Toyota UZ is a group of eight-cylinder engines with a V-shaped block layout. This engine has 32 valves (4 per cylinder). It was used mainly on expensive sports cars, premium cars and expensive SUVs of the Toyota and Lexus brands. In 1989, three variations of this engine were released: the 1UZ FE, 2UZ-FE, and 3UZ-FE engines. Each of these engines was installed only with an Aisin automatic transmission.

Today, the UZ model range has been replaced by UR. The UZ series is still produced today, but only for the domestic market for the Crown Majesta 4WD. The engine version installed in this car is 3UZ-FE.

Motor history

The first power units were released in 1989. At that time, they were produced by the Tahara plant company. The idea for creating the UZ series was the need for powerful engines for heavy premium sports cars. But the very first 1UZ FE was installed in the then new Toyota Celsior sedan. At the same time, the engine was installed by Lexus in a new sedan with the LS400 index.

After the debut of the motor in the first two models, it became widespread in the following models:

Toyota

- Crown.

- Aristo.

- Soarer.

Lexus

- SC 400.

- GS 400.

You can parse the letter designation as follows. Each index indicates one of 5 motor parameters.

- 1 — unit number within the series;

- U - symbol of the ruler;

- Z—type of fuel—gasoline;

- F - standard power range;

- E - distributed injection with electronic control.

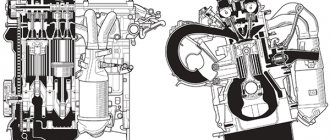

The engine type is determined by the required performance for large and heavy premium segment cars. To meet the needs, he created an FE engine with a cylinder capacity of 4 liters. This volume is provided by 8 cylinders having a V-shaped arrangement and a 90-degree camber angle.

It is worth noting such a fact as the fact that this series of engines has never been installed with manual transmissions. In 1998, the engine was included in the top 10 best engines on the US market according to the famous magazine "Ward's AutoWorld magazine". This engine was equipped with a VVT-i system.

Despite this layout, the block has quite acceptable dimensions. The crankshaft has 5 supports, and the connecting rods have a dual structure. In turn, driven by aluminum-silicon pistons. The ratio of geometric dimensions is close to a square, which is why the engine turned out to be so successful.

Due to the fact that the engine block is made of aluminum, the motor fits into a relatively low weight of 220 kg. The power of this engine is about 260 horsepower.

Pros and cons of the engine

It so happened that over the years of operation, no serious problems were identified with the unit, and the characteristics of the UZ series engine are still set as an example for power plants.

Rare deficiencies are associated with the age of the installation, or appear due to improper use:

- Poor quality fuel damages spark plugs;

- Difficult installation and maintenance of the water pump, load on the drive belt;

- A broken belt on engines with a VVT device leads to valve failure;

- Structurally difficult access to spark plugs;

- The first power plants had complex settings and installation of the distributor.

Despite its shortcomings, the 1UZ FE engine has a sufficient service life, which reaches 500,000 km when replacing lubricant and consumables on time.

Lubricant replacement:

Evolution

In 1995, the 1UZ-FE engine was modified. The compression in the cylinders was increased to 10.5 bar, and the design of the pistons and connecting rods was also improved, although not significantly. The purpose of these modifications was to reduce the weight of the entire structure. The improvements did not go unnoticed and the engine received an additional 5 horsepower and 10 Newton of torque.

In 1997, the engine was modified again, but much more significantly. The engine's performance was most influenced by new camshafts with Toyota's proprietary VVT-i system. The intake manifold has also been redesigned. In the new version it has been strengthened and made of aluminum. The distributor was removed from the ignition design and was replaced with a fully electronic ignition system. A coil was installed on each cylinder, and the distributor was replaced with Hall sensors. Last but not least was increasing the compression ratio by another tenth. All these modifications allowed the 1UZ-FE V8 to increase power by 30 horsepower and develop torque to an impressive 407 Nm.

Service regulations 1UZ FE

With proper and timely maintenance, the 1UZ FE motor will not cause much trouble to its owners.

Basic procedures that must be completed on time:

- Change the oil every 10 thousand kilometers;

- Change the timing belt kit every 50-70 thousand kilometers;

- Change spark plugs (DENSO iridium) every 80-100 thousand km.

In addition, on the 1UZ FE engine it is necessary to regularly check the pump, which sits deep in the collapse of the BC. The water pump is constantly under stress, as the belt is bent under pressure, which over time deprives the unit of its tightness. Due to the depth of the pump, it is difficult to immediately determine the leak, so the owner must be attentive to reducing the liquid level in the RB (tank).

DENSO iridium spark plug is recommended by the manufacturer for 1UZ FE

The second point: attachments and components associated with the engine. During operation, they may lose their original properties, which inevitably affects the operation of the motor. For example, if the supports that secure the body of the power unit wear out, vibration and noise will begin. In the first modifications of the 1UZ FE, the BSZ ignition system was also considered a weak link. Unprofessional intervention has always led to problems, so all work with this unit must be entrusted to specialists from technical centers.

Specifications

Characteristics and design features of 3 modifications of 1UZ-FE.

| Parameter | Meaning | ||

| Manufacturing company | Toyota Motor Corporation | ||

| Years of manufacture | 1989-1995 | 1995-1997 | 1997-2002 |

| ICE model | 1UZ-FE, petrol | 1UZ-FE VVT-i, petrol | |

| Cylinder configuration | V-shaped, at an angle of 90° | ||

| Number of cylinders | 8 | ||

| Working volume, cm3 | 3968 | ||

| Cylinder diameter, mm | 87,5 | ||

| Piston stroke, mm | 82,5 | ||

| Compression ratio | 10,0 | 10,4 | 10,5 |

| Number of valves per cylinder | 4 (2 for inlet and 2 for outlet) | ||

| Type of timing mechanism | DOHC, OHV | DOHC, OHV, VVT-i | |

| Cylinder firing sequence | 1-8-4-3-6-5-7-2 | ||

| Max. engine power, hp / shaft rotation speed, rpm | 256 / 5400 | 261 / 5400 | 290 / 6000 |

| Max. torque, Nm / shaft speed, rpm | 353 / 4600 | 363 / 4600 | 407 / 4000 |

| Type of internal combustion engine power system | Multiport electronic injection | ||

| Type of internal combustion engine ignition system | Contactless, with 2 coils and 2 distributors | Electronic, with separate coils for each cylinder | |

| Lubrication system type | Combined, partly under pressure and partly by spraying | ||

| Cooling system type | Liquid, closed type with forced circulation | ||

| Recommended octane number of gasoline | 95 | ||

| Type of transmission coupled with internal combustion engines | 4-speed automatic transmission | 5-speed automatic transmission | |

| Product weight, kg | 225 | 220 | 226 |

| BC and cylinder head material | Aluminium alloy | ||

| Piston material | Aluminum-silicon alloy | ||

| Environmental Compliance | — | EURO 2 | |

| Engine mileage life (approximate), thousand km | 350-400 | ||

Operation and care

To ensure that the engine works out its intended life and does not upset the owner ahead of time, the installation is looked after and the procedures required by the regulations are followed:

- Every 100,000 km, the timing belt of the power plant is changed. In order to protect the structure and avoid troubles with the gas distribution mechanism, it is advisable to carry out the procedure before the deadline established by the technical regulations;

- When installing the belt, check the readings of the control marks;

- Before installing the automatic tensioning mechanism, check the functionality of the product. Check that the pusher extends beyond the body by 10.5 millimeters;

- Every 10,000 kilometers, change the working lubricant of the power plant. The manipulation is combined with the change of filter elements. It is important to choose the right oil according to the characteristics specified in the engine instructions. You need to buy material from official representatives;

The engine is sensitive to spark plugs. Spark plugs with platinum electrodes are installed on engines of the UZ series without the VVT-I device. Units with installed VVT-I mechanisms require the use of spark plugs with iridium electrodes.

Belt installation (motor “1UZ FE”):

Interesting Facts

In order to emphasize the premium nature of the Lexus GS400, it was equipped with different settings for the electronic units, which is why it produced slightly higher values than the engine versions installed by Toyota. The modified version produced about 300 horsepower and 420 Nm.

Although the engine has a large displacement and high power, each of the UZ series is capable of consuming a moderate amount of fuel. This was achieved through well-designed throttle settings and injection systems. The engine was installed in a large number of cars, but if we take it as a whole, the consumption on the highway is no more than 7-9 liters per hundred. Of course, such figures are achievable in moderate driving mode. In the urban cycle, this figure will be more than 14-16 liters.

Advantages and disadvantages

It is rare that a drive can boast such an impeccable reputation as the 1UZ engine. All those almost 20 years that it rolled off the assembly line, the 1UZ engine was produced in the FE version, without undergoing significant changes. Over time, it was replaced by larger UZ engines: 2UZ-FE (4.7 l) and 3UZ-FE (4.3 l).

It should be noted that fuel consumption is within reasonable limits. For the combined cycle, it is about 12 liters per hundred, which is comparable to the appetite of the Volga GAZ-31105, which is a representative of approximately the same class as Toyota and Lexus, with a significantly lower power unit.

The main advantage of Uzet is its huge resource, reaching half a million or more kilometers.

A description of the shortcomings will not take up much space:

- Poor location of the water pump, which makes it difficult to service and leads to increased load on the toothed belt, which is also the timing drive. As a result of a belt break, the valves on modifications with VVT (VVT) bend.

- Access to candles is difficult.

- The first engines were distinguished by the difficulty of servicing the distributor ignition.

- It is easy to damage the automatic timing belt tensioner when replacing the belt.

Applicability on cars

In addition to the previously mentioned models of Celsior and LS400 sedans, the 1UZ-FE engine and other variations were installed on other Toyota models. In total, the engine was installed on 4 more Toyota models and 2 Lexus models. From the premium segment, the engine was installed in the famous Crown sedan and Crown Majesta limousine (until 2002). The engine was also installed in the Soarer coupe and Aristo business sedan. Lexus used this power unit for the SC400 luxury coupe and GS400 sedan.

of Toyota 1 UZ 4.0 power units .

The 1UZ power unit is an extremely successful motor. Finding flaws is almost impossible, most of them are more personal whims than design flaws. In fact, there are no engineering miscalculations or significant shortcomings. Most of the cases in which something has to be done with the motor are either a consequence of time or manner of use, and the user, without having problems with breakdowns, often forgets about scheduled maintenance. The only thing you can’t save on with this engine is spark plugs and fuel. It would be much more correct to initially overpay for better quality spark plugs, because replacing them is not the easiest task. Otherwise, the 1UZ-FE is a very reliable power unit. It is often referred to as a “millionaire”. Without major repairs, the engine can easily last 500,000 km.

Tuning of 1UZ-FE engines. Mechanical supercharger

One of the initial ways to increase the output of the 1UZ-FE would be to install a mechanical supercharger. Eaton offers a ready-made compressor kit of the M90 series. It includes:

- Intake manifold.

- Fuel regulator.

- Compressor.

For this kit it is worth additionally installing:

- Direct exhaust type.

- Exhaust manifold 4-2-1.

- Fuel pump.

At a boost of 0.4 atmospheres, the 1UZ engine develops about 330 horsepower. This configuration of modifications is the most durable and common way to increase power.

To achieve greater performance, you will need to additionally install forged pistons, increase the compression to 8.5, and also replace the connecting rods and studs with analogues from ARP. For increased power, the load on the cooling system increases. To avoid problems, it is worth installing an intercooler. In the fuel system, you will have to replace the injectors from 2JZ-GTE, Walbro 255 lph. The exhaust line should be widened to 3 inches. With this kind of modification, the changes will also affect the control units. VEMS would be a good choice for such a whale. The boost can be increased to 0.7 atmospheres. The result will be more than 400 horsepower.

Reliability, problems and repair of the Toyota 1UZ 4.0 l engine.

The ancestor of the Toyota UZ family (which later included the 2UZ and 3UZ), the 1UZ engine, appeared in 1989 and was intended for the top models of Toyota and Lexus. This 4-liter engine was intended to replace the old 5V engine and successfully coped with its task, simultaneously gaining a reputation as one of the most durable and reliable Toyota engines.

The 1UZ-FE cylinder block is aluminum, with a camber angle of 90°, with pressed-in thin cast iron liners. On top there are two aluminum cylinder heads, two camshafts each and 4 valves per cylinder. There are no hydraulic compensators, so the 1UZ requires periodic valve adjustment. Since 1995, the engine has been slightly updated, lightweight connecting rods were used (were 628 grams, now 581 grams) and pistons with a compression ratio of 10.4, and power increased to 260 hp. Since 1997, 1UZ-FE received a VVTi system on the intake shaft, the intake channels were changed, the diameters of the intake and exhaust valves increased, the cylinder head gasket was changed, a long two-stage ACIS intake manifold was used, and the ignition system was modified. Also, the 1UZ-FE VVTi uses new pistons with a compression ratio increased to 10.5, as well as an electronic throttle valve. A timing belt was used in the timing drive; its service life is 100 thousand km. On versions without a VVTi variable valve timing system, if the timing belt breaks, the valves do not bend. Versions with VVTi cannot boast of this.

The production of this power unit continued until 2002, when it was supplanted by the 4.3 liter 3UZ-FE.

Problems and disadvantages of Toyota 1UZ 4.0 liter engines.

Engine 1 is a case where you have to look for flaws with a magnifying glass. 1UZ-FE does not have any design flaws, shortcomings or illnesses. All malfunctions encountered on these power plants are most often associated with age, operating style or irregular maintenance. Spark plugs can quickly die from low-quality gasoline, and replacing them is fraught with some difficulties. 1UZ-FE itself is extremely reliable and is often popularly called a millionaire. This engine is capable of traveling 500 thousand km or more.

1UZ turbo

With modification of the piston group, a turbine can be used. The turbo kit can be assembled based on the turbo kit from the Garett GT40. Otherwise, all components can be selected separately, based on individual requests. But self-assembly of a turbo kit should only be trusted to experienced mechanics. The turbo kit includes:

- wastegate;

- blow-off;

- boost controller;

- oil drain;

- oil supply;

- thermal insulation;

- pipes;

- clamps;

- VEMS brains;

The final result will be a power of about 450 horsepower or more.

To whom - tuning, and to whom - swap

For thrill-seekers, the power of stock engines is not always enough. The 1UZ engine provides ample boosting capabilities:

- The most affordable and common option is to install an Eaton M90 compressor as part of a kit. If we add here the “pants” 4-2-1, complemented by a direct-flow exhaust, with a boost of 0.4 bar, you can get 330 hp. With.

- 4 hundred “horses” will be provided by the installation of a ShPG with forged pistons, injectors from 2JZ-GTE, a 3-inch exhaust, an intercooler and a VEMS control unit. The pressure should be increased to 0.7 bar.

- A higher increase in power will be provided by using a Garrett GT40-based turbo kit instead of a compressor, or a independently selected set, including a blow-off, boost controller and VEMS processor. At the output of the 1UZ turbo it is possible to obtain 450 hp. With.

- Two Garrett VNT25 units form a 1UZ twin turbo with a power of about 500 “horses”.

Many people use the 1UZ swap for various domestic cars: Volga, UAZ, Gazelle, GAZ-66 and a number of others. Even owners of Japanese cars, such as Toyota Altezza, Toyota Chaser, Toyota Mark 2, Mitsubishi Pajero, install this unit. In addition, it is used on small river boats and homemade airboats. It is not for nothing that in 1997 the Americans developed and certified the FV2400-2TC aircraft engine for private light aircraft based on this engine.

Probably not a single Japanese power unit has received such recognition in the automotive world as Toyota's Uzet.

Thanks to its reliable design and ease of maintenance, this engine is still in demand by numerous enthusiasts, as well as in various types of transport equipment, not only automobile, but also air or water.

1UZ twin turbo

The twin turbo setup is a more correct setup for the V8. This kit can be assembled based on the Garrett VNT25. This kind of assembly can be purchased ready-made and installed bolt-on. The twin turbo assembly will have a number of advantages: less turbo lag, more durable.

For any of the proposed cases, if desired, it is permissible to use more boost and more powerful superchargers. But this will require modification of the shafts and other components. But it’s worth remembering: more power means less resource.