Japanese engine and automatic transmission for GAZelle: what to look for

In the case of the GAZelle, many drivers seek to modify and modify the car to improve various characteristics, as well as to increase the level of reliability and comfort.

One of these radical decisions is the desire to install an imported engine with a gearbox on the GAZelle. Moreover, this method allows you to install an automatic transmission on a Gazelle, which is also a fairly popular option.

Taking into account the fact that a huge number of spare parts enter the territory of the Russian Federation from the Far Eastern region, and the engines themselves, gearboxes and other units from Japan are deservedly considered “indestructible”, for obvious reasons the choice often falls on them.

In simple words, a competent approach and relatively small investments make it possible to equip a GAZelle with a reliable Japanese gasoline or diesel engine, as well as a manual or automatic transmission.

It is quite obvious that such a solution has many advantages:

- It becomes possible to significantly improve the acceleration dynamics, the torque becomes higher. The increase in power allows you to confidently overtake on the highway, as well as drive at higher speeds. At the same time, it is possible to reduce fuel consumption, since Japanese engines are more productive and economical.

- You can install either a gasoline engine (which, if necessary, is additionally equipped with LPG) or a diesel engine. At the same time, the high reliability of Japanese units can significantly reduce the cost of spare parts and consumables (breakdowns occur less frequently, spare parts cost almost the same compared to the prices of parts for domestic internal combustion engines). We can also talk about the higher profitability of such modified commercial vehicles (the vehicle does not stand idle for frequent repairs).

- Comfort and ease of use are increased thanks to the ability to install an automatic transmission in a GAZelle paired with the engine. In fact, with an automatic transmission, a domestic budget truck becomes comfortable, reliable and easier to drive.

The main thing is to correctly calculate the possibility of installing units on a car with minimal intervention.

You also need to separately take into account power, torque and other characteristics, as well as subsequent loads on the engine and transmission during operation

For example, installing an engine with a large “reserve” of power (V6 engines) may not be as rational as it seems at first glance. The fact is that too powerful a motor with high torque leads to failure of standard axles, gearboxes and other elements of the Gazelle transmission. The load on other systems (for example, the braking system) also increases.

As for the automatic transmission, this solution is suitable if the car is used mainly in the city, but the operating conditions are not too severe. The reason is that the automatic machine does not “like” overloads, slipping, etc.

Considering that engines and automatic transmissions in GAZelles are often installed from lighter cars (often passenger cars), then you need to take into account the weight of the GAZelle, as well as the maximum loads when transporting goods

Taking into account the above, the optimal scheme can be considered the installation of a small and simple naturally aspirated 4-cylinder engine of up to 3.0 liters and a power of up to 170 hp. paired with a hydromechanical automatic transmission. By the way, Toyota and Nissan engines are in great demand and popularity for the Gazelle, and older designs at that.

Japanese engines of the 90s are highly reliable and have a long service life, they have cast iron cylinder blocks, a timing chain drive (does not require constant attention), etc. Automatic transmissions paired with such engines are also simple, 4-speed, have a long service life, are not so demanding on the quality of transmission oil, are not very susceptible to overheating, etc.

If we compare such internal combustion engines with a standard Gazelle engine (for example, 406 or 409), the Japanese engine is more powerful, better balanced, the unit is more reliable, and has a longer service life. At the same time, its power is not “excessive”, that is, it will not quickly damage other elements of the transmission.

An automatic transmission (subject to compliance with the rules for operation and maintenance) can easily cover 200-250 thousand km. without the need for any repairs. At the same time, the automatic transmission selector is quite easily integrated into the Gazelle’s interior. The convenient location of the automatic transmission lever makes it easier for the driver to interact with the gearbox.

Swap Gazelles

Product Catalog "

Swap of Gazelles is, first of all, an opportunity for you to work calmly, and not be downtime due to repairs, or break down right on the road. It just so happened that Gazelles, workers, have proven themselves well. But as for the good reviews about the Gazelle as a car - this, of course, is not praise. Simple in design, poor performance, not powerful and very voracious, these are the “+” that the owner of a Gazelle car receives. Of course, the price is tempting, despite the fact that foreign cars of a similar class cost much more.

Many of you have thought about replacing the internal combustion engine. This applies to both Next owners and Gazelle Business owners.

And we can offer you reliable Japanese motors of the JZ, UZ, VZ series.

But, first, let's determine what type of machines it is better to install on. Simply put, the power of the internal combustion engine is proportional to the purposes of the entire car.

1jzge vvti 2.5 liters and 200 hp. In-line, 6 cylinder. VVTI system, 4-range automatic transmission.

Suitable for cars with a load of no more than 1000-1500 kg. Optimal for short-wheelbase Gazelles.

2jzgevvti 3.0 liters and 240 hp. In-line, 6 cylinder. VVTI system, 4-range automatic transmission.

Suitable for cars with a load of 1000-2000 kg. Optimal for short-wheelbase Gazelles.

1uz fe non vvti - 4.0 liters, V8. There is no vvti system. Power is 240 hp, but at the same time more torque - 2 more cylinders work. Suitable for vehicles carrying 1500-2500 kg of cargo.

5vz fe non vvti - V6 3.3 liters. There is no vvti system. Power 180 hp, Suitable for vehicles carrying 1000-2000 kg of cargo. Well suited for long-wheelbase Gazelle models.

1uzfe vvti - V8, 4 liters. The vvti system is installed, thanks to which the internal combustion engine has high power and high torque. This internal combustion engine will be useful to you if you have a long-wheelbase Gazelle and you carry loads over 3000 kg.

What do we offer?

— Turnkey installation of Japanese transmission

— Maintenance of internal combustion engines and automatic transmissions according to service intervals

— Technical support in case of any emergency situations

— Flat floor in Gazelle

— Indication of the position of the automatic transmission in the Gazelle

— Maintaining the operation of all devices for monitoring power unit parameters:

speedometer, tachometer, dash meter, oil needle, fuel, temperature.

All internal combustion engines come with documents.

Swap of Gazelles is carried out by appointment. The time required to install any Japanese internal combustion engine is 21 working days.

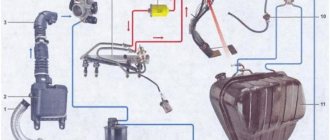

Examples of fastenings and solutions for swapping Gazelles with Japanese engines

Operating principle of a manual transmission

The operation of this device is carried out according to the principle of gear ratio. The basis of the design is an intermediate shaft that connects the other two - input to output. To change the gear ratio, the driver switches gears. This is a manual transmission with movable carriages.

Its disadvantage is the noise when disconnecting and engaging with another gear, moreover, this is a rather complicated process. Moreover, if you divide the speed of the first gear by the speed of the second, it will be equal to the number of teeth of the first gear divided by the number of teeth of the second.

There is no such problem in a mechanical gearbox with constant mesh gears. The principle of its operation is that a conditional connector moving along the shaft connects it to the gears. In this case, the teeth are constantly in an interlocked state.

Operating principle of a manual transmission

The output gears are in a non-rigid connection with the shaft; for this purpose, there is a gap between them. If, using a conditional connector, the shaft is rigidly connected to only one gear, it will set the rotation speed. When a conditional connector rigidly connects a shaft to certain gear elements, the speeds change. In fourth gear, the output and input shafts become directly connected.

The process of switching gears on a manual transmission

Each gear has a synchronizer, consisting of a friction cone and a locking ring. The gear is rigidly attached to the shaft, and a freely moving coupling is put on it. As the clutch moves, it engages the synchronizer teeth, and the gear and input shaft rotate in unison. The desired clutch is achieved, but when closed, the gear and shaft rotate at different speeds.

It is the blocking ring that allows you to equalize speeds. It can not only rotate with the gear, but also move along the axis. Before moving the clutch, the driver depresses the clutch pedal, but there is no power flow. When moving, the clutch presses the locking ring against the synchronizer cone. Due to the high friction force between these two parts, the speed of the gear becomes equal to the speed of the shaft.

The clutch then moves further and engages the gear so that it is locked with the shaft. Using the same principle, the transition to other gears is carried out, which is switched using a lever. The fifth position of the box is intended to rotate the output shaft at a speed higher than that of the input. For reverse gear, a device of three gears is used. The gears are not synchronized with the mechanism, so the gearbox must be stopped before reverse is engaged.

The principle of operation of a manual transmission in different gears

Pros and cons of mechanics

This simple mechanism is less prone to breakdowns, and this is what is installed on most cars. The cost of such a box is lower and, if necessary, you will have to pay less for repairs. If you compare the weight, it is lighter than the automatic one. At the same time, its fuel consumption is 10-15% less.

This type of box is often chosen if the machine is operated in difficult conditions. In the event of a breakdown, you can tow the car without fear of breaking the box. The engine starts even if the battery is broken or the ignition is faulty.

The disadvantages are listed:

- Difficult operation - learning to drive with a manual transmission is more difficult, it is easy to get confused when changing gears. As a result, the mechanism may fail.

- Inconvenient control when traveling around the city - during a traffic jam, the driver gets more tired, as he is forced to constantly press the clutch with his foot.

- Loss of power when changing gears.

Installation of Japanese diesel engines on gazelle, ZIL, UAZ, GAZ

I suggest you install on your Gazelle cars (all modifications, including Business), contract Japanese diesel engines NISSAN TD27T and QD32T. I order the engine and gearbox in Vladivostok from customs (not from local dealerships). Advantages: they have a cast iron cylinder head, which does not warp due to temperature; There are no cracks between the valve seats; There is no timing belt in these internal combustion engines - there are no problems associated with breaks and expensive repairs; The Nissan diesel engine warms up well and in this respect is in no way inferior to a gasoline engine (after a few minutes of warming up, the car’s windshield “comes off” and warm air blows from the stove); Fuel injection pump – mechanical (in modification T): simple (the amount of injected fuel is controlled by the driver) and time-proven its reliability; if your car's electronics fail, you can always get to your destination by carrying out; Fuel injection pump - electronic (in the ETI modification): the most powerful torque, giving simply “mad” traction to your car and more economical fuel consumption. By installing a diesel engine on a GAZelle, you will also forget about problems with gas equipment. It is well known that engines running on gas often have problems associated with burnout of valves and failure of the cylinder head. By installing a Japanese diesel engine on a GAZelle and removing bulky gas equipment, you will give your car the proper load-carrying capacity. Among other things, you can always sell both the gasoline engine and gearbox previously installed on your GAZelle, thus compensating for part of the money spent to install a diesel engine on your GAZelle. The Nissan diesel engine gives the GAZelle dynamics that significantly exceed gasoline performance and, even more so, gas engines (“locomotive” thrust of a diesel engine leaves far behind the memories of the pitiful driving characteristics of an internal combustion engine operating on gas). By installing a diesel engine in a GAZelle, you will feel how your even fully loaded car in top gear can easily “storm” almost any hill, and you will forget the time when the GAZelle’s native gasoline engine forced you to overcome such obstacles by frantically tugging the gearshift lever (downshifting). By installing a Japanese diesel engine on a GAZelle, you add smooth driving along the highway and a constant temperature in city traffic jams to the asset of your car. All details by phone. There is a Gazelle with a Nissan engine and a UAZ with an Isuzu, made by me in the Rostov region. You can drive and feel the power of the car. Call. Valery. In addition to Gazelle and UAZ, I can also supply internal combustion engines to ZIL and GAZ.

And now my objections, based on personal experience:

- I’m not a fan of drifting and speeding up at traffic lights, so the power and quick acceleration of the manual turned out to be only a potential advantage for me, which was not useful to me. But, having driven tens of thousands of kilometers through city traffic jams, I appreciated how convenient it is when you don’t have to constantly grab the lever and press the clutch.

- Oil consumption is higher - I don’t deny this, but these are minor things. You need to change the oil on time and generally take care of the car, then there won’t be any wild oil leaks.

- In winter, I started up without much trouble even at -28°C - it couldn’t be colder, the climate is like that. And I calmly drive along the snow-covered, unclean road in a low gear, watching how the manual skids.

- Repairs are affordable in any case - be it manual or automatic. But if you operate it wisely and treat it with care, the machine will serve faithfully, and much longer than stated by the manufacturer.

Here's another observation. Outside the city, on off-road terrain, the automatic car also shows good cross-country ability. Contrary to the belief of the “mechanics”, the automatic transmission is capable of quickly changing gears, so I skipped even where the mechanics sat tightly.

Of course, I haven’t renounced manual transmission forever—I sometimes drive a company car with a manual transmission. I don’t think that changing gears is backbreaking work; the arms and legs remember and do their job.

But still, here is my firm opinion: any automatic transmission is much more comfortable than a manual one. When you've been driving for more than a hundred thousand kilometers, once you've tried something better, you won't want to go back to the worst.

Apply the gas brake, press it quietly and enjoy the ride, and don’t have to think about how many revolutions there are on the tachometer. You can consider it laziness or degradation - but I don’t care! Machines should be for people, not the other way around.

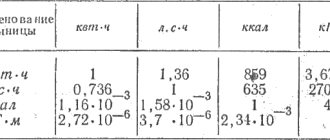

Specifications

The main disadvantage of a “long” engine is that when it gets very hot, the gas joint becomes leaky. Because of this, cracks form on the cylinder head. After 300-400 thousand km traveled. mileage there is excessive oil consumption. Exhaust valves burn out and sometimes cracks appear.

From everything written above we can conclude: Gazelle is a unique car. If you have the opportunity and great desire to install the “heart” of the Gazelle, which will not only be economical in fuel consumption, but also greatly increase its functionality. The gazelle becomes hardy, powerful, and easy to control. She is very obedient in winter, on serpentine roads. With a good engine, a Gazelle can transport cargo and you don’t have to worry about the car not going uphill. Go on long trips with confidence and not worry about breakdowns.

Comparison of 4-speed and 5-speed gearboxes

If you want to make a thorough comparison of the two options, you should consider maintenance costs and ride comfort (speed and ride comfort). As mentioned earlier, if price is a key factor, then choose a 4-speed manual.

For those who value travel comfort more, a 5-speed automatic transmission was specially created. The final decision always remains with the driver, but today it is extremely difficult to find a 4-speed manual. Be sure that it is better and more comfortable to find additional funds to guarantee maximum comfort while traveling than to use more budget models! The purchase of a 5-speed gearbox is more likely to pay off in fuel consumption, since on average, a 5-speed gearbox has a fuel consumption that is 10-20% lower than a 4-speed gearbox.

Option to replace “automatic” with “manual”

As a rule, the reason for such a replacement is the failure of a rather expensive automatic transmission. The second reason is simple fuel economy. Please note that if the machine is in working order, it may not be advisable to invest money in re-equipping a car with a non-guaranteed result of a noticeable improvement.

In any case, replacing an automatic transmission with a manual one is easier than vice versa. Selective technical procedures are carried out for each car, since each make and model is individual. But for all cars, when replacing an automatic transmission with a manual transmission, there is a certain list of general technical measures.

- Lifting the car on a lift and dismantling the internal combustion engine components that prevent the dismantling of the automatic transmission.

- Removal of interior panels and instrument panels, which also interfere with conversion work.

- De-energizing the power supply system by disconnecting the battery.

- Removing the starter if it is located in the lower part of the engine compartment.

- Disconnecting the automatic transmission electrical wires from the gearbox casing, disconnecting the cable or gear shift lever drive, as well as disconnecting the speedometer cable.

- Next comes the transmission fluid radiator tubes from the automatic transmission. They are disconnected, then the transmission oil is drained.

- Fixing the internal combustion engine, unscrewing the connecting bolts between the automatic transmission and the engine.

- Disconnecting the intermediate shaft from the gearbox and dismantling the support and automatic transmission mounting brackets.

- The automatic transmission torque converter unit is dismantled, after which the automatic transmission is disconnected from the engine using jacks.

- After complete dismantling of the automatic transmission components, install the flywheel on the crankshaft and the mechanical drive cables.

- The automatic transmission selector is being replaced with a manual transmission selector.

- This is followed by installation of the clutch pedal and clutch master cylinder.

- Next, the manual transmission is installed.

- In parallel, after complete assembly, the ECU is often flashed.

List of main parts that are primarily needed when replacing an automatic transmission with a gearbox:

- Transmission;

- gear selector;

- selector drive cables;

- flywheel (with fastening);

- clutch disc and basket;

- engine and gearbox mounting brackets and pedal assembly;

- clutch master and slave cylinders and CV joint drive suspension;

- Manual transmission ECU, wiring.

It must be remembered that brands and models of cars differ greatly from each other in the technical features of assembly and installation of components and assemblies. This means that when reinstalling gearboxes on a car, it is necessary to thoroughly study the space designed to accommodate the unit.

It is necessary to take measurements and select suitable brackets, drill additional holes necessary for installing the gearbox. It is often necessary to approach the issue from the perspective of an engineer, since after replacing an automatic transmission with a manual transmission, the box must be reliable and operational.

Let us add that there are cases when, when installing a manual transmission in a car that is equipped with an automatic transmission, the electronic control unit (ECU) does not require replacement or flashing. This feature is due to the fact that on cars of the same brand, the ECUs for automatic transmissions and manual transmissions can be identical.

In this case, there will be no need to completely change the wiring harness going to the vehicle's attachments. However, complete identity is extremely rare. As a result, difficulties arise, so without proper experience it is better to contact specialized service stations that provide services for replacing automatic transmissions with manual transmissions and vice versa.

It is important to understand that not all car services are ready to provide these services. Moreover, the newer and more technologically complex the car, the more expensive the box, other elements, as well as replacement work will cost.

With old vehicles, everything is exactly the opposite, that is, the older the car, the cheaper it will cost to replace the gearbox.

For example, the minimum prices for reinstalling a transmission on a VW Passat B5 start at $700. The contract transmission itself will cost, on average, another $500. If we consider the Passat B3, the work of replacing an automatic transmission with a manual transmission will cost 400-500 dollars, a used transmission will cost from 200 US dollars.

Swap kit 5vz

If desired, you can also install an engine on the Gazelle that was produced for SUVs of the Toyota brand. These are such well-known models as: Land Cruiser Prado, 4Runner, Tundra. If you properly care for the engine, the service life can be up to 500 thousand km. Power 198 l. s., with a torque of 298. Produced from 1998 to 2003. It was also installed on GAZ-3111 vehicles from 2000 to 2002. Traditional cast iron V block with an engine capacity of 3.4 liters. The 5vz swap kit for Gazelle is the optimal solution to all problems associated with the domestic engine and gearbox. You can purchase Japanese swap kits at any time at an affordable price. The application can be submitted at the company’s office, by phone or on the official website. Delivery is carried out to all regions. Before registration, it is recommended to clarify all the details with the manager. If you need high-quality swap kits for the Gazelle and other domestic cars, then it is better to purchase from the Sakura company. Here customers will find a large selection and the lowest prices. Buy today.

Video from our client. Test Drive

Features of converting a transmission in a car

When installing an engine and a set of additional equipment, specialized companies provide a guarantee on all units and on the work performed. The client always receives a package of documents with which he must contact the traffic police to register changes.

Gazelle gearbox device

Related video: Installing a Japanese engine in a GAZelle

Publications on the topic

The process of independently replacing kingpins on a Gazelle

The procedure for adjusting the steering gear of a Gazelle car

GAZ-330232 - technical capabilities and operational parameters

Ford motor

The second most famous is the Ford engine. When installing this motor, the car owner forgets about a number of problems associated with repair work. And also, if you install such an engine on a Gazelle, you can invest your finances once - buying a kit and the engine itself, as well as installation. After installation, large fuel costs are reduced. This is very beneficial when traveling long distances with a heavy load. Fuel consumption on the highway is 8-9 liters. per 100 km. revolutions up to 100 km/h. The engine has a belt, but the quality of the manufacturer remains at the top, so you don’t have to worry about breakdowns during the trip. The technical data of the engine allow the car to drive easily and without unnecessary stress. It will not be difficult for the car to drive onto a hill. The gazelle becomes easy to control on serpentines.

Ford engine installed in a gazelle

To overhaul the engine, the Gazelle must “run” about 500 thousand km. Before that you need to change the oil and filters. The only thing is that if you have an imported FORD engine, then instead of the usual antifreeze, you should fill in imported antifreeze. This will prolong the life of the motor and also improve its functionality in the cold season.

Japanese engine and automatic transmission for GAZelle: what to look for

In the case of the GAZelle, many drivers seek to modify and modify the car to improve various characteristics, as well as to increase the level of reliability and comfort.

One of these radical decisions is the desire to install an imported engine with a gearbox on the GAZelle. Moreover, this method allows you to install an automatic transmission on a Gazelle, which is also a fairly popular option.

Taking into account the fact that a huge number of spare parts enter the territory of the Russian Federation from the Far Eastern region, and the engines themselves, gearboxes and other units from Japan are deservedly considered “indestructible”, for obvious reasons the choice often falls on them.

In simple words, a competent approach and relatively small investments make it possible to equip a GAZelle with a reliable Japanese gasoline or diesel engine, as well as a manual or automatic transmission.

It is quite obvious that such a solution has many advantages:

- It becomes possible to significantly improve the acceleration dynamics, the torque becomes higher. The increase in power allows you to confidently overtake on the highway, as well as drive at higher speeds. At the same time, it is possible to reduce fuel consumption, since Japanese engines are more productive and economical.

- You can install either a gasoline engine (which, if necessary, is additionally equipped with LPG) or a diesel engine. At the same time, the high reliability of Japanese units can significantly reduce the cost of spare parts and consumables (breakdowns occur less frequently, spare parts cost almost the same compared to the prices of parts for domestic internal combustion engines). We can also talk about the higher profitability of such modified commercial vehicles (the vehicle does not stand idle for frequent repairs).

- Comfort and ease of use are increased thanks to the ability to install an automatic transmission in a GAZelle paired with the engine. In fact, with an automatic transmission, a domestic budget truck becomes comfortable, reliable and easier to drive.

The main thing is to correctly calculate the possibility of installing units on a car with minimal intervention.

You also need to separately take into account power, torque and other characteristics, as well as subsequent loads on the engine and transmission during operation

For example, installing an engine with a large “reserve” of power (V6 engines) may not be as rational as it seems at first glance. The fact is that too powerful a motor with high torque leads to failure of standard axles, gearboxes and other elements of the Gazelle transmission. The load on other systems (for example, the braking system) also increases.

As for the automatic transmission, this solution is suitable if the car is used mainly in the city, but the operating conditions are not too severe. The reason is that the automatic machine does not “like” overloads, slipping, etc.

Considering that engines and automatic transmissions in GAZelles are often installed from lighter cars (often passenger cars), then you need to take into account the weight of the GAZelle, as well as the maximum loads when transporting goods

Taking into account the above, the optimal scheme can be considered the installation of a small and simple naturally aspirated 4-cylinder engine of up to 3.0 liters and a power of up to 170 hp. paired with a hydromechanical automatic transmission. By the way, Toyota and Nissan engines are in great demand and popularity for the Gazelle, and older designs at that.

Japanese engines of the 90s are highly reliable and have a long service life, they have cast iron cylinder blocks, a timing chain drive (does not require constant attention), etc. Automatic transmissions paired with such engines are also simple, 4-speed, have a long service life, are not so demanding on the quality of transmission oil, are not very susceptible to overheating, etc.

If we compare such internal combustion engines with a standard Gazelle engine (for example, 406 or 409), the Japanese engine is more powerful, better balanced, the unit is more reliable, and has a longer service life. At the same time, its power is not “excessive”, that is, it will not quickly damage other elements of the transmission.

An automatic transmission (subject to compliance with the rules for operation and maintenance) can easily cover 200-250 thousand km. without the need for any repairs. At the same time, the automatic transmission selector is quite easily integrated into the Gazelle’s interior. The convenient location of the automatic transmission lever makes it easier for the driver to interact with the gearbox.

Diesel engine for GAZelle - which option can be installed?

The diesel engine in a GAZelle gives the car owner a number of operational advantages compared to a gasoline internal combustion engine. The most important thing is that fuel consumption is significantly less. This article will discuss diesel engines suitable for GAZelle, technical characteristics and installation features.

Content

What brands of engines are suitable for GAZelle

When driving a vehicle with a gasoline engine, many motorists wonder whether it is possible to install a diesel engine on a GAZelle? And really, with current gasoline prices you can’t travel much. The diesel engine in the GAZelle is popular among many motorists because it is economically beneficial. The GAZelle car line includes the following types of internal combustion engines: 402 engine, 405 and 406.

In some cases, installing a new engine is much preferable and more profitable than repairing it. But of course, not every engine is suitable in terms of dimensions and parameters; you should consider which internal combustion engines are suitable for a car of the GAZelle family:

- cummins;

- nissan;

- GAZ 560.

Installing a diesel engine gives the car a number of advantages, such as:

- Fuel quality. Modern diesel engines are not picky about fuel quality.

- Reliability. Such engines are highly reliable; if you change the oil on time, you can drive more than 500 thousand km without the need for repairs.

- Traction. Cars with such internal combustion engines have high traction at low speeds.

Now it’s worth considering each motor in more detail.

Cumminis

Cummins is an American-made engine that is assembled in China. Cars with such engines consume fuel economically, and they also have many positive qualities. Owners of cars with a Cummins diesel engine note the following advantages:

- no dips or vibration;

- quiet engine operation;

- stable and sustainable work.

Here is a small list of the main technical characteristics:

- 4 cylinders;

- engine volume 2.78 l;

- 120 hp;

- turbocharging

According to the manufacturers, the mileage life of such a car before major repairs is 500 thousand km. In this case, fuel consumption varies from 8 to 11 liters, depending on driving speed.

But due to our low-quality fuel and many counterfeit spare parts, there are cases when it is necessary to repair the internal combustion engine earlier than the stated period; there have been cases when it had to be repaired already at 200 thousand kilometers. This engine has a design flaw; the oil sump is made of plastic, and it is quite easy to damage it on our roads.

Nissan

Diesel engines from the Japanese manufacturer Nissan are also quite popular in the domestic market. A car with such an engine can cover 600 thousand kilometers without major repairs. They are produced in several models:

The advantages of these engines that should be noted: high maintainability, reliable design, fuel consumption is 8-12 liters. The cast iron cylinder head housing (cylinder head) does not suffer from overheating. Also a distinctive feature is the quick access to operating temperature. Many motorists say about such engines: I install such an engine, and it works like a clock, quietly and stably.

GAZ 560

You can also install a domestic engine from the GAZ 560 on the GAZelle. Based on the results of the tests, the following results were summed up:

- unpretentious to fuel;

- starts well at sub-zero temperatures;

- high efficiency;

- low fuel consumption.

For a GAZelle (since it is mainly a commercial vehicle that carries out transportation), the main thing is that the car operates stably and without interruptions. For example, such an engine installed on the GAZelle Next car has proven itself from the best side. During the operation of the vehicle, it coped with its tasks perfectly. Now it’s worth considering the installation process itself, which you can do yourself.

Diesel engine installation process

The replacement process itself is not complicated and will not be difficult, but if the owner is not confident in his abilities and does not have the necessary tools, it is better to leave this matter to specialists and take the car to a service station. However, if the motorist nevertheless decides to replace it on his own, then the first thing he should do is study the design of the engine; diesel and gasoline engines differ from each other.

The first step is to remove the hood, then turn off the power from the battery, and remove all additional equipment. Then, using a special winch, you need to pull the engine out of the engine compartment.

Now the new motor must be installed in the engine compartment, with the gearbox housing going in first. All fasteners should be lubricated with engine oil, then gradually lowering the engine, they are inserted into the grooves and tightened thoroughly.

Now all the removed parts are installed on the car in the reverse order. Next, you should start the engine and check it for proper operation, check that all warning lights on the instrument panel are working. If the engine works perfectly, the job can be considered done.

From this it can be seen that the replacement process itself is quite simple, you just need to have time and an assistant. By the way, if you change the engine at a service station, it will be quite expensive.

Results

It's time to take stock. By installing a diesel engine in your car, the owner will significantly reduce the cost of purchasing fuel. Of course, initially you will have to pay a tidy sum for the purchase of a new engine, but then this money will quickly be recouped. In addition, cars with such engines have proven themselves excellent during operation. Many motorists who converted their car from gasoline to diesel were satisfied.

Best regards, Maxim Markov!

carsmotion.ru

What's the result?

As you can see, the ability to install a Japanese engine and automatic transmission on a Gazelle allows you to significantly modernize the car, adapting the car taking into account specific requirements and tasks

At the same time, it is important to understand that the issue of installing the engine and gearbox must be approached with the maximum degree of responsibility.

It is important to correctly calculate the power of the installed engine, as well as immediately make a decision on the type of transmission required for certain tasks (automatic transmission on a Gazelle or manual transmission). At the same time, you need to take into account the need for additional alterations and improvements (transmission elements, brake system, etc.). https://www.youtube.com/embed/ag6fRbfLyRE

Tips and tricks

First of all, you should purchase a contract engine and gearbox from a trusted supplier. You also need to be prepared for the fact that after installation, officially “legalizing” such a swap of engine and gearbox can be difficult and costly. The installation itself must be performed by qualified specialists who provide a guarantee for the work done.

As practice shows, it is best to install units on the Gazelle that have previously been successfully installed by one or another company or service station. Often, such organizations independently carry out qualified selection, search and acquisition of the necessary contract units.

- Further, if such an engine and gearbox have already been installed on another similar car before, the installation technology itself will be more or less worked out, the craftsmen will know and take into account possible difficulties and nuances. In some cases, this allows you to avoid certain problems both during installation and during operation.

For example, after installing a 1JZ engine and automatic transmission on a Gazelle (the units were taken from the Toyota Mark II model), the owner encountered a problem. During active engine braking, the torque converter began to actually “block” the gearbox as a result of a lack of pressure. This blocking turned out to be due to the fact that the weight of the Gazelle is much greater than the Toyota passenger model, from where the units for installation were taken.

As a result, when you press the brake, all wheels (including the drive ones) were blocked, which posed a certain danger due to loss of controllability.

We also recommend reading the article about what a contract engine and gearbox are. From this article you will learn about the advantages and disadvantages of such units, as well as what you need to consider before purchasing a contract engine and gearbox.

Also, installing a powerful motor led to the need to remake the cardan and change the axle gearbox. The gearbox was taken from the Sobol model (the fastest), however, this element also turned out to be unable to withstand the significantly increased torque for a long time.