- home

- Engine

- …

Starting a car, or rather its engine, is carried out by such an important component as the starter. This is a fairly strong part, it can work for many thousands of kilometers, but “nothing lasts forever under the sun” (as they say). Both it itself and its attached parts, such as the bendix or solenoid relay, may fail. A fairly common breakdown is when clicks are heard from under the hood, but startup does not occur. There are several reasons here and they are not as critical as they might seem at first glance...

The main function of the starter is to start the car engine, and it does not work for a long time (maximum 5-7 seconds) and then turns off (this is implemented on many foreign cars and domestic cars, for example VAZ). If the shutdown does not occur, it can easily burn out, all because large starting currents (from 250 to 600A), it all depends on the class of the car, its power unit and the time of year (in winter it is more difficult to crank the crankshaft because the oil is thick). Before moving on to the reasons for the breakdown, I would like to briefly tell you what this unit consists of.

Starter device

If you don’t get into the weeds, this is an ordinary POWERFUL electric motor, which is used for only one task - spinning the crankshaft to start the engine. But as I wrote above, it should not be constantly engaged, and therefore a “special unit” brings a certain gear into engagement with the flywheel and removes it after starting.

This gear is called “BENDIX” , it is the one that meshes with the flywheel. However, the Bendix device is much more complicated; it is essentially an overrunning clutch (it can rotate in one direction, but not in the other).

The Bendix pushes out a special unit, which is (usually) attached to the top of the starter and is called a “retractor relay” . As you understand, it has one task - to engage it with the flywheel and, after starting, to remove it and put it back. The principle of this unit is based on the operation of an electromagnet, one of its contacts is always connected to the negative (through the starter housing, then through the vehicle ground), and the other to the positive of the battery (through the ignition switch). In order not to overload you with complex technical information, you need to understand that this magnet has a winding, let’s call it “retracting”, as well as a “core”, which, under the influence of these windings, moves in and is held (it is rigidly connected to the BENDIX). When you turn the key in the ignition, the “retractor winding” works; it acts on the core, the “BENDIX” extends, which engages with the flywheel and then the starter spins the engine. After starting the engine, the winding opens, a special spring moves the core to its original position, and the BENDIX disengages.

At the end there will be a useful video, watch it, all questions will disappear.

In simple words, the “retractor relay” engages and then removes the BENDIX gear from engagement with the flywheel.

Battery is very low

We have already mentioned that this is the most common and common case. And to understand why this happens, let's figure out how a car starter functions. As soon as we turn the key in the closed circuit, by closing the contacts, the supply voltage is supplied to the contact group of the solenoid relay, and the electromagnetic component of the current sets the starter armature in motion. It, in turn, closes the circuit between the starter motor and the battery and at the same time moves the Bendix gear, establishing the engagement of the starter shaft with the crankshaft flywheel.

When the battery is severely discharged, its charge may be sufficient to move the armature core, but there is no talk of cranking the crankshaft. If the starter clicks but does not turn, this means that the Bendix gear is mating with the crankshaft with a characteristic sound, but there is not enough battery charge for more. But there is one nuance here: since the voltage supplied by the battery is too low, the electromagnet cannot hold the core, and it returns to its original position (the action of the spring is stronger than the electromagnetic one). Over a short period of time, the charge is slightly restored and sets the core in motion again - this cycle can be repeated several times.

What should you do when the starter does not turn when you turn on the starter, but just clicks? First of all, make sure that it is the battery that is to blame: with the ignition on, try turning on several consumers at the same time and pressing the horn. If the battery is dead, you will not hear a signal or it will be far from normal (wheezing, fading, distorted sound).

The starter clicks but does not start the engine

Well, now we come to the most interesting part. Why can there be clicks when turning the key in the ignition, but the engine does not start ? In 60% of cases the problem is in the solenoid relay. However, there may be problems with the wires, which should be checked immediately:

- Low battery . Many people confuse the clicking sounds of the starter with a discharged or failed battery (there will be a kind of crackling sound, but it will not be a one-time sound). There simply isn’t enough power to crank the engine, you just need to recharge or replace the battery.

- Poor contact at the positive terminal . The very first thing we do is look at the terminals on the battery; if there are oxides, then they need to be removed. The thing is that the positive wire goes to exactly one contact of this retractor relay. If the contact is bad, then the system will not work well (and it’s not just the clicks).

- Poor contact at the relay itself. The wire from the battery can also oxidize at the starter itself. This often happens from high mileage. You need to unscrew both power wires (usually they go to the relay) and clean them well. Perhaps the reason will disappear

- Poor ground contact. The negative terminal is attached to ground (often to the car body or engine), if there are oxides here again, either from the terminal side or from the contact point, then they also need to be removed.

- Solenoid relay. This is a common breakdown (especially on old VAZs) - when you turn the key, you hear clicks, but nothing happens. However, if you turn the key several times, for example two or three times, the engine may start on the fourth time. THIS IS DEFINITELY A RELAY; it needs to be changed or cleaned.

- The teeth of either the BENDIX or the flywheel crown have broken . Of course, then not only clicks will be heard, but also a strong crunching sound from under the hood. This happened to me only once in practice.

In my practice, when I had front-wheel drive VAZs, first of all we clean the terminals and contacts of the starter, and then remove the solenoid relay and look at it. It may be better to replace it right away and not have to suffer.

Why doesn't the starter turn the engine, where to look

During prolonged use of the starter, problems may arise with its starting. It also happens that he doesn’t show any signs of life at all or “idles.” In this case, it is necessary to carry out a number of diagnostic measures aimed at identifying the malfunction.

If the armature of the device’s electric motor does not rotate, you should make sure that:

- ignition switch;

- battery;

- ground wire;

- solenoid relay.

It is advisable to start diagnostics with the contact pair of the ignition switch. Sometimes an oxide film on the contacts prevents the flow of current to the starter solenoid relay. To rule out this reason, just look at the ammeter readings at the moment you turn the ignition key. If the arrow deviates towards the discharge, then everything is in order with the lock. Otherwise, there is a reason to make sure it is working properly.

The starter motor is designed for high current consumption. In addition, a large amount of current is spent on converting electrical energy into mechanical energy. Thus, the characteristics of the starter’s operation impose certain requirements on the battery. It must provide the required current value for its effective operation. If the battery charge does not correspond to the operating value, starting the engine will be very difficult.

Related article: What to do if the car does not start or does not start the first time

Interruptions in the starter operation may be due to a lack of mass with the car body and engine. The ground wire must be firmly fixed to the cleaned metal surface. You also need to make sure the integrity of the wire. It should not have visible damage or areas of sulfation at the attachment points.

You should also check the operation of the solenoid relay. The most obvious sign of its malfunction is the characteristic clicking sound of the solenoid core at the moment the ignition switch contacts close. To repair it you will have to remove the starter. But you shouldn’t make hasty conclusions. For the most part, the malfunction of the “retractor” is associated with the burning of the contact group, the so-called “nickels”. Therefore, first of all, you need to audit your contacts.

Low battery charge

A faulty battery can cause the car's starter to fail. Most often it manifests itself in the winter season, when the battery is under the greatest load.

Diagnostic measures in this case come down to:

- checking the density of the battery electrolyte;

- checking the battery charge level.

Depending on the operating conditions, the density of the battery electrolyte should be the specified value. You can check the density using a hydrometer.

Read also: 10 tips on how to start a car in severe frost

The concentration of sulfuric acid for the middle band is 1.28 g/cm3. If, after charging the battery, the density in at least one bank is lower by 0.1 g/cm3, the battery must be repaired or replaced.

In addition, it is necessary to monitor the electrolyte level in the jars from time to time. Failure to comply with this requirement may result in the electrolyte concentration in the battery becoming noticeably higher. This will lead to the battery simply failing.

To check the battery charge level, just press the car signal. If the sound does not go down, then everything is fine with it. This check can be supported by a load fork. It should be connected to the battery terminals, then apply a load for 5 - 6 seconds. If the voltage drop is not significant - up to 10.2 V, then there is no cause for concern. If it is below the specified value, then the battery is considered faulty.

Malfunction in the starter control electrical circuit

The starter belongs to the electrical equipment of the car. There are often cases when interruptions in its operation are directly related to damage to the control circuit of this device.

To detect this type of malfunction, you should:

- make sure there is no damage to the power cable;

- check the functionality of the contact pair;

- make sure the fuse is working properly.

To identify the problems presented, it is advisable to use a multimeter. For example, in order to inspect the entire starter electrical circuit, it is advisable to ring all connecting wires for a break. To do this, the tester should be set to ohmmeter mode.

Useful to know: How to remove air from a car's cooling system

Particular attention should be paid to the contacts of the ignition switch and the solenoid relay. There are cases when the return spring, due to wear, does not allow the contacts to contact properly.

If you can hear clicks from the solenoid relay, there is a possibility that the power contacts will burn out. To verify this, it is enough to close the positive terminal of the “pull-in” with the terminal of the stator winding of the electric motor of the device. If the starter starts, the low current carrying capacity of the contact pair is to blame.

Starter problems

Problems with the starter can be caused by both mechanical damage to its working elements and problems with its electrical equipment.

Mechanical damage includes:

- slipping of the freewheel;

- jamming of the freewheel drive lever;

- increased wear of the motor armature bushings.

Signs indicating slipping of the overrunning clutch are expressed in the fact that when the key is turned to the “starter” position, only the electric motor of the unit starts, and the Bendix refuses to come into contact with the flywheel crown.

Eliminating this problem will not be possible without removing the device and inspecting the overrunning clutch. It often happens that during the work process, its components simply become contaminated. Therefore, sometimes to restore its functionality it is enough to wash it in gasoline.

The overrunning clutch drive lever is also subject to increased mechanical wear. The symptoms of this malfunction will be the same: the starter motor rotates, and the bendisk refuses to engage with the flywheel crown. Rod wear can be compensated using repair bushings. But, it is best to replace it. This will save time and nerves for the owner.

Related article: Where is the safest place in the car for a child?

The starter armature rotates inside copper-graphite bushings. Like any other consumable, bushings wear out over time. Failure to promptly replace such elements can lead to serious problems, including replacing the starter.

As wear on the armature seats increases, the likelihood of contact between insulated parts increases. This leads to destruction and burnout of the armature winding. The first sign of such a malfunction is increased noise when starting the starter.

Malfunctions of the starter electrical equipment include:

- interturn short circuit;

- increased wear of the collector;

- wear/loose fit of brushes;

- broken wires in the winding.

If the insulation of the conductive elements of the starter is damaged, it completely loses its functionality. An interturn short circuit or break of the stator winding, as a rule, is not spontaneous. Such breakdowns can be caused by increased production of the working components of the starter.

The brush-collector unit deserves special attention. During prolonged use, carbon-graphite sliding contacts noticeably wear out. Failure to replace them in a timely manner may result in damage to the collector plates. To visually determine the performance of the brushes, in most cases it is necessary to dismantle the starter.

It would not be superfluous to say that some craftsmen, endowed with “colossal intelligence,” replace traditional graphite brushes with copper-graphite analogs, citing the high wear resistance of copper. The consequences of such innovation will not take long to arrive. In less than a week, the collector will lose its function forever.

Solenoid relay

All malfunctions in the operation of the solenoid relay can be divided into four categories:

- operational wear of working elements;

- burnout of contact elements;

- mechanical damage to individual components;

- violation of the integrity of the electromagnet winding.

Brushes

During operation of the device, the starter brush-collector assembly requires systematic diagnostics and timely maintenance, which involves the following actions:

- timely replacement of brushes;

- checking the collector assembly for signs of burning and contamination;

- ensuring the necessary clamping force of the current-collecting elements.

Similar material: How to check the starter relay, winding, and bendix for functionality

The functionality of the brushes is checked using a simple 12 V car light bulb. One end of the light bulb should be pressed against the brush holder, and the other end should be applied to the ground. If the light is off, the brushes are fine. The light bulb emits light - the brushes have run out.

Winding

As mentioned above, the starter winding itself rarely fails. Problems with it often result from mechanical wear of individual parts.

Nevertheless, in order to make sure of its integrity in the event of a breakdown on the housing, it is enough to check it with a regular ohmmeter. One end of the device is applied to the winding terminal, and the other to ground. The arrow deviates - the integrity of the wiring is broken. The arrow stands rooted to the spot - there is no reason to worry.

Starter malfunctions, if we exclude manufacturing defects, are mostly the result of improper operation or improper care. Timely replacement of consumables, careful handling, and compliance with factory operating standards will significantly increase its service life and save the owner from unnecessary expenses and nervous shock.

Is it possible to repair the solenoid relay?

On older modifications of starters, this was possible. After clicks appear, simply remove the relay and disassemble it.

There is a contact pad inside, usually a plate and two contacts. Oxides can form between them, as well as plastic film from a long start-up. We need to clean this part and performance will be restored.

Watch this helpful video.

HOWEVER. New modifications of the relay are NOT SEPARABLE. They cannot be easily disassembled (without destroying the case) and cleaned. Often a replacement is needed. YES, they break down once every 120 - 150,000 km (and maybe less often) and replacing them is not that expensive.

The starter hums, but does not turn the engine

Here the problem is of a slightly different nature and the BENDIX is to blame (it does not click when it fails). A whirring sound indicates that the armature is engaging the flywheel, but no starting occurs. The starter works, turns the armature at high speed, but the engine flywheel does not spin. As I wrote to BENDIX, this is a kind of overrunning clutch, it rotates in one direction and should not rotate in the other (that is, it should be automatically locked with special eccentrics inside), this is done for a smooth start, and also so that the starter does not burned out.

If the eccentrics fail (or the elements that stop them), BENDIX will rotate in both directions. Hence the buzzing noise - this gear simply rotates in the splines of the flywheel.

Can this gear be repaired? Hypothetically, it is possible, but it is not worth your labor costs, the whole point is that it is quite difficult to find the eccentrics inside, and then it may not be possible to put the system back together correctly.

It is necessary to replace this entire assembly; often this will require removing the starter and disassembling it almost completely.

Now let's watch a detailed and useful video.

This is where I end. To briefly summarize, the clicks can appear, firstly, from a bad battery, secondly, from bad contacts (be it the battery terminals, or the body, contacts of the retractor relay), thirdly, the retractor relay has failed, fourthly, broken gear teeth or flywheel, then a crunching sound will be heard along with the clicks, fifth - if a buzzing is heard, then the bendix has most likely failed and needs to be replaced. Of course, it happens that the starter itself fails, but this happens after very long runs.

I hope I helped you, YOURSINCERELY - AUTOBLOGGER.

Similar news

- Is it necessary to warm up the engine? Before the trip? Let's sort out winter and...

- Sensors for an injection engine. Let's look at the VAZ as an example

- The car won't start. Very detailed information about the starter, as well as others...

Add a comment Cancel reply

There is no voltage supplied to the starter from the battery

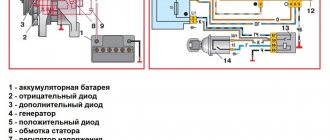

If a click is heard, but the starter motor does not spin when the starter motor is turned on, the reason may be a break in the electrical wiring in the area connecting the battery to the starter. But such symptoms are typical for most of the malfunctions described above, so for an accurate diagnosis you will need a tester and a control light. This is clearly visible in this figure:

If the power wire connecting the “plus” of the battery to contact “30” of the retractor relay breaks, the starter will be inactive, although the relay will click as before. In some cases, the problem can be diagnosed by a banal external inspection of the wiring, but most often you will need a tester, which few drivers carry with them. So road repairs are unlikely here.