If you are a car owner, then you will be interested in knowing why the starter turns but does not engage the flywheel. This problem, unfortunately, is not so rare, especially for older cars. If many years ago drivers had not even heard of a starter, since the engine was started using a handle, today this device is a mandatory component of any engine. Now you don’t need to get out of the car to start the engine; just insert the ignition key into the lock to turn on this device, or use a special button.

Why does the starter spin but does not engage the flywheel?

, we will tell everyone, since the principle of operation of this unit is the same for all similar devices, regardless of the car model or manufacturer. Among the many diseases of this device, today we will highlight and consider in more detail one, these are the problems of the overrunning clutch, or as drivers also call it, Bendix. In this case, the starting device itself has no problems, but it is the clutch that fails.

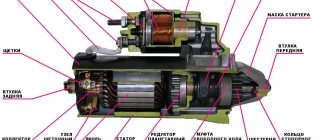

This unit is a kind of gear that transmits the rotation of the armature to the flywheel of the motor to start it. A prerequisite for the correct operation of this device is the removal of this gear from the meshing zone after the successful start of the motor. To be more precise, it is not only a gear, it is a mechanism that also sometimes has malfunctions. Most drivers know that the starter is a DC electric motor, sometimes it has high power to ensure the start of engines with large displacement.

The principle of operation of this device is that before the armature begins to rotate, a special device called a solenoid relay engages the bendix with the flywheel crown, and then current is supplied to the starter windings and it begins to rotate the engine crankshaft.

Read more about him here.

The rotation of the power unit shaft leads to compression of the fuel mixture and ignites it at the right moment, after which the engine begins to work independently. At this moment, the flywheel speed begins to exceed the armature shaft speed, and the overrunning clutch comes into operation. The driver turns off the power to the power windings, the armature stops rotating, and the retractor relay disengages the bendix from the flywheel.

At a certain moment, this unit must move forward, engage and lock on the armature shaft. The question arises as to how this can be done. This knot can be divided into two parts, upper and lower. The lower part is a hollow shaft with two different diameters. The smaller part has splines that transmit rotation of the starter shaft; the larger diameter contains a cage with rollers.

In the normal position, there is no interaction between the rollers and the lower cylinder; it appears only after the rotation begins. At this moment, they move to the center and lock the shaft, and in such a way that it can only rotate in one direction. This will be prevented by rollers that are pressed by springs. After the engine flywheel gains speed, it begins to rotate the overrunning clutch, the rollers begin to diverge, freeing the gear and shaft from being locked. The solenoid relay returns the bendix to its original position.

In cases where the rotation of the starter is clearly audible, but the crankshaft stands still, the fault should be looked for, first of all, in the overrunning clutch of this product. This is possible in the case when the gear does not lock on the armature shaft. After long-term use, natural wear occurs on the rollers and pressure springs, which cannot ensure reliable fixation of the gear.

Also, quite often the cause of this phenomenon can be the transformation of the lubricant that is embedded in this device into a thick lump, which then prevents the free movement of the rollers and springs to secure them on the starter shaft. This problem is caused by dust getting into this unit and mixing it with lubricant. It is also impossible to exclude the possibility of damage to the teeth of the overrunning clutch gear or the flywheel ring. For various reasons, this sometimes happens.

In such cases, you will have to replace the bendix or reinstall the flywheel crown. Reinstallation at home is problematic, since you need a press to perform this operation. Some starter models have an overrunning clutch drive made of plastic. There are times when it breaks down, after which starting the engine becomes impossible. Unfortunately, manufacturers produce such couplings in most cases as non-dismountable units, so they have to be replaced entirely.

The service life of the starter and its components largely depends on the number of starts of the power unit. It has been noted by experts that such problems occur most quickly in vehicles that transport passengers. We tried to pay attention to the fact why the starter turns, but does not engage the flywheel. Some problems can be avoided with proper operation, so follow the rules for starting the engine, do not overload the starter and its components, and it will serve properly for a long period.

Starting system for a modern car

Today, motorists have a much easier time than several decades ago, when the car was started with a crank. In those days, one could only dream of starting the engine from inside the car.

Nowadays, it is enough to insert the key into the ignition or press a special button for the car to start. But problems also occur in this case, if the nodes, so to speak, “get sick.” No matter how modern a car is, over time it becomes outdated, and more and more problems arise.

This is interesting: How to remove a dent on a car with your own hands

One of them just implies poor engagement of the flywheel by the starter. Why does this happen? Experts, as soon as the topic comes up, mention the problem of the overrunning clutch or bendix.

Purpose of Bendix in a car

An overrunning clutch is a gear mechanism capable of transmitting anchor rotation to the engine flywheel. Thus, the engine starts.

Attention. A prerequisite for trouble-free operation of the components of the automotive system is the removal of the bendix after the engine has been successfully started.

You should know that a clutch is not just a gear, but a mechanism that also develops malfunctions.

To more fully understand the cause of the problem with the flywheel engaging, it will be useful to consider the general principle of operation of the entire starting system.

The starter is a DC electric motor. In some cases, it develops much more power than required. Thus, it becomes possible to run the internal combustion engine with maximum displacement.

In a modern starter, an important role is played by a relay - a special unit that brings the clutch into contact with the flywheel some time before the armature false start. Then only voltage is applied to the starter winding, after which it begins to rotate the crankshaft of the car engine.

The rotation of the crankshaft becomes a source of compression of the combustible mixture, followed by its ignition. As soon as this happens at the right moment, the internal combustion engine begins to function automatically.

At this very moment, the metonymic cycle of the flywheel begins to dominate the revolutions of the starter shaft (armature), and the bendix is already engaged. As soon as the driver turns off the car, the starter shaft no longer rotates, and the traction drive disengages the clutch.

It is important to understand that the bendix itself consists of 2 parts: upper and lower (HFB and LFB). The latter acts in the form of a hollow shaft having two different calibers. One of the parts of the shaft is equipped with splines that transmit rotation of the starter, and the other part contains a cage with rollers.

There is no interaction between the videos and the NCB initially. It occurs only after, when the first revolutions appear. The rollers are brought to the middle, thereby limiting the shaft. This happens in such a way that the shaft can only rotate in one direction. The rollers, thanks to their springs, do not allow them to rotate in the other direction.

Once the flywheel gains speed, it will be able to rotate the bendix. In this case, the rollers move apart, opening the stopper. The gear mechanism returns to its primary position.

Bendix often freezes in the mornings when it is cold. Experienced drivers recommend cranking the starter several times, thereby heating the bendix and enabling its operation.

What to do if the engine does not start, but the starter clicks?

If the starter makes sounds similar to clicks, it must first be dismantled. The starter consists of an electrical part, a solenoid relay, brushes and a winding. For single clicks, it is better to start checking with the solenoid relay.

To start the starter, it is connected directly. To do this, we close the large terminals with a screwdriver, trying to ensure that the screwdriver does not come into contact with the ground. If after this the starter begins to rotate, it means that the retractor relay is not working. You can clean the contacts, but this will not have a long-term effect - the relay will still have to be replaced.

The brushes may also be faulty. The degree of their wear can be easily determined visually. A winding malfunction is indicated by a change in its color. Also, a burnt winding emits a characteristic smell - in this case it can only be replaced.

Along with high efficiency and relative reliability, fuel-injected cars have one unpleasant drawback - the difficulty of repair. It happens that the injector suddenly stops starting, and it becomes difficult to do anything with it. It’s good if you have the opportunity to call a tow truck or show the car to a professional, but what should those motorists do who are left with the problem alone? Let's figure it out by examining in detail all the reasons why the injector starts poorly or refuses to start at all, as well as how to “treat” such a malfunction.

Inoperability

Not the starter, but the bendix does not engage the flywheel. This is how you need to understand the problem. Let's look at the reasons why this might happen.

- If the mechanism does not lock on the starter shaft. This is often caused by the fact that over time, the rollers with springs wear out and are no longer able to provide reliable engagement.

- Hardening of the grease is also a common cause of this problem. It simply turns into a thick lump, limiting the movement of the Bendix roller-spring system. As a result of this, no engagement occurs. A common cause of grease hardening is dirt or dust getting inside the starter.

- It is also possible that the bendix teeth or flywheel ring are worn out. In this case, there will also be no engagement. If the problem is in the crown, then it is simply replaced with a new one. The same is done with Bendix, which is being updated.

Attention. In some situations, if the cause of the Bendix malfunction is contamination, thorough cleaning of the device helps. On the other hand, experts do not recommend using a repaired Bendix. It's better to install a new one right away.

It will be useful to know that some types of starters are equipped with a plastic Bendix drive. This means that such a product breaks easily, and starting the internal combustion engine becomes impossible.

It will also be important to note that the operational service life of the starting system depends on the number of engine starts performed. The more of them, the less resource the mechanism has. And most often, problems with starting, i.e., engagement of the starter and flywheel occur in passenger vehicles (buses, minibuses, taxis).

If you operate the machine correctly and follow the basic rules of proper engine starting, especially in cold weather, the service life of the device can be significantly increased. Of no small importance here, of course, is the overload of the starter and other elements of the starting system.

Video Bendix work

Forget about fines from cameras! An absolutely legal new product - NANOFILM, which hides your license plates from IR cameras (which are installed in all cities). More details at the link.

- Absolutely legal (Article 12.2.4).

- Hides from photo and video recording.

- Installs independently in 2 minutes.

- Invisible to the human eye, does not deteriorate due to weather.

- 2 year warranty

The starter turns, but the car does not start: reasons

If the starter turns, but the engine does not start, you need to make sure that the starter is working properly. During activation, it should not click, buzz, or make other unusual sounds. A serviceable element emits a steady buzzing sound during operation. If you hear extraneous noise, the problem is in the ignition system.

Before completely disassembling the car, you need to check the starter. An element can be considered faulty if its gear does not engage with the flywheel ring - then a strong grinding noise is heard. In 90% of cases, this indicates wear of the teeth - which means they have stopped gripping normally.

The reason for the engine not starting may be a solenoid relay that is stuck. In this case, the starter motor will vibrate. By the way, this problem can be solved by turning on the ignition system multiple times.

The flywheel crown may be loose. This malfunction occurs especially often on cars of the domestic automobile industry. Clutching with the starter will occur, but with a lot of noise. The problem is solved by replacing the flywheel. It is also necessary to check the fuel system.

The human factor is of great importance. For example, the fuel pump is deactivated if you forget to turn off the alarm system. And if there is no gasoline in the tank, starting the engine will be impossible. Pay attention to the exhaust pipe - it can simply be plugged. Also, the pipe may become clogged with soil or something else due to the fault of the driver if he was inattentive when backing up.

FakeHeader

Comments 8

The retractor should supply bendix to the flywheel and voltage to the starter armature. If it buzzes, then voltage is supplied. This means Bendix is not for sale. The bendix and the hands are definitely to blame. If the bendix did not initially return from the flywheel, then it is faulty. The problem is in the fork, the spring, the gear itself. Plus, perhaps I didn’t assemble it correctly or lost something. No money for a starter - buy a Bendix. Try to simulate battery operation without installing it on the car. And remember, a new spare part does not mean it is working. This concerns spare parts for Zhiguli. And you have a Bendix of unknown freshness.)

the issue was resolved. I had never dealt with a starter before, except for a motorcycle one, which is why the difficulties arose. It turns out that my bendix was initially faulty, because it was difficult to move along the axis - the fork did not push it out and pushed it in with difficulty. As a result, on Sunday I completely disassembled the starter and replaced the bendix, fork and brushes. Now everything is cool, it works like a clock. By the way, the brushes were 40% smaller than new ones, they would soon make themselves felt! Thank you for your feedback!

This is interesting: The advantage of an atmospheric engine over a turbocharged one

I somehow struggled with the starter at 21099! And he took it apart and sorted it out, whatever he did! In the end, I got tired of it all, went to the store and bought a new one!

Now I don’t have extra money for this car) I’ll try to resurrect it

My father recently had the same problem, although the starter is only a year old. In the end I bought a new one. We tried everything, and even installed a new crown, but the starter didn’t care. He buzzed like a madman and refused to hit the crown. And the most interesting thing was that when it was not tightened with the bolts, there was engagement, but as soon as the bolts were tightened, the starter refused to engage.

Are the teeth on the flywheel normal? Doesn't throw out the bendex before it engages.

Itching is normal, ideal. And why? I washed the bendex with water and lubricated it - in the end it stopped popping up, it was popping up before

Other reasons why the starter turns, but the engine does not start

If fuel is supplied and the ignition works, but the engine does not start from the starter, a thorough diagnosis of electrical circuits and components is required. The cause may be a blown fuse, power failure, failure of the control relay, oxidation, corrosion or destruction of contacts, etc. In some cases, on fuel-injected cars, the engine ECU itself fails.

Quite often the starter turns, but the engine does not start after washing the engine compartment or actively driving through puddles. The reason is moisture entering the engine and equipment, which leads to malfunctions of electronic systems. For this reason, it is recommended to follow certain rules when washing the engine.

Also, do not forget that the ECM sensors that interact with the ECU may fail. As an example, we can consider the case when the engine, when trying to start, seizes a little, but does not start. At the moments of seizure, strong shaking of the motor is noted. The culprit in such a situation may be either the crankshaft position sensor (crankshaft position sensor, Hall sensor) or the starter itself. In the first case, a faulty sensor sends incorrect signals to the control unit, as a result of which the ECU is unable to correctly adjust the composition of the fuel-air mixture and fuel supply.

In the second case, so-called “interference” may be to blame. The specified electromagnetic interference, for example, from the starter to the crankshaft sensor, does not allow the electronic device to generate the correct signal to the computer. If there are malfunctions in the operation of the DPKV, the engine will not start, although fuel will be supplied normally, and the starter itself will turn the crankshaft well. Also pay attention to the car alarm, which may block the engine from starting due to failures in the main unit or additional immobilizer.

Every car enthusiast has ever encountered or heard about such a situation from friends or acquaintances. We are talking about a case where the starter spins at idle or, as they say, still slips or skips and does not engage the flywheel. This topic is very popular to discuss on automobile forums, but we will return to it again, because the correct information is not always written there, more often the guesswork of some car enthusiasts and advice, following which, some car owners buy and change the wrong part in which the problem lies. Such a malfunction may be permanent, or it may appear periodically, but as a rule, it quickly progresses and becomes permanent.

When the symptoms described above appear and the starter does not engage the engine, there is no need to wait until this malfunction becomes permanent, otherwise it will come to the point where you will have to start the car with a pusher or call a tow truck. To understand why this happens to the starter, we need to remember its design, its structure. Many would immediately say, “Everything is clear here, the problem is with the solenoid relay,” but it turns out no, it’s not the problem. If the retractor had not worked, then the starter would not have started at all, since the current would not have been transmitted through the relay nickels to the starter motor itself.

If we think logically, since there is no engagement of the starter with the engine, then most likely the fault is in some rotating part. The starter has several rotating elements - an armature, a planetary gearbox, a bendix or an overrunning clutch. This is where the problem lies. It is very rare, but there is such a breakdown as wear of the armature splines, this can give such symptoms of slipping, but again, this happens extremely rarely. More often there is a defect in the planetary mechanism (starter gearbox), the teeth on the plastic or metal planetary gear are eaten away and the effect of the starter motor slipping relative to the bendix or overrunning clutch appears. And finally, the most common breakdown in starters is wear of the mechanism inside the bendix itself or the overrunning clutch. As a rule, rollers or springs wear out. In some cases, it is possible to repair the bendix by replacing these elements, but more often and easier to install a new bendix.

Our warehouse has bendixes for almost all types of imported cars and equipment. Replacement is carried out quickly and professionally, the warranty on replaced parts is 1 year. If you are faced with such an unpleasant situation, if the starter starts to work incorrectly, do not despair, our specialists will be happy to help you deal with this problem. Call our numbers, write in the chat, the specialist will advise you, suggest a faster and more profitable way to solve the problem. In our workshops we can quickly remove the starter from the car and repair it; Bendixes are available for almost all types of transport. After repair, the starters are checked at a specialized stand and installed back on the car.

Other useful articles

Repair and service

The driver of a car with either a gasoline or diesel power unit may find himself in a situation where the starter spins but the engine does not start. This also happens with turbocharged and naturally aspirated engines - finding the cause of the malfunction in these cases is not easy. It is much easier to solve the problem when the ignition turns on but the fuel pump does not pump.

Town, Lite, Master, - Ace. Diesel engine ⇒ Starter does not engage flywheel or jumps out

Post by Boris.Stupin » Dec 13, 2021, 12:01 pm

Post by Master2603 » Dec 13, 2021, 12:03 pm

Post by Vasily Garynych » Dec 13, 2021, 12:09 pm

Post by Boris.Stupin » Dec 13, 2021, 12:25 pm

Posted by brembist » Dec 13, 2021 12:31 pm

Post by aleksey.arbuzov » 14 Dec 2021, 19:07

Post by Boris.Stupin » 24 Dec 2021, 20:48

Post by aleksey.arbuzov » 24 Dec 2021, 20:59

Post by Alekseu.Pekynov » Jan 19, 2021, 2:00 p.m.

Post by Alexander 70rus » 13 Feb 2021, 17:18

I didn’t create a new topic, I’ll write here, I decided to service the starter (cleaning, lubrication), disassembled the gearbox, washed it, cleaned the holder with a brush, the brushes were fine, but I didn’t understand how to remove the armature from the stator. Who can tell? Here is a photo.

Posted after 1 minute 40 seconds: How do I get it out?

The reason is the power supply

There is also no need to rule out a malfunction of the electrical component of the car. A problem may occur in the solenoid relay. It is installed on the starter and is a magnet made of two coils.

- One of the windings is retractable - it extends the gear and closes the contacts to supply current to the starter brushes. Integrated with the control terminal and directly with the electric motor.

- The second coil creates additional force so that the overrunning clutch receives reliable engagement with the flywheel. That's what it's called - holding. Connects to control pin and housing.

Common malfunctions of this part are: complete combustion of one or both windings, wear of the nickels (contact plates), destruction of the return spring or armature, interturn short circuit of the starter. In any case, the bendix is not locked and rotation is not supplied to the car engine. This is the reason that the clutch spins idle - it does not engage with the flywheel. A faulty relay is usually replaced, since the windings are rarely repairable.

Testing the pull-in coil of the relay with a multimeter

Another difficulty relates to the starter itself. It is often repairable; its removable parts are easily replaced - brushes, armature, stator. But the most common reason when a car does not start is due to worn bushings.

Bushings are rolling bearings that hold the armature on both sides. When they are severely worn, the rotor begins to play, its position changes, as a result of which it sticks. Hence the starter's idle operation.

This is what happens specifically, and quite often on modern cars, when the starter operates on worn bushings:

- the electric motor begins to require more voltage;

- because of this, the current in the vehicle’s on-board network decreases sharply;

- the voltage drops below 9, and then the ECU turns off;

- the system does not generate a spark, the starter turns the shaft, but the internal combustion engine does not start.

Of course, the bushings are also replaced. But it’s even better, if possible, to replace the entire starter - especially if it has been working for a long time.

Battery power problems

The following problems may occur in the electrical power supply and starter control circuits:

- The battery charge is only enough to activate the relay coil. After turning the key to the “start” position, a click is heard, but there is no buzz from the electric motor, and the lights on the dashboard dim. Sometimes a series of ineffective clicks is heard.

- There is a malfunction in the ignition switch or control relay. The Bendix clicks, but the starter does not engage.

- Poor contact in power circuit connections.

In the first situation, it is enough to charge or replace the battery for the starting device to start functioning. However, it is worth figuring out why the discharge occurred and eliminating the causes, otherwise you risk encountering a similar problem somewhere along the road.

Determining if the ignition switch or control relay is broken is quite simple: set the gear shift lever to the neutral position, take a thick wire and connect the “plus” of the battery directly to the power contact of the starter. The buzzing of the electric motor will indicate that the lock contact group or control relay needs to be replaced.

Advice. If the car does not start due to the ignition switch, you can start the power unit using the above method - turn on the ignition and connect the starting electric motor directly.

If the battery terminals are oxidized or there are other problems in the power circuit, the current is not enough to activate the starter, although power is generally supplied. Clean the terminals and other connections on the power cables to resolve the problem.