of cars equipped with these engines believe that the thermostat is the weak link in the cooling system circuit. Often the unit jams and the motor overheats or does not heat up at all. The solution to the problem is to completely replace the thermostat.

The thermostat distributes the flow of coolant. It has two valves - bypass and main. The thermostat operation diagram is as follows.

When the engine is not warmed up, the main valve is still closed. The liquid moves in a small circle, which begins in the cooling jacket and cylinder head, and then passes past the radiator. In this case, the antifreeze will return back to the pump.

When operating temperature is reached, the main valve will open and the bypass valve will close. When the temperature reaches 94°C, the main valve will open fully. The liquid will move along the jacket in the block. Then it will go through the main valve, and then into the radiator. This is a large circle of the ZMZ-406 cooling system.

DIY pump repair

The centrifugal engine coolant pump is a dismountable unit. If for any reason you decide not to install a new pump and begin repairing the existing pump, then it is possible to replace individual elements. You can try to replace the centrifugal pump bearings, shaft, impeller, etc. This approach sometimes allows you to reduce the cost of repairs, but it is not always possible to find the necessary spare parts on the open market.

It should be noted that access to the pump for partial or complete disassembly is often difficult. Some car models are designed in such a way that you will first need to slightly unscrew the power unit mounts. This will need to be done from below, so it is highly desirable to have an inspection hole, certain skills and available tools.

Replacing the oil pump ZMZ-406

1. Drain the oil from the engine crankcase.

2. Remove the oil sump.

3. On the engine mod. 402 unscrew the two nuts 1 and remove the pump 2 with the receiver assembly.

4. On the engine mod. 406, unscrew the three bolts and remove the pump and receiver assembly.

Disassembly

Engine oil pumps mod. 402 and 406 are similar in design.

1. Remove the hex shaft of the oil pump drive.

2. Remove the mesh from the receiver by bending the edges of the mesh.

3. Unscrew four bolts 3 and remove receiver 2 and partition 1

4. Remove drive gear 1 with the shaft and driven gear 2. If you need to remove the drive gear from the shaft, knock out the pin.

5. Remove cotter pin 1, washer 2, spring and plunger of the pressure reducing valve installed under washer 2.

6. Wash the pump parts with gasoline and blow with compressed air.

Inspection and repair

1. If there is wear from the gears on the partition (cover for mod. 402), it must be sanded so that there are no traces of wear left.

2. Inspect the body. If it is very worn, the pump needs to be replaced.

3. The gears in the pump housing must rotate completely freely.

4. The pressure reducing valve plunger must move completely freely in the body.

5. Inspect the pressure reducing valve spring. If there are visible cracks or broken coils, replace the spring.

The length and stiffness of the spring are selected at the factory in such a way that the operation of the pressure reducing valve is optimal, so the length and stiffness of the spring cannot be changed in any way.

The free length of the spring should be 50 mm, the force to compress the spring by 10 mm should be 46 N (4.6 kgf) for an engine mod. 406.

For engine mod. 402, in order to compress the spring to a length of 40 mm, it is necessary to apply a force of 43.5–48.5 N (4.35–4.85 kgf). If the spring does not meet at least one of these requirements, it must be replaced.

Assembly

The pump is reassembled in the reverse order. When assembling the engine pump mod. 402, a cardboard gasket 0.3 mm thick must be placed under the pump cover.

It is prohibited to install a gasket of a different thickness or use sealant, paint, etc. when installing the gasket, as this will reduce the performance of the pump.

Install the pump in the reverse order of removal.

Source