Engine power system repair

The main malfunctions of the power system of a gasoline engine with a carburetor are:

- stopping the fuel supply to the carburetor;

- formation of a too lean or rich combustible mixture;

- fuel leakage, difficulty starting a hot or cold engine;

- unstable engine operation at idle;

- interruptions in engine operation, increased fuel consumption;

- increased toxicity of exhaust gases in all operating modes.

The main reasons for stopping the fuel supply may be : damage to the valves or diaphragm of the fuel pump; clogged filters; freezing of water in fuel lines.

In order to determine the reasons for the lack of fuel supply, you need to disconnect the hose supplying fuel from the pump to the carburetor, lower the end of the hose removed from the carburetor into a transparent container so that gasoline does not get on the engine and prevent it from catching fire, and pump up the fuel using the manual pump lever of the fuel pump or turning the crankshaft with the starter. If a stream of fuel appears with good pressure, then the pump is working.

Then you need to remove the fuel filter from the inlet fitting and check whether it is clogged. A pump malfunction is indicated by poor fuel supply, intermittent fuel supply and no fuel supply. These reasons may also indicate that the fuel supply line from the fuel tank to the fuel pump is clogged.

The main reasons for a lean combustible mixture may be : a decrease in the fuel level in the float chamber; sticking of the needle valve of the float chamber; low fuel pump pressure; contamination of fuel jets.

If the throughput of the main fuel jets changes, this leads to an increase in the toxicity of exhaust gases and a decrease in the economic performance of the engine.

If the engine loses power, “shots” are heard from the carburetor, and the engine overheats, then the causes of these problems may be: poor fuel supply to the float chamber, clogged nozzles and nozzles; clogging or damage to the economizer valve, air leaks through leaks in the carburetor and intake manifold.

Loss of engine power when running on a lean mixture may occur due to slow combustion of the mixture and, as a result, lower gas pressure in the cylinder. When the combustible mixture becomes lean, the engine overheats because combustion of the mixture occurs slowly and not only in the combustion chamber, but throughout the entire volume of the cylinder.

In this case, the heating area of the walls increases and the coolant temperature rises.

To repair and eliminate defects, it is necessary to check the fuel supply. If the fuel supply is normal, you need to check whether there is any air leakage in the connections, for which you start the engine, close the air damper, turn off the ignition and inspect the junction of the carburetor and the intake pipe. If wet spots of fuel appear, this indicates the presence of leaks in these places. Eliminate defects by tightening the nuts and bolts. If there is no air leakage, check the fuel level in the float chamber and, if necessary, adjust it.

If the jets are clogged, they are blown out with compressed air or, as a last resort, carefully cleaned with soft copper wire.

Fuel leaks should be repaired immediately due to the possibility of a fire and excessive fuel consumption. It is necessary to check the tightness of the fuel tank drain plug, the connections of the fuel lines, the integrity of the fuel lines, the tightness of the diaphragms and connections of the fuel pump.

The reasons for difficulty starting a cold engine can be: lack of fuel supply to the carburetor; malfunction of the carburetor starter; ignition system problems.

If fuel is supplied well to the carburetor and the ignition system is working properly, a possible reason may be a violation of the adjustment of the position of the air and throttle valves of the primary chamber, as well as the pneumatic corrector of the starting device. It is necessary to adjust the position of the air damper by adjusting its cable drive and check the operation of the pneumatic corrector.

Unstable engine operation or stopping of its operation at low idle speed can be caused by the following reasons: incorrect ignition installation;

the formation of carbon deposits on the spark plug electrodes or an increase in the gap between them; violation of the adjustment of the gaps between the rocker arms and the camshaft cams; decreased compression; air leakage through the gaskets between the head and the intake pipe and between the exhaust pipe and the carburetor.

Carburetor Maintenance

Although carburetors have been practically replaced by injection systems, they are still in service and, which is very pleasing, are very driver-friendly elements of the propulsion system. Even an inexperienced car enthusiast can work with a carburetor, although he should also acquire service manuals for his specific car model

(or find information online). The list of materials and tools for working with various carburetors is almost always the same:

- Carburetor cleaner;

- Latex gloves;

- Rags;

- A can of compressed air;

- A brush with not too stiff bristles;

- Protective glasses;

- Volume capacity for parts;

- Carburetor removal tools (depending on model).

Dismantle the carburetor in accordance with the manual. In most cases, it is enough to pull back the return spring, remove the rods, hoses, pipes, loosen the clamps, and then unscrew the nuts. We still advise you to consult manuals, find relevant information on forums or even video tutorials

– access to the World Wide Web will be very useful here.

After the carburetor is removed, disassemble it, place all the parts in a container, pour the cleaning agent into it and leave it for a few minutes. Afterwards, continue cleaning with a brush and a can of air. Brushes with metal bristles are not suitable

- you need to take a regular toothbrush. Be especially careful with the jets! It is better to blow them thoroughly, and if this does not solve the problem of contamination, then very delicately clean them with a toothpick. Replace gaskets if necessary. In stores you can find relatively inexpensive carburetor repair kits, which include everything needed for repairs. If the moving parts of the unit are not damaged, it can be quickly returned to service. Do not forget also that after disassembling, cleaning, assembling and installing the carburetor, it will probably have to be reconfigured.

We should also talk about carburetor cleaners. A magical remedy, if you think about it - just spray the spray inside the unit, and it will be cleaned of contaminants. Actually cleaners

It is recommended to use every 5-7 thousand kilometers.

If the carburetor has not been cleaned for a long time, spray alone will not be enough. The unit will have to be disassembled, and the parts will have to be soaked in a cleaner and then rubbed with a brush. The use of the popular WD-40

, as well as other cleaning products that contain oil, is strictly prohibited.

Carburetor engine diagnostics: power system

Even taking into account the fact that cars equipped with a carburetor are an outdated solution, such cars continue to be popular in the CIS and are firmly established in the lower price segment. At the same time, the relatively simple power system of a carburetor engine requires special attention and needs regular maintenance.

This approach makes it possible to achieve stable operation of the internal combustion engine in different modes, as well as reduce fuel consumption and exhaust toxicity levels. Next, we will look at the main malfunctions of the power supply system of engines with a carburetor, which usually arise during vehicle operation.

Engine power system with carburetor: features and problems

As you know, a car internal combustion engine, regardless of the type of engine and type of fuel (carburetor, injection, gasoline or diesel), runs on a mixture of fuel and air.

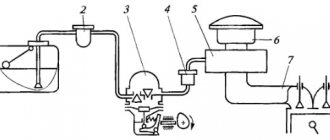

Air is “sucked in” by the engine from the atmosphere, and fuel is supplied from the fuel tank through the fuel lines due to the operation of the fuel pump (mechanical or electric). The so-called fuel-air working mixture consists of fuel and air, which are mixed in strictly defined proportions. Then the working mixture is burned in the cylinders.

On certain engines, fuel supply and mixture formation can also be implemented in different ways. In injection engines (except engines with direct injection), fuel is first supplied to the intake manifold through injectors, after which it is mixed with the air there. The mixture then enters the combustion chamber.

In a diesel engine, fuel is injected directly into the combustion chamber, where pre-supplied, compressed and heated air is already located. By the way, a diesel engine has the most complex fuel system.

For this reason, diagnosing the power supply system of a diesel engine is an important and responsible procedure, since the overall service life of such engines greatly depends on the proper operation of the diesel power system.

- If we talk about a carburetor, this is the simplest mechanical metering device; a carburetor engine has external mixture formation. This means that a ready-made working mixture of fuel and air enters the cylinders. The preparation of the air-fuel mixture occurs in the carburetor, where both fuel and air are supplied.

As a rule, carburetors are mechanical devices, that is, the design does not involve the active use of electronic components. The only exceptions can be considered only certain later developments, which are actually transitional devices from a carburetor to a monoinjector. Such carburetors contain separate electronic actuators.

Advantages and disadvantages

When talking about the differences between carburetor systems and injection systems, even knowledgeable people often reduce the discussion to a discussion of the advantages and disadvantages of the former. Of course, the transition to injectors was not spontaneous - it was preceded by serious changes in mechanical engineering, as well as the requirements of potential buyers for personal transport. Let's look at what the carburetor can boast of and what is its weakness:

- Advantages

: simplicity, low cost, low octane requirements for fuel, relatively good dynamics; - Disadvantages

: low efficiency, sensitivity to low and very high temperatures, high fuel consumption, inability to meet the Euro environmental standard.

By the way, the latter is one of the most serious reasons why carburetors are viewed with caution in Western countries - they do not meet even the most “gentle” requirements of environmental standards. However, they install it on motorcycles, but the environmental requirements for this type of transport are less stringent. The low efficiency factor is also not in favor of the unit. A tenth of it is spent only on the operation of the fuel system. Partly, the shortcomings of carburetors are compensated by their “omnivorousness” and ease of repair.

Selection of a new carburetor

Despite the fact that carburetor systems are extremely durable, sometimes they require not so much a major overhaul as an almost complete replacement. For example, if the air and fuel channels are completely coked, if the connections are bent and serious mechanical damage occurs to the carburetor, it needs to be completely replaced

. What’s great is that you don’t have to replace the carburetor with exactly the same one - today some companies produce more economical, powerful and quiet analogues. However, when choosing a new unit you need to pay attention to:

- Diffuser. With proper selection, preference should be given to diffusers whose diameter is no more than 0.8 of the diameter of the mixing chamber;

- Main fuel jet. A jet of suitable throughput can be determined experimentally, but we recommend that you first consult with a specialist;

- Air jet. Likewise;

- Throttle diameter. The diameter range depends on the power of the individual engine cylinders.

It is also worth paying special attention to selecting a suitable accelerator pump. Don’t forget that when choosing a carburetor you should find out as much as possible about the manufacturer

. Here are the most famous and reliable manufacturers and suppliers:

Car enthusiasts can also find carburetors on sale from various little-known companies

, whose factories are located in China, Turkey, Thailand and Indonesia. In terms of the quality of their products, they are inferior to the above-mentioned companies, however, given the simplicity and reliability of carburetors, even their products can pleasantly surprise. One of the key features of these manufacturers is also a democratic pricing policy. Czech and Polish companies are pleasantly pleased with both their price and assortment. As a rule, in their catalogs you can find not only the units themselves, but also everything necessary for their repair and maintenance.