Characteristics of motor 2101

For its time, the engine design was advanced; today it allows you to successfully carry out overhauls and tuning on your own in the garage. The manufacturer's plant has created several generations of internal combustion engines, but there have never been any problems with consumables and spare parts.

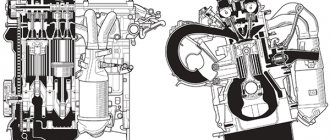

Prototype engine 124 Fiat

The technical characteristics of the 2101 engine look like this:

| Manufacturer | VAZ |

| Engine brand | VAZ-2101 |

| Years of production | 1970 – 1983 |

| Volume | 1198 cm3 (1.2 l) |

| Power | 47.2 kW (64 hp) |

| Torque | 87.3 Nm (3400 rpm) |

| Weight | 114 kg |

| Compression ratio | 8,5 |

| Nutrition | DAAZ-2101 carburetor (vertical double-row, sequential throttle opening) |

| Motor type | in-line |

| Number of cylinders | 4 |

| Location of the first cylinder | near the timing chain |

| Number of valves on each cylinder | 2 |

| Cylinder head material | aluminum alloy |

| Allowable warpage | manifold gaskets (intake/exhaust) 0.08 mm cylinder head gasket 0.05 mm |

| Valve seat | width 2 – 2.4 mm, angle 45° |

| Camshaft | one upper cylinder head inside, phase width 232°, exhaust valve advance 42°, intake valve lag 40° |

| Camshaft oil seal | diameters – 40 mm, 56 mm, width 7 mm |

| Cylinder block material | cast iron |

| Cylinder diameter | class A – 76 – 76.01 mm class B – 76.01 – 76.02 mm class C – 76.02 – 76.03 mm class D – 76.03 – 76.04 mm class E – 76.04 – 76.05 mm |

| Pistons and rings | piston made of aluminum alloy with tin coating, cast iron rings, compression outside chrome plated (top) and beveled (bottom) |

| Piston diameter | class A – 75.94 – 75.95 mm class C – 75.96 – 75.97 mm class E – 75.98 – 75.99 mm |

| Gaps | piston/cylinder wall – 0.153 – 0.173 mm (standard) or 0.19 mm (maximum) piston rings – 110 mm relative to the cut plane |

| Upper compression ring | 1.535 – 1.555 mm |

| Lower compression ring | 3.957 – 3.977 mm |

| Oil scraper ring | 2.015 – 2.035 mm |

| Gap between piston groove and ring | 0.03 – 0.07 mm |

| Crankshaft | cast iron, casting |

| Number of main bearings | 5 |

| Gearbox neck diameter | 50.795 – 50.775 mm |

| Main journal gap | 0.1 – 0.5 mm |

| Connecting rod bearings | shaft journal diameter – 47.814 mm liner thickness – 1.448 mm liner width – 28.025 – 28.975 mm |

| Crankshaft oil seals | front – diameters 42 mm, 60 mm, width 7 mm rear – diameters 85 mm, 105 mm, width 10 mm |

| Piston stroke | 66 mm |

| Fuel | AI-92 (A-76 allowed) |

| Environmental standards | Euro 2 |

| Fuel consumption | highway – 7.8 l/100 km combined cycle 9.2 l/100 km city – 12 l/100 km |

| Oil consumption | maximum 0.7 l/1000 km |

| Engine oil for 2101 | 5W-30 and 15W-40 |

| Engine oil volume | 3.75 l |

| Replacement frequency | every 5000 km |

| Operating temperature | 80° |

| Motor life | declared 200,000 km actual 500,000 km |

| Adjustment of valves | nuts and feeler gauge |

| Cooling system | forced, antifreeze-A40 |

| Coolant quantity | 9.75 l |

| water pump | polymer impeller, mounted on a block |

| Ignition | coil B117A |

| Candles for 2101 | original – A17-DV, you can install any suitable size with two electrodes |

| Gap between spark plug electrodes | 0.5 – 0.6 mm |

| Valve train chain | double-row roller, 114 links |

| Cylinder operating order | 1-3-4-2 |

| Air filter | dry with replaceable cardboard cartridge and pre-cleaner, temperature adjustment according to the season |

| Oil filter | recommended Mann W914/2 |

| Flywheel | 129 teeth, 0.62 kg internal hole diameter – 25.67 mm outer diameter – 27.75 mm number of mounting holes – 6 pieces no offsets |

| Flywheel mounting bolts | M10x1.25 mm, length 23.5 mm |

| Valve stem seals | Manufacturers Horse or Corteco |

| Compression | pressure in the cylinders from 10 – 14 bar, pressure difference in individual cylinders within 1 bar |

| Oil temperature | 80°С |

| Thermostat temperature | 80 – 84°С |

| Valve pressure inside the radiator cap | 0.7 – 1 bar |

| Content of harmful products in the exhaust | CH <200%, CO <0.5% |

| XX speed | 850 –1000 min-1 |

| Tightening force of threaded connections | spark plug – 37.24 Nm flywheel - 83.3 Nm clutch bolt - 29.4 Nm bearing cap - 80.36 Nm (main) and 50.96 Nm (connecting rod) cylinder head - two stages 39.2 Nm, 112.7 Nm |

The 2101 engine was created for low-octane fuel, so it was usually operated on A-76 gasoline, despite the fact that the manufacturer recommended the use of AI-92 - AI-93 gasoline. Initially, the cylinder diameter was 76 mm, in subsequent modifications it was increased, and again returned to this size more than once.

ICE design

What kind of oil to pour into the VAZ 2101 engine

The higher quality the oil, the longer the service life of the engine. Currently, hundreds of varieties and dozens of oil brands are available to car owners, but they are divided into 3 categories :

- mineral oils (natural - used for used engines);

- semi-synthetic motor oils (artificial - for extreme trips);

- synthetic oils (semi-synthetic - for general purpose).

To make the right choice, you need to be guided by the manufacturers' data. You also need to take into account that artificial and semi-artificial oils contain additives that destroy gaskets on older car models. For this reason, you should not use the engine of an old VAZ 2101 with artificial oil. Otherwise, it may result in a quick breakdown.

As for viscosity, it is indicated by two numbers and a letter between them, for example 5W-50. The first part of the marking indicates viscosity at negative temperatures. The second is when heated.

When choosing oil for a VAZ 2101 engine, you must:

- Give preference to products recommended by the manufacturer.

- If the mileage is more than one hundred thousand kilometers, it is recommended to replace synthetic oil with semi-synthetic oil.

- It is recommended to change the oil every 10-15 thousand kilometers.

- In cars manufactured before 2000, it is recommended to use standard type oils (AZMOL SUPER 15W-40, 20W-40; SHEL HELIX 10W-40, etc.).

- In cars after 2000, use “super” oil (LADA-SUPER 5W-40, 10W-40, 15W-40; MOBILE SUPER M15W-40, etc.).

- For fast trips, it is better to use a substance with a high degree of viscosity when heated (0W-50, 5W-50, 10W-50, etc.).

- For trips in winter, the best option would be 10W-40.

Table “Selection of oil according to VAZ recommendations”

| Minimum engine cold start temperature, ͦС | SAE viscosity grade | Maximum ambient temperature, ͦС |

| -35 | 0W-30 | 25 |

| -35 | 0W-40 | 30 |

| -30 | 5W-30 | 25 |

| -30 | 5W-40 | 35 |

| -25 | 10W-30 | 25 |

| -25 | 10W-40 | 35 |

| -20 | 15W-40 | 45 |

| -15 | 20W-40 | 45 |

Design Features

Initially, at the design stage, a feature for the engine was the overhead camshaft:

- The piston stroke decreased by 5.5 mm compared to the Fiat 124 standard;

- the cylinder diameter increased by 3 mm.

This modernization ensured acceleration and rapid acceleration. In addition, the 2101 engine had the following design nuances:

- timing chain transmission;

- unfinished carburetor models;

- major overhaul after 20,000 km.

Valve train chain

Immediately after the release of the first internal combustion engine of this series, the manufacturer AvtoVAZ released a manual in which it indicated which oil to fill in the engine and provided a description of the internal combustion engine parameters to increase the service life of the engines. Thus, the owners of the next three generations of engines had no questions about what oil to pour and in what quantity.

Timing mechanism

History of the creation of the Zhiguli 2101 8 valve engine

The lower engine, which was installed on a Fiat 124 donor car for a penny, was immediately rejected by Soviet designers, as it turned out to be difficult to maintain and repair. Then Italian engineers proposed a prototype of their promising power unit with an overhead camshaft.

The in-line cylinder block is cast from cast iron, the head is made from aluminum. A double-row chain is responsible for the timing drive, the resource of which is enormous. But there are no hydraulic compensators, so the thermal clearances of the valves will have to be adjusted manually approximately every 15,000 kilometers. However, at that time this was considered the norm.

The design is shown in detail in a short computer animation.

You can find the online manual for this engine here

Forged pistons are also available for this engine.

The engine is found under the hood of four domestic car models:

| 2101 | 1970 — 1988 |

| 2102 | 1971 — 1986 |

| 2103 | 1972 — 1984 |

| 2105 | 1980 — 1983 |

Similar engines from other manufacturers:

Judging by the reviews of the owners, the only advantage of this engine can be considered its maintainability and the price of spare parts. As for the rest, there are only disadvantages: reliability is low, fuel consumption is too high for such a working volume, there are problems during operation in winter.

It is advisable to change the oil at least once every 10,000 kilometers. To do this, you will need approximately 3.75 liters of any high-quality mineral water such as 10W-40 or 15W-40. Watch the video for details.

Experienced drivers claim an engine life of 150 - 250 thousand kilometers, but only with proper maintenance and the use of high-quality fuel. By the way, the manufacturer’s brochure modestly indicates only 125,000 km.

The most common causes of engine overheating are: a malfunction of the thermostat or pump, a fan wedge, or depressurization of the cooling system circuit.

The capricious Weber and Ozone carburetors constantly require intervention in their operation. I always have to clean or adjust something.

Most often, unregulated valves are to blame for the loud operation of the power unit. In second place is the wear on the camshaft. And if not, then it’s probably worth preparing for a major overhaul.

Unstable operation of the internal combustion engine is usually caused either by the failure of one of the components of the ignition system, or by loss of compression in the cylinder due to burnout.

Other breakdowns include frequent failure of the cylinder head gasket, oil leaks from the seals and fogging around the valve cover.

You can buy such a motor for a couple of thousand; they are not in great demand. Owners of VAZ classics usually prefer more powerful versions. An ideal example with low mileage will cost about 20,000 rubles.

| State: | boo |

| Working volume: | 1.2 liters |

| Power: | 59 hp |

| For models: | VAZ 2101, 2102, 2103, 2105 |

* The price for this engine is for reference only

Blogger Evgeniy Travnikov expresses his opinion about classic internal combustion engines.

Advantages and disadvantages

In the first years of operation, the 2101 engine revealed the following shortcomings:

- noisy operation of the chain drive;

- increased gasoline consumption in the engine due to defects in carburetors;

- frequent ignition adjustments;

- Difficult adjustment of valve clearances.

Solex carburetor

However, a cylinder head improved with a camshaft, an improved intake manifold and an exhaust manifold of the simplest design compensated for these shortcomings. A little later, DAAZ Ozone carburetors were developed, replacing which made it possible to improve the characteristics of internal combustion engine modes.

Carburetor Ozone

Do-it-yourself VAZ 2101 engine tuning

Tuning the VAZ 2101 engine with your own hands allows you to maintain the operation of the car at a high operating level, and in some situations significantly improve driving performance. However, it would be stupid to demand high competitive advantages from a car over modern innovations in the automotive industry.

Therefore, improvements should be treated primarily with research and historical interest. Only in this case will the car owner get a lot of pleasure from experimenting with his four-wheeled “friend.”

The following upgrade options are currently available and in demand.

Engine replacement

pros:

- gives new life to the car, extending its overall service life;

- allows you to make the “penny” much more maneuverable and powerful.

Minuses:

- the need to reinstall half of the car components (brake system, clutch, etc.) to more advanced ones;

- costs of time, effort and finances.

Maintenance

Considering the design of the internal combustion engine, the manufacturer recommends the following maintenance schedules:

| Maintenance object | Time or mileage (whichever comes first) |

| Valve train chain | replacement after 100,000 km |

| Battery | 1 year/20000 |

| Valve clearance | 2 years/20000 |

| Crankcase ventilation | 2 years/20000 |

| Belts that drive attachments | 2 years/20000 |

| Fuel line and tank cap | 2 years/40000 |

| Motor oil | 1 year/10000 |

| Oil filter | 1 year/10000 |

| Air filter | 1 – 2 years/40000 |

| Fuel filter | 4 years/40000 |

| Heating/Cooling Fittings and Hoses | 2 years/40000 |

| Coolant | 2 years/40000 |

| Oxygen sensor | 100000 |

| Spark plug | 1 – 2 years/20000 |

| Exhaust manifold | 1 year |

With timely cleaning, the lubrication, cooling and fuel supply system operates longer without major repairs.

Motor VAZ 2106

The baton of the engine, which became a real breakthrough in the Soviet market, was taken over by the VAZ 2106 engine.

It became a natural modification of the 2103 in order to increase the technical characteristics of VAZ engines in the direction of power.

The engineers achieved it:

- increasing the working volume to 1600 cm3, using the cylinder diameter, which again became 79 mm.

- The pistons for this VAZ engine were used from 21011 and it, like the donor, had two repair sizes. These VAZ engines had no other fundamental differences from the 2103, since they were equipped in the same way as their older relatives, with an “Ozone” carburetor and an ignition distributor with the same vacuum regulator.

But the 2106 engine did not find much sympathy among the owners, just as rotary engines on VAZs were once exported, since the owners of 2103, 2121, 2107 tried to select the more reliable VAZ 2103 engine.

This was due to the lower viability of the 2106 and instability of operation when using lower quality fuel. The saddest outcome was burnout of the valves and the unit required major repairs in these cases much more often than 2103.

Malfunctions: causes, elimination

Unlike motors with a timing belt drive, the 2101 valve bends much less frequently. The main malfunctions of the internal combustion engine are:

| Breaking | Cause | Elimination |

| Blue smoke | rupture of valve seals, bushings and cylinder head gaskets, wear of rings | replacement of consumables and seals |

| Engine overheating | Fan or thermostat failure | replacement of attachments |

| Oil consumption increases | leaks in valve covers, worn out pistons/cylinders | replacing gaskets, installing the next repair size of pistons and rings |

| Knock | crank bearings, connecting rod bearings, increasing valve clearance | replacement of consumables field of qualified diagnostics |

The speed limit of “kopecks” with 2101 engines was 145 km/h, and the car accelerated to “hundreds” in 18–20 seconds in a straight line.

Car VAZ 2101 Kopeyka

What engine can be installed on a VAZ 2101

Owners of vintage cars may sooner or later face the issue of engine failure. If other parts are in order, but the car is needed for work purposes, and not for show-off, then replacing the engine is the most rational and profitable solution in this case.

When looking for alternative equipment, you need to pay attention to a number of points.

- Dimensions. The space under the hood of the VAZ 2101 must match the dimensions of the new engine system (otherwise cutting of the body may be necessary).

- Power. The power of the device must be identical to the capabilities of the previous engine (otherwise the body will have to be strengthened and half of the components will have to be modernized).

- Drive unit. It is better to use engines from rear-wheel drive vehicles (front-wheel drive vehicles may require modernization of the transmission, brake elements and suspension).

Which engine to choose?

- It is better to opt for native engines: VAZ 21011, 2103, 2106 or even 2113 . This will allow you to spend a minimum of effort on alterations, and in some cases get an almost new engine (which cannot be said about worn-out engines from foreign cars).

- 2108-2170 models , you will need to cut the body and there is no way to do without it. But overall, there won’t be too many problems, and therefore, “the game is worth the candle.”

- You can also pay attention to the 1.7 Niva (you will need to supplement the engine with an oil pump and a sump).

- 21126 engine from Lada Priora is also a good solution. One and a half liters of volume and almost 100 horsepower will “invigorate” the VAZ 2101 and give it a new life.

- When using foreign cars as a donor, you must be prepared that the transplant procedure will take longer. The best engines for the VAZ 2101 will be: Fiat Argenta 2.0i, BMW M10, BMW M20, Renault Logan, Volkswagen 2.0i 2E, Lancia Thema and Mitsubishi Galant.

Replacement instructions

Changing the lubricant in the VAZ 2106 transmission may be required when purchasing a used car. Having bought a used car, you should check the condition of the lubricant and its level. If it is not known what kind of oil was used, it is better to replace it. The lubricant should also be changed if it is coffee or black in color or if it contains silver dust.

How much to pour?

The VAZ 2106 lubricant should be checked every 10 thousand kilometers. In this case, its level should reach the lower edge of the drain hole. The check should be carried out with the car sitting for some time at rest so that the liquid drains from the walls. To check, unscrew the filler cap and see what level the oil is at. If the level is insufficient, the liquid should be added.

Transmission oil

The VAZ 2106 gearbox oil can be filled with 80W-90, 85W-90 from any manufacturer. The quality of the transmission fluid determines how the car will start at sub-zero temperatures. If you have the financial opportunity, it is better to use synthetics or semi-synthetics. How much oil to pour depends on the gearbox. About 1.6 liters are poured into a five-speed gearbox, and 1.35 liters into a four-speed gearbox. The grease is poured with a syringe until it flows over the edge.

Tools

To carry out the replacement procedure, you will need the following tools:

- open-end or socket wrench size 17 (if the part is stuck, you can use a head with a knob);

- 12 hex with a longer tube to increase the lever of action;

- two-liter container for waste liquid;

- a special syringe for filling lubricant, the end of which has a curved tube, or a regular syringe with a hose about 20-25 cm long attached to it;

- clean rag.

It is better to carry out the replacement in an inspection pit, overpass or lift - it is more convenient to drain the lubricant.