Signs of a malfunctioning cooling system

| Characteristic signs of a faulty cooling system | Possible causes of failure |

| Engine overheating |

|

| Engine hypothermia |

|

| Coolant leaking outside |

|

| Coolant leaking inside |

|

There are only four external signs of a breakdown in the engine cooling system. So, these include:

- engine overheating during operation;

- engine hypothermia (the engine warms up slightly, for example, in the cold);

- coolant leaking out;

- Coolant leakage inside (into other vehicle systems).

In addition, problems in the cooling system can be judged by the warning light on the dashboard (red float or yellow expansion tank). Each car is equipped with a corresponding indicator, which is activated when the coolant boils. Also, when the engine overheats, its power drops significantly, the dynamic characteristics of the car decrease, and in the worst case, when it has already boiled, steam can come out from under the hood (from the radiator or tank). All this is very harmful for the engine, because when it overheats, it wears out, which significantly reduces its service life, and can even completely damage the engine.

If there are external coolant leaks on the asphalt under the car or on individual parts of the engine compartment, the car owner may notice corresponding stains. Antifreeze has a specific sweet smell, so you can often sense a leak accordingly. If a fluorescent element is added to the antifreeze, the leak can be detected using an ultraviolet lamp. However, this must be done in advance, when pouring new fluid into the system.

Internal leaks are more difficult to detect. If antifreeze gets into the engine oil, the car's exhaust gases will be in the form of white smoke. Also, when checking the condition of the engine oil, there will be a white mass similar to sour cream in it. This directly indicates that there is antifreeze in the oil. Accordingly, it is necessary to carry out diagnostic and repair work with a complete replacement of both fluids.

Difficulties with pressure in the cooling system

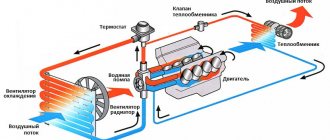

Operating principle of the engine cooling system

In fact, there can only be 2 such problems in the cooling system - it is either too high or too low. Let's try to deal with each of them.

If the pressure increases excessively, the cooling system components may fail. For example, there are known cases when the safety valve did not work and the interior heater radiator simply burst. The pipe may also burst or be torn from its mounting. This will lead to loss of coolant, engine failure due to overheating and costly repairs.

If during operation you are faced with the fact that one of the pipes in your car constantly breaks off, this means you have high pressure in the cooling system. The reason for such a malfunction in all cases is the same - the safety valve does not work. It is very easy to fix this problem - you just need to change the cap on the radiator or expansion tank.

Low pressure in the cooling system can be indicated by a not too warm air flow from the interior heating deflectors. There may be several reasons in this case:

- The valve installed in the expansion tank plug is “soured” in the open position and the cooling system communicates with the atmosphere. It is very easy to verify this. Once you have started the car and it has warmed up enough, simply open the cap on the expansion tank. If the valve is working properly, you should hear a characteristic hissing sound. Otherwise, the valve is faulty. Then the coolant begins to boil at a lower temperature, steam-air plugs form and the heater in the cabin begins to heat much worse. Moreover, the engine itself quickly “boils”. Replacing the plug will help fix the problem; fortunately, buying a new one is not particularly difficult now.

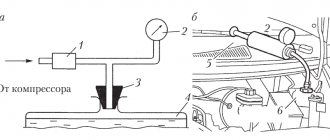

- Antifreeze leakage. If you cannot find where the air is “sucking” into the radiator, you can check this without much difficulty in almost any garage. To do this, you will need a car pump with a pressure gauge and a minimum set of tools. Remove the thin pipe from the expansion tank, plug it with a bolt of suitable diameter and compress it with a clamp. Connect the pump to the tank and start pumping. You need to pump air into the system until the pressure gauge shows 1.4–1.6 bar (usually the safety valve on the plug is activated in this interval), and watch where the liquid begins to ooze. If there are no leaks on the engine, then be sure to check the interior - it happens that the leak is inside. Fix the leak and everything will work as it should.

- Low coolant level. If the level is higher than normal when heated, the coolant expands and begins to flow out, which accordingly entails an increased overconsumption of antifreeze. If the level is too low, the liquid begins to boil and air pockets form, due to which, in turn, low pressure forms in the system. To prevent such situations, regularly check the antifreeze level in the tank and maintain it within normal limits.

Which method of eliminating system pressure problems is right for you depends on each individual case.

For our part, we can only advise you to carry out all routine maintenance and maintenance on time. And then your car will delight you with reliable operation for many years.

Causes of cooling system malfunction

There are many reasons that lead to partial and even complete failure of the cooling system. Depending on which nodes were damaged, the following main causes of failure are distinguished:

- violation of maintenance of the cooling system (in particular, the car owner forgets to periodically add/change antifreeze or uses coolant with parameters inappropriate for the car);

- use of low-quality system parts (pipes, taps, radiator);

- use of poor coolant that does not meet the requirements;

- critical wear or complete failure of individual elements of the vehicle cooling system;

- performing poor-quality repairs or maintenance of both the engine in general and its cooling system in particular;

- significant clogging of cooling surfaces.

However, the reasons listed are only a generalization of the problems with the mentioned system. The real reasons are the wear and tear of specific components.

Why might the motor overheat?

A lot of heat is given off by the coolant in the radiator, therefore it is impossible to warm up the antifreeze to operating temperature. The thermostat malfunctions for several reasons. Often this is the use of antifreeze, the resource of which has long been exhausted. Scale forms and gradually settles on the thermostat elements. And then there is a disruption in the operation of all components of the system.

A similar malfunction can be caused by pouring water into the engine cooling system. Therefore, you need to change the fluid in the system as often as possible, and do not pour water from the tap. It is worth noting that the antifreeze resource is approximately 80-90 thousand kilometers. Therefore, when replacing a pump that has a similar resource, it is advisable to flush the entire cooling system and also replace the antifreeze. In many ways, the malfunctions of the VAZ-2106 engine cooling system are similar even to those that appear on foreign cars.

Basic malfunctions of the engine cooling system

The cooling system of a car engine consists of a large number of individual parts - radiator, fan, pipe system, sensors. If at least one element does not work correctly, the entire system begins to work worse. Therefore, the cause of the breakdown may be:

- Radiator clogged . It is this element that is intended for the forced removal of thermal energy from the engine. If it becomes clogged externally (a large amount of dust and dirt gets into its slots) or internally (the core becomes clogged with a significant amount of rust and liquid sediment), then the efficiency of the unit is sharply reduced. Accordingly, the radiator, like the entire cooling system, must be periodically cleaned both outside and inside using special cleaners or improvised means.

- Faulty pump . For this reason, the cooling system either leaks from under the cooling pump bearing, or the circulation of liquid through the cooling jacket is disrupted. There are several reasons for pump failure. Among them are banal wear of its blades or internal parts, weakening of the drive, and violation of tightness. Often, corrosion can be observed on metal impellers, but the plastic impeller simply breaks off and turns.

- Incorrect operation of the thermostat . The main task of this unit is to block the flow of antifreeze or antifreeze into the radiator until the engine has warmed up sufficiently. On most cars, it opens only when the coolant temperature reaches +87... +95°C. Accordingly, if it fails, the engine will heat up for a very long time, especially in cold weather. If the thermostat is stuck and does not open at all, then the temperature in the system will be higher than normal until it boils. When it is open constantly, the temperature is below normal.

Another malfunction can be considered the use of antifreeze with inappropriate parameters, for example, ordinary water. As you know, in cold weather it crystallizes, which usually leads to mechanical failure of the elements of the cooling system. Therefore, you need to choose antifreeze in accordance with the requirements of the car manufacturer .

Methods for troubleshooting a cooling system

The choice of cooling system repair method depends on the reasons that caused its malfunction. We list them in the same order as the reasons.

- Radiator clogged. It must be cleaned from the outside and preferably rinsed from the inside. As a rule, the radiator is removed from the car for cleaning. In parallel with cleaning, you can check its tightness. Please note that if the car is equipped with two radiators, for the engine cooling system and for the air conditioner, then both radiators must be dismantled and cleaned.

- Pump failure. This unit cannot be repaired, so immediately replace it with a similar one. The choice of pump is based not only on the manufacturer, but also on the material of the impeller - metal or plastic.

- Problems with the thermostat. There is a similar situation here; usually the thermostat is not repaired, but replaced with a new one.

- Cooling Fan. If the fan impeller is damaged, then it must definitely be replaced. If the mechanical drive has loose tension, it should be tightened to the appropriate value. If the belt is damaged, it should be replaced with a new one. If the thermal relay or drive motor fails, these components must also be replaced. In rare cases, you can try to restore the electric motor (repairing bearings, rewinding the winding). The hydraulic fan drive needs to be topped up with oil and the condition of the bearings checked.

- Depressurization of the system. A fairly common cause of failure, which is however difficult to diagnose. This is due to the fact that the leak can be very small and located in a hard-to-reach place. The first thing you need to do is check the condition of the engine oil to see if there are any white clots in it, which are the antifreeze leaking into it. If this is the case, then you need to check the condition of the cylinder head gasket, the cylinder head plane itself, the condition of the heat exchanger and its gasket, and the condition of the cylinder block for leaks. And of course, you need to check all the pipes to see if there are any traces of leaking coolant on them, and also inspect the elements of the engine compartment to see if there are any traces of antifreeze on their surface. When a coolant leak occurs from the radiator or a crack in the pipe, then as a temporary measure, you can fill in antifreeze with a sealant that will plug the leak.

- The temperature sensor has failed. Needs replacement with a new similar one. First you need to remove it from the car and perform additional diagnostics using a multimeter (ohmmeter) and/or thermometer.

- Low antifreeze level. If there is insufficient amount of coolant in the service interval, it must be added (in this case, you must be aware of which antifreezes can be mixed with each other and which cannot!), or replaced with a new one.

- Broken valve on the radiator cap. Usually the cap and its valve cannot be restored, so it must be replaced. However, you first need to check the radiator cap for functionality.

Prevention of normal operation

A properly functioning cooling system of any car is able to ensure normal engine operation even at very high ambient temperatures. A decrease in its effectiveness is usually caused by the fact that the car owner does not pay due attention to checking the operation of the system. In fact, in order for the cooling system to work smoothly and without interruption, you need to follow a few simple rules:

- While driving, constantly monitor the coolant temperature gauge, as well as the warning light that lights up when it boils. If the indicator lights up, you must stop the car as soon as possible and try to find out the reason.

- Constantly monitor the coolant level in the system. Typically, according to regulations, antifreeze is changed after approximately 60.120 thousand kilometers. Other automakers recommend changing it every two to three years. However, it would not be superfluous to monitor the appropriate level during the service interval, especially if you suspect that the engine cooling system is not working correctly.

- Use antifreeze with the prescribed characteristics. In the documentation for any car, the manufacturer directly indicates what coolant needs to be poured into the system. This applies to its class, compliance standard and quantity. The manufacturer is also less often indicated, but this is rather an exception and direct advertising.

- Check the cooling system for leaks. In particular, whether there are external or internal antifreeze leaks. Along with eliminating the leak (if any), you must also remember to add fluid to the required level or replace it with a new one.

- Check the condition of the radiator. Often its outer surface becomes clogged with dust and dirt, which significantly reduces its performance.

- Do not overload the engine. In particular, it is not recommended to frequently develop excess power on the engine. For example, when driving an overloaded car, using a sporty driving style (at high speeds, with slipping, sudden starts), towing heavy trailers. All this significantly wears out both the engine as a whole and its cooling system in particular.

- Periodically clean the cooling system. This can be done when replacing antifreeze with a new one, or when clear signs appear that the efficiency of the system has decreased.

By following such direct advice, the car owner can not only ensure the normal operation of the cooling system, but also significantly extend its service life.

Good afternoon. In today's post, I would like to look at typical engine cooling system malfunctions, their symptoms and consequences for the engine. Traditionally for our site, the article contains a large number of photos and video materials and will be of interest to a wide range of readers.

Preventing problems

Comprehensive testing of a cooling system is a rather complex and time-consuming task. Typically, wear, clogging, mechanical damage and other problems are identified during the inspection process. But the car owner should perform several simple operations to check this system before each trip:

- with a cold engine, inspect the expansion tank, make sure there are no signs of leaks, check the coolant level (the norm is between the min and max marks);

- if the level is close to the minimum permissible level or lower, add coolant of the same brand that was used before. In the absence of a compatible coolant, it is permissible to increase the level using distilled water, but you can fill no more than half a liter;

- Check the fluid level again with the engine warm by carefully and slowly unscrewing the expansion tank cap (it gets very hot!). If the fluid level drops below the minimum after starting the engine, this indicates a leak due to damage to the hoses or pipes.

It is unacceptable to add cold fluid when the engine is warm, or to start the engine after draining the fluid from the system! If the decrease in the liquid level in the tank is insignificant and is due not to leakage, but to evaporation, you should add distilled water rather than antifreeze; it is this that evaporates first, resulting in an increase in the density of the liquid. Care must be taken to ensure that no gasoline gets into the coolant.

To prevent breakdowns of the cooling system, it is necessary to use high-quality antifreeze

If the coolant level is fine and there are no leaks, but the engine heats up excessively or, conversely, does not warm up when starting, a more detailed diagnosis of the cooling system is needed.

An antifreeze leak is sometimes mistaken for a harmless buildup of condensation under the hood. Therefore, if moisture is detected, it is not superfluous to check the hoses; if, when trying to compress or bend them, it turns out that they have lost their elasticity, they need to be replaced as soon as possible to prevent or eliminate leaks.

Why does the engine overheat?

Thermostat failure.

A failed thermostat is the most common cooling system failure. The thermostat, despite its simple design, is in an aggressive environment, becomes covered in oxides and fails... The engine will overheat if the thermostat is stuck in the closed position, since antifreeze will not enter the main radiator. Such a malfunction can be treated by replacing the thermostat with a new one, which it makes sense to “weld” before installation.

Clogged radiator.

We have a separate article about a radiator clogged with dust and cleaning it. A clogged radiator with plastic tanks inside, if heavily soiled, is almost impossible to clean. Radiators with brass tanks used to be soldered and pierced with a cleaning rod, but in modern radiators this is not possible. If the contamination is not severe, it makes sense to flush the cooling system. If the radiator is heavily contaminated, it is usually replaced.

Faulty pump.

If you did not change the antifreeze in a timely manner and the corrosion inhibitors it contained stopped working, then you may well see this picture:

The pump may also jam or slip (in this case, you will hear the belt whistling).

The pump is usually replaced.

Late ignition.

On old engines, if the ignition was adjusted incorrectly, overheating occurred, but today such engines are already rare.

Why does the engine take a long time to warm up?

The thermostat is stuck open or has changed temperature characteristics.

Everything is very simple - the thermostat is the main element that sets the temperature regime of the engine, its task is to limit the amount of antifreeze entering the main radiator. If all the coolant passes through the main radiator, the engine will take a very long time to warm up, and in winter it will not be able to warm up at all.

The viscous coupling is jammed.

Some vehicles use a mechanically driven cooling fan. In most cases, it is done through the so-called. viscous coupling. Here's how it works:

If the viscous coupling is stuck, the cooling fan will constantly rotate at maximum speed, and engine warming up will slow down, but if the thermostat is working, the engine will still maintain temperature.

Less common causes

It is also possible that some vehicles that have a power-driven fan will experience hypothermia. Therefore, many drivers replace a mechanical fan with an electric one. It is worth noting that the latter practically does not turn on in winter if the outside temperature is below zero degrees. Just pay attention to the fact that the entire system must be perfectly sealed. There should be no cracks in it. All seals and gaskets must be intact and without damage. Under no circumstances should the radiator be allowed to leak. Such malfunctions exist in the VAZ-2110 engine cooling system; they are similar for all cars.