07/14/2021 10,060 Transmission

Author: Victor

An automatic transmission is a more advanced and modernized option compared to a manual transmission. This type of gearbox is characterized by a rather complex design. Malfunctions that may arise in its operation will be more difficult to diagnose, unlike mechanical units. For what reasons does the automatic transmission kick in and how can a car owner solve this problem, you will learn from this article.

[Hide]

Does it kick when it's cold or hot?

It happens that the automatic transmission kicks and jerks at all speeds or when shifting from 1 to 2. You need to figure out whether it kicks when it's hot or when it's cold.

Causes

It does not matter whether this problem occurs when starting off or when driving at low speeds. The reasons for this behavior of the unit are usually the following:

- There is a lack of transmission oil in the system.

- The substance used for lubrication has lost its technical properties and has become of low quality.

- Problems have appeared in the operation of the main unit of the unit - the torque converter. In particular, we are talking about difficulties in the functioning of the blocking device.

Remedy

Problems of this kind can be eliminated in several ways:

- Add lubricant to the transmission system. You need to find the inspection and filler holes on the gearbox, fill in the fluid so that it meets the standard. It is advisable not to overfill it.

- If the problem lies in quality, the lubricant must be replaced. When draining, pay attention to the condition of the substance. If there are traces of deposits and dirt in it, then it makes sense to wash the box. Otherwise, the unclean oil that remains in it will mix with the new one. Accordingly, fresh lubricant will also lose its properties in the near future.

- Problems with the operation of the blocking device are resolved by computer checking the unit.

The video below will allow you to learn more about the torque converter lock-up device, as well as malfunctions that can occur in its operation. The material was filmed and published by Dmitry Yakovlev.

Causes of hot and cold shocks

Car owners notice how the automatic transmission kicks when hot. So why do shocks appear when switching the automatic transmission? Cold and hot shocks may indicate the following common problems:

- insufficient oil level in the automatic transmission.

- The oil poured in, designed to lubricate the parts, is of poor quality, so owners sometimes note that after changing the oil, shocks appeared in the automatic transmission.

- the appearance of incorrect operation of the torque converter (in the absence of adequate locking operation, a kick appears)

To resolve this problem you need to take certain simple steps:

- check the fluid level in the automatic transmission (if necessary, add oil to the required level)

- Completely replace the fluid in the gearbox.

- carry out detailed diagnostics of the unit.

The box jerks when accelerating

Sometimes it happens that the automatic transmission kicks when it’s hot and jerks while accelerating the car. Below we will look at why this happens.

Causes

What causes the car to jerk when accelerating:

- Some components of the transmission unit have worn out.

- The automatic transmission often kicks into gear as a result of violation of operating rules. Therefore, before using your car with an automatic transmission, it is recommended to carefully study the service manual for the car.

- Twitching may occur due to a violation of the timing or quality of maintenance of the unit.

- Making mistakes when changing the oil in the gearbox.

Remedy

To get rid of the twitching problem, do the following:

- Diagnose the quantity and condition of the lubricating fluid. If necessary, replace it and flush the transmission. The level must be normal.

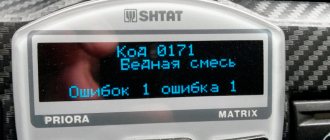

- Carry out a detailed inspection of the condition of the unit. It is not recommended to disassemble the automatic transmission yourself, especially if you do not have experience in this. You can go to a service station or do a computer check. To do this, you will need a PC, software and a diagnostic adapter. The scanner is connected to the computer and a special connector, after which the program is launched. This method will allow you to identify fault codes that will indicate problems with the transmission.

- Be sure to familiarize yourself with the operating features of the gearbox. Study the service book and take into account all the nuances described in it.

You can learn more about diagnosing the fluid level and adding oil to the automatic transmission from the video (material published by the Live Video Blog channel).

Safe time to replace transmission fluid in an automatic transmission

Manufacturers fill ATF into 6-speed units “for their entire service life.” This means that the box will travel 150,000 km, and then a scheduled overhaul will begin with the replacement of the working fluid.

The service life of an automatic transmission is calculated based on ideal operating conditions:

- the operating temperature of the unit is 75 - 90℃;

- the car moves smoothly, without sudden starts and braking;

- the machine does not tow trailers weighing more than recommended;

- The driver regularly services the vehicle.

If these instructions are followed, ATF will maintain its performance properties after a mileage of 100,000 km. But real driving conditions are far from the calculated ones. Traffic jams, heat, and rough driving in the city increase the load on vehicle components. Parts wear out faster even when driving aggressively on the highway.

The working fluid in the box becomes contaminated with metal shavings, friction dust, and adhesive detachments. The slurry loses its original viscosity and is not able to fully transmit the torque of the torque converter. Additives mixed with slag do not lubricate parts and do not provide friction for clutches. ATF does not have time to cool. The pressure drops. Dirt clogs the valve body channels, causing a “stroke” of the machine.

Read

Changing the oil in the automatic transmission of Land Rover Freelander 2

To prevent shocks from appearing, you need to change the oil in the automatic transmission as it gets dirty. Auto mechanics consider the optimal replacement period to be 50 - 60,000 km. Under severe operating conditions of the machine and in “maintenance-free” units - no later than 40,000 km.

How to properly change the oil in an automatic transmission?

If the transmission shifts jerkily and with shock, the reason may lie in the lubricant itself. How to change and add new fluid:

- Warm up the engine to operating temperature and allow it to cool for about 10 minutes.

- Climb under the bottom of the car and find the drain plug on the gearbox. This hole can be protected by a tray. Place an old container under it to collect waste fluid. Unscrew the bolts on the crankcase or the drain plug.

- Remove the filler or inspection hole cap.

- Wait until all the lubricant has left the system. This will take some time.

- Once the fluid is drained, clean the area around the hole. Also clean the plug itself and assess the condition of the seal on it. If it has fallen apart or is very worn, it must be replaced.

- Replace the cover along with the drip tray (if present). Tighten all bolts.

- Using a construction or medical syringe with a hose, fill the system with the required volume of liquid. It will depend on the specific vehicle. Before replacing, read the service book about exactly how much lubricant is needed. If there is no filler hole, use the inspection hole. Add the substance until it starts to come out.

- Screw the plug into place and start the engine. Perform a test drive and evaluate the quality of the transmission. At first, kicks may be observed when downshifting or upshifting. But with time it will pass. After this, check the box for leaks. If there are traces of oil leakage from the system, this problem needs to be solved.

1. Remove the automatic transmission pan, unscrew the drain plug and drain the fluid from the system

2. Screw the plug into place and fill in new lubricant through a funnel or syringe with a hose.

Why did the jerking appear after the replacement?

If the problem recurs after changing the lubricant, it is usually due to the use of the wrong fluid. It does not fit the vehicle. Or you didn't put enough into the system.

Remedy

To solve the problem, you first need to make sure the quality of the oil. In the service book for the car, read what standard of lubricant must be poured into certain boxes. Buy the appropriate fluid and add it to the transmission. You can replace it either yourself or at a service station. If the level of the substance is insufficient, then it is necessary to add it to the system.

BMW 7 series › Logbook › Push/kick of the automatic transmission when braking. Change of oil. Flashing.

From the very first day after purchase, there was a slight push/kick in the automatic transmission during hard braking, when shifting from third or second gear to first, as if someone had slightly hit you from behind. There were no shocks when accelerating. First of all, they checked the oil level, color, and presence of chips. Everything was normal, only the pan gasket was slightly sweating. In the future, I constantly monitored the level. I read a bunch of information on this topic, it turned out that this is a very common problem on the E65, many have measured themselves and drive like this. Resetting the adaptation helped to reduce the shocks to a minimum for a couple of weeks; replacing the elastic cardan coupling also did nothing. The experts condemned mechatronics. I drove like this for 2 years. But I was confused by the connection of these shocks to the time of year. I noticed that in the fall and at the end of winter (in wet weather) the tremors are stronger, you can even say that at this time of year they were continuous kicks/blows, in the winter there were rare tremors, and in the summer, at a temperature of 25+ they completely disappeared. In connection with this, it was decided to completely change the oil in the box, including flushing. It took 15 liters of original ZF Lifeguardfluid 6

, + tray with filter, + adapter and connector. The result, the automatic transmission began to work smoother, the shifts were much softer, but the shocks remained... There was one more option, an acquaintance who used to work at the dealer said that BMW had an order regarding this problem, and therefore it was necessary to update the firmware in several blocks with new, corrected ones. I signed up to flash all the units in the car to the latest current versions. The process itself took 3-4 hours, the result is there - not a single shock anymore. The gearbox is unrecognizable, only sometimes you can feel the gear shift itself at the place where there was a push-kick-blow. As it turned out, all my blocks had firmware from the factory, dated 2004. After that, no one ever updated them. For example, those that are installed now, the latest current firmware for E65 from 2013, in which many software bugs have been eliminated. It seemed that the engine also began to run a little smoother. If anyone is tormented by such jolts and kicks when braking, first try updating the transmission blocks, or better yet, all the blocks in the car, to the latest software.

Issue price: Oil at the current exchange rate: 1100 rub. per liter + tray, adapter, connector for 10 thousand, + work Re-flashing of all units in Moscow: 7-15 thousand.

Causes of shocks when shifting gears

It happens that shocks appear when switching to a lower or higher speed. Let's look at the causes and solutions to the problem.

Insufficient fluid level in transmission

Lack of lubrication will lead to incorrect operation of the unit as a whole. If it becomes more difficult to switch gears from first to second or third, you need to diagnose the oil level.

Remedy

The problem of automatic transmission kicking when hot when there is a lack of fluid can be eliminated by adding it to the system.

It is important to consider one point. When adding oil to the transmission, you can only use the fluid that is already in the transmission. If the lubricants are different in composition, this can lead to their mixing and loss of properties. As a result, a complete replacement of the substance will be required. It is necessary to diagnose the lubricant level in the transmission and make sure that the cause of the shortage is not related to its leakage. This problem can occur when the seals or sealing elements wear out. You will need to drain all the oil from the system and then refill it.

A detailed video on the topic of eliminating transmission fluid leaks using the example of a Mercedes car is presented below (the material was filmed by user StaniSlav B.).

Dirty transmission oil

Contaminated fluid in the gearbox often causes jolts and kicks. Deposits usually form as a result of mixing different oils or when using the same lubricant for a long time.

Remedy

This type of problem can be eliminated by thoroughly cleaning the gearbox. For this purpose, special flushing oil is used. Depending on the amount of dirt in the system, this process may need to be performed several times. You need to do the following:

- Warm up the engine to operating temperature.

- Place an old bucket or cut-off bottle under the transmission. The container will be used to collect used lubricant.

- Unscrew the drain plug or bolts on the oil pan, wait until all the fluid comes out of the system, and screw it back.

- Having previously read the instructions on the packaging label, fill the gearbox with flushing oil in the required volume. Turn on the engine and perform a test drive.

- Drain the lubricant from the system again and check its quality. If necessary, clean the unit again.

- Add new oil to the box.

Detailed instructions for cleaning an automatic transmission yourself using the example of a Mercedes Vito are presented by the Secret Garage channel.

Insufficient heating of the transmission fluid

The reason why the automatic transmission kicks when hot may be due to insufficient heating of the lubricant. Because the fluid temperature is too low, the main components of the transmission unit cannot heat up. This contributes to the formation of tremors.

Remedy

The only solution to the problem is to warm up the box to operating temperature.

The automatic transmission kicks: what to do?

The first thing you should pay attention to is the oil level in the automatic transmission and its condition. As noted above, many do not consider it necessary to change the ATF, but this is not true

All manufacturers recommend performing a complete replacement every 100-150 thousand kilometers, and a partial replacement every 60-80 thousand.

Another reason is that the wrong oil was filled in. Many manufacturers indicate the required ATP in the operating instructions. Drivers do not always follow these recommendations and pour what they consider necessary. The result is kicking, jerking, unstable operation or untimely gear shifting. If you continue driving like this, you may end up with a major overhaul. In any case, the reason must be found as quickly as possible if you notice that the automatic transmission is kicking. What to do in this case? First of all, check the automatic transmission oil level. This is often done with the car running and warm. Much can be understood by the color of ATP. Darkening or lightening indicates that it is time to replace it.

Jerking when braking (software problems)

Sometimes the automatic transmission kicks when the driver presses the brake. This is usually due to problems with the unit's software.

Causes

The appearance of kicks during braking may be due to problems with the software used to control the transmission system.

Remedy

It is unlikely that you will be able to solve this problem on your own. To eliminate it, you will need to reinstall the control automation, in particular , perform a firmware update. But doing it yourself is not so easy. If the car is still under warranty, then you should definitely seek help from representatives of the dealer company.

The video shows the process of flashing an automatic transmission unit using the example of a VW Tiguan (material published by the SBll channel).

Practice shows that new automatic transmissions often require updates. Thanks to this, it is possible to achieve not only elimination of kicks, but also optimization of the operation of the transmission as a whole. Before flashing, representatives of the dealer company perform a complete computer diagnostics of the vehicle.

Possible solutions to the problem

In most cases, the following techniques help to get rid of kicks when switching an automatic transmission:

- Complete change of transmission oil, it is advisable to fill in the original. When replacing, the tray and magnets are cleaned and the filter is replaced. The pallet must be removed during maintenance work.

- Complete disassembly of the box to clean the valves. The operation is especially important for the line pressure valve.

- Carrying out the two above procedures together with automatic transmission diagnostics. During testing, it is important to check the valve resistance.

- Washing the automatic transmission using a product specially designed for this purpose.

- Updating the control automation firmware. Possible in a service center for new automatic transmissions. This eliminates not only shocks when shifting gears, but also ensures smooth operation and improves fuel efficiency.

Recently, many automatic transmission service centers have been faced with the failure of the step-down resistor, which is present in almost all types of boxes of this type. It serves to reduce the current to the main line control valve, which is controlled by the line pressure solenoid. That is, it participates in the process of softening gear shifting, reducing the current supplied from the control unit to the solenoid.

We recommend: Self-replacement of the coolant temperature sensor: 2 types and 7 signs of their malfunction

If it is thrown out of the chain, switching will occur at the maximum pressure that the oil pump can create - too abrupt and uncomfortable, with a kicking sensation. To identify the problem, find the location of the resistor and check its resistance with an ohmmeter. If it differs from the nominal one in one direction or another, it is replaced with a new one or made from parts purchased in a radio store connected in parallel, since a fairly large current will pass through them.

Vibrations when engaging reverse gear

Problems with the automatic transmission sometimes occur when reverse gear is activated. Let us examine in detail the causes and methods of eliminating this malfunction.

Causes

What does this behavior of the unit indicate:

- Problems with the controller installed on the transmission. Over time, the automatic transmission sensor begins to function incorrectly due to its inoperability or dirty contacts. The connector may also be damaged.

- The vehicle is not warmed up.

- Problems with lubrication in the transmission system.

Dmitry Mashkov in his video will talk about which is the best method to use for flushing an automatic transmission - full or partial.

Remedy

There are several methods for eliminating kicks and vibration when engaging reverse gear:

- It is necessary to perform a detailed diagnosis of the gearbox sensor. If you do not know where this device is located, study the service book for the car. It should indicate the automatic transmission diagram with the location of the controller. Or contact a service station. You can check the sensor using special equipment or by installing a new, known-good device. When replacement does not help, check the condition of the contacts on the mechanism itself and its connector. Sometimes the problem lies in their clogging or oxidation. Then the problem can be solved by cleaning the plugs. If the sensor connection wiring is damaged, it is necessary to determine the location of the break and eliminate it.

- If vibrations during reverse gear activation are due to a cold engine, fully warm up the vehicle's powertrain to operating temperature.

- Check the transmission fluid level in the gearbox. If there is a shortage, add it to the system. Assess the quality of the lubricant. If the oil is too dirty, replace it and flush the unit.

- If this does not help, perform a detailed diagnostic of the automatic transmission using a computer and appropriate software.

Diagnostics

Automatic transmissions have already become popular among domestic motorists, although twenty years ago no one could have thought that this would happen. As a result of many advantages, the demand for these units is constantly growing. Of course, like any other component in a car, an automatic transmission can periodically fail or function incorrectly. In fact, there can be many problems with the unit, but if the automatic transmission does not change speeds, then the only way out is diagnostics.

But, first of all, you need to reliably make sure that this malfunction is really related to the operation of the unit. You must ensure that all vehicle systems are functioning properly if you are unable to change gears. In principle, one of the main faults due to which the automatic transmission does not change gears is often a lack of working fluid in the system. As a rule, this is usually due to a worn out oil seal of the unit, which causes fluid to leave the automatic transmission.

A lack of lubricant level in the box may be due to the following factors:

- Liquid leak. Oil can escape through the crankshaft seals, the cylinder head gasket, the oil filter seal, or through the oil reflective caps. If transmission oil (hereinafter referred to as TM) escapes through the seals, this indicates their wear, which can be caused by the use of chemicals or poor-quality lubricants. The cylinder block gasket could wear out due to overheating of the engine or incorrect tightening of the screws during disassembly and reassembly of the engine. If the problem is with the oil filter, then most likely it is due to the fact that the sealing rubber cannot stay in place. If oil leaks from the automatic transmission due to the reflective caps, then the problem is their wear caused by overheating.

- Breakdown of the vacuum corrector. Inside this device there is a special membrane that reacts to the level of vacuum in the collector. If the integrity of this element is violated, then the TM will get into the car engine. In this case, the unit can function for a long time even with a significantly reduced level of lubrication, but over time it will simply fail.

- If the TM goes into the cooling system. If the tightness of the oil cooler is broken, then the lubricant will go into the engine radiator, since the oil pressure in the automatic transmission radiator is always higher than the pressure in the cooling system. And when the engine turns off, the process of lubricant leakage into the coolant begins. As a result, an emulsion begins to appear in both the internal combustion engine and the automatic transmission. When antifreeze gets into an automatic transmission, it corrodes the clutches, as a result of which corrosion begins to form on the latter. In the event that gears have not been changed for a long time, the problem can be solved by replacing the oil cooler. It is also a good idea to rinse the automatic transmission with working fluid. Having done this, you can try to bring the unit back to life.

- If the pipe that connects the automatic transmission to the oil cooler breaks. In this case, all the lubricant will come out of the transmission in a matter of minutes, so the unit will simply stop working.

Automatic transmission disassembled

This is only a small part of the reasons why an automatic transmission may not change gears. A more complete list is presented in the table.

Repair cost

The price for repairing an automatic transmission depends on several factors:

- Transmission damage level. It's one thing when the problem is an oil leak and only the seals or gaskets need to be changed. It's a different matter when repairs to the torque converter or its locker are necessary. Prices for reflashing are also different.

- ONE HUNDRED. Depending on the service station, the cost of services can vary greatly.

- Vehicle models. In practice, repairing either too old or completely new cars is expensive. Spare parts for such machines are always more expensive. But parts for older gearboxes are not so easy to find.

How much oil do you need to fill in an automatic transmission?

Information about the exact filling volumes of a particular box is contained in the manual, because the standards for each type of device for different cars are different, it all depends on the features of the structure. How much oil needs to be poured into the gearbox also depends on the replacement method. The average volume of the box is 6 – 8 liters; when updating the liquid, it can take about 3 liters. A partial replacement does not imply a complete oil change, so you usually fill in new transmission fluid in the same volume that was drained, and then adjust its level as necessary.

With a slight overflow, you don’t have to worry about serious consequences, and it’s unlikely that you’ll be able to notice that the level is exceeded by 1 – 1.5 cm during the operation of the box. It’s another matter if the volume of oil poured into the automatic transmission significantly exceeds the permissible norm. In this case, an unpleasant result with subsequent repair or replacement of the device will not take long to occur.

Signs of oil overflow:

Any deviations from the normal functioning of the device should alert the driver, since over time the situation only gets worse and can lead to severe damage to the automatic transmission.

Video “How to check a car gearbox”

You can learn how to check an automatic transmission yourself from the video (the material was filmed and published by the AutoMen Selection of Cars channel).

Do you have any questions? Specialists and readers of the AUTODVIG website will help you ask a question

Was this article helpful?

Thank you for your opinion!

The article was useful. Please share the information with your friends.

Yes (83.33%)

No (16.67%)

X

Please write what is wrong and leave recommendations on the article

Cancel reply

Rate this article: ( 13 votes, average: 4.54 out of 5)

Discuss the article:

Checking the oil level in the automatic transmission

To obtain the most accurate results, you need to check the transmission fluid level both in a warm state and in a cold state, using a dipstick. Before checking, you should pay attention to the car manufacturer's recommendations in this regard. Many devices have o and “HOT”; you need to navigate according to the scale that corresponds to the condition of the oil.

The procedure is carried out with a warm transmission or after starting the engine for 3 - 5 minutes, after which you can begin:

How to remove excess oil from the box?

Sucking oil with a syringe

It is not difficult to eliminate oil overflow in an automatic transmission, but you must first determine this violation. The following symptoms indicate a lubricant overflow in the machine:

To eliminate the problem of overflow, you need to drive the car into an inspection hole or lift it using a lift. After this, you need to remove the oil filter. Allow the transmission fluid to drain, then screw the filter into place and check the level with the dipstick. If you have drained too much, pour some back in, but do not exceed the MAX mark on the dipstick.

You can also suck the oil out of the automatic transmission through the dipstick hole, eliminating the overflow problem. Place the IV tube on a large medical syringe and insert the end into the dipstick hole. Suck out a certain amount so that the lubricant is within normal limits.

Source

Ways to remove excess oil

With a slight overflow, the problem is not acute, so there is no need to panic. When an excess of liquid is detected in a timely manner, there is no need to involve service employees in the process. If a motorist has poured oil into the automatic transmission when replacing it, he is able to completely cope with the task on his own. Often the solution is to remove the oil filter. When the liquid completely drains from the filter element, it is replaced. If such manipulations do not help eliminate the problem, the excess amount of lubricant is removed by sucking it out.

To remove excess oil yourself in this way, you will need a 10 cc syringe and a dropper. Next, we perform a number of simple steps:

If the volume of oil poured is more significant, then the excess will need to be drained through a special hole.

The procedure for removing excess grease is quite simple, so even a novice motorist can cope with it. The main thing is to observe the condition of monitoring the fluid level, so as not to cause troubles associated with a lack of lubricant. It is necessary to check the volume and condition of ATF at the intervals established by the car manufacturer's regulations or more often in the presence of unfavorable operating conditions of the vehicle.

In what cases does the box kick?

There are many reasons why the normal operation of an automatic transmission is disrupted. Let's consider the main ones, as well as possible solutions to problems:

- The automatic transmission kicks while driving. This indicates a malfunction of the valve body or torque converter. They will probably need to be replaced.

- Shocks are felt in the automatic transmission during braking. A sign of a faulty clutch or valve body. Replacement of failed spare parts will be required.

- The box jerks when engaging reverse gear. A broken sensor or possible problems with the torque converter. Replacement required.

- The automatic transmission kicks when cold. Transmission components are worn out. Replacement of worn parts.

Let's look at some cases in more detail.

High temperature and low valve pressure

Before identifying the reasons for the incorrect operation of the machine, you should make sure the quality of the oil being poured. The duration of operation of the box, as well as the degree of wear of components and assemblies, depends on this.

The oil in the box is in constant interaction with rubbing parts and is exposed to high temperatures. Such conditions reduce viscosity and change the structure of the liquid. Therefore, after traveling a distance of about 50,000 kilometers, the transmission oil must be changed.

The filter in the automatic transmission also gradually deteriorates, and its particles enter the oil, changing its composition and properties. In addition, particles contaminating the filter reduce its throughput. This entails a decrease in pressure in the box and deterioration in the performance of the clutches. This is exactly the case when the driver feels the automatic transmission kicking when it’s hot.