Technical characteristics of the 3s fe engine

During production, the power plant received several modifications - 3s - FE/FSE/GE/GTE. Depending on the modification, the technical specifications differ.

- Type of power unit – four-stroke petrol;

- Number of working cylinders – 4;

- The arrangement of the working cylinders is in-line vertical;

- The number of valves per working cylinder is two inlet and two exhaust;

- Gas distribution mechanism - two camshafts installed in the upper part of the power plant;

- The total volume of working cylinders is 1998 cm3;

- Curb engine weight – 140 kg;

- Compression – 9.8;

- Fuel system – distributed fuel injection. The 3S GE engine has a carburetor fuel system;

- Fuel system control – electronic;

- Cylinder block – cast iron;

- Working cylinder diameter – from 86 to 86.03 millimeters;

- The piston stroke from bottom to top dead center is 86 mm;

- The operating temperature of the power unit is 95°;

- Compliance with environmental standards – Euro 4;

- Average fuel consumption per 100 km – 9.5 liters;

- The fuel used is gasoline AI-95, AI-92;

- Engine life 3s fe – 300,000 km;

- The cooling system is forced liquid.

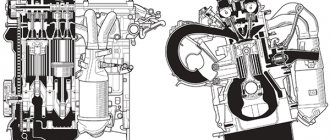

Engine design 3s fe

The motor design is reliable. The manufacturer claims a resource of 300,000 km. The actual engine life exceeds this figure. The engine is unpretentious to fuel quality and works well regardless of operating conditions.

Cooling system

The manufacturer equipped the 3s fe engine, the characteristics of which are given above, with a forced-type liquid cooling system. This design allows the vehicle to be used under various loads, regardless of the ambient temperature. Antifreeze or antifreeze is used as a cooling liquid.

The movement of liquid in the cooling jacket is carried out by a pump.

It is secured separately to the power plant using bolts. The pump is belt driven from the crankshaft. Cooling of the coolant is carried out in the radiator. The movement of the air mass through the radiator honeycombs is carried out using a fan. The cooling system is equipped with an expansion tank.

REFERENCE: For quick warm-up in the cold season, a thermostat is included in the cooling system. At low coolant temperatures, the thermostat closes a large circulation circle. Once the required temperature is reached, a large circulation circle opens. The thermostat response temperature is 80 - 84o.

Gas distribution mechanism

The Toyota 3s fe engine has a timing belt with two cam-type camshafts. The timing mechanism is driven by a belt. The camshafts are overhead. To adjust the thermal gap, hydraulic compensators are provided.

The intake and exhaust tracts are closed by sixteen valves. This design increases power performance. The disadvantage of the timing belt is the design of the valve adjustment. Special washers are provided for adjustment. Adjustment is carried out by selecting washers of the required thickness.

Lubrication system

The engine has a combined lubrication system. Moving parts operating under heavy loads are lubricated with oil under pressure. The gas distribution mechanism and other parts operating under light load are lubricated by splashing lubricant. The manufacturer recommends using a lubricant with a viscosity of 5w30.

Oil pressure is pumped into the system by a gear-type pump.

To clean the lubricant from large abrasive particles, the pump oil receiver is equipped with a metal mesh. The lubricant is cleaned from small particles and metal shavings using a paper filter element.

Power supply and engine starting

The power plant control is electronic. The control unit receives information from various sensors; after processing the data, the microprocessor regulates the systems necessary for the normal operation of the power unit.

The engine is started by an electric starter. The electric starter is controlled remotely from the vehicle's cabin. The power supply to the power plant is provided by a 12V battery and a DC generator.

ATTENTION: The battery is used to supply electricity when the internal combustion engine is switched off. After startup, power supply is provided by a DC generator.

Description of marking

The 3s fe marking has the following meaning:

- “3” – determines the volume of the power plant – 2 liters;

- “S” – arrangement of working cylinders – in-line;

- “F” – Number of valves per working cylinder – 4;

- “E” – electronic control of the fuel system.

Advantages and disadvantages

The design of the power unit has the following advantages:

- Simplicity of design. A person with minimal technical knowledge can service and fix minor faults. Minor repairs do not require specialized equipment;

- Resistance to loads. The cast iron block and liquid cooling system allow the motor to be used at different ambient temperatures;

- Large motor resource. The use of the power unit without repair exceeds the indicators declared by the manufacturer;

- High power. Depending on the modification, the maximum engine power is from 110 to 130 hp. This is sufficient for the intended use of a passenger vehicle;

- Economical. The engine consumes 9.5 liters of gasoline. On a Karina car and other models, when driving quietly, this figure decreases;

IMPORTANT: When driving aggressively or when driving on poor quality road surfaces, fuel consumption increases.

- Gas distribution mechanism drive. One camshaft is belt driven from the engine crankshaft. The second cam-type camshaft is driven by the gear of the first shaft. This reduces the noise level when the engine is running;

The 3s fe motor has some disadvantages:

- Complex valve adjustment design. To adjust a Toyota valve engine, it is necessary to select washers of the appropriate size;

- Inconvenient location of the power plant number. The 3s fe engine number is located on the rear of the power unit at the gearbox mounting location. To view numerical combinations, you must use specialized devices;

- High load on the timing belt. Due to the high load, it is necessary to change the belt more often than stated by the manufacturer.

Description of the power plant

Everyone who produces equipment labels the product, this eliminates confusion and confusion. Toyota Corporation is no exception; the company's designations are informative and minimize contradictions.

Name: 3S FE DOHC 16V 2.0 engine.

- “3” – internal marking, informs about the use of design solutions;

- “S” – a series of units with in-line cylinders;

- “F” is a family of engines, the volume of which varies from 2.0 to 2.2 liters;

- “E” – designation of injection, electronic type (EFI);

- “DOHC” – double overhead camshaft (Double Over Head Camshaft);

- “16 V” – the number of valves, in our case, sixteen;

- “2.0” is the volume of the power plant.

Engine Toyota 3S Fe 1996 year:

When ordering spare parts for the power plant, the engine number 3S FE is placed on the rear of the block, above the bell housing. You will also need the model of the car on which the engine was originally installed, and the year of manufacture. The serial number itself is a six-digit number.

Toyota 3S FE engine serial number location:

When designing the power plant, the 2S-FE engine was taken as the base model of the 3S engine. The increase in power of the unit occurred due to changes in piston diameter and stroke. Now the installation developed a torque of 186 kgf*cm and was combined with an automatic transmission.

The changes made to the installation were initially tested on a carburetor engine, which was labeled 3S-FC. After modifications and elimination of shortcomings, a new fuel supply using injection was installed on the engine. The L4 DOHC scheme and until 1991 both variants of power plants were produced.

During the period, four modifications to the power plant were carried out. The low-power engine developed 115 horsepower and a torque of 162 Nm. The power plant, produced from 1998 to 2000, developed 128 horsepower and had a torque of 178 Nm. The restrictions on the units were imposed by the application of environmental standards; the losses were not large, two horsepower.

Power unit maintenance

For normal operation of the internal combustion engine, it is necessary to carry out regular maintenance. Failure to comply with this rule may lead to deterioration in performance or complete failure of the unit.

For service you need:

- After covering 10,000 km, change the engine oil. A semi-synthetic lubricant with a viscosity of 5w30 is suitable. The oil filter should be replaced at the same time as the oil;

- After 20,000 km, it is necessary to check the thermal clearance of the valves of the gas distribution mechanism. Clean the crankcase ventilation. Check the functionality of the spark plugs and the integrity of the attachment belts;

- After the car has covered 40,000 km, the manufacturer recommends replacing the coolant and air filter. If necessary, flush the cooling system.

Service interval

When wondering what volume and what kind of oil to pour into the 3S-FE engine, you need, first of all, to decide on the frequency of maintenance. First of all, the operating conditions of the vehicle influence the regularity of engine oil renewal.

If the car constantly drives over bumpy terrain, through melting snow, on a dusty road surface, or through salt masses against icing of roads, the oil must be changed more often than established standards. Driving habits also have a direct impact on the frequency of lubricant changes.

Table from the 3S-FE manual

If you use the roof rack of a vehicle or have a trailer in tow, as well as during frequent but short trips in sub-zero temperatures, long periods of travel at low speeds or idling, it is also necessary to renew the lubricant more often than recommended by the manufacturer.

Maintenance frequency:

- engine oil, as well as the 3S-FE oil filter, require replacement every 10 thousand kilometers or once a year, and if the car is used in difficult conditions - twice as often ;

- oxygen sensor - performance check and replacement are necessary every 100,000;

- It is recommended to check the 3S-FE valve clearances for functionality and adjust the level every 20,000 or every two years;

It is better to change the oil every 7-8 thousand

- timing belt – replacement is necessary every 100,000;

- attachment drive belts require regular inspection every 20,000, and replacement every 60,000 or every two years;

- coolant - 40,000 or every two years;

- spark plugs need to be checked once every 10,000, and replaced half as often (check once a year, replace once every two years), and in the case of platinum spark plugs, checking is not necessary, but replacement is required every 80 thousand or once every six years;

- For a battery, a typical check frequency is once every 10,000;

- components and assemblies of the heating and cooling system are checked every 40,000 or once every two years, as are the fuel tank cap and fuel drives (after four years of vehicle operation or a mileage of 80 thousand kilometers);

- fuel filter 3S-FE - replacement every 40,000 or every four years.

Possible malfunctions and ways to eliminate them

- Engine oil pressure does not go out 3s fe. If a malfunction occurs, check the functionality of the oil pressure sensor. A lack of pressure in the system can be caused by a failure of the gear pump. If a malfunction is detected, replace the gear-type pump with a new part;

- The 3s fe engine does not start. There are various reasons why the 3s fe engine does not start. It is necessary to check the functionality of the fuel system and ignition system. Measure the compression in the working cylinders. Replace faulty parts with new ones. The power unit may not start due to incorrect operation of the electronic control unit. To check the performance of the ECU, specialized equipment is used;

- Increased fuel consumption. An increase in fuel consumption occurs when the air filter or injectors are heavily soiled. It is necessary to replace the filter element and clean the nozzles from dirt;

REFERENCE: some car owners do tuning of the 3s fe engine. Tuning improves the technical characteristics of the power unit and increases power performance.

From the above it follows that the 3s fe power unit installed on Toyota cars is distinguished by its quality and technical characteristics. Design features allow the power plant to be used at different ambient temperatures. The engine is load-resistant and unpretentious to the quality of gasoline.

Engine fault overview

Despite the thoughtfulness and unpretentiousness of the 3S-FE engine, drivers face some problems:

- increased fuel consumption. Occurs due to improper operation of the throttle valve or one of the sensors that transmit incorrect information to the ECU. Contaminated injectors also interfere with the formation of a normal mixture. Carbon deposits on the pistons lead to excessive fuel consumption due to changes in the volume of the combustion chamber and loss of power;

- increased appetite for butter. Often found in cars with mileage over 200,000 km. Carbon deposits on the pistons indicate severe burns through compression and oil control piston rings and leaking valve seals. The malfunction may also be in the sensors: lambda probe, intake air temperature sensor or map sensor;

- Long cold start. The problem is due to a breakdown of the fuel injectors or temperature sensor;

- Unstable engine operation, loss of power. The reason is a breakdown of the EGR valve or engine oil getting into the spark plug wells: the ignition occurs with misfires, and the engine stalls at idle;

- motor vibrations. The problem occurs when the side cushions wear out or there is a loss of pressure in one of the cylinders.

Engine problems can be corrected by replacing or cleaning the elements. The 3S-FE design allows for simple repairs even in garage conditions.

https://www.youtube.com/watch?v=KcCTjpVy-sc

Description of the 3S FE motor

With the advent of distributed electronic injection, a version of the 3S FE injection engine was developed. The design of the 3S engine was so reliable that its modification was installed “on everything that drives,” that is, on almost all Toyota models from 1997 to 2001. releases.

By default, S3 and all its modifications are “million-dollar” engines with a corresponding mileage resource.

Explanation of markings

In the Russian Federation, motor designations are regulated by the domestic standard GOST R53638. Western and Asian manufacturers use their own markings, and Nissan and Toyota have the most informative markings, so the Japanese 3S FE DOHC16V 2.0 engine is deciphered as follows:

- 3 – design solution of the internal combustion engine, in this case the volume is about 2 liters;

- S – a series of engines with in-line cylinders and multiple fuel injection;

- F – 4 valves on each cylinder;

- E – EFI injection system (electronic type);

- DOHC – two camshafts as a drive, rotation is transmitted to one of them from the crankshaft by a timing belt, to the second by a gear from the previous camshaft;

- 16 V – hydraulic gap compensation;

- 2.0 – internal combustion engine volume.

A series with one letter index after the first digit indicates that the internal combustion engine was developed before 1990. The main design features of this type of internal combustion engine are:

- the pump is bolted to the cylinder block and rotates by a belt drive;

- the axial play of the cast iron crankshaft is adjusted by thrust semicircular washers inside the main bearing (middle), the adjustment procedure is contained in the official manual;

- the system was designed before 1990, that is, according to old safety standards, it can be operated on AI-92 gasoline;

- Initially, the manufacturer recommended the use of 5W50 oil; after 1996, Toyota cars came off the factory assembly line with 5W30 lubricant;

- the design of the valve drives was not fully developed by the designers from the beginning; to adjust the clearance parameters, you will have to pull out the shafts, throwing off the phase settings, select washers according to their thickness, and assemble the components in the reverse order;

- it is physically impossible to dismantle the intake manifold separately from the cylinder head;

- the exhaust manifold is protected by a thermal shield

Otherwise, the design of the 3S-FE engine is quite reliable; it is considered more economical in comparison with the previous 3S carburetor engine.

What cars is it used in?

By default, the 3S FE engine was installed on the following Toyota car models:

- Caldina – 1st and 2nd generation, station wagon;

- Camry – 2nd – 4th generation, sedan body;

- Carina – 6th and 7th generation, sedan body;

- Carina ED – 2nd and 3rd generation, sedan body;

- Celica – 5th and 6th generation, coupe body;

- Corona – 8th generation coupe, 9th generation sedan and hatchback, 10th generation sedan and hatchback;

- Corona Exiv – 1st and 2nd generation, sedan body;

- Corona Premio – 1st generation, sedan body;

- Curren – 1st generation, coupe body;

- Gaia – 1st generation, minivan body;

- Ipsum – 1st generation, minivan body;

- Lite Ace Noah – 1st generation, minivan body;

- Nadia – 1st generation, minivan body;

- Picnic – 1st generation, minivan body;

- RAV4 – 1st generation, open body and SUV (Japan, USA);

- Town Ace Noah – 5th generation, minivan body;

- Vista – 3rd – 5th generation, sedan body;

- Vista Adreo – 1st generation, station wagon.

Malfunctions and repairs of the 3S-FE/3S-FSE/3S-GE/3S-GTE engine

The Toyota 3S engine is one of the most popular engines in the S series and Toyota in general, it appeared in 1984 and was produced until 2007. The 3S engine is a belt engine, the belt needs to be changed every 100 thousand km. Throughout the entire production period, the engine was repeatedly refined and modified, and if the first models were 3S-FC carburetors, the latest ones are the 3S-GTE turbo with a power of 260 hp, but first things first.

Toyota 3S engine modifications

1. 3S-FC - a carburetor variation of the engine, installed on cheap versions of the Camry V20 and Holden Apollo cars. Compression ratio 9.8, power 111 hp. The engine was produced from 1986 to 1991 and is rare. 2. 3S-FE - injection version and main engine of the 3S series. Two ignition coils were used, it is possible to fill in 92-grade gasoline, but 95 is better. Compression ratio 9.8, power from 115 hp. up to 130 hp depending on the model and firmware. The motor was installed from 1986 to 2000, on everything that drives. 3. 3S-FSE (D4) - the first Toyota engine with direct fuel injection. There is a VVTi variable valve timing system on the intake shaft, an intake manifold with an adjustable cross-section of channels, pistons with a recess to direct the mixture, modified injectors and spark plugs, an electronic throttle valve, and an EGR valve for re-burning exhaust gases. Compression ratio 9.8, power 150 hp. Despite the overall technology, this engine has earned a reputation as a constantly breaking and always problematic engine, breakdown of the fuel injection pump, EGR, problems with the variable intake manifold, which requires cleaning from time to time, problems with the catalyst, you constantly need to monitor and clean the injectors, monitor the condition candles, etc. The 3S-FSE engine was installed from 1997 to 2003, when it was superseded by the new 1AZ-FSE. 4. 3S-GE - an improved version of 3S-FE. A modified cylinder head was used (developed with the participation of specialists from Yamaha), the GE pistons have counterbores and, unlike most engines, a broken timing belt does not lead to a meeting of the pistons and valves, and there was no EGR valve. Over the entire period of production, the engine was subject to changes 5 times: 4.1 3S-GE Gen 1 - the first generation, produced until 1989, compression ratio 9.2, weak version developed 135 hp, more powerful, equipped with an adjustable T-VIS intake manifold, up to 160 hp 4.2 3S-GE Gen 2 - the second version of the GE engine, produced until '93, in which the T-VIS variable intake manifold was replaced with ACIS. Shafts with phase 244 and lift 8.5, compression ratio 10, power increased to 165 hp. 4.3 3S-GE Gen 3 - the third version of the engine, was in production until 1999, the camshafts changed: for automatic transmission phase 240/240 lift 8.7/8.2, for manual transmission phase 254/240 lift 9.8/8.2. The compression ratio increased to 10.3, the power of the Japanese version was 180 hp, the export version was 170 hp. 4.4 3S-GE Gen 4 BEAMS/Red Top - fourth generation, produced in 1997. A VVTi variable valve timing system was added, the intake (from 33.5 to 34.5 mm) and exhaust ports (from 29 to 29.5 mm) were increased, the camshafts were changed, now it is 248/248 with a lift of 8.56/8.31, the compression ratio is 11.1, the power has reached 200 hp. s., with automatic transmission 190 hp. 4.5 3S-GE Gen 5 is the fifth and latest generation of GE. Dual VVT-i variable valve timing system is now on both shafts, intake and exhaust ports are the same as on Gen 1-3. Power 200 hp The manual transmission version had wide camshafts, titanium valves, a compression ratio of 11.5, enlarged intake valves (from 33.5 to 35 mm) and exhaust valves (from 29 to 29.5 mm). Power 210 hp 5. 3S-GTE. In parallel with the GE series, their turbo modification was produced - GTE. 5.1 3S-GTE Gen 1 - the first version, produced until 1989. It is a decompressed 3S-GE Gen1 to SZh 8.5, with an adjustable T-VIS intake manifold and a CT26 turbine installed on it. Power 185 hp 5.2 3S-GTE Gen 2 - second version, phase 236 shafts, lift 8.2, CT26 turbine with double casing, compression ratio 8.8, power 220 hp and the engine was produced until ’93. 5.3 3S-GTE Gen 3 - third version, changed the turbine to CT20b, threw out the T-VIS manifold, camshafts 240/236, lift 8.7/8.2, coolant 8.5, power 245 hp. Produced until '99. 5.4 3S-GTE Gen 4 is the latest version of the GTE engine and the 3S series in general. The principle of exhaust gas intake was changed, the camshafts were replaced with 248/246 with a lift of 8.75/8.65, the compression ratio was increased to 9, the power was 260 hp. The last motor in the 3S series was discontinued in 2007.

Malfunctions and their causes

1. Failure of the fuel injection pump on the 3S-FSE is accompanied by gasoline entering the crankcase and severe wear of the SG. Signs: the oil level is rising (the oil smells like gasoline), the car jerks, runs unevenly, stalls, the speed fluctuates. Solution: change the injection pump. 2. EGR valve, this is an eternal problem on all engines with an exhaust gas recirculation system. Over time, when using low-quality gasoline, the EGR valve becomes coked, begins to jam, and eventually stops working completely; at the same time, the speed fluctuates, the engine stalls, does not move, etc. The problem can be solved by systematically cleaning the valve or plugging it. 3. The speed drops, it stalls and doesn’t move. All problems with idle speed, in most cases, can be solved by cleaning the throttle body, but if that doesn’t help, then clean the intake manifold. In addition, the cause may be the fuel pump and dirty air filter. 4. High fuel consumption on 3S, sometimes even absurd. Adjust the ignition, clean the injectors, BDZ, idle air valve. 5. Vibrations. Eliminated by replacing the engine mount, or the cylinder does not work. 6. 3S gets hot. The problem lies in the radiator cap, replace it.

Where are the faults?

No specific diseases were noted with GE, except for the possibility of bending the valves when the timing belt breaks. Although the piston heads of the entire family, except for the latest modification, are equipped with recesses, in the event of a break, the valves of other generations also bend.

The name “Beams” is precisely consonant with the last sound made by the engine in this situation. Such cases are not observed only in generations under 3 gen, and only if you are lucky.

Attention: premature destruction of the toothed belt is most often caused by drips of antifreeze and liquid lubricant on the rubber, which soften the material. In this case, the cord remains intact, and the drive pulley simply cuts off several teeth on the inner surface of the product.

Engine tuning Toyota 3S-FE/3S-FSE/3S-GE/3S-GTE

Chip tuning. Atmo

Toyota engines 3S-GE and 3S-GTE are perfectly adapted to modifications, as evidenced by the Le Mans 3S-GT engines with a power of up to 700 hp, there is no point in modifying the simpler 3S-FE/3S-FSE, to increase their output you will have to replace everything that is possible, the stock FE will not withstand the increased load, and given its age, the tuning will end in a major overhaul. It's easier and cheaper to replace 3S-FE with 3S-GE/GTE. What about GE, they are pretty well pressed without you and me, in order to move further you need to install a light forged ShPG, a lightweight crankshaft, everything must be balanced. We grind the cylinder head, intake exhaust ports, finish the combustion chambers, valves with titanium plates, camshafts with phase 272, lift 10.2 mm, direct-flow exhaust on a 63mm pipe, with a 4-2-1 spider, Apexi S-AFC II. In total, this will give up to a 25% increase in hp. and your 3S will spin at 8000 rpm. For further movements, you need to install shafts with a phase over 300 and maximum lift, split gears, turn off VVTi, 4-throttle intake (from TRD for example) and spin at 9000 rpm until it falls apart.

Turbine for 3S-GE/3S-GTE

For trouble-free operation of the GTE version, we simply make a chip and get our +30-40 hp. and no questions. To get serious power you need to remove the standard turbine, look for a turbo kit with an intercooler for the required power (the most balanced option is the Garrett GT28) and, depending on this, choose more powerful injectors (from 630cc), forged bottom (preferably), phase 268 shafts, fuel pump from Supra, straight exhaust on 76 pipe, AEM EMS setting. The config will show about 350 hp. A further increase in power is possible using a kit based on the Garrett GT30 or GT35, with a reinforced bottom end; it will drive fast, loudly, but not for long.

Toyota 3S FE engine: characteristics, malfunctions and tuning

Japanese automakers have always been famous for their reliable and economical engines. Motors produced several decades ago are still in successful use today, delighting car owners with reliability and excellent technical characteristics. The 3S FE four-cylinder petrol engine from Toyota is very popular.

This two-liter injection engine appeared in 1986 and, with minimal changes, remained on the assembly line until 2000.

Maintenance and repair

This point is one of the most important when owning an old-style motor. Although the 4S engine was smaller in volume compared to the 3S, it was never a worse option. It was simply chosen for other needs. After all, not everyone needs more than 125 horsepower. For most, this is still enough. But the engine is a million-dollar engine and it is very difficult to “kill” it. A huge number of people recognized this power unit as one of the best creations of Toyota.

Description

The 3S FE modification was one of the first from Toyota with a direct fuel injection system. The use of an injector has significantly improved the power characteristics of the new engine, its idle speed has improved, and fuel consumption has also been significantly reduced in comparison with the carburetor version of this engine.

The Toyota 3S FE engine itself is actually an improved version of the 3S, so it retains its legendary reliability and relative simplicity of design.

- The in-line cast iron four was distinguished by increased resistance to overheating, and the simplicity of its design allowed the car owner to carry out service work himself. The repair was also not difficult, so it could be carried out in most auto repair shops.

- The service life of the 3S engine is set at 300 thousand kilometers, but it is not uncommon to see cars that were able to travel more than a million kilometers without major engine overhauls.

- A special feature of this power unit is the presence of two ignition coils, which improves the flammability of the fuel-air mixture. The 3S engine runs confidently on 92 and 95 gasoline. Depending on its version, the power rating can range from 115 to 130 horsepower. The engine shows maximum torque from the very bottom, so car owners did not experience a lack of traction.

- It is also necessary to note the excellent efficiency indicators of this engine. When installed on a Toyota Camry sedan, the car consumed about 10 liters of fuel in the combined cycle, which is an excellent indicator for a heavy full-size sedan and a two-liter engine. It must be said that this engine shows optimal fuel-efficient and dynamic performance on 95 gasoline.

Initially, the Toyota 3S FE engine was actually a modernized 3S engine, which received an injector and an automatic injection control system.

- One of the features of the 16 valve 3S engine is the use of a special valve timing mechanism, which consists of two small camshafts driven by a belt rather than a chain, as on most Toyota engine models.

- The combined lubrication system simultaneously sprays oil and lubricates moving elements under high pressure, which ensures reliable and durable operation of the moving elements of the motor.

- The 3S engine uses a fully electronic ignition system that provides optimal thrust over the widest possible rev range.

- The 3S engine is fuel efficient, regardless of the octane number of the fuel used. We also note the use of a forced liquid cooling system, which is reliable and allows you to avoid overheating of the power unit even under conditions of increased load on the engine.

- Despite all its advantages, including unsurpassed reliability and durability, this motor had one significant drawback - increased noise. This increased noise was due to the design features of the base power unit. In 1996, the engine was modernized, which made it possible to significantly reduce the noise levels of this engine.

- At the same time, problems arose with an overloaded timing belt, which experts recommended changing every 40-50 thousand kilometers.

Design Features

The 3S-FE internal combustion engine is designed simply and thoughtfully. The cylinder blocks are made of cast iron, the cylinder heads are made of aluminum. There are two camshafts. There are no hydraulic compensators. The cylinder heads are poorly ventilated, so the engine is not suitable for forced loads. Fuel supply system is injection with electronic multipoint injection.

The disadvantages of the 3S-FE engine include the noisy operation of the exhaust system and noticeable rustling of the pulleys and rollers. After 200,000 km, a good oil appetite and high fuel consumption appear. The engine is piled up against the engine shield, making access for maintenance difficult.

A serious problem was discovered after the 1996 modernization. The designers reduced the mass of the piston group by 0.7 kg, leaving the crankshaft unchanged. To save money, the updated crank mechanism was not balanced, which led to vibration. Under its action, the bolt heads of one of the connecting rods are torn off. The part breaks loose and pierces the cylinder block. To prevent an accident during repair of the piston group, it is necessary to change the connecting rod bolts and tighten them strictly with the nominal torque.

Modifications to the unit in 1996 affected the ignition system. Mechanical distributors were replaced with dual coils that operate on 2 spark plugs. This doubled the load on the spark plugs and wiring.

Some 3S-FE models have an EGR gas recirculation system. An electric vacuum valve and a vacuum modulator-membrane are used for control. When the gas becomes rarefied, the EGR valve opens. After the EGR valve closes, the exhaust gases pass through the modulator filter. Every 2 years, it is advisable to blow out the filter with compressed air.

Improving the motor, the designers released a new version 3S-FSE. The unit was equipped with a D4 direct injection system and power was added, but overall the attempt was unsuccessful. The engine ran intermittently due to a broken fuel injection pump. Insufficient lubrication of the crankshaft and the accumulation of carbon deposits in the intake manifold forced owners to often visit the service center.