Engine characteristics

The power and economic capabilities of an internal combustion engine when operating under various operating conditions can be assessed by the technical and technological characteristics obtained as a result of various tests - bench, road, test site, operational, etc. The

characteristics of an engine are the dependence of the main indicators of its operation (power , torque on the output shaft, fuel consumption) on one of the operating mode parameters (crankshaft speed, external load, etc.). The characteristics of the engine determine its performance, level of technical excellence, correct adjustments, as well as its purpose.

The main characteristics of automobile engines are determined by GOST 14846-81 “Automotive engines. Bench testing methods":

speed characteristic - the dependence of the main effective indicators of engine operation on the speed of rotation of its crankshaft;

adaptability coefficient - the ability of the engine to overcome short-term overloads;

load characteristics – dependence of specific and hourly fuel consumption on the power developed by the engine;

idle characteristics - the dependence of hourly fuel consumption on the crankshaft speed when the engine is running without load;

regulatory characteristics - the dependence of power and economic performance indicators on the composition of the working mixture ignited in the engine cylinders, the ignition or injection timing, engine temperature and other adjustable factors.

Load characteristic

The load characteristic is the change in hourly and specific fuel consumption depending on the load value. Operation in load characteristic modes is most typical for engines that are used to drive electrical units, pumps, compressors, and tractors. In particular, the load characteristic simulates the operation of an engine in a car when it moves at a constant speed in one of the gears under conditions of variable resistance from the road.

The purpose of obtaining the load characteristic is to determine the fuel efficiency of the engine.

Conditions for obtaining the load characteristic:

- an independent variable is the load on the engine (since with increasing load, to overcome it, the engine must increase power Ne, average effective pressure pe and torque Mk, then the load is expressed as a percentage relative to one of these parameters;

- constant value – crankshaft rotation speed;

- dependent variables are specific fuel consumption gе and hourly fuel consumption Gt.

Speed characteristic

The speed characteristic of an engine is the dependence of the main effective indicators of its operation (effective power, torque on the output shaft, specific and hourly fuel consumption) on the crankshaft speed with a constant supply of fuel to the cylinders in a steady-state thermal regime.

There are external and partial speed characteristics. The speed characteristic obtained with full fuel supply (fully open throttle or the corresponding position of the diesel fuel pump rack) and at ignition timing or the start of fuel injection according to the engine specifications is called external engine speed characteristic. The external speed characteristic allows you to determine the maximum power performance of the engine and evaluate its efficiency at full load.

The characteristics corresponding to constant intermediate positions of the throttle valve or fuel pump rack are called partial engine speed characteristics. In other words, any characteristic obtained when the engine control element is not fully opened is called a partial speed characteristic.

The speed characteristics of a real engine are based on the results of bench tests. The shaft of a running engine is loaded using a brake, ensuring that the rotation speed is fixed from the minimum stable to the maximum permissible. At the same time, at each frequency, the braking torque Mt in (N×m) and the hourly fuel consumption in kg/h are measured.

Based on the test results, curves are constructed depending on the effective torque and hourly fuel consumption on the engine shaft speed. Then, using the formulas:

find the effective power and specific fuel consumption, and then display their graphical dependencies.

Depending on the completeness of the engine with auxiliary devices and equipment, the net power (full configuration) or gross power (incomplete configuration) is determined. The following characteristic crankshaft rotation speeds are distinguished:

- minimum rotation speed at which stable engine operation is possible with full fuel supply;

- rotation speed corresponding to the highest torque;

- rotation speed corresponding to the highest engine power;

- the highest possible crankshaft speed set by the speed limiter.

The idle speed characteristic is a special case of the engine speed characteristic.

The external speed characteristic of a newly designed engine can be constructed using empirical dependencies, where the maximum power and the corresponding specific fuel consumption and rotational speed are taken from the thermal calculation data of the engine during its design.

Engine response and adaptability

The ability of an engine to increase power with increasing crankshaft speed is called its throttle response. Engine throttle response directly affects the car's throttle response, i.e. its ability to accelerate and accelerate. The speed characteristic largely reflects the degree of engine response: the steeper the Ne curve, the greater the engine response. If you compare the speed characteristics of a carburetor engine and a diesel engine, you will notice that the Ne power curve of a diesel engine is steeper, i.e., a diesel engine has greater throttle response.

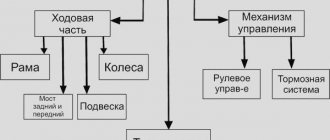

Classification of internal combustion engines

Car engines are divided into several types and classifications, depending on the design and operation of the internal combustion engine. Classification of internal combustion engines according to international standards:

- For the type of injection of the fuel mixture:

- Those that run on liquid fuels (gasoline, kerosene, diesel fuel).

- Those that run on gaseous fuels.

- Those that operate on alternative sources (electricity).

- Consisting of work cycles:

- 2 stroke

- 4 stroke

- According to the method of mixture formation:

- with external mixture formation (carburetor and gas power units),

- with internal mixture formation (diesel, turbodiesel, direct injection)

- According to the method of ignition of the working mixture:

- with forced ignition of the mixture (carburetor, engines with direct injection of light fuels);

- with compression ignition (diesels).

- By number and arrangement of cylinders:

- one-, two-, three-, etc. cylinder;

- single row, double row

- According to the method of cooling the cylinders:

- with liquid cooling;

- air cooled.

Power

Such engine characteristics as power are one of the most important. As a rule, it is from this that one can draw a conclusion about how quickly the car will behave on the road and how comfortable it will be to drive.

Power is usually measured in horsepower. As a rule, the minimum value of the parameter is about 60–70 units, while the maximum values for cars on the market reach several hundred.

Horsepower is a conventional unit that was included in the characteristics of the internal combustion engine only due to the convenience and ease of approximate representation of the actual capabilities of the car.

Often in documentation, power is indicated in kilowatts, which is often convenient when studying specialized literature and selecting characteristics. A detailed comparison of horsepower and kilowatts can be found in the special documentation.

In addition to power, internal combustion engines are characterized by their displacement, which is expressed in cubic centimeters. For modern cars, the current values are 1000–4000 units. The working volume is usually called the value that characterizes the total volume of all cylinders provided in the internal combustion engine.

A comparison of naturally aspirated and turbocharged internal combustion engines shows that variants equipped with a turbo significantly benefit in terms of power and allow the engine to produce characteristics that owners of conventional internal combustion engines can only dream of.

Engine capacity

The working volume of the internal combustion engine determines its power. This parameter is measured in cm3, but more often in liters. It is determined by summing the internal volume of all cylinders of the power unit. The calculations are based on the cross section of the cylinder and multiplied by the stroke length of the piston. The result is a working volume. The parameter also determines the amount of fees in many countries around the world. Accordingly, the larger the volume, the more powerful the engine, which means its owner will pay a higher premium. A promising direction in modern developments are internal combustion engines with variable volume. This is a technology where, under certain conditions, the cylinders are turned off.

Torque

Another important characteristic in the list of main indicators for internal combustion engines is torque. Obviously, the greater this characteristic, the better the car will accelerate and drive. However, to understand how important this indicator is, it is worth understanding what it means.

Technical documentation always displays torque in units such as newton meters. Analyzing this formulation in the literal sense, we can come to the conclusion about how much force the engine applies to the wheel to move the car one meter.

It turns out that if the overall torque of one car is higher than that of another, then to move the car one meter, the motor applies slightly more energy.

What does this give? Firstly, more force allows the wheel to pick up speed faster. Provided that the tires on the car are not “bald” and the road surface is not icy, such a car will accelerate more intensely.

In addition, applying more force simultaneously reduces fuel consumption, since the engine has to spend much less energy to achieve the same acceleration time as a car with a less powerful power unit.

Main engine parameters

When faced with the need to choose a new car, modern car enthusiasts do not always know by what parameters to evaluate a particular vehicle. The most important device in a car is the internal combustion engine. Based on its characteristics, the capabilities of the entire car are assessed, but it is quite difficult to independently understand the structure of the motor. It is clear that it is difficult for novice and non-professional drivers to choose a new iron “friend”, due to their lack of awareness of the important parameters of the power unit. In order to understand a little the structure of the internal combustion engine and answer the question: “what is the principle of its operation?”, Let’s look at the characteristics.

Fuel

Another indicator that plays a significant role when choosing an internal combustion engine is the type of fuel and its consumption.

Typically, fuel consumption is measured in liters per 100 kilometers and is presented for three driving modes: highway, city and mixed. For the highway, the consumption is predictably minimal, while for the city its peak value is indicated. The mixed cycle displays the flow rate at its average value.

Fuel may vary. Its main type for an internal combustion engine is gasoline. Diesel internal combustion engines are more common in industrial equipment: they have higher torque and lower fuel consumption. In addition, diesel combustion requires high pressure, so this fuel is safer during storage and relatively fireproof.

New types of engines are hybrid ones. The main source of power is gasoline. The second part of the engine is represented by a storage battery and an electric motor with a generator: working in tandem, both motors allow the car to develop more power along with consumption, which is several times less than that of a classic internal combustion engine.

Peculiarities

The most important indicator of a piston internal combustion engine is the number of cylinders. On production cars there can be from 1 to 16. This factor affects the design of the engine, as well as the power; it can be different with the same number of cylinders.

The cylinders can be arranged in a row and at an angle to each other. When they are located at an angle relative to the crankshaft on both sides, the camber angle affects the characteristics of the internal combustion engine. As the angle increases, the center of gravity of the engine shifts downward, which improves the operation of the cooling and lubrication systems, an improvement in dynamic performance is observed, and inertia increases. As the angle decreases, weight and inertia decrease, but the temperature conditions worsen.

A boxer engine with an internal combustion mechanism is used in the automotive industry, the cylinder camber angle of which is 180°, while the advantages and disadvantages of the internal combustion engine are maximized. With a W-shape, four or more cylinders are used and they are included in a common drive. The in-line V-type engine is very rarely used; it is a synthesis of two standard varieties. Arranged in series, several cylinders are tilted at a certain angle relative to each other, this helps to improve temperature characteristics.

Important! These types of internal combustion engines differ in weight and size. An increase in the number of cylinders leads to a change in all characteristics: the working volume increases, its power increases, but fuel consumption also increases.

Cylinder arrangement

There is such a thing as engine configuration; it is determined by the layout of the cylinders and their location. There are 2 main types: in-line, when the cylinders are arranged in a row, and V-shaped. The second type is most often used in the modern automotive industry. In this case, the cylinders are located at an angle and connected to the crankshaft, forming the Latin letter V. This arrangement has subtypes:

- W-shaped arrangement of cylinders;

- Y-shaped arrangement of cylinders.

Less commonly used are layouts that form the shape of the Latin letters U and H.

Characteristics

Basically, the operation of an internal combustion engine is characterized by three indicators: power, torque and crankshaft speed. Power is denoted by horsepower (hp), sometimes expressed in kilowatts (kW). It affects the overall dynamics of the car, its speed and acceleration time. Torque affects the creation of traction force, is indicated in newtonometers (Nm), ensures smooth operation of the engine when changing gears and ensures acceleration of the car from low speeds. The maximum number of revolutions of the crankshaft affects the speed and dynamic nature of the vehicle.

No less important are the following characteristics of an internal combustion engine:

- The type of fuel used for an internal combustion engine can be gasoline, gas or diesel. Fuel brands differ in octane number; it must correspond to the type of engine and its characteristics. The use of inappropriate fuel leads to a loss of power and a reduction in the service life of the engine;

- The fuel consumption of an internal combustion engine is divided into urban, suburban and mixed. Indicated by the number of liters per hundred kilometers of vehicle mileage;

- engine oil consumption. It is measured in liters per thousand kilometers. Oils can be synthetic, semi-synthetic and mineral, they differ in thickness and viscosity. Their use is regulated by changes in seasonal temperatures; in winter, oils with low designations 0W40, 5W40, 10W40 are used, and in summer 15W40, 20W40. Transmission oils 70W90 or 95W100 cannot be used in the engine, as this will lead to jamming;

- resource durability - this parameter determines the frequency of maintenance. Typically, engine maintenance work is carried out between 5,000 and 30,000 kilometers. There are warranty and post-warranty maintenance periods.

- Internal combustion engines have a number of different design features:

- fuel system - can be gasoline or diesel. Gasoline engines develop greater power at a higher number of crankshaft revolutions, while diesel engines have high torque and are characterized by stable operation;

- On modern internal combustion engines, an electronic gasoline injection system (injection) is used; it shows better technical and economic indicators than the carburetor system. Due to poor mixing of the fuel-air mixture, the carburetor system has low efficiency, difficult-to-adjust mechanical adjustments lead to excessive fuel consumption;

- The gasoline injection system can be single-point or multi-point type. The disadvantage of a single-point system is that with a sharp decrease in load, fuel consumption increases. The multipoint type has a direct and distributed internal injection system. This creates a uniformly distributed mixture, which makes engine operation stable in all modes. But with direct injection, although there is an increase in power, durability and a decrease in fuel consumption, the cost increases significantly, since high-quality fuel is required and failures are observed at low speeds at the beginning of movement.

What is engine power

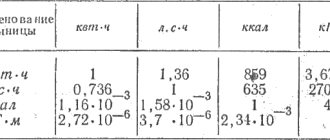

Power should be understood as a physical quantity that shows the work performed by the engine per unit of time. In rotational motion, power is defined as the product of torque and the angular speed of rotation of the crankshaft. It is usually indicated in horsepower (hp), but it can also be measured in kW.

There are several units of measurement called "horsepower", but, as a rule, what is meant is the so-called "metric horsepower", which is equal to ≈ 0.7354 kW. But in the USA and Great Britain, horsepower in cars is equal to 0.7456 kW, that is, 75 kgf*m/s, which is approximately equal to 1.0138 metric.

- 1 kW = 1.3596 hp (for metric calculus);

- 1 kW = 1.3783 hp (English standard);

- 1 kW = 1.34048 hp (electric “horse”).

If we convert the power of 1 horsepower into kilowatts (in industry or energy), then it will be approximately equal to 0.746 kW. The concept of horsepower is not included in the International System of Measurements (SI), so measuring power in kW will be more correct.

The more power, the higher the speed the car can develop.

Types of power

To determine engine characteristics, power concepts such as:

- indicator;

- effective;

- liter

The indicator power is the power with which the gases press on the piston. That is, no other factors are taken into account, but only the pressure of the gases at the moment of their combustion. Effective power is the force that is transferred to the crankshaft and transmission. The indicator will be proportional to the engine displacement and the average gas pressure on the piston.

The effective engine power will always be lower than the indicated one.

There is also a parameter called liter engine power. This is the ratio of engine volume to its maximum power. For gasoline engines, the liter power is on average 30-45 kW/l, and for diesel engines - 10-15 kW/l.

How to find out the power of a car engine

Of course, the value can be found in the documents for the car, but sometimes you need to find out the power of a car that has been tuned or has been in operation for a long time. In such cases, you cannot do without a dynamometer. It can be found in specialized organizations and at service stations. The car's wheels are placed between drums that create resistance to rotation. Next, movement with different loads is simulated. The computer itself will determine the engine power. It may take several attempts for a more accurate result.