02/02/2021 6,515 Ford Focus

Author: Ivan Baranov

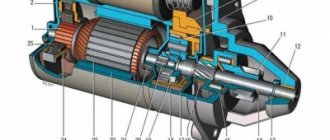

The ignition system in any car consists of many different mechanisms and components that ensure normal engine starting. One of the devices designed to start the engine is the starter unit. You can learn more about why the Ford Focus 2 starter may fail and how to properly repair it in this article.

[Hide]

Fuel supply system

Sometimes the car does not start due to problems in the fuel supply system. They can be of the following type:

Ford Focus won't start

- the injectors are clogged or there is simply no power supplied to them;

- the fuel filter has failed;

- fuel pump is broken;

- There are other problems in the gasoline supply line from the tank.

This car is equipped only with an injection engine. Therefore, the presence of a certain pressure in the fuel system plays an important role. If the engine shaft rotates, but the car does not grab, or simply stalls, it is worth checking the pressure in the fuel supply system. This can be done at the junction of the ramp with a fitting. You will need to use a pressure gauge with the appropriate thread.

There are often problems associated with the operation of the injectors. Most often, they simply become clogged - especially if the car is often filled with low-quality gasoline. It is difficult to clean the injectors yourself.

It is advisable to seek help from specialists. Also, food may simply not come to them. You can check its presence with a regular tester - by setting the mode switch to constant voltage and the limit of 20 V.

Often the problem lies in the fuel filter. It needs to be changed every 40-50 thousand km. Sometimes, when using low-quality fuel, it fails a little earlier.

This part is consumable. Therefore, you should simply purchase a new filter. If the car doesn't start well, the problem may be low fuel level.

It is undesirable to allow 100%!p (MISSING) gasoline consumption - a zero level can cause failure of the fuel pump. This occurs due to air being sucked in instead of liquid.

As a result, the pump overheats and breaks down. Replacing it will be relatively inexpensive. Repair is not advisable. If possible, it is advisable to check the integrity of the fuel line - it is laid under the bottom of the car.

Checking spark plugs

If the ignition system is in order and fuel is supplied to the engine, then the problem may lie in the spark plugs. Checking for a spark is not difficult:

- it is necessary to remove the candlesticks from all candles;

- one needs to be unscrewed and connected to the armored wire;

- Next, you should “turn” the engine.

If there is a bright blue spark between the central electrode and the side electrode, there are no problems with the operation of the spark plugs. If the flash color is red or there is no flash at all, it should be replaced.

It should be noted: according to the recommendation of the car manufacturer, spark plugs should be changed every 10 thousand km. If there is a spark, you should check the functionality of the ignition coil.

You don't need any special tool for this. All you need is a tester - it allows you to ring the winding. The resistance should fluctuate between 2-3 ohms. If it tends to infinity or is equal to 0, then the coil must be replaced with a new one. Problems often arise with the crankshaft position sensor.

Separately, you should check the fuse that supplies voltage to the starter - it is not present on all cars. It should be noted that the current flowing through it is quite large. Typically, such a fuse can easily withstand 200 A.

Emergency engine starting methods

When the starter does not click or make any sounds at all, the engine can be started if it is closed “directly”. This is not the best solution, but in cases where you need to go urgently and there is no other option, you can use it.

Let's consider the situation of how to start the engine directly using the example of a VAZ-2110 car. So, the sequence of actions will be as follows:

- engage neutral gear and set the car to the handbrake;

- turn on the ignition by turning the key in the lock and open the hood, since we will carry out further actions in the engine compartment;

- remove the air filter from its seat and move it to the side in order to get to the starter contacts;

- disconnect the chip going to the contact group;

- use a metal object (for example, a screwdriver with a wide flat blade or a piece of wire) to short-circuit the starter terminals;

- as a result of this, provided that the other components listed above are in good working order and the battery is charged, the car will start.

After this, install the chip and air filter back. An interesting fact is that in most cases the engine will continue to be started using the ignition key. However, you should remember that the breakdown still remains, so you need to look for it yourself or go to a car service center for help in order to fix it.

We offer you another method that will be useful to you if you need to start the engine in an emergency. It is only suitable for front wheel drive passenger cars with manual transmission! The algorithm of actions is as follows:

- it is necessary to jack up the car by hanging any of the front wheels;

- turn the hung wheel outwards all the way (if the left wheel - then to the left, if the right wheel - then to the right);

- wrap a tow rope or strong rope around the surface of the tire 3-4 times, leaving 1-2 meters free;

- engage THIRD gear;

- turn the key in the ignition;

- pull strongly on the end of the cable, trying to spin the wheel (it is better to do this not in place, but with a slight run-up);

- when the car starts, first of all set the gear to neutral (this can be done without pressing the clutch pedal) and wait until the wheel stops completely;

- lower the hanging wheel to the ground.

The described method of spinning the wheel of front-wheel drive cars is reminiscent of the method of starting a crooked starter (using the crank) used in old rear-wheel drive cars (for example, VAZ “classic”). If in the latter case the starter is spun using a handle, then in front-wheel drive cars it is spun from the axle shaft on which the raised wheel is located.

Bendix starter

The car does not start - the starter turns. Where to dig

The reasons that the starter does not turn may be a malfunction of the retractor relay, a weak battery charge, bad electrical contacts in the circuit, mechanical failure of the starter, and so on. It will be useful for every car owner to know what to do if the starter does not turn the engine. Indeed, in most cases, repairs can be done yourself. Moreover, a breakdown usually occurs at the most unforeseen moment, when it is not possible to use the help of a car repairman. Next, we will consider in detail the causes of the malfunction and methods for eliminating them.

Emergency engine starting methods

When the starter does not click or make any sounds at all, the engine can be started if it is closed “directly”. This is not the best solution, but in cases where you need to go urgently and there is no other option, you can use it.

Let's consider the situation of how to start the engine directly using the example of a VAZ-2110 car. So, the sequence of actions will be as follows:

- engage neutral gear and set the car to the handbrake;

- turn on the ignition by turning the key in the lock and open the hood, since we will carry out further actions in the engine compartment;

- remove the air filter from its seat and move it to the side in order to get to the starter contacts;

- disconnect the chip going to the contact group;

- use a metal object (for example, a screwdriver with a wide flat blade or a piece of wire) to short-circuit the starter terminals;

- as a result of this, provided that the other components listed above are in good working order and the battery is charged, the car will start.

After this, install the chip and air filter back. An interesting fact is that in most cases the engine will continue to be started using the ignition key. However, you should remember that the breakdown still remains, so you need to look for it yourself or go to a car service center for help in order to fix it.

READ VAZ 2114 Starter Doesn't Turn When Hot

We offer you another method that will be useful to you if you need to start the engine in an emergency. It is only suitable for front wheel drive passenger cars with manual transmission! The algorithm of actions is as follows:

- it is necessary to jack up the car by hanging any of the front wheels;

- turn the hung wheel outwards all the way (if the left wheel - then to the left, if the right wheel - then to the right);

- wrap a tow rope or strong rope around the surface of the tire 3-4 times, leaving 1-2 meters free;

- engage THIRD gear;

- turn the key in the ignition;

- pull strongly on the end of the cable, trying to spin the wheel (it is better to do this not in place, but with a slight run-up);

- when the car starts, first of all set the gear to neutral (this can be done without pressing the clutch pedal) and wait until the wheel stops completely;

- lower the hanging wheel to the ground.

The described method of spinning the wheel of front-wheel drive cars is reminiscent of the method of starting a crooked starter (using the crank) used in old rear-wheel drive cars (for example, VAZ “classic”). If in the latter case the starter is spun using a handle, then in front-wheel drive cars it is spun from the axle shaft on which the raised wheel is located.

The starter does not turn

The reasons that the starter does not turn may be a malfunction of the retractor relay, a weak battery charge, bad electrical contacts in the circuit, mechanical failure of the starter, and so on. It will be useful for every car owner to know what to do if the starter does not turn the engine. Indeed, in most cases, repairs can be done yourself. Moreover, a breakdown usually occurs at the most unforeseen moment, when it is not possible to use the help of a car repairman. Next, we will consider in detail the causes of the malfunction and methods for eliminating them.

The starter clicks but doesn't turn over

Very often, when the starter malfunctions, it is not the mechanism itself that is to blame, but its retractor relay. It is important to understand that when you turn on the ignition, it is not the starter that clicks, but the mentioned relay. Malfunctions consist of one of the following reasons:

- Failure of the power wire that connects the starter windings and the traction relay. To solve the problem it is necessary to replace it.

- Significant wear on starter bushings and/or brushes. In this case, they need to be replaced.

- Short circuit on the armature winding. You can check this using a multimeter. As a rule, the winding is not repaired, but another starter is purchased and installed.

- Short circuit or break in one of the starter windings. The situation is similar to the previous one. The device needs to be replaced.

- The fork in the bendix is broken or deformed. This is a mechanical failure that is difficult to fix. The optimal solution in this situation would be to replace the bendix or the fork separately (if possible).

Where is the starter located on a Ford Focus 2?

REMOVAL OF THE STARTER

We remove the starter for repair or replacement when it fails, as well as when dismantling the gearbox. Disconnect the wire terminal from the negative terminal of the battery. We remove the mudguard of the engine compartment (see “11.2. Ford Focus II. Removing the mudguard of the engine compartment and the front wheel arch liner”).

Use a 13mm socket to unscrew nut 1, and a 10mm socket to unscrew nut 2.

Disconnect the wire block from the starter traction relay.

Using a 13mm socket, unscrew the three starter mounting bolts. The bottom bolt also secures the wiring harness bracket.

For clarity, the starter mounting bolts are shown on the removed power unit.

We remove the starter from the clutch housing...

...and remove the starter. To assess the health of the starter drive...

... use a screwdriver to turn the drive gear. The gear must turn in one direction with the drive shaft, and in the other direction on the drive shaft. Otherwise, replace the drive with a new one. Use a screwdriver to move the drive gear along the shaft. The gear should move easily along the shaft without jamming. If the gear sticks on the shaft, the drive must be replaced. To check the starter, we connect the “positive” terminal of the battery with wires to “light up”...

...with the upper contact bolt of the traction relay, and the “negative” one with the starter housing. Using a screwdriver, we bridge the upper contact bolt and the control terminal of the traction relay. When carrying out this operation, care must be taken, since sparking is possible in the area where the terminals are closed. Do not connect the screwdriver to ground while closing the terminals. At the same time, the drive gear should move out and the starter motor will turn on. Otherwise, check the electric motor and traction relay. To check the electric motor...

...we connect the “positive” terminal of the battery with wires to the lower contact bolt of the traction relay, and the “negative” terminal to the starter housing. In this case, the motor shaft must rotate. Otherwise, the electric motor is faulty. To check the traction relay, we connect the “positive” terminal of the battery with wires to the control terminal of the traction relay, and the “negative” terminal to the starter housing. In this case, the drive gear should move out. If this does not happen, the traction relay is faulty. Install the starter in reverse order.

DISASSEMBLY THE STARTER

We disassemble the starter to replace the traction relay, brush holder with brushes and drive elements.

Using a 13mm wrench, unscrew the nut of the lower contact bolt of the traction relay...

...and remove the nut and wire tip.

Using a Phillips screwdriver, unscrew the two screws securing the traction relay.

Remove the traction relay.

We take out the anchor of the traction relay...

...and the armature spring.

Using a 8mm head, unscrew the two coupling bolts.

Remove the front cover.

Use a 5.5 socket to unscrew the two bolts...

...and remove the back cover.

Remove the brush holder.

We remove the armature from the starter housing. Using a screwdriver...

...remove the drive lever support.

Remove the drive from the front cover.

Use a screwdriver to pry off the cover...

...and remove the cover of the planetary gearbox.

We take out the three satellites of the planetary gearbox.

Remove the restrictive ring.

Using pliers, remove the locking ring.

Remove the overrunning clutch with the drive gear assembly.

Use a screwdriver to move it out of the groove...

...and remove the retaining ring.

Remove the ring gear from the drive shaft

Using pliers we open the locking ring...

...and remove it from the groove of the overrunning clutch.

Remove the drive lever. By external inspection we check the condition of the commutator and armature windings. Charring of windings is not allowed. If the collector is slightly burned, we clean its plates with fine abrasive sandpaper. If the commutator is severely burned and worn, the armature should be replaced. Scoring and envelopment of the sliding bearing material on the shaft journals are eliminated using the finest sandpaper, followed by polishing. The ends of the windings must be well soldered to the lamellas. Blackening of windings and separation of varnish insulation from them is not allowed.

Using an ohmmeter, we check the short circuit of the armature winding to its core. The resistance should be very large (tend to infinity). We replace the faulty anchor.

We check the insulated brush holders for short circuit to ground. The resistance should be very large (tend to infinity). Otherwise, replace the brush holder with a new one. If the brushes are severely worn, replace the brush holder assembly. We assemble the starter in the reverse order. We apply CV joint-4 lubricant to the gears of the planetary gearbox. We install the brush holder before installing the armature in the starter housing. Before installing the brush holder on the armature commutator, we slide the brushes into the guides and tie them with wire. After installing the brush holder on the armature commutator, install the back cover and attach the brush holder to it. After this, we untie the wire, and the brushes, under the action of the springs, will move towards the commutator.

We install the traction relay so that its control terminal is located on the right side.

Reasons why the starter does not turn

Often the reason that the car does not start and the starter does not turn the flywheel is a discharged battery. This reason is not directly related to the breakdown of the starter, however, before diagnosing this unit, it is necessary to check the charge of the battery and, if necessary, recharge it. Most modern car alarms block the starter circuit if the voltage level from the battery is 10 V or lower. Therefore, you will not be able to start the engine under this condition. To prevent this from happening, monitor the battery charge level and recharge it periodically if necessary. Also be aware of the density of the electrolyte. However, we will assume that everything is in order with the battery charge level.

Let's consider one particular case... Owners of a 2007-2008 Ford Focus 2 car may encounter a problem when the starter does not turn due to an error in the original immobilizer. Diagnosing this breakdown is very simple - to do this, just turn on the battery power directly to the starter. However, it works without problems. As a rule, official dealers replace the immobilizer under warranty.

The reasons that the starter does not turn and “shows no signs of life” may be the following situations:

- Deterioration or loss of contact in the starter circuit. This may occur due to corrosion or deterioration of the bolted wires. We are talking about the main “ground” contact attached to the machine body. It is also necessary to check the ground of the main and starter solenoid relays. According to statistics, in 80% of cases, problems with a non-working starter come down to malfunctions in the car’s electrical circuit. Therefore, in order to eliminate the problem, it is necessary to inspect the wiring, that is, inspect the starter power circuit, tighten the bolted connections on the blocks and terminals. Using a multimeter, check for voltage on the control wire going to the starter; it may be damaged. To check it, you can close the starter “directly”. How to do this is described below.

- The starter solenoid relay is faulty. This could be a break in its windings, a short circuit in them, mechanical damage to internal components, and so on. It is necessary to diagnose the relay, find and eliminate the fault. You will find additional information on how to do this in the corresponding material.

- Short circuit in the starter winding. This is a fairly rare, but critical problem. It occurs most often in starters that have been used for a long time. Over time, the insulation on their windings is destroyed, as a result of which an interturn short circuit may occur. This can also happen due to mechanical damage to the starter or when it is exposed to aggressive chemicals. In any case, it is necessary to check for a short circuit, and if it occurs, then the solution would not be repair, but a complete replacement of the starter.

- Problems with the ignition switch contact group, which may be the reason why the starter does not turn. If the contacts in the ignition switch are damaged, then no current passes through them to the electric motor, and accordingly, it will not spin. The test can be done using a multimeter. Check whether voltage is supplied to the ignition switch and whether it leaves it when you turn the key. It is also necessary to check the fuses of the contact group (usually located in the passenger compartment, under the “dashboard” on the left or right side).

- Slipping of the freewheel of the starter drive. In this case, repair is impossible; the mechanical drive of the starter must be replaced.

- The drive moves tightly along the shaft thread. To fix it, you need to disassemble the starter, clean the threads of debris and lubricate them with machine oil.

Next, we will analyze the problems, the symptoms of which are the fact that the starter cranks the crankshaft very slowly, which is why the engine does not start.

- The viscosity of the engine oil does not match the temperature conditions. This situation can arise when the engine oil becomes very thick in extreme cold and prevents the crankshaft from rotating normally. The solution to the problem is to replace the oil with an analogue with the appropriate viscosity.

- Low battery. If it is not charged enough, then there is not enough energy to turn the crankshaft at normal speed using the starter. The solution is to charge the battery or replace it if it does not hold a charge well. This situation is especially relevant for winter.

- Poor contact of brushes and/or poor tightening of wire tips going to the starter. To eliminate this breakdown, it is necessary to inspect the brush assembly, change the brushes if necessary, clean the commutator, adjust the tension of the springs in the brushes or change the springs.

Let's list a few more atypical situations due to which the starter does not turn both cold and hot. So:

- The problem is with the control wire that goes to the starter. If its insulation or contact is damaged, it will be impossible to start the engine using the key. We recommend that you review it. To do this you will need the help of another person. One of you should try to start the engine using the ignition key, while the other one pulls the wire, trying to “catch” the position in which the necessary contact will occur. Another option is to apply a direct “” from the battery to the mentioned control wire. If the engine starts, you need to look for the cause in the ignition switch; if not, in the insulation or integrity of the wire. If the problem is a damaged wire, then the best option is to replace it.

- Sometimes the permanent magnets in the starter stator become detached from the housing. To eliminate the damage, you need to disassemble the starter and re-glue them to their designated places.

- Fuse failure. This is not a common, but probable reason that the starter does not work and does not turn the engine. First of all, we are talking about fuses for the contact group of the ignition system.

- The return spring on the starter retractor relay flies off. To eliminate the malfunction, it is enough to remove the specified relay and install the spring in place.

READ Timing belt replacement for Ford Kuga diesel

Where is the starter located on a Ford Focus 2?

- Ford Focus 2 Engine Timing Belt Replacement

- Timing tool

- Replacing VCT couplings

- Adjusting valves Ford Focus 2

- Replacing the starter bendix

- Throttle valve Ford Focus 2

- Spare parts for clutch replacement

- Rear suspension silent blocks Focus 2

- Replacing generator bearings

- Water in the cabin C-max

- Replacing brake discs

- Thermostat A16XER

- Scheduled maintenance MITSUBISHI ASX

- Fuel pressure regulator 2112

- Review of Ford Focus 2

Starter Ford Focus 2. Bendix replacement

It all started with the fact that when starting the engine, breakdowns began to appear. In principle, it was clear that the problem was in the Bendix, but there was no time to deal with it. About a week passed from the moment of particularly alarming symptoms (2-3 breakdowns in a row), until I was able to hardly start the engine 10 times. I had to cancel all my plans and put the car in the garage while I looked for a spare part and fixed the problem.

I bought a Bosch Bendix as a replacement. 1006 209 804

Removing the starter

The Ford Focus 2 starter is attached to the engine with three 13 bolts, the first two can be accessed from above, the third from the bottom. It is better to immediately remove the air filter housing and throttle assembly.

Disconnect the battery, lift the car, remove the engine protection. We unscrew the starter bolts and open the solenoid relay connector, here it is

Bottom bolt

and the top two

It is easier to remove the starter with all the wires from the generator to the positive terminal of the battery. Unscrewing the wires from the solenoid relay is inconvenient. Unscrew the terminal from the generator

and from the battery positive

Next, you need to cut the clamp and remove the latches securing this wire. During assembly, you can secure it with cable ties.

We move the starter to the right (as it goes), moving it out of the clutch housing. There you will see a connector nearby, we also disconnect it so that it does not interfere.

The Ford Focus 2 starter can be removed downwards, but there is not enough space in the engine compartment, so I show in the photo its position before it was removed; in other positions it was not possible to do this, the lower pipe of the cooling system is in the way. It needs to be pressed in a little and pushed back.

Removed starter Ford Focus 2, BOSCH marking 0001108408

Disassembling the starter

Next we proceed to disassembly. I’ll say right away that I couldn’t remove the retractor, the torx bolts soured, one of them became crumpled and I left this matter; in the future I’ll have to drill them out and prepare a replacement. I had to remove and insert the bendix through the fork. There is nothing complicated about this.

Since we have already disassembled it, we inspect the condition of the commutator, brushes and check the lubrication. But the most interesting thing is removing the Bendix retaining ring.

To remove it, you need to knock down the upper race with a head or mandrel of suitable diameter, then use a screwdriver to pry up and remove the ring, the race, and you can pull out the bendix itself, loosening the power fork a little, because the solenoid relay is not removed.

Problems may arise when assembling the retaining ring. I advise you to remove the ring, compress it with pliers, and then place it on the shaft. It will most likely deform and become not very round, but if this is not done, it will not shrink in place with pliers, since it is very elastic. An open-end wrench size 12 or 13 will help you put the clip in place; we use it as a fork. It will hold.

New and old Bendix:

Next, we clean the starter from the inside, it is also advisable to disassemble the gearbox, wash and lubricate the gears of the gearbox mechanism

Be careful when inserting the rotor into the housing; the magnet pulls the rotor in sharply and the brushes may remain in your hands.

A 22mm head will help you put everything back in place.

A few more photos of the disassembled gearbox. This starter has gears on needle bearings marked INA. The same starter in the C-Max had a gearbox with gears on bushings.

Now we lubricate everything, assemble it and install it on the car. After this overhaul, the sound of the starter became quieter and more pleasant, the Bendix works properly.

Parts codes:

- Bendix (Bosch) - 1 006 209 804

- Solenoid relay (Bosch) - 2 339 304 047

- Brush unit - 1 004 336 526

- Repair kit for starter Ford Focus 2 - 1 007 010 093 (circlip and bendix limit skirt, lock washer for the armature and rubber band installed on the fork)

Signs of a faulty starter

There are actually many reasons why a car won't start. However, a faulty starter can be determined by the appearance of one or more of the following symptoms:

- the starter does not turn on;

- the starter clicks, but does not turn the engine crankshaft;

- when the starter is turned on, the crankshaft rotates very slowly, which is why the engine does not start;

- You can hear the metallic grinding sound of the Bendix gear, which does not mesh with the crankshaft.

Next, let's move on to discussing the possible causes of a possible breakdown. In particular, we will analyze situations when the starter either does not rotate at all or does not rotate the engine crankshaft.

Starter relay malfunction

If the relay malfunctions, there is only one problem: the engine does not start or does not start the first time. But there can be a lot of problems directly with the element itself. It is worth noting that the starter must be diagnosed and checked every time you contact a service station for the purpose of maintenance. In this case, you will be able to prevent possible future malfunctions and replace elements that have lost their working life. The main relay failures include:

- Mechanical damage to the relay housing.

- Burning of contacts.

- Broken electrical wiring.

- Technical fluids entering the relay.

- After starting the power unit, the starter continues to rotate (a characteristic buzzing sound can be heard).

- Short circuit in the windings.

- The return spring is deformed or weakened.

- Souring of the core inside the housing.

We can check whether the starter solenoid relay is working properly, diagnose the starter, and replace the solenoid relay.

The starter solenoid relay can be checked for the amount of current that the starter relay is capable of passing when closed. Replacing the retractor starter takes 15-20 minutes.

The relay is checked using an ohmmeter and an ammeter. The windings must not have short circuits to the housing or breaks. When closed, the contact plates must pass a current of at least 70 amperes. If the readings differ when checking, then the part must be replaced.

The primary diagnostic stage is assigned to the driver and is carried out at the moment the engine starts. You can easily understand that the element is faulty: if the starter retractor clicks and the engine starts unstably, then the next step is to contact a specialized service station.

Checking the starter relay

Drivers, in the event of breakdowns, ask themselves the question: how to check the starter retractor relay themselves? The check comes down to the following steps:

- If, when the engine starts, you hear a click from the core and the starter rotates, this indicates its serviceability. If the core clicks and the starter does not rotate, then the relay contacts are most likely burnt.

- If the starter rotates, but the engine does not turn, this indicates a malfunction of the bendix or fork.

Starter malfunctions and their manifestations on the car related to the starter solenoid relay:

- When trying to start the engine, the starter is silent or clicks. The traction starter is not working properly; also, with the same symptoms, there may be wear on the brushes, a short to ground in the armature or stator.

- The starter rotates slowly, turns tightly, “takes over.” There may be wear on the bushings, a short to ground in the armature or stator, or, less commonly, a relay malfunction.

- The starter rotates, but the engine does not turn over; the starter turns at idle. The starter relay is fine, the bendix needs to be replaced.

- The starter rotates after the engine starts. The starter relay is faulty, a rare occurrence.

Starter retractor relay Valeo Starter retractor relay Ford

There are also relay malfunctions on the starters of Mitsubishi, Hitachi, Mitsubishi, Nissan Almera, Maxima cars.

Starter relay for MitsubishiStarter relay for Nissan

Bosch starter relays are among the most reliable.

Bosch starter relay

Buy a starter relay

To purchase a high-quality and reliable part, you should resort to the services of only specialized companies that directly supply components from manufacturers. In this case, you can buy a starter solenoid relay , which will have a high margin of reliability and durability. It is worth noting that the price of a starter solenoid relay depends on its overall dimensions and design complexity, therefore, in order not to make a mistake with your choice, contact a specialist.

The price of the solenoid relay can be determined by providing the starter number and the manufacturer. Or by car make.

Call us by phone, or +7 (905) 513-64-75.

The starter does not turn when hot

Sometimes car owners have problems when the starter does not turn “hot”. That is, with a cold engine, after a long period of parking, the car starts without problems, but when it heats up significantly, problems arise. In this case, the most common problem is incorrectly selected starter bushings, that is, having a smaller diameter than required. When heated, a natural process of increasing the size of parts occurs, which is why the Niva starter shaft does not rotate. Therefore, choose bushings and bearings in accordance with the manual for your car.

Also, in extreme heat, contacts in the vehicle's electrical system may deteriorate. Moreover, this applies to all contacts - on the battery terminals, the solenoid and main starter relay, on ground, and so on. Therefore, we recommend that you inspect them, clean and degrease them.

The starter is a simple but extremely important mechanism in a car. Therefore, its failure is critical, as it does not allow the engine to start. In most cases, problems are related to the car's electrical wiring, poor contacts, broken wires, and so on. Therefore, if the starter does not turn over and does not start the engine, the first thing we recommend is that you inspect the contacts (main ground, relay contacts, ignition switch, etc.).

Ford Focus 3 won't start, starter won't turn, relay clicks

For an experienced driver, the list of assumptions for which the starter has failed is greatly narrowed by a single click.

Of course, if you do not have much driving experience, you will probably blame the solenoid relay for the breakdown. This assumption is erroneous, since during operation the relay makes certain clicks, but they are practically inaudible. In this article we will tell you the main reasons why the second Ford Focus starter model does not turn.

Starter Ford Focus 3

If the relay does not retract, the problem is most likely electrical. And in this case, you need to follow the circuit from the ignition switch. Check if everything is in order: Where is the starter relay block and fuse, and, moreover, where is the autostarter located? We hope that the starter does not turn the Ford Focus, everyone who deals with Ford Focus 2. In other cases, there is a risk of removing and disassembling the starter. Incorrect operation of the starter on a Ford Focus 2 Problems with the starter do not end there.

It may not work correctly, and this is the first sign that it will soon need to be repaired.

With your own hands, or with the help of a service station, you will have to find out the reasons why the starter rotates slowly. This can be heard immediately and the case may overheat.

The cause may be bearings or bushings that have gotten into water or dirt, as well as misalignment of the armature due to wear of the bushings or bearings. Here, too, you cannot do without removing and disassembling the autostarter. The next trouble may be the anchor. Overheating of the starter can cause intense wear; the starter does not turn the Ford Focus, as a result of which the armature may begin to short-circuit to the stator.

This manifests itself in a decrease in engine speed during startup. Under unfavorable conditions, starting the car becomes impossible. Thickening of the lubricant is especially noticeable in winter.

Effective methods for dealing with Ford Focus starter malfunctions

The reason for this is wear of the bushings. Also, such a problem can arise when the design of the starter assembly, which consists of four brushes, becomes unusable. In addition, the starter may stop working if the bearings wear out or dirt gets into the mechanism.

In such situations, it is possible to hear an uncharacteristic sound when the device is operating, and the starter itself stops rotating normally. Which starter is better to replace the one that the starter does not turn the Ford Focus Not all problems that arise with the Ford Focus 1 starter can be solved without replacing this mechanism.

When choosing a suitable starter, it is recommended to pay attention not only to its cost, but also to its technical characteristics.

Why doesn't the starter turn on a Ford Focus 2?

Starters die in different ways - some drive with the problem for months, others have it break down already at the second factory. If the Ford Focus starts up even a little differently, this is a reason to turn to specialists. We list the possible signs:

- The engine starts slowly. Over time, the contacts in the car oxidize, the wiring dries out (and sometimes rots). If diagnostics show that the contacts are in order, the problem is hidden in brush wear or winding short circuit.

- The starter turns, but the engine does not. The main reason is that the bendix does not engage with the flywheel crown. In this case, the plug and solenoid relay are diagnosed.

- The FF2 starter does not turn, but the relay clicks. Insufficient voltage is being supplied to the solenoid. The starter does not turn over if there are problems with the contacts or the solenoid relay.

Starter parts that often fail

- The car starts with a grinding noise. If you hear such a sound, you should not hesitate to repair it. The grinding noise occurs when the Bendix teeth slip on the flywheel crown. This happens when the bendix wears out or the shaft bearing is stuck. If the problem is not corrected in time, the flywheel will also have to be replaced.

- The starter does not turn or make any sounds. No voltage is applied to the contacts. If current flows and the starter does not turn, the reason is in the solenoid relay.

- The Ford Focus engine starts, the starter continues to operate. This happens when the bendix does not return to its original position. The cause of the problem is soldering of the main contacts of the solenoid.

- When trying to start the car, a noise is heard, and the Ford Focus starter does not turn. The reason is worn brushes. Also, the mechanism does not turn and is noisy if the winding is bad.

Effective methods for dealing with Ford Focus starter malfunctions

The ignition system in any car consists of many different mechanisms and components that ensure normal engine starting. One of the devices designed to start the engine is the starter unit. You can learn more about why the Ford Focus 2 starter may fail and how to properly repair it in this article.

THE PROBLEM IS THIS: The key is on “START” - there are clicks from under the hood, it seems like two, and it won’t start. By jerking the key back and forth like this 15-20 times, it starts. The battery spins a little and it starts. Changed the retractor. I cleaned the ground and cleaned the contacts on the battery. everything is useless. And a very interesting click is heard right behind the glove box. I took it off and it clicks right here somewhere, but I don’t understand where.

I'll tell you right away. I wrote about this problem on one forum, and after 5 minutes ADMIN said “this is a solenoid relay,” “read the forum,” and closed the topic. And what do you think? I ordered a retractor, received it 2 weeks later, installed it, but the problem remained. Conclusion - let others speak. I READ

about a similar problem here. his battery died.

Tell the experts, maybe some fuse has died? Maybe it’s some kind of sensor that is not working, for example the Start Prohibition Switch (this is the first time I’ve heard about it, I read it in the MANUAL)

Probably the storter is moping, the commutator is burnt out, or the brushes are not fitting well to the commutator. Or maybe the brushes were worn out on the starter. In a word, when starting, the retractor bridges the contacts, the bendex engages, but on the starter itself there is no contact on the brush or brushes.

Definitely brushes or commutator. You need to disassemble, look, clean if necessary. Assess the condition of the brushes and most likely replace them.

Capella Wagon, GWEW-201957, 2.0 FS-ZE (170 hp), 2WD, 2000

Cheer up guys

THE PROBLEM IS THIS: The key is on “START” - there are clicks from under the hood, it seems like two, and it won’t start. By jerking the key back and forth like this 15-20 times, it starts. The battery spins a little and it starts. Changed the retractor. I cleaned the ground and cleaned the contacts on the battery. everything is useless. And a very interesting click is heard right behind the glove box. I took it off and it clicks right here somewhere, but I don’t understand where.

I'll tell you right away. I wrote about this problem on one forum, and after 5 minutes ADMIN said “this is a solenoid relay,” “read the forum,” and closed the topic. And what do you think? I ordered a retractor, received it 2 weeks later, installed it, but the problem remained. Conclusion - let others speak. I READ

about a similar problem here. his battery died.

Tell the experts, maybe some fuse has died? Maybe it’s some kind of sensor that is not working, for example the Start Prohibition Switch (this is the first time I’ve heard about it, I read it in the MANUAL)

Behind the *glove compartment* the fuel pump relay clicks, although it is located at the passenger’s feet along with the *brains*.

When the problem lies elsewhere

Why is it important to make a diagnosis, and only then repair? The reason may be something else:

- Ignition system. There may be carbon and other deposits on the surface of the spark plug electrode, which is why the Ford Focus will not start. If the engine does not even rotate, it is worth inspecting whether power is being supplied to the ignition system coils.

- Fuel system. Let's see if the pump on the Ford Focus is working properly and if the filter is dirty. If the pump does not “hum” when you turn on the ignition, it is definitely not receiving power. If the problem occurs in winter and you have a diesel Ford Focus, the fuel in the filter may have thickened.

- Engine ECU. Over time, the Ford Focus electronic unit board may oxidize. The paths are burning out. The unit should be diagnosed for errors. If errors appear again after resetting, it is worth inspecting the system to which it relates. The Ford Focus ECU is responsible for all settings and changes in the operating modes of the internal combustion engine, so finding the problem may take a long time.

Computer diagnostics of ECU

- Timing belt The belt jumped and the ignition marks were off. How can this happen if replacing the belt on a Ford Focus was done correctly? Over time, the belt teeth wear out and tension disappears (therefore, it is worth checking its condition on a Ford Focus every 15,000 km).

Don't rush to buy a battery

Let's imagine a situation: it's winter, we get into a car and try to start the engine. We notice that the engine barely turns. The first thing that comes to mind is that the battery is dead. We check (it turns out that the voltage is 11-11.5 V), charge. The problem disappears, but not for long. After 3-4 days the situation repeats itself. We buy a new battery for a Ford Focus - after a week it is discharged again. Bad battery or current leak? Neither one nor the other.

The reason is this: a worn starter takes on 2-3 times more energy when turned on. It turns out that frequent starts and driving short distances simply kill our battery - the generator does not have time to renew the charge.

If you are faced with a similar situation, remember the last time the starter on your car was repaired or replaced. In 90% of cases, it is he who draws all the “juice” from the battery.

Checking the battery and electronic control unit

If the starter turns, but is relatively sluggish and the car starts poorly when cold, then you should check the condition of the battery. Often it is its low charge level or complete inoperability that is the main reason for the inability to start the car. It's very easy to check if it works:

- using a multimeter - the switch is set to measure DC voltage with a limit of 20 V - the voltage should be 12.6 V;

- A hydrometer measures the density of the electrolyte - the standard value depends on the ambient temperature.

If the battery voltage is lower than nominal, or other problems are present, then the question of why the car does not start will be answered. It is enough to replace the battery or recharge it in a warm room. Battery problems occur especially often in winter. The discharge is carried out quickly, other problems arise in cold weather.

Another common reason for the inability to start a car engine is a malfunction of the electronic engine control unit. It will be impossible to check its performance without a special device. You will need to connect the adapter via the CAN bus.

Regardless of the type of engine installed, version of the Ford Focus 1 car, the CAN bus for connecting a special diagnostic device is located under the steering wheel. Using it you can get detailed information about the vehicle. Including errors that are present in the engine.

Often the car does not start when hot, or simply stalls while driving. In this case, you need to conduct a diagnosis. During this process, you can detect other faults that may be present. Often on cars with high mileage, the ignition switch fails. Checking it is very simple - just call its contacts in all positions without exception. If the ignition switch fails, then you just need to buy a new one.

The process of diagnosing a Ford Focus 1 car is relatively simple and usually does not cause any difficulties. You just need to carefully check all typical breakdowns. Usually the problem lies in the spark plugs or a faulty ignition switch.

How to check

To find out the cause of the malfunction, you will have to remove the mechanism from the car. The part must be carefully fixed in a vice and the “plus” must be applied to the upper terminal of the relay and the switching contact. Apply the “mass” to the mechanism body. When voltage is applied, the bendix should extend and rotate.

If the device does not work as it should, check the retractor. Let's pump up the "plus" to the relay, the "ground" to the housing. The Bendix gear should click out. You can check the bendix itself. We envelop the coupling body in a soft gasket and clamp it in a vice. We turn the gear. It should only rotate in one direction. If it rotates in both directions, the bendix needs to be replaced.

If the mechanism turns slowly or makes noise, it is worth checking the brushes. You will need a 12-volt lamp. We connect one terminal to ground, the other to the brush holder. If the lamp lights up, there is a breakdown in the protection - the brushes need to be replaced.

What to do if the Ford Focus 2 starter does not turn

Every time we turn the ignition key, we turn the starter to start the engine. The starter is one of the most loaded parts in a car. We can start the engine 10 or more times per day. And so every day, from year to year. Imagine what happens to the node during this time. It is not surprising that owners are faced with a malfunction - the starter does not turn. It’s good if the breakdown happened near your home. But you shouldn’t tempt fate - it’s better to eliminate it in advance, at the first sign. Let's find out why the starter on a Ford Focus 2 does not turn, how to check it and whether it makes sense to repair it.

READ Ford Focus 3 Horn Replacement

Removing and checking the Ford Focus II starter

There may be several reasons why it is necessary to remove the starter of a Ford Focus 2 car. First of all, this is a replacement or repair if it breaks; it is also worth noting that removing the starter is necessary when dismantling the gearbox. It is important to remember that before removing the Ford Focus 2 starter, you must disconnect the negative terminal of the battery.

Instructions for removing the starter Ford Focus 2

- Since some of the work is performed under the engine, it is necessary to remove the lower protection. To do this, use a Torx T-30 wrench to unscrew all the screws that secure it to the lower elements of the car.

How to check the Ford Focus 2 starter

- Using a flat-head screwdriver, turn the starter drive gear. In one direction it must rotate together with the drive shaft, and in the opposite direction on the drive shaft. If this does not happen or the gear moves and rotates with difficulty, then the drive shaft must be replaced.

- The functionality of the starter can be checked by connecting battery power to its contacts. It is important to remember that the positive wire should go to the top bolt of the starter, and the negative wire to its housing.

- To check the retractor relay ( Bendix starter Ford Focus 2 ), close the upper contact (1) and the control contact (2).

In this case, the retractor mechanism should work, the gear will move along the shaft, and the starter motor will start. If the gear does not move, the Ford Focus 2 starter bendix must be repaired or replaced. The starter motor is checked as follows. We connect the positive battery wire to the lower bendix bolt, and the negative wire to the starter housing, and the engine should turn on. If this does not happen, it must be replaced or sent for repair. - To check the Bendix Ford Focus 2 , connect the plus from the battery to the control contact, and the minus to the starter housing. The retractor mechanism should engage and extend the gear. If this does not happen, the Bendix Ford Focus 2 is faulty and must be repaired or replaced.

Installing the Ford Focus 2 starter is performed in the reverse order.

When to change and when to repair?

There is an opinion that it is cheaper to repair a mechanism than to buy a new one. This statement is true, but not in all cases. When choosing between repair and replacement, you need to consider several factors:

- the extent of the breakdown;

- cost of parts;

- availability of spare parts.

If the cause of the malfunction is brushes, bushings or bendix, it makes sense to restore the old mechanism. The cost of the parts is low, and after repair, such a mechanism will last at least 5 years.

Please note that repair is advisable when the remaining parts have a good residual life.

If diagnostics show that in six months or a year the mechanism will begin to “crumble,” we will lose not only the money spent on removal and installation, but also precious time. In such a situation, we install a new mechanism and forget about the problem for a long time.

In what cases is it better to immediately replace the mechanism? Replacement is relevant if the main elements - the armature and the solenoid relay - are faulty. A complete overhaul will not be much cheaper (and sometimes more expensive due to labor costs) than the cost of a new part for a Ford Focus.

Let's sum it up

The starter is one of the most critical parts in a car. If you notice that your car starts slowly or makes noises when starting, there is no need to delay diagnostics. The earlier the problem is detected, the cheaper the repair. You should not engage in amateur activities without proper experience. After diagnosis, it is important to make the right decision about repair or replacement. Consider the opinion of the mechanic. It is cheaper to spend a large amount once than to disassemble a part every six months. The same rule should be followed when choosing a new starter. Chinese parts have a short resource. It is better to choose the original or at least a good analogue.

Possible starter malfunctions

Since the Ford Focus 2 starter is considered one of the main components of the system, its breakdown can cause inconvenience for the car owner. There can be several states of a non-working mechanism.

Ford Focus 2. Blown fuse for Starter and Alternator 150 Amp. part.1.

For example, if the device turns, but the engine does not start, then the reasons may be as follows:

- The Bendix gear is worn out, causing it to spin. The problem can be solved by replacing the gear, which is quite likely assembled with the clutch.

- The teeth on the flywheel crown are worn unevenly or knocked out. Such a malfunction in a Focus 1 or 2 is quite rare, however, it can also occur. In this case, the crankshaft flywheel must be replaced.

- Another reason may be the planetary gearbox, in particular its plastic gear, which could be worn out.

Starter device for Ford Focus car

If the starter does not turn, then first of all you should diagnose the condition of the rotor or stator windings. You also need to listen to whether the solenoid relay clicks or not. If there is no click, then the cause is most likely electrical.

In this case, it is necessary to pay attention to diagnostics:

- lock contact group;

- the functionality of the starter fuse;

- control relay;

- integrity of contacts on wires.

It should also be noted that the starter device may generally not work correctly. For example, if the unit overheats and generally rotates very slowly, and a sound uncharacteristic of its operation is heard, then perhaps the problem lies in the bearings. They could wear out, dirt could also get on them, and in some cases, due to their wear, the anchor becomes warped.

As for overheating itself, it is usually caused by the armature shorting to the stator, which again is due to wear of the bushings. In addition, the design of the starter assembly includes four brushes that could wear out. As you can see, there can be quite a lot of faults in general, starting from the Bendix starter and ending with brushes and bearings (the author of the video about diagnosing the mechanism at home is the Auto Electrician HF channel).

Causes of starter malfunction of the 2nd Ford Focus model and their solution

First situation. You can hear the relay and solenoid relay clicking.

The operation of most existing electrical appliances is accompanied by specific sounds, so-called clicks. With such sound accompaniment, the electrical device, at least partially, still functions.

Solenoid relay Ford Focus

All existing relays use the electromagnetic method of connecting contacts. When voltage is applied to the contact terminals, located on flexible brackets, charges of different polarities are located, attracting each other. Thanks to this attraction and movement with a certain acceleration of the surface of the terminals, they hit, and the driver hears a peculiar sound. Drivers with extensive experience can easily determine the malfunction of any relay using sound alone.

To carry out a normal engine start, absolutely all elements must be in good working order. When starting the engine, the following components and parts are used:

- Starter relay;

- Ignition well;

- Battery;

- Starter and solenoid relay.

The second situation is when the Ford Focus 2 starter does not turn, but the relay clicks are heard.

If you hear the relay clicking, it means that there are at least some signs of life in your engine starting system. The most common causes of problems with the Ford Focus 2 starter are:

- Damage to electrical wiring or loose contact;

- The battery is low;

- The ignition switch is faulty;

- The solenoid relay is broken;

- The starter is faulty (no contact on the brushes).

In most cases, the cause of normal operation is a low battery. Since this is the only power source, when discharged, it simply cannot turn the starter armature and gives up its entire energy supply to the operation of the relay. In this case, charge or replace the battery with another one.

It is much more difficult to understand the reasons for the breakdown of the starter, since to do this it will need to be removed, and this is quite time-consuming and inconvenient. To carry out diagnostics, you will need a working battery. Connect the ground to the starter housing, and the positive terminal to the stud after the relay. If the starter works, then the relay needs to be replaced. If the starter does not work, then you will need to look for the problem internally.

DIY mechanism repair

If you have never repaired a starter before and are not sure that you can repair it yourself, then it is better to contact a specialist. But in general, any car owner can cope with this task.

To repair the mechanism yourself, follow these steps:

- First, unscrew all the screws that secure the lower protection of the power unit. To do this you will need a T30 sprocket wrench.

- After this, using wrenches 13 and 10, you need to unscrew nuts 1 and 2, respectively, they are shown in the photo. Having done this, you can disconnect the contact connector of the solenoid relay.

- To dismantle the starter device, you will need to unscrew three screws that secure the unit to the car's power unit. To unscrew, you will need a 13mm wrench. At this stage, note that one of the three screws is connected to a clamp that secures the wiring harness. So, after following these steps, you can remove the starter from the car.

- Now you can start diagnosing and repairing. Using a flat-tip screwdriver, you need to turn the device drive gear. Ideally, it should turn with the drive shaft, and in the other direction - on the drive shaft. If the gear does not move or does so with great difficulty, the drive shaft must be replaced.

- Next, you need to connect the starter contacts directly to the battery, this will determine the performance of the unit as a whole. When diagnosing, remember that the positive terminal of the battery must be connected to the top screw of the device, and the negative terminal to ground, that is, the body of the unit.

- The next step will be to diagnose the solenoid relay. To do this you need to close the top contact with the control contact. At the moment of closure, the retractor element should operate, while the gear should move along the shaft, and the electric motor will automatically start. If the gear does not move, then it will be necessary to replace or more thoroughly repair the bendix.

- As for the electric motor, it must also be checked. For diagnostics, connect the positive cable from the battery to the lower bendix screw, and the negative terminal is connected to ground, that is, the housing. After connecting, the device should turn on; if this is not the case, then the engine is changed or repaired.

- It would not be superfluous to carry out a separate diagnosis of the Bendix. To do this, you need to connect the positive terminal of the battery to the control contact, and the negative terminal to the body of the device. When connected, the retractor should activate and extend the gear. If this does not happen, then the bendix has failed and should be replaced.

Sources:

https://etlib.ru/blog/551-ne-krutit-starter https://ddcar.ru/blog/poleznoe/ne-krutit-starter-FORD-FOCUS-2 https://avtozam.com/FORD/ FOCUS/neispravnosti-startera/

Where is the starter located on a Ford Focus 2?

One day it may happen that the car simply does not want to start, due to a faulty starter.

Such a sad story can happen to every car enthusiast, so it is important to know how to replace the starter on a Ford Focus 2. Like its predecessor, the second generation of this car has retained excellent maintainability, thanks to which even a person inexperienced in such things can carry out most of the removal/installation operations of certain parts and assemblies yourself, but it is better to carry out repairs in specialized service centers. Specifically, removing the starter will not take much time and effort, but you will have to be careful, since the engine compartment is designed very compactly, and with one awkward movement you can increase the number of parts that require repair.

Tools required to remove the starter:

- Flathead screwdriver.

- Socket wrenches for 13 and 10.

- Asterisk, also known as TORX T-30.

How to remove the starter for a Ford Focus 2:

1) And so, replacing the starter on a Ford Focus 2 begins with the fact that you need to write down a code that unlocks the audio system. You will have to turn off the power to the on-board network, which will necessitate its subsequent introduction. Without it, you won't be able to listen to music after the repair.

2) Remove the cover, and then unscrew the battery mounting bracket.

3) Remove all terminals - both positive and negative.

4) Using a T-30 TORX wrench, known in our country as an “asterisk”, unscrew the oil dipstick (without dismantling it, you cannot get to the nuts of the bolts that secure the starter).

5) Then, using socket wrenches 10 and 13, unscrew the two nuts that secure the wires suitable for the solenoid relay. It is also necessary to disconnect the crankshaft sensor connectors.

6) Since the starter is attached to the engine with 3 bolts, we need to unscrew them with a 13mm wrench. After this, you can dismantle the starter through the bottom of the engine, but before that you need to remove the lower engine protection.

A faulty starter can be sent for repair or a new starter can be purchased. Assembly, as very often happens, is done in reverse order. Therefore, after reading these instructions, you will perfectly imagine how, in the event of a breakdown, remove the starter from the car and install a new one.

Tell us, what difficulties did you encounter when replacing the starter?